Professional Documents

Culture Documents

Improving The Indigenous Processing of Kocho

Improving The Indigenous Processing of Kocho

Uploaded by

Angeline GCopyright:

Available Formats

You might also like

- Production of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Document5 pagesProduction of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Gregory Kalona100% (1)

- Food Additives, E-NUMBERS PDFDocument12 pagesFood Additives, E-NUMBERS PDFjiatrou6350No ratings yet

- Effect of Microbial Fermentation On Nutritional and Safety Value of Cassava-Based FoodDocument13 pagesEffect of Microbial Fermentation On Nutritional and Safety Value of Cassava-Based FoodDessalegnNo ratings yet

- Artikel 3 EngDocument8 pagesArtikel 3 EngAndri PratamaNo ratings yet

- Comparative Evaluation of Microbiological and Nutritional Qualities of Various Cereal-Based Paps (Ogi) in Ondo State, NigeriaDocument10 pagesComparative Evaluation of Microbiological and Nutritional Qualities of Various Cereal-Based Paps (Ogi) in Ondo State, NigeriaIJEAB JournalNo ratings yet

- Ecnu 03 000078Document17 pagesEcnu 03 000078gonichamba97No ratings yet

- Coconut Coir and Beans Straw As Substrates For MushroomDocument7 pagesCoconut Coir and Beans Straw As Substrates For MushroomLily Khalidatussoleha Mohamad KhalidNo ratings yet

- Artículo Ejemplo en AmarilloDocument8 pagesArtículo Ejemplo en AmarilloNaty Ale MayorgaNo ratings yet

- Achievements in The Life SciencesDocument8 pagesAchievements in The Life Sciencessameer sahaanNo ratings yet

- Khatir 2022Document10 pagesKhatir 2022Monyet...No ratings yet

- Nutritional Profile of Three Different Mushroom Varieties Consumed in Amaifeke, Orlu Local Government Area, Imo State, NigeriaDocument9 pagesNutritional Profile of Three Different Mushroom Varieties Consumed in Amaifeke, Orlu Local Government Area, Imo State, Nigerialukasz27rNo ratings yet

- 1995cultivation Preparation and ConsumptionofEnseteDocument12 pages1995cultivation Preparation and ConsumptionofEnseteBelay TesfayeNo ratings yet

- Ajol File Journals - 82 - Articles - 71409 - Submission - Proof - 71409 973 154313 1 10 20111031Document8 pagesAjol File Journals - 82 - Articles - 71409 - Submission - Proof - 71409 973 154313 1 10 20111031alhassan bellochindoNo ratings yet

- Effects of Storage Media and Duration On Nutritional Qualities of CowpeaDocument6 pagesEffects of Storage Media and Duration On Nutritional Qualities of CowpeaKadiri ZizitechNo ratings yet

- Chemical CompositionDocument11 pagesChemical CompositionYohannes AynieNo ratings yet

- Optimization of Enset Fermentation in The Production of Kocho Using Response Surface MethodologyDocument9 pagesOptimization of Enset Fermentation in The Production of Kocho Using Response Surface MethodologyHelen WeldemichaelNo ratings yet

- 1 PBDocument8 pages1 PBTri TegarNo ratings yet

- Effect of Preprocessing Techniques On Pearl Millet PDFDocument9 pagesEffect of Preprocessing Techniques On Pearl Millet PDFRama RaoNo ratings yet

- IOSR JournalsDocument4 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)No ratings yet

- Effects of Different Processing Methods On The Nutrient Composition of Kapok (Ceiba Pentandra) Seed MealDocument6 pagesEffects of Different Processing Methods On The Nutrient Composition of Kapok (Ceiba Pentandra) Seed MealEduard MorenoNo ratings yet

- Nutritional Evaluation of Spent and Uninoculated Mushroom Substrate of Pleurotus Ostreatus Grown On Cassava Peels and SawdustDocument6 pagesNutritional Evaluation of Spent and Uninoculated Mushroom Substrate of Pleurotus Ostreatus Grown On Cassava Peels and SawdustInternational Journal of Advances in Applied Sciences (IJAAS)No ratings yet

- Nutritional Value of Mealworm, Tenebrio Molitor As Food Source PDFDocument6 pagesNutritional Value of Mealworm, Tenebrio Molitor As Food Source PDFAlexis MolinaNo ratings yet

- Lactobacillus Plantarum As Starter Culture Kunnu-Aya Produced FromDocument9 pagesLactobacillus Plantarum As Starter Culture Kunnu-Aya Produced FromMunam MustafaNo ratings yet

- 1 PBDocument15 pages1 PBRahmilia Alifa PutriNo ratings yet

- RS - Volume 9 - Issue 4 - Pages 378-391Document14 pagesRS - Volume 9 - Issue 4 - Pages 378-391samirNo ratings yet

- Sugarecane TopDocument5 pagesSugarecane TopFantahunNo ratings yet

- J Sci Food Agric - 2023 - Ngoh Newilah - Influence of Contrasting Cultivation Altitudes On The Physicochemical DigestiveDocument9 pagesJ Sci Food Agric - 2023 - Ngoh Newilah - Influence of Contrasting Cultivation Altitudes On The Physicochemical DigestiveCédric KENDINE VEPOWONo ratings yet

- Food Science and Biotechnology Volume 22 Issue 1 2013Document7 pagesFood Science and Biotechnology Volume 22 Issue 1 2013Fayzan LabNo ratings yet

- Original Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursDocument8 pagesOriginal Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursRONEL JOEL BAZAN COLQUENo ratings yet

- 10 11648 J Ijfet 20200402 12-1Document7 pages10 11648 J Ijfet 20200402 12-1MelakuNo ratings yet

- Proximate Composition, Total Phenolic Content, and Sensory Analysis of Rice Bran TempehDocument6 pagesProximate Composition, Total Phenolic Content, and Sensory Analysis of Rice Bran TempehNethania IreneNo ratings yet

- Effect of Coagulant On Physcicochemical Tofu-2019Document10 pagesEffect of Coagulant On Physcicochemical Tofu-2019icha allisaNo ratings yet

- Tepung SorghumDocument8 pagesTepung Sorghumnugraha widyatmonoNo ratings yet

- Maeda, 2003Document8 pagesMaeda, 2003María Belén VignolaNo ratings yet

- Zeenat Project FullDocument11 pagesZeenat Project FullLegit CafeNo ratings yet

- Biochemical and Functional Properties of PDFDocument12 pagesBiochemical and Functional Properties of PDFValeria OlmedoNo ratings yet

- 5776-Article Text-16109-19703-10-20191008Document7 pages5776-Article Text-16109-19703-10-20191008Kenzi LucsenteNo ratings yet

- Physicochemical and Functional Properties of NativDocument8 pagesPhysicochemical and Functional Properties of NativEmmanuel KingsNo ratings yet

- Ejemplos Ref. Bibliografica Repo-carrasco-Valencia2009Document6 pagesEjemplos Ref. Bibliografica Repo-carrasco-Valencia2009Alexandra GarciaNo ratings yet

- An Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaDocument6 pagesAn Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaLeycoline AlmrenNo ratings yet

- Cassava Retting Water An Alternative Source For Industrial Cellulase EnzymeDocument6 pagesCassava Retting Water An Alternative Source For Industrial Cellulase EnzymeEditor IJTSRDNo ratings yet

- 1690128278aavs 11 9 1451-1456Document6 pages1690128278aavs 11 9 1451-1456Robi Amizar SikumbangNo ratings yet

- Paper TropicsDocument8 pagesPaper Tropicsdarobin21No ratings yet

- Trox 2011Document6 pagesTrox 2011Daniel AriasNo ratings yet

- ArticleDocument7 pagesArticleanrauzanaNo ratings yet

- Coconut Water As MediumDocument5 pagesCoconut Water As MediumCandy Kim50% (2)

- 2132-Article Text-9077-1-10-20131226Document11 pages2132-Article Text-9077-1-10-20131226Krystian BonghanoyNo ratings yet

- Assessment of Indegenious Fermentation Practice of Kocho in Different Area of EthiopiaDocument25 pagesAssessment of Indegenious Fermentation Practice of Kocho in Different Area of EthiopiaHelen WeldemichaelNo ratings yet

- Abstrak Isrm (1) BacterialDocument1 pageAbstrak Isrm (1) Bacterialkendah sukendahNo ratings yet

- Extraction and Characterization of Starch From Yard-Long Bean (VignaDocument7 pagesExtraction and Characterization of Starch From Yard-Long Bean (VignaAhadian AsrorNo ratings yet

- Low Cyanide High Protein Dry Fufu Powder Processed From Cassava Using Starter Culture Isolated From The Fermenting MashDocument7 pagesLow Cyanide High Protein Dry Fufu Powder Processed From Cassava Using Starter Culture Isolated From The Fermenting MashEditor IJTSRDNo ratings yet

- 388517444400Document7 pages388517444400cmcb624No ratings yet

- Processing and Quality Evaluation of Crackers From Cassava FlourDocument4 pagesProcessing and Quality Evaluation of Crackers From Cassava FlourDBNo ratings yet

- Effects of Varying Dietary Levels of Carica Papaya Seed Meal Powder (PSM) On Growth and Histology of Gonads in Oreochromis Niloticus LarvaeDocument10 pagesEffects of Varying Dietary Levels of Carica Papaya Seed Meal Powder (PSM) On Growth and Histology of Gonads in Oreochromis Niloticus LarvaeMawdaNo ratings yet

- Maheswari227 82020PCBMB8536Document7 pagesMaheswari227 82020PCBMB8536pennylanecortez12No ratings yet

- Kel 2 Biotekling-1Document19 pagesKel 2 Biotekling-1Annisa TsaniNo ratings yet

- Studies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisDocument5 pagesStudies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisAnoif Naputo AidnamNo ratings yet

- Isolation and Sensory Evaluation of Saccharomyces Cerevisiae From Palm Wine (Elaeis Guinneensis) Gotten From Different Sites in EnuguDocument10 pagesIsolation and Sensory Evaluation of Saccharomyces Cerevisiae From Palm Wine (Elaeis Guinneensis) Gotten From Different Sites in EnuguEmmanuel KingsNo ratings yet

- Somatic Embryogenesis for Micropropagation of Coconut (Cocos nucifera L.)From EverandSomatic Embryogenesis for Micropropagation of Coconut (Cocos nucifera L.)No ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Investigatory ProjectDocument25 pagesInvestigatory ProjectThe Unknown GuyNo ratings yet

- The Potential of Hibiscus Bougainvilleaorange Peeland Grapes Extracts As An Organic InkDocument3 pagesThe Potential of Hibiscus Bougainvilleaorange Peeland Grapes Extracts As An Organic InkXile LeadNo ratings yet

- BP Template (AutoRecovered) 1Document36 pagesBP Template (AutoRecovered) 1baljinder kaurNo ratings yet

- Module 2 Multi Skill Foundation Course (Life Sciences)Document13 pagesModule 2 Multi Skill Foundation Course (Life Sciences)SayaniHazraNo ratings yet

- Dil Maya Subba PDFDocument55 pagesDil Maya Subba PDFUgyenNo ratings yet

- Mushroom SpawnDocument32 pagesMushroom Spawnchiomablessing858No ratings yet

- Hazardous - Resistance List KL10K Coil Coating v1.2Document6 pagesHazardous - Resistance List KL10K Coil Coating v1.2ajajsainNo ratings yet

- Roasted Sitaw Beans As Potential Coffee Alternatives and Dietary Fiber in Concepcion, TarlacDocument14 pagesRoasted Sitaw Beans As Potential Coffee Alternatives and Dietary Fiber in Concepcion, TarlacJuan Miguel Munoz100% (1)

- BSc. BT Sem I U-2 CarbohydratesDocument62 pagesBSc. BT Sem I U-2 CarbohydratesGurpreet SinghNo ratings yet

- Starches ReviewerDocument6 pagesStarches ReviewerimjuuNo ratings yet

- Bactreial Growth CurveDocument29 pagesBactreial Growth CurveEZHIL NNo ratings yet

- Effect of Calcium Nitrate and Potassium Nitrate Priming On Seed Germination and Seedling Vigour of Papaya (Carica Papaya L.)Document6 pagesEffect of Calcium Nitrate and Potassium Nitrate Priming On Seed Germination and Seedling Vigour of Papaya (Carica Papaya L.)boonyongchiraNo ratings yet

- Baby SoapDocument1 pageBaby SoapEndang WahyuniNo ratings yet

- Cheese Under MAPDocument25 pagesCheese Under MAPqualitaNo ratings yet

- 1 Geek General Agri McqsDocument143 pages1 Geek General Agri Mcqswaheed abidNo ratings yet

- Design and Fabrication of Cocopeat MachineDocument18 pagesDesign and Fabrication of Cocopeat MachineRatikant GaikwadNo ratings yet

- Prathista ppt1Document19 pagesPrathista ppt1Sai SriyaNo ratings yet

- Ensure: Product InformationDocument4 pagesEnsure: Product InformationCamilleNo ratings yet

- 3 A. Prosiding ICSTLM LengkapDocument19 pages3 A. Prosiding ICSTLM LengkapMa IntangNo ratings yet

- Classification of LipidsDocument18 pagesClassification of LipidsD Kaur100% (1)

- INDIGENOUS USE OF PATANI Phaseolus Lunatus Linn LEAVES AMONG ILOCANOS MERCITA QUEYPO QUEDDENGDocument10 pagesINDIGENOUS USE OF PATANI Phaseolus Lunatus Linn LEAVES AMONG ILOCANOS MERCITA QUEYPO QUEDDENGHannah Iza ForrosueloNo ratings yet

- Proceeding 1 (Cellulolytic and Proteolytic Yeast)Document6 pagesProceeding 1 (Cellulolytic and Proteolytic Yeast)Syifa AuliaNo ratings yet

- Green BuffDocument5 pagesGreen BuffJuthi Rahman100% (1)

- Group Contribution Model For Predicting Viscosity of Fatty CompoundsDocument8 pagesGroup Contribution Model For Predicting Viscosity of Fatty Compoundsmalek malakiNo ratings yet

- Protein Glue in The Packaging Industry 2017Document13 pagesProtein Glue in The Packaging Industry 2017jpsingh75No ratings yet

- CBSE Class 7 Science Notes Chapter 1 Nutrition in PlantsDocument5 pagesCBSE Class 7 Science Notes Chapter 1 Nutrition in Plantsgtbit.cse.aashishNo ratings yet

- Intelligent PackagingDocument8 pagesIntelligent PackagingJuan Pablo BongiornoNo ratings yet

- Activity # 3 (50 Points) : Name: Christian C. Pacamarra Course: Bacomm 2ADocument3 pagesActivity # 3 (50 Points) : Name: Christian C. Pacamarra Course: Bacomm 2AChano Pacamarra100% (1)

- Expt 2: Estimation of Glucose by Benedict's Quantitative ReagentDocument21 pagesExpt 2: Estimation of Glucose by Benedict's Quantitative ReagentMuhammad Hanif100% (1)

Improving The Indigenous Processing of Kocho

Improving The Indigenous Processing of Kocho

Uploaded by

Angeline GOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improving The Indigenous Processing of Kocho

Improving The Indigenous Processing of Kocho

Uploaded by

Angeline GCopyright:

Available Formats

Nutrition & Food Yirmaga, J Nutr Food Sci 2013, 3:1

http://dx.doi.org/10.4172/2155-9600.1000182

Sciences

Research Article Open Access

Improving the Indigenous Processing of Kocho, an Ethiopian Traditional

Fermented Food

Melese Temesgen Yirmaga*

Department of Food Science and Post Harvest Technology, Institute of Technology, Haramaya University, Ethiopia

Abstract

The experiment was carried out using factorial combination of two enset varieties, three fermentation time, and

two processing methods with tree replication, to investigate the effects of fermentation time, variety and processing

methods on physicochemical qualities, chemical composition, microbial quality and sensory acceptance of kocho.

In this study, kocho samples were prepared from Kinnare and Astare enset variety, and processed by modified and

traditional Gurage kocho processing methods. The modifications were made by adding minimally boiled pulp of

chopped pseudo stem in traditional processing methods of kocho. All processed kocho samples were then fermented

for 10, 20 and 30 days. The results revealed that physicochemical qualities, chemical composition, microbial quality

and sensory acceptance of kocho were affected by fermentation time, enset variety and processing methods.

Kocho samples of Kinnare variety resulted in higher TTA and lower pH than those of Astare variety, which

showed 0.55% LA and pH of 4.86. Modified Gurage kocho processing method resulted in lower TTA and higher pH

value. As fermentation time increased, crude fiber, ash and carbohydrate contents decreased; moisture and crude

protein contents increased; however, crude fat content of kocho samples did not show significant change. Higher

crude protein, crude fat and carbohydrate contents were recorded for kocho samples from Kinnare variety, on the

other hand, kocho samples from Astare variety resulted in higher crude fiber, total ash, and moisture content.

Kocho of Kinnare variety had resulted in higher counts of LAB, yeast and mold, total aerobic bacterial and lower

counts of coliform bacteria. Kocho samples processed by traditional Gurage processing method resulted in higher

yeast and mold counts and coliform counts, while kocho samples prepared by modified Gurage processing method

resulted in higher LAB, and total aerobic bacterial count. Sensory evaluation showed that kocho bread baked from

kocho of Kinnare variety, prepared by modified Gurage processing, followed by fermentation, was the most liked

than kocho breads from Astare variety in the study.

Keywords: Indigenous processing; Enset variety; Minimally boiled from the mixture of the decorticated (scraped) leaf sheaths and grated

pulp; Fermentation time corm (underground stem base). However, there are many constraints

on kocho which influence quality attributes due to the variation in

Introduction variety selection, duration of fermentation, and method of processing.

Enset is one of the potential indigenous crops for food, and the This study was, therefore, designed to evaluate the suitability of two

varieties, appropriate processing methods, and optimized fermentation

Enset cultivation system is economically viable, and is one of the

time for kocho production.

few successful indigenous and sustainable agricultural systems [1].

It is sustainable because it has been providing food for humans for Materials and Methods

generations from the same plot, and maintains the quality of life of the

people. It grows in a wide range of environmental conditions. Even Experimental procedure and sample preparation

though it is grown in many wide areas, the dwellers of the central and The study experiment was organized in a factorial design with

southern parts of Ethiopia are the only people that use Enset as a staple two Enset varieties (Kinnare and Astare), two processing method

and co-staple crop. (traditional and modified), and three fermentation time with three

Since Enset (Ensete ventricosum) products such as Bulla and Kocho replication. The samples were obtained fron Gurage Zone, Gunchire

are one of the main energy sources and serve as the staple and co-staple woreda, in SNNP, Ethiopia. The two enset variety (Kinnare and

food for many people in Ethiopia, knowledge of the fermentation Astare) were selected for kocho preparation, based on the consumption

process is of particular interest for proper utilization of the crop. The

fermented kocho is often stored in pits that are lined with Enset leaves.

The kocho must be left in a storage pit for a minimum of a month, but it *Corresponding author: Melese Temesgen Yirmaga, Department of Food

can be stored for many months and even for several years [2]. Science and Post Harvest Technology, Institute of Technology, Haramaya

University, PO Box 1848 Dire Dawa, Ethiopia, E-mail: mele121921@yahoo.com,

The length of fermentation time varies from a few weeks to several meleset@haramaya.edu.et

months, depending on ambient temperatures of incubation. In the

Received November 29, 2012; Accepted December 26, 2012; Published

cooler regions, it is kept in a pit for years, and the quality is said to December 28, 2012

increase with increasing fermentation time. In warmer regions, Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an

fermentation is rapid and is therefore, terminated within 3 to 6 months Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182. doi:10.4172/2155-

[3]. After the fermentation is completed, a portion is removed from the 9600.1000182

pit and the liquid is squeezed out of it, resulting into a moist fibrous Copyright: © 2013 Yirmaga MT. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

kocho. The major foods obtained from Enset are kocho, bulla and use, distribution, and reproduction in any medium, provided the original author and

amicho. However, kocho is the bulk of the fermented food obtained source are credited.

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182.

doi:10.4172/2155-9600.1000182

Page 2 of 6

frequencies and local preference of Enset varieties for kocho and bulla Where M3 is the weight of sample

preparation. All analysis was done at the Food Science and Post Harvest

Total crude fat content: A 3 g dried sample of kocho was extracted

Technology, and Pathology Laboratories Haramaya University from

with 100 ml petroleum ether, for a minimum period of 4 hrs in the

May-August 2012.

soxhlet extractor. The solvent was then evaporated by heating on a

Two varieties (Kinnare and Astare) of Enset were processed into steam bath. The flask containing the extracted fat was dried on steam

kocho, according to Gurage processing method of kocho and bulla bath to a constant mass. The total crude fat was calculated as percentage

preparation. During harvest, leaves and older leaf sheaths were first by weight:

removed from the designated plants for kocho and bulla preparation. W2 - W1

Crude fat, percent by weight = ×100

The internal leaf sheaths were separated from the pseudostem down to W

the true stem, which was section between corm and pseudostem. Then, Where, W1=weight of the extraction flask

the true stem was separated or stumped from the underground corm.

W2=weight of the extraction flask plus the dried crude fat (g)

The concave side of the leaf sheath was peeled and cut into pieces of

about half meter length (approximate length), and split lengthwise, in W=weight of the sample

order to shorten the leaf sheath to a workable size. Then, the pseudostem

was decorticated using a locally made bamboo scraper, while the leaf Total crude protein content: Crude protein was analyzed by micro

sheath is held on an incline against a wooden plank. To decorticate Kjeldahl method. The general procedure included the following steps

the leaf sheath, the women might sit on the ground (often on Enset of digestion: 2 g sample was digested by adding 5 ml of concentrated

leaves), and use one leg to hold the leaf sheaths in place. The working sulfuric acid, in the presence of potassium sulfate catalyst in a Kjeldahl

area used for decortication was covered with Enset leaves. Then, the flask, then neutralization and distillation as the digest was diluted with

corm was grated separately by serrated animal bone after uprooting and 30 ml distilled water. 25 ml of NaOH (40%) was added to neutralize the

removal of any soil from its surface with a locally made knife. After sulfuric acid. Upon addition of NaOH, the ammonium was distilled

the completion of decorticating and grating, the leaf sheath pulp was off and trapped into a boric acid and solution containing methyl blue

spread on fresh Enset leaves covering the ground, after which the grated and methyl red indicators. Finally, titration of the ammonium attached

corm was mixed on the decorticated pulp. Turning, mixing, rinsing, to borate anion was titrated with standardized HCl, and total crude

and chopping of the decorticated pulp and starter was continued over a protein of kocho was calculated as total nitrogen, according to AOAC

period of time, until the mixture is partially fermented, when it is then [7].

referred to as kocho. The samples were subjected for analysis after 30 Total ash content: Ash content of kocho was determined, according

days of fermentation. to AOAC [7] method. Clean drying dish were dried at 120°C in hot air

The modified method used for kocho samples were prepared by oven and ignited at 550°C for about 3 hours in a muffle furnace (MF 120,

modifying the traditional preparation method. Following the same nuve, Kabul, Turkey). Then, cooled in desiccators and weighed using

harvesting and processing method as the above traditional method, two analytical balance. Then, 2 gram of kocho powder sample was put and

varieties of Enset (Kinnare and Astare), kocho samples were prepared weighed (M2). The sample was dried at 105°C for 1hr and carbonized

by adding minimally boiled decorticated Enset pulp that is ready for by blue flame of Bunsen burner, until the contents turn black. The

fermentation. The pulp was boiled at 72°C for 20 minutes. Then it dish with its contents was transferred to a muffle furnace and ignited

was cooled to 40°C, and added to the decorticated pulp prepared by at about 550°C, until washing was complete. The residue was weighed

traditional Gurage processing methods. Finally, kocho powder samples (M3). The total ash was expressed as percentage on dry basis as follow:

were taken from 10, 20 and 30 days fermented kocho for experimental M3 - M1

Total Ash(%) = × 100

analysis, from both traditional and improved preparation methods. M2 - M1

Total carbohydrate content: Total carbohydrate was determined

Physico-chemical analysis by difference.

Moisture content: Moisture content of the sample was analyzed by Total Carbohydrate(%) = 100 - (%M + %P + %F + %Fb + %A)

oven drying method [4]. A drying dish was dried in an oven at 105°C

Where, %M=Moisture content in percent

for 1 hr, and placed in desiccators to cool. The weight of the drying dish

(W1) was determined. 2 g of kocho samples were weighed in the dry %P=Crude protein content in percent

dish (W2) oven dried at 105°C for 2 hr, and after cooling in a desiccators

to room temperature, it was again weighed (W3) [5,6]. %F=Crude Fat content in percent

%Fb=Fiber content in percent

Chemical analysis

%A=Ash content in percent

Total crude fiber content: A 2 g sample was transferred to 400

ml beaker. After digestion with 1.25% sulfuric acid and washed with Titratable acidity value

distilled water, and then digested by 1.25% NaOH, the sample was

filtered in coarse porosity crucible in apparatus, at a vacuum of about The titratable acidity of kocho was determined by titrating the

25 mm. The residue left after refluxing was washed again with 1.25% sample with a standard base (NaOH) to the phenolphthalein endpoint

sulfuric acid near the boiling point. The residue was then dried at 95°C [8]. A 10 g kocho sample was blended with 90 ml distill water, and

overnight, cooled in desiccators, and weighed (M1). After mashing for filltered through 750 mesh size sieve. 10 ml volume of the sample was

2 hrs at 500°C, it was cooled in desiccators, and weighed again (M2). titrated with 0.1N standard solution of NaOH, after addition of 3 drops

The total crude fiber was expressed in percentage as: of phenolphthalein indicator. As the color of the sample changed to

pink, the volume of NaOH consumed until end point reached was used

M1- M2

Total crude fiber(%) = to calculate the titratable acidity, expressed in terms of the predominant

×100

M3 organic acid.

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182.

doi:10.4172/2155-9600.1000182

Page 3 of 6

pH value decreased due to excessive leaching during pit fermentation. In

contrast, in this study, kocho moisture content was slightly increased

The pH of kocho sample was determined from 1/10 dilution of with increase in fermentation time due to using of equal amount of little

sample by glass electrode attached to digital pH meter at the 10th, 20th quantity water during intermediate mixing, and no leaching effect was

and 30th days of fermentation time. 10 g of kocho sample was mixed observed. The difference in moisture content was probably contributed

with 90 ml of distilled water. After calibrating the pH meter at 7.00 with by difference of initial moisture content of the Enset varieties, and

buffer solution, the pH sample was measured. unequal loss of liquid during squeezing process stage.

Microbiological assay The highest values were obtained from kocho prepared from

The total microbial population was estimated using the procedure Astare variety, while the lowest moisture content was recorded for

that had been followed by Bracket. Kocho samples were taken aseptically kocho samples prepared from Kinnare. Such a difference could be as a

from each replication using pre-sterilized pipette, and immediately result of genetic differences existing between the varieties [11]. Kocho

subjected to serial dilution. Sample (1 ml) was serially diluted in 9 prepared by traditional Gurage method has the highest moisture

ml of 0.1% peptone water that was kept in the refrigerator. The serial content, and the lowest moisture content was recorded from improved

dilution was done in the range of 10-1 to 10-7 series of test tubes. For preparation. The difference in moisture content of kocho was attributed

the estimation of total aerobic bacteria, the sample of 1 ml was taken to the difference observed in the time taken, especially at squeezing

from the test tube aseptically using discrete pipette, and was plated on stage. In Gurage traditional processing, the scrapped pulp was slightly

plate count agar. Finally, all plates were incubated at 30°C for 2 days. squeezed, but in improved processing, the scrapped pulp was squeezed

The growth in bacteria was inspected after 2 days, and the colonies were for more extended time to extract the spent liquid for raw material

counted using standard colony counter. of bulla production. The general result showed lower moisture was

observed in kocho samples that were prepared from Kinnare, than from

For the estimation of total coliform population, the sample of 1 ml Astare and pulp squeezing effort. This difference in moisture among

was aseptically taken from the test tube using sterilized discrete pipette, kocho products processed from Kinnare and Astare were partly due

and was plated on duplicate Violet Red Bile Agar (VRBA) [9]. Finally, to difference in moisture due to the method of processing and loss of

they were placed inverted and incubated at 37°C for 1 day. Afterwards, evaporation during fermentation period.

the growth of coliforms was inspected and the colonies were counted

using standard colony counter. For the estimation of yeast and molds, the Crude fiber content

sample of 1 ml was aseptically taken from the test tube using sterilized

As it can be seen from table 1, the crude fiber content of kocho

discrete pipette, and was plated on Rose-Bengal chloramphenicol agar

samples showed significant difference due to the variety processing

base (oxoid CM549) [9]. Then, they were placed, inverted and incubated

method and fermentation time. Kocho samples made from Astare

at 25°C for 3 to 5 days. The growth in yeast was inspected after 3 days,

variety had more crude fiber content than kocho from Kinnare variety,

and non growth plates were incubated for two days more, to complete

4.42% and 3.37% crude fiber content, respectively. Similarly, the slightly

the recommended incubation period. For lactic acid bacteria, volumes

highest value, 3.96% in crude fiber content were recorded for kocho

of 0.1 ml of the appropriate dilutions were spread-plated on pre dried

samples processed from traditional method than modified processing

surfaces of MRS agar (de Man, Rogosa and Sharpe Agar), and incubated

methods. This is due to the modified processing method, which digests

under anaerobic conditions at 30°C for 48 hrs [10].

the fibers found in the content due to the addiction of molten pulp, but

Sensory evaluation processing method did not have a significant difference in crude finer

content. As the fermentation time increased, the crude fiber content of

Descriptive sensory evaluation was used in the screening of kocho kocho was decreased, 10, 20, and 30 days of fermentation resulted 2.67%,

bread, based on their sensory quality characteristics. A total of 30 2.29% and 1.89% crude fiber, respectively. The decrease in fiber content

panelists were involved in the sensory evaluation. Sixteen cuts of kocho during fermentation could be attributed to the partial solubilization or

bread samples were presented for panelists to evaluate the taste, color, degradation of cellulosic and hemi-cellulosic structural materials in the

flavor, and overall acceptability of the samples. During the evaluation plant (pulp) by microbial enzymes [12] and in this also, fermentation

period, the panelists attended two sessions. Eight samples were served

at each session and then, all panelists were allowed to taste and evaluate

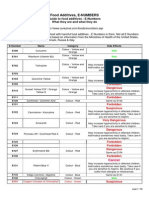

the samples for each quality feature using rating scale. All panelists were MC Crude Fiber Ash Crude fat Crude Protein CHO

(% wb) (% db) (% db) (% db) (% db) (% db)

instructed to make their own individual assessments, according to the

Variety

evaluation criteria provided for each samples on the basis of taste, color,

Astare V1 60.20 4.42 2.33 1.04 3.17 32.75

flavor, and overall acceptability. Finally, the scores of all judges were

Kinnare V2 57.15 3.37 2.18 1.27 3.43 35.53

added and divided by the number of judges to find the final mean score.

Processing Methods

Statistical analysis Traditional PM1 60.50 3.96 2.24 1.20 3.47 34.00

A factorial combination of the two enset varieties, two processing Improved PM2 63.3 3.75 2.29 1.11 3.26 31.24

methods, and three fermentation times with three replications was used Fermentation Time

in the study. The difference between the treatments was determined by 10th days FT1 46.78 2.67 3.41 1.60 4.42 44.08

the analysis of variance for factorial experiment, using SAS, and the 20th days FT2 46.66 2.29 3.39 1.52 4.78 39.63

comparison of the mean was done by LSD tests. 30th days FT3 44.55 1.89 3.52 1.50 5.09 33.80

Mean 46.03 2.28 3.44 1.54 4.76 39.17

Results and Discussion CV 0.89 1.47 0.36 5.21 1.24 0.52

Moisture content Table 1: The main effect of Enset variety, processing methods and fermentation

time on moisture content, crude fiber, ash content, crude fat, crude protein, and

During the fermentation of kocho, the moisture content was carbohydrate content of kocho samples prepared for the study.

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182.

doi:10.4172/2155-9600.1000182

Page 4 of 6

increases the breakdown of dietary fiber to soluble and digestible form, also known that fermentation had the general effect of increasing the

and which decrease the total indigestible crude fiber content. essential amino acid content of kocho. The same trends in increasing of

crude protein were observed in barley fermented product [15].

Ash content

Carbohydrate

The ash content difference among variety, processing method, and

fermentation time was not highly significant (Table 1). Kocho samples As the finding of the study, there was significant difference in

prepared from Astare varieties subjected by improved processing carbohydrate content among the varieties, processing methods, and

method had showed the highest ash content, 2.33% and 2.39%, fermentation time. The maximum carbohydrate content (53.53%)

respectively. for kocho samples was obtained from kinnare, while the minimum

carbohydrate content (32.75%) was obtained from astare. Similarly,

The difference in ash content may be due to genetic or cultivar

the carbohydrate content had showed significant difference due to

variation of Enset varieties [13]. Concerning fermentation time, it

the processing method. On the other hand, the highest carbohydrate

indicated that fermentation decreased the ash content of enset, and

content (34.00%) was found in kocho processed by traditional than

thus, kocho has lower ash content than Enset plant [14]. This could

minimally modified method (31.24%).

due to fermentation, which imparts the solubility of minerals and

other organic constituents, which contribute the total ash content in As the fermentation time increased (at 30 days of fermentation

kocho. On the other hand, the ash content of kocho prepared by two time), the carbohydrate content of kocho sample decreased. The

processing methods had almost the same ash content. Therefore, the highest carbohydrate content (44.08%) was recorded at 10 days of

concentration ash in kocho did not significantly affect by the variety, fermentation time, and the lowest value (33.80%) was recorded at

processing method, and the ash content is highly depending on the fermentation time of 30 days. The reduction of carbohydrate content

fermentation time. during the fermentation process was possibly due to the breakdown

of more complex components by enzymes produced by fermenting

Crude fat content microorganisms. And this might be also associated with the reduction

In this study, the crude fat content reached higher value depending of crude fiber content, also advanced the decrease in carbohydrate

on the variety and fermentation period. There was positive correlation content. Therefore, decrease in carbohydrate content is related with the

between variety and fermentation period on fat content of kocho addition of fermentation time, resulting to enzymatic degradation and

sample. An effect was observed due to fermentation time difference on depolimeraization of carbohydrate to their smaller forms. The general

the kocho in crude fat content. When fermentation time elongates, the trend observed in this study as presented from table 1 was decreasing

crude fat content in kocho had decreased, 1.60% and 1.52% for 10, 20 carbohydrate content due to increasing fermentation time.

and 30 days of fermentation time. This could be due to fermentation,

Titratable Acidity (TTA)

which increase the degradation of fats by lepolytic enzymatic activities

and microbial proliferation causing the consumption of nutrients. In this the study, there was significant difference in titratable acidity

percent among the varieties, processing methods and fermentation

Concerning processing methods, almost the equal amounts of

time. The maximum titratable acidity percent among the two Enset

crude fat contents of kocho were recorded from kocho processed by

varieties was found in kocho prepared from Kinnare than stare, 0.61%

traditional and modified methods used in this study, 1.20% and 1.11%,

and 0.55%, respectively.

respectively. The higher crude fat content (1.27%) was recorded from

kocho of kinnare, and the lower crude fat content (1.04%) was recorded Similarly, different amounts of titratable acidity percent were

from Astare variety kocho. The difference in crude fat content among recorded from kocho prepared by two processing methods during

Enset varieties was most probably attributed by varietal variation. kocho fermentation. Highest titratable acidity percent (0.57%) of kocho

sample was recorded from traditional Gurage processing of kocho, while

Crude protein content lowest titratable acidity percent (0.50%) was obtained from modified

The crude protein content of kocho samples prepared from processing methods.

traditional method of kinnare variety were the highest (3.47% and An effect of fermentation time on titratable acidity percent was

3.43%, respectively) of all, while the lowest crude protein content of highly significant during 10, 20, and 30 day’s fermentation time, as

kocho were obtained from modified processed method of astare variety, presented on table 2. The titratable acidity percent was significantly

3.26% and 3.17%, respectively. This could be associated with the crude

protein difference in variety and the addition of pre heated pulp to well

increase the solubility of proteins into their smaller units, which results Variables pH TTA (%)

to lower crude protein content in the product. varieties

Astare V1 4.86 0.55

There was remarkable increase in crude protein content of kocho

Kinnare V2 4.78 0.61

samples as fermentation time increased from 10, 20 and 30 days. The

Processing methods

highest crude protein content (5.09%) was obtained at 30 days of

Traditional PM1 4.34 0.57

fermentation, while the lowest value (4.42%) was recorded at 10 days

Modified PM2 4.52 0.50

of fermentation.

Fermentation time

On the other hand, in both varieties, as the fermentation time 10th days FT1 4.64 0.27

increased, the crude protein content was also slightly increased. The 20th days FT2 4.28 0.49

crude protein content of kocho increased due to the action of fermenting 30th days FT3 3.79 0.87

microorganisms in the synthesis of some amino acids, and improved Table 2: Effect of Enset variety, processing methods and fermentation time on pH

the quality of the protein, as determined by amino acid profiles. It is value and Titratable acidity (%) of kocho.

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182.

doi:10.4172/2155-9600.1000182

Page 5 of 6

inclined from 10-30 days of fermentation period. Accordingly, the Total aerobic bacteria Coliform LAB Yeast & Mold

Variable

highest (0.87%) titratable acidity percent was found at 30 days of (cfu/g) (cfu/g) (cfu/g) (cfu/g)

fermentation time, and the lowest (0.27%) titratable acidity percent was Varieties

obtained for 10 days of fermentation time. Astare V1 8.64 2.77 8.00 4.13

Kinnare V2 8.66 2.71 8.05 4.38

pH value Processing methods

As the TTA content of kocho increased, the pH value was dropped. Traditional PM1 11.15 2.36 7.52 3.89

pH value of kocho samples would be affected by Enset varieties, Modified PM2 6.11 1.01 7.60 2.23

processing methods, and fermentation time. Among Enset varieties, the Fermentation time

highest pH value (0.86) of kocho samples was founded from Astare,but 10th day FT1 15.02 7.26 15.11 3.98

the lowest pH value(0.78) was founded from kinnare variety. This is

20 day FT2

th

6.51 15.23 2.55

inversely related with titratable acidity percent for the same Enset 15.38

varieties, used for kocho preparation. 30th day FT3 15.93 3.70 16.11 2.60

Concerning processing methods, the maximum pH value (0.57) Table 3: Effect of Enset variety, processing methods and fermentation time on

microbial quality of kocho samples.

was recorded for kocho samples from modified processing method,

and the minimum value (0.50) was obtained from kocho samples from processing method of kocho, respectively. The use of minimally

traditional processing methods. This is also inversely related with preheated pulp during kocho preparation can contribute to low count of

titratable acidity percent for the same processing methods used for coliform due to thermal effect and high production of TTA and lowerd

kocho preparation. pH.

Finally, the effect of fermentation time was significant on pH As revealed from the above table, effect of fermentation time on

value of kocho samples. As increasing fermentation time increase, the the yeast and mold count of kocho was remarkably significant. The

pH value of kocho samples declined. Therefore, the highest pH value highest counts of yeast and mold reached log 3.98 cfu/g at 10 days of

was (4.62) founded at 10 days and the lowest pH value (3.79) was fermentation time of kocho, and lowest count of yeast and mold reached

founded at 30 days of fermentation time. This is inversely related with log 2.60 cfu/g at fermentation time of 30 days. This reduction in yeast

titratable acidity percent for the same fermentation time used for kocho mold might be anaerobic condition of kocho fermentation, followed

preparation. by a decrease in Ph, and increases in TTA, possibly contributed. The

From the above table, at 10 days of fermentation time, lowest counts traditional processing method also showed high yeast mold count

of total BC (log 15.02/g) was recorded and the highest counts of total than pre heat modified method. This could be due to heat effect on

BC (log 15.93 cfu/g) was reached at 30 days of fermentation time kocho. reduction of yeast mold. Similarly, kocho obtained from kinnare variety

Ashenafi [16] explained that kocho and bulla had high counts of aerobic had maximum yeast and mold log 4.38 cfu/g and the minimum yeast

mesophilic bacteria and yeasts as increasing fermentation time increase. and mold log 4.13 cfu/g was found from kocho samples prepared from

astare variety.

On the other hand, variations on count of total aerobic bacteria were

Concerning Lactic acid Bacteria count, the highest counts of LAB

observed in kocho prepared from different Enset varieties. Higher total

(log 16.11 cfu/g) were recorded at 30 days of fermentation time, and

bacterial count reached log 8.66 cfu/g in kocho of Kinnare variety. The

the lowest counts of LAB (log 15.11 cfu/g) were obtained at 10 days

lower total bacterial count (log 8.64 cfu/g) was recorded from Astarte

of fermentation time. The result indicated that when the fermentation

variety kocho. The difference in total bacterial count between varieties

time increased, the counts of LAB also increased due to the ability of

was due to slow time in fermentation process, difference in production

LAB growing at low pH of kocho, when counts of other fermenting

of organic acids, dominantly lactic acid, and pH drop of fermenting

microbes decreased. However, LAB counts of kocho prepared from

mass. Therefore, fermentation starts earlier in kinnare variety than in different Enset varieties and processing methods did not indicated

Astare variety, or Astare variety had more delay time of fermentation variation in counts.

and low count of aerobic bacteria.

The data from this experiment indicate that there was relationship

As the fermentation time increased from 10 to 30 days, counts of between the kocho quality parameters and sensory evaluation results.

coliform in kocho was significantly decreased, as counts of coliform The prepared kocho ketchups had good flavor characteristics, flavor,

in kocho sample from log 7.26 cfu/g at 10 days of fermentation time texture, and fairly overall acceptability. The highest color acceptance

to log 3.70 cfu/g at 30 days of fermentation time. This clearly showed mean score (7.91) was obtained from kocho bread baked from 30 days

that counts of coliform in kocho decreased as the fermentation time fermented kocho. The lowest color acceptance score (6.35) was given to

increased. Similarly, coliform counts in kocho from different Enset kocho bread baked from 20 days fermented kocho. As the fermentation

varieties had showed variation. The highest count of coliforms (log 2.77 time of kocho increased, its bread color acceptance also increased.

cfu/g) was recorded from kocho of astare variety and the lowest count The fermenting microorganisms decompose some of complex

of coliforms (log 2.71 cfu/g) was recorded from kinnare kocho. The carbohydrates, pigments from the cellular structure of kocho pulp, by

difference in counts of coliform of kocho between varieties of Enset was producing active enzymes. Kocho breads baked from kinnare variety

possibly due to variation in organic acid production and early lowered had high score than kocho bread baked from astare variety. Similarly,

in pH value. processing method showed clear difference in color acceptance and the

highest score was found from kocho breads baked under traditional

In addition to this, kocho prepared by different processing methods

method that pre heat modified methods (Table 4).

had showed variation on counts of coliform (Table 3). The highest (log

2.36 cfu/g) and lowest count of coliforms (log 1.01 cfu/g) in kocho was Concerning the flavor, as the fermentation time of kocho increased,

recorded from kocho prepared by gurage traditional and modified its bread flavor level also increased. On the other hand, The highest

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182.

doi:10.4172/2155-9600.1000182

Page 6 of 6

Variables Color Texture Flavor Over all acceptance Analytical Chemists, Washington DC, USA.

Variety 5. Sarabakos GD, Kosaropoulos AE (2002) Handbook of Food Processing

AstareV1 6.12 6.27 2.23 4.55 Equipment. Food Engineering Series, Springer.

KinnareV2 7.05 7.05 2.04 5.33 6. Dadzie BK, Orchard JE (1997) Routine post-harvest screening of banana/

Processing Methods plantain hybrids: criteria and methods. INIBAP Technical Guidelines 2.

Bioversity International 47.

Traditional M1 5.95 3.21 2.82 4.44

Modified PM2 4.83 5.41 2.48 5.17 7. AOAC (1995) Official methods of analysis. (16th edn), Gaithersburg, MD.

Fermentation Time 8. Lefebvre D, Gabriel V, Vayssier Y, Fantange-Faucher C (2002) Simultaneous

HPLC Determination of Sugars, Organic Acids and Ethanol in Sourdough

10th days FT1 5.56 8.42 1.55 4.30

Process. LWT-Food Science and Technology 35: 407-414.

20th days FT2 6.35 8.94 1.90 4.94

9. Harrigan WF (1998) Laboratory methods in food microbiology. (3rd edition), Gulf

30th days FT3 7.91 9.91 2.07 5.78

Professional Publishing Academic, Sandi ago, CA.

Table 4: Effect of enset variety, processing methods and fermentation time on

10. ISO 15214 (1998) Microbiology of food and animal feeding stuffs-Horizontal

sensory attributes of kocho samples (Mean score).

method for the enumeration mesophilic lactic acid bacteria-Colony-count

technique at 30 degrees C. Standard Catalogue.

flavor level mean score (2.07) was obtained from kocho bread baked

from 30 days fermented kocho, while the lowest flavor (1.55) was given 11. Tobiaw DC, Bekele E (2011) Analysis of genetic diversity among cultivated enset

(Ensete ventricosum) populations from Essera and Kefficho, southwestern

to kocho bread baked from 10 days fermented kocho. Kocho breads part of Ethiopia using inter simple sequence repeats (ISSRs) marker. Afr J

prepared from astare varieties subjectd with traditional processing Biotechnol 10: 15697-15709.

methods showed high flavor score than kinnare varieties subjected with

12. Wizna, Abbas H, Rizal Y, Dharma A, Kompiang IP (2009) Improving the quality

modified processing method. of tapioca by-products (onggok) as poultry feed through fermentation by

Bacillus amyloliquefaciens. Pakistan Journal of Nutrition 8: 1636-1640.

Finally, as the fermentation time of kocho increased, both texture

property and overall acceptability increased. Moreover, kocho 13. Nurfeta A, Tolera A, Eik LO, Sundstøl F (2008) Yield and mineral content of

ten Enset (Ensete ventricosum) varieties. Trop Anim Health Prod 40: 299-309.

brads from kinnare Variety showed good texture profile and overall

acceptability. In line with this, kocho breads prepared from modified 14. Urga K, Fite A, Biratu E (1997) Natural fermentation of Enset (Ensete

ventricosum) for the production of Kocho. Ethiop J Health Dev 11: 75-81.

method showed better texture and over all acceptability.

15. Adebowale OJ, Maliki K (2011) Effect of fermentation period on the chemical

Conclusion composition and functional properties of Pigeon pea (Cajanus cajan) seed

flour. International Food Research Journal 18: 1329-1333.

In conclusion, extending of fermentation time, difference in

16. Ashenafi M (2002) The microbiology of Ethiopian foods and beverages: A

processing methods and different Enset variety had resulted differences review. SINET: Ethiopian Journal of Science 25: 97-140.

in chemical composition, physic-chemical characteristics, microbial

proliferation and sensory attributes of kocho. Kocho fermented for

30 days, prepared from Astare variety and processed by modified

processing method, resulted in best quality in physic-chemical quality,

chemical composition, microbial quality and sensory acceptance.

Using of pre heat processing method improved the quality of kocho and

reduced delay time in fermentation process. Therefore, fermentation

played a significant role in kocho preparation by enrichment of

the product through development of flavors, aromas, and textures,

by slightly enhancing protein content and preserving the product

through production of natural preservative. Generally, the selection of

appropriate varieties improved processing methods and recommended

fermentation time were good practice for the processing of tradition

food products, such as kocho an Ethiopian traditional fermented food.

References

1. Tsegaye A (2002) On indigenous production, genetic diversity and crop

ecology of Enset (Ensete ventricosum (Welw.) Cheesman). Doctoral Thesis,

Wageningen University Netherlands 198. Submit your next manuscript and get advantages of OMICS

2. Brandt SA, Spring A, Hiebisch C, McCabe JT, Tabogie E, et al. (1997) The Group submissions

Tree Against Hunger. Enset-based agricultural systems in Ethiopia. American Unique features:

Association for the Advancement of Science with the Awassa Agricultural

Research Centre, Kyoto University for African studies and University of Florida, • User friendly/feasible website-translation of your paper to 50 world’s leading languages

• Audio Version of published paper

Washington DC, 56.

• Digital articles to share and explore

3. Gashe BA (1987) Kocho fermentation. J Appl Bacteriol 62: 473-477. Special features:

4. AOAC (1990) Official Methods of Analysis. (15 edition), Association of Official

th • 250 Open Access Journals

• 20,000 editorial team

• 21 days rapid review process

• Quality and quick editorial, review and publication processing

• Indexing at PubMed (partial), Scopus, DOAJ, EBSCO, Index Copernicus and Google Scholar etc

• Sharing Option: Social Networking Enabled

Citation: Yirmaga MT (2013) Improving the Indigenous Processing of • Authors, Reviewers and Editors rewarded with online Scientific Credits

Kocho, an Ethiopian Traditional Fermented Food. J Nutr Food Sci 3: 182. • Better discount for your subsequent articles

doi:10.4172/2155-9600.1000182 Submit your manuscript at: http://www.editorialmanager.com/lifesciences

J Nutr Food Sci

ISSN: 2155-9600 JNFS, an open access journal Volume 3 • Issue 1 • 1000182

You might also like

- Production of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Document5 pagesProduction of Animal Feed Concentrates From Sour Sop and Pineapple Peels Using Solid State Fermentation.Gregory Kalona100% (1)

- Food Additives, E-NUMBERS PDFDocument12 pagesFood Additives, E-NUMBERS PDFjiatrou6350No ratings yet

- Effect of Microbial Fermentation On Nutritional and Safety Value of Cassava-Based FoodDocument13 pagesEffect of Microbial Fermentation On Nutritional and Safety Value of Cassava-Based FoodDessalegnNo ratings yet

- Artikel 3 EngDocument8 pagesArtikel 3 EngAndri PratamaNo ratings yet

- Comparative Evaluation of Microbiological and Nutritional Qualities of Various Cereal-Based Paps (Ogi) in Ondo State, NigeriaDocument10 pagesComparative Evaluation of Microbiological and Nutritional Qualities of Various Cereal-Based Paps (Ogi) in Ondo State, NigeriaIJEAB JournalNo ratings yet

- Ecnu 03 000078Document17 pagesEcnu 03 000078gonichamba97No ratings yet

- Coconut Coir and Beans Straw As Substrates For MushroomDocument7 pagesCoconut Coir and Beans Straw As Substrates For MushroomLily Khalidatussoleha Mohamad KhalidNo ratings yet

- Artículo Ejemplo en AmarilloDocument8 pagesArtículo Ejemplo en AmarilloNaty Ale MayorgaNo ratings yet

- Achievements in The Life SciencesDocument8 pagesAchievements in The Life Sciencessameer sahaanNo ratings yet

- Khatir 2022Document10 pagesKhatir 2022Monyet...No ratings yet

- Nutritional Profile of Three Different Mushroom Varieties Consumed in Amaifeke, Orlu Local Government Area, Imo State, NigeriaDocument9 pagesNutritional Profile of Three Different Mushroom Varieties Consumed in Amaifeke, Orlu Local Government Area, Imo State, Nigerialukasz27rNo ratings yet

- 1995cultivation Preparation and ConsumptionofEnseteDocument12 pages1995cultivation Preparation and ConsumptionofEnseteBelay TesfayeNo ratings yet

- Ajol File Journals - 82 - Articles - 71409 - Submission - Proof - 71409 973 154313 1 10 20111031Document8 pagesAjol File Journals - 82 - Articles - 71409 - Submission - Proof - 71409 973 154313 1 10 20111031alhassan bellochindoNo ratings yet

- Effects of Storage Media and Duration On Nutritional Qualities of CowpeaDocument6 pagesEffects of Storage Media and Duration On Nutritional Qualities of CowpeaKadiri ZizitechNo ratings yet

- Chemical CompositionDocument11 pagesChemical CompositionYohannes AynieNo ratings yet

- Optimization of Enset Fermentation in The Production of Kocho Using Response Surface MethodologyDocument9 pagesOptimization of Enset Fermentation in The Production of Kocho Using Response Surface MethodologyHelen WeldemichaelNo ratings yet

- 1 PBDocument8 pages1 PBTri TegarNo ratings yet

- Effect of Preprocessing Techniques On Pearl Millet PDFDocument9 pagesEffect of Preprocessing Techniques On Pearl Millet PDFRama RaoNo ratings yet

- IOSR JournalsDocument4 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)No ratings yet

- Effects of Different Processing Methods On The Nutrient Composition of Kapok (Ceiba Pentandra) Seed MealDocument6 pagesEffects of Different Processing Methods On The Nutrient Composition of Kapok (Ceiba Pentandra) Seed MealEduard MorenoNo ratings yet

- Nutritional Evaluation of Spent and Uninoculated Mushroom Substrate of Pleurotus Ostreatus Grown On Cassava Peels and SawdustDocument6 pagesNutritional Evaluation of Spent and Uninoculated Mushroom Substrate of Pleurotus Ostreatus Grown On Cassava Peels and SawdustInternational Journal of Advances in Applied Sciences (IJAAS)No ratings yet

- Nutritional Value of Mealworm, Tenebrio Molitor As Food Source PDFDocument6 pagesNutritional Value of Mealworm, Tenebrio Molitor As Food Source PDFAlexis MolinaNo ratings yet

- Lactobacillus Plantarum As Starter Culture Kunnu-Aya Produced FromDocument9 pagesLactobacillus Plantarum As Starter Culture Kunnu-Aya Produced FromMunam MustafaNo ratings yet

- 1 PBDocument15 pages1 PBRahmilia Alifa PutriNo ratings yet

- RS - Volume 9 - Issue 4 - Pages 378-391Document14 pagesRS - Volume 9 - Issue 4 - Pages 378-391samirNo ratings yet

- Sugarecane TopDocument5 pagesSugarecane TopFantahunNo ratings yet

- J Sci Food Agric - 2023 - Ngoh Newilah - Influence of Contrasting Cultivation Altitudes On The Physicochemical DigestiveDocument9 pagesJ Sci Food Agric - 2023 - Ngoh Newilah - Influence of Contrasting Cultivation Altitudes On The Physicochemical DigestiveCédric KENDINE VEPOWONo ratings yet

- Food Science and Biotechnology Volume 22 Issue 1 2013Document7 pagesFood Science and Biotechnology Volume 22 Issue 1 2013Fayzan LabNo ratings yet

- Original Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursDocument8 pagesOriginal Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursRONEL JOEL BAZAN COLQUENo ratings yet

- 10 11648 J Ijfet 20200402 12-1Document7 pages10 11648 J Ijfet 20200402 12-1MelakuNo ratings yet

- Proximate Composition, Total Phenolic Content, and Sensory Analysis of Rice Bran TempehDocument6 pagesProximate Composition, Total Phenolic Content, and Sensory Analysis of Rice Bran TempehNethania IreneNo ratings yet

- Effect of Coagulant On Physcicochemical Tofu-2019Document10 pagesEffect of Coagulant On Physcicochemical Tofu-2019icha allisaNo ratings yet

- Tepung SorghumDocument8 pagesTepung Sorghumnugraha widyatmonoNo ratings yet

- Maeda, 2003Document8 pagesMaeda, 2003María Belén VignolaNo ratings yet

- Zeenat Project FullDocument11 pagesZeenat Project FullLegit CafeNo ratings yet

- Biochemical and Functional Properties of PDFDocument12 pagesBiochemical and Functional Properties of PDFValeria OlmedoNo ratings yet

- 5776-Article Text-16109-19703-10-20191008Document7 pages5776-Article Text-16109-19703-10-20191008Kenzi LucsenteNo ratings yet

- Physicochemical and Functional Properties of NativDocument8 pagesPhysicochemical and Functional Properties of NativEmmanuel KingsNo ratings yet

- Ejemplos Ref. Bibliografica Repo-carrasco-Valencia2009Document6 pagesEjemplos Ref. Bibliografica Repo-carrasco-Valencia2009Alexandra GarciaNo ratings yet

- An Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaDocument6 pagesAn Evaluation of Oxalate Content in Cassava Roots and Sweet Potato Tubers in Areka, EthiopiaLeycoline AlmrenNo ratings yet

- Cassava Retting Water An Alternative Source For Industrial Cellulase EnzymeDocument6 pagesCassava Retting Water An Alternative Source For Industrial Cellulase EnzymeEditor IJTSRDNo ratings yet

- 1690128278aavs 11 9 1451-1456Document6 pages1690128278aavs 11 9 1451-1456Robi Amizar SikumbangNo ratings yet

- Paper TropicsDocument8 pagesPaper Tropicsdarobin21No ratings yet

- Trox 2011Document6 pagesTrox 2011Daniel AriasNo ratings yet

- ArticleDocument7 pagesArticleanrauzanaNo ratings yet

- Coconut Water As MediumDocument5 pagesCoconut Water As MediumCandy Kim50% (2)

- 2132-Article Text-9077-1-10-20131226Document11 pages2132-Article Text-9077-1-10-20131226Krystian BonghanoyNo ratings yet

- Assessment of Indegenious Fermentation Practice of Kocho in Different Area of EthiopiaDocument25 pagesAssessment of Indegenious Fermentation Practice of Kocho in Different Area of EthiopiaHelen WeldemichaelNo ratings yet

- Abstrak Isrm (1) BacterialDocument1 pageAbstrak Isrm (1) Bacterialkendah sukendahNo ratings yet

- Extraction and Characterization of Starch From Yard-Long Bean (VignaDocument7 pagesExtraction and Characterization of Starch From Yard-Long Bean (VignaAhadian AsrorNo ratings yet

- Low Cyanide High Protein Dry Fufu Powder Processed From Cassava Using Starter Culture Isolated From The Fermenting MashDocument7 pagesLow Cyanide High Protein Dry Fufu Powder Processed From Cassava Using Starter Culture Isolated From The Fermenting MashEditor IJTSRDNo ratings yet

- 388517444400Document7 pages388517444400cmcb624No ratings yet

- Processing and Quality Evaluation of Crackers From Cassava FlourDocument4 pagesProcessing and Quality Evaluation of Crackers From Cassava FlourDBNo ratings yet

- Effects of Varying Dietary Levels of Carica Papaya Seed Meal Powder (PSM) On Growth and Histology of Gonads in Oreochromis Niloticus LarvaeDocument10 pagesEffects of Varying Dietary Levels of Carica Papaya Seed Meal Powder (PSM) On Growth and Histology of Gonads in Oreochromis Niloticus LarvaeMawdaNo ratings yet

- Maheswari227 82020PCBMB8536Document7 pagesMaheswari227 82020PCBMB8536pennylanecortez12No ratings yet

- Kel 2 Biotekling-1Document19 pagesKel 2 Biotekling-1Annisa TsaniNo ratings yet

- Studies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisDocument5 pagesStudies On Bio-Ethanol Production From Orange Peels Using Bacillus SubtilisAnoif Naputo AidnamNo ratings yet

- Isolation and Sensory Evaluation of Saccharomyces Cerevisiae From Palm Wine (Elaeis Guinneensis) Gotten From Different Sites in EnuguDocument10 pagesIsolation and Sensory Evaluation of Saccharomyces Cerevisiae From Palm Wine (Elaeis Guinneensis) Gotten From Different Sites in EnuguEmmanuel KingsNo ratings yet

- Somatic Embryogenesis for Micropropagation of Coconut (Cocos nucifera L.)From EverandSomatic Embryogenesis for Micropropagation of Coconut (Cocos nucifera L.)No ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Investigatory ProjectDocument25 pagesInvestigatory ProjectThe Unknown GuyNo ratings yet

- The Potential of Hibiscus Bougainvilleaorange Peeland Grapes Extracts As An Organic InkDocument3 pagesThe Potential of Hibiscus Bougainvilleaorange Peeland Grapes Extracts As An Organic InkXile LeadNo ratings yet

- BP Template (AutoRecovered) 1Document36 pagesBP Template (AutoRecovered) 1baljinder kaurNo ratings yet

- Module 2 Multi Skill Foundation Course (Life Sciences)Document13 pagesModule 2 Multi Skill Foundation Course (Life Sciences)SayaniHazraNo ratings yet

- Dil Maya Subba PDFDocument55 pagesDil Maya Subba PDFUgyenNo ratings yet

- Mushroom SpawnDocument32 pagesMushroom Spawnchiomablessing858No ratings yet

- Hazardous - Resistance List KL10K Coil Coating v1.2Document6 pagesHazardous - Resistance List KL10K Coil Coating v1.2ajajsainNo ratings yet

- Roasted Sitaw Beans As Potential Coffee Alternatives and Dietary Fiber in Concepcion, TarlacDocument14 pagesRoasted Sitaw Beans As Potential Coffee Alternatives and Dietary Fiber in Concepcion, TarlacJuan Miguel Munoz100% (1)

- BSc. BT Sem I U-2 CarbohydratesDocument62 pagesBSc. BT Sem I U-2 CarbohydratesGurpreet SinghNo ratings yet

- Starches ReviewerDocument6 pagesStarches ReviewerimjuuNo ratings yet

- Bactreial Growth CurveDocument29 pagesBactreial Growth CurveEZHIL NNo ratings yet

- Effect of Calcium Nitrate and Potassium Nitrate Priming On Seed Germination and Seedling Vigour of Papaya (Carica Papaya L.)Document6 pagesEffect of Calcium Nitrate and Potassium Nitrate Priming On Seed Germination and Seedling Vigour of Papaya (Carica Papaya L.)boonyongchiraNo ratings yet

- Baby SoapDocument1 pageBaby SoapEndang WahyuniNo ratings yet

- Cheese Under MAPDocument25 pagesCheese Under MAPqualitaNo ratings yet

- 1 Geek General Agri McqsDocument143 pages1 Geek General Agri Mcqswaheed abidNo ratings yet

- Design and Fabrication of Cocopeat MachineDocument18 pagesDesign and Fabrication of Cocopeat MachineRatikant GaikwadNo ratings yet

- Prathista ppt1Document19 pagesPrathista ppt1Sai SriyaNo ratings yet

- Ensure: Product InformationDocument4 pagesEnsure: Product InformationCamilleNo ratings yet

- 3 A. Prosiding ICSTLM LengkapDocument19 pages3 A. Prosiding ICSTLM LengkapMa IntangNo ratings yet

- Classification of LipidsDocument18 pagesClassification of LipidsD Kaur100% (1)

- INDIGENOUS USE OF PATANI Phaseolus Lunatus Linn LEAVES AMONG ILOCANOS MERCITA QUEYPO QUEDDENGDocument10 pagesINDIGENOUS USE OF PATANI Phaseolus Lunatus Linn LEAVES AMONG ILOCANOS MERCITA QUEYPO QUEDDENGHannah Iza ForrosueloNo ratings yet

- Proceeding 1 (Cellulolytic and Proteolytic Yeast)Document6 pagesProceeding 1 (Cellulolytic and Proteolytic Yeast)Syifa AuliaNo ratings yet

- Green BuffDocument5 pagesGreen BuffJuthi Rahman100% (1)

- Group Contribution Model For Predicting Viscosity of Fatty CompoundsDocument8 pagesGroup Contribution Model For Predicting Viscosity of Fatty Compoundsmalek malakiNo ratings yet

- Protein Glue in The Packaging Industry 2017Document13 pagesProtein Glue in The Packaging Industry 2017jpsingh75No ratings yet

- CBSE Class 7 Science Notes Chapter 1 Nutrition in PlantsDocument5 pagesCBSE Class 7 Science Notes Chapter 1 Nutrition in Plantsgtbit.cse.aashishNo ratings yet

- Intelligent PackagingDocument8 pagesIntelligent PackagingJuan Pablo BongiornoNo ratings yet

- Activity # 3 (50 Points) : Name: Christian C. Pacamarra Course: Bacomm 2ADocument3 pagesActivity # 3 (50 Points) : Name: Christian C. Pacamarra Course: Bacomm 2AChano Pacamarra100% (1)

- Expt 2: Estimation of Glucose by Benedict's Quantitative ReagentDocument21 pagesExpt 2: Estimation of Glucose by Benedict's Quantitative ReagentMuhammad Hanif100% (1)