Professional Documents

Culture Documents

Injection Pump Specification Model: Vest +3Oos-R

Injection Pump Specification Model: Vest +3Oos-R

Uploaded by

Ventas R11Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Pump Specification Model: Vest +3Oos-R

Injection Pump Specification Model: Vest +3Oos-R

Uploaded by

Ventas R11Copyright:

Available Formats

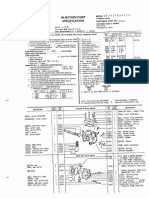

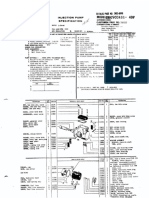

INJECTION PUMP

SPECIFICATION Model m2825~c321)1

EDITIONNo. 5 MIEO l-30-8'

ENGINE 350 V-8 FULLLOADRPM 4000

Oldsmobile

APPLICAllONAUToHOTIVE COV. REGULATION 10 % ISSUED BY: J. HcMahon

VEHICLE '978

I&V,% NOTED (2 5 RPM)

2c SET THROTTLE FOd 21 + 2 MM3ISTROKE I& 1250 RPM

d LOCK THROTTLE LEVER IN POSITION AND INSTALL

1 INJECTION LINES 093“ I D BY 25” LONG

THROTTLE LEVER PROTRACTOR 122089 ONTO SHAFT

2 NOZZLES~ 0 5 mm Orlflce Plate (Rel S B 334)

e ALIGN O” ON PROTRACTOR WITH SCRIBE MAKR ON TIMING

WINDOW BOSS UNLOCK THROTTLE LEVER AND ROTATE

3 NOZZLE OPENING PRESSURE 1700 _, 25 PSI

58O TOWARD W 0 T POSITION ADJUST MAX TRAVEL

4 CALIBRATING OIL-SAE J967 (Latest Revwon) SCREW TO THIS %I0 SETTING

TEMPERATURE 110.115°F (at Inlet) 1 CHECK TOTAL THROTTLE TRAVEL WITH THROTTLE IN LOW

IDLE POSITION, ALIGN O” ON PROTRACTOR WITH SCRIEE

5. LOW PRESSURE PLUMBING SYSTEM PER S B 334

MARK ON TIMING WINDOW BOSS MOVE THROTTLE TO

6 CAM MOVEMENT READ-OUT DEVICE 21734 W 0 T READING SHOULD BE BETWEEN 70” AND I34O

ALL FUEL READINGS ARE AT 500 STROKES 13 CHECK POINTS

PUMP OPERATINO SPEED HALF ENOlNE SPEED

a AT 1500 RPM (WOT) DE-ENIiRGIZE El.ECTRIC SHUT OFF

PUUP PICCEss0RlEs

FUEL SHOULD BE 4 mm3islroke MAXIMUM RE ENERGIZE E S 0

1. Electric Shut-off (12V ETR) (TEST WITH 8.8 VOLTS MAX.) MM31 MAXIMUM PRESSURE (l(‘d)

THRTL CAM

2. Speed Advance 5 Miwmax Governor II STROKE CYL VAR MOVEMENT T PUMP HSG

RPM POS

3. Dellvery Valve b1500 10IDL 2 MAX

4. Temperawre Compensatcng Leaf

cl500 WOT 1 50-3 00 t; 12

PUMP SETTINOS

d 1500 ADJUST 10 11 350550 8 12

1 ROLLER-TO.ROLLER DIMENSION 19710 + 0002“’ e 3600 WOT(19e) 6 008 00 I) 12

M

‘ aximum Eccenlr~clty: 008” TIR

14ooO WOT 39 * 3 4 w-110 812

2 LINKAGE GAP. 135” l0 160”

94100 WOT 32 MIN 5

3a USE GAUGE 21914 TO SET THROTTLE AT 41O CCW, AS

h44W WOT 13 MAX 5 8”Y” 125 MAX ii 12

MEASURED BETWEEN THROTTLE BALL STUD AND THROTTLE

SHAFT VERTICAL CENTERLINE

I 575 LO IDL 1012” 3 4 12

..

b

USE L I SCREW TO ADJUST. IF NECESSARY CHECK d OF

ADJUST LOW IDLE SCREW UNTIL CONTACT IS MADE WITH

BALL STUD TO VERTlCAL$ OF SHAFT AT 39Ql3O (USE GAGE

IDLE STOP BOSS THIS WILL INSURE 41O WHEN GAUGE IS

21914)

REMOVED FROM PUMP

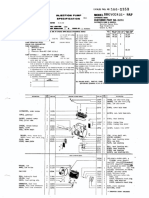

14 AIR TIME PUMP USING GAGE 21916 (PER SB334) SET TO

4 OPERATE PUMP AT 1000 RPM (WOT) FOR 10 MINUTES TO

-4.5" to -5.5 -

BRING TO OPERATING TEMPERATURE AND CLEAR AIR FROM

15 NAME PLATE LEFT Viewmg Trans Pump End

SYSTEM

16 TIMED LEFT V~ew~na Trans Puma End

CHECK E S 0 FOR PULL IN WITH 8 80 VOLTS MAX

17 TIMED TO CAM (FOR GEL END OF’INJECTION)

THROTTLE LEVER IN LOW IDLE POSITION AT 400 RPM

18 TIMED TO THIS CYLINDER (FROM T PUMP END) Q

SET T PUMP PRESSURE @ 2000 RPM (WOT) FOR%-64ps1

19 SPECIAL NOTES 8

vEsT STAND +3oos-rPRESSURE SET AT 5 k 0 5 pso a Torque all lasteners per XL784 or SRI%

CHECK FOR MINIMUM LIFT OF 18“ HG AT 400 RPM

b Pump lo be tested with Fltllngs 22109 X 21606 installed

SET RETURN OIL TO 250.350 ccimln (j 2000 RPM (WOT)

c Seal MaxImum Travel AdlustIng Screw with Retamtng

CHECK HOUSING PRESSURE AT 2000 (WOT) FOR 8-12 ps,

Cornpound #21915

WITH GOVERNOR COVER REMOVED AND THROTTLE SHAFT

d Open Petcock Ior pressure check ONLY

IN LOW IDLE POSITION (STEP 3b). SET MIN MAX GOVERNOR

e II necessary to obtain advance requirements. use alternate

ASSEMBLY FOR 10 + 2 mm3istroke at 575 RPM (FUEL

inner Advance Spring 1121911 and/or alternate Head Locating

READING WITH COVER INSTALLEDi

Screw Assembly (I 22240 COUNTER

11 SET ADVANCE FOR 3-3 5O AT 2000 RPM (WOT)

12a FUEL DELIVERY 42 .t 2 5 mm3istroke @Q2000 RPM (WOT) N,OTE PUMP MOUNTING HORIZONTAL. PUMP ROTATION CLOCKWISE

20 SEAL PUMP FASTENERSPER XL874 OR SO365

MAXIMUM CYLINDER VARIATION 3 rnnl 3istr0ke

b CHECK CRANKING DELIVERY iic 200 RPM (WOT) 15 mm3ist

MIN 12 IIS! mm T.P PRESS AND O-10 PSI HSG PRESSURE

=

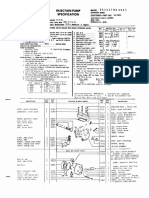

IfaT.

RT NO

!.m

SCREW, cover hold-down 3 2351

LOCKWASHER.cover screw 3 1582

13521 WASHCR.cover screw

21606 ELBOW. return line ;crr,r,ector

CONN. ASSY.. return line 1

GASKET, governor uver 1 SEAL, return line cwnector

COWER. qcverllor ccntrol

iCREWASSEMBLY,vent or 2;661

SHAFT, drive 1 1204 thru 21665and 22733 ~r 22734

LS required

SEAL, drive shaft (BLACK) 2

SCKEW. head locking

w, torque screw

SEAL, drive shaft (RED) 1 I860 SEAL, torque screw

SEAL, pilor tube 1 3622 SCREW, torque

PIN, shaft retaining 1 12GC

COVER, timing lire 1 0567 ?OUSING ASSEMOLY

SCREW, timing line cover 2 99lE (See Service Assemblies)

PLATE, name 1 0394

, .-_. ZRSKET, timing I!ne cover

* APPLY A LIBERAL. COATING OF SYN-KUT BASE

SCREW, name plate 2 4 1241 COMPOUND TO SEALS BEFOREASSEMBLING

SEALS TO SHAFT AND SHAFT TO PUMP.

= ==

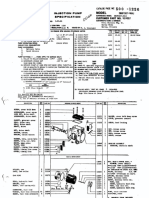

DB2825PC3241

21727 HYD. HEAD & ROTORASSEMBLY

P-4 11036

ROLLER, cam 2 2119T

SHOE, cam roller 2 2Dllt

21111 12216 SCREW, hyd. head plug

C4M RING 1

1143E SCREW, hyd. head plug

OR 22075 (O.S.) FOR O.E.M.

ONLY - INCREASE SPECIFIED 20721 CONNECTOR,fuel line

R-R BY .006" 21287 SCREW, locking plate

SEAL, hydraulic head 1 1130' PLATE. locking

SPRING, leaf 1 11191 :z SEAL, locking plate

SCREW, leaf spring 1 1117! 13837 SCREW, delivery valve

16441 STOP, delivery valve

1644. SPRING, delivery valve

L___.+ 1381! VALVE, delivery (SB143R)

I OR 13820 (Oversize) as req'd.

== -

5 1nr*o rmrll D‘X"I,,Iou

TRANSFERPUMP CROUP

!% --

ISCAL. transfer pump 1 !O!j26 - -2053L RETAINER, rotor

21232 LINER, transfer pump

15G95 SPRING, trans. pump blade

2052f RING, liner locating

212OL REGULATORASSY., trans. pump

BLADE, transfer pump (Basic) 4 I8137

Use 20511 or 20512 as req',

19831 ROLLPIN

SPRING, regulating 1 21198

IJ!lSTDN. regulating 1 19895 1522t PLUG ASSV.. end plate adj.

SCREEN, inlet filter

!XAL, inlet filter screen 19832

RING. screen retainer 1' !0529

I'LATE. trans. pump pressure 1 !0523 CAP, transfer pump end

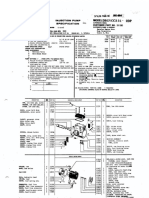

= ==

SPRING, idling 1 '1266 NUT, pivot shaft

GOV.' ARM AND TLMPERATURE jli175 SPRING, min-max.

COMPENSATOR ASSEMBLY RING, retain&

+--SHAFT. gov,ernor. arm pivot 1 ,2i!14 BLOCKASSJMBLY

>EaL. pivot shaft 2 STUD, guide

LlSB8

WASHER, guide stud

I'IY !1760 - 2ia9 ARM ASSY., metering valve

SLEEVE : !1757 SPRING, metering valve arm

ROD, min.-max. ~0". pdl 1 !11'58 VALVE, metering or 22256

SLEEVE, thrust .4483 RETAINER ASSY., gov. weight

31R 21312 RETAINER ASSY.. gov. wt.(Basi

WIIIER, thrust sleeve 1 RETAINER, governor weight

;'1!;$

WEIGHT, 9overnor HUB ASSY.. governor weight

RINIG. gov. cage retaining 6l 12;1e5

RING. flexible retaininn

SPRING. idling NUT. pivot shaft

GOV.. ARM AND TEMPERATURE : WAS~HER.max. speed spring

COMPENSATOR ASSEMBLY SPRING, min.-max.

SHAFT. governor arm pivot 1 BLUCKASSEMBLY

STUD. guide

SEAL, pivot shaft 2

WASHER, guide stud

**SEC SERVICE ASSEMBLIES AIM ASSY.. metering valve

SLIXVE. rain-max governor SPRING, metering valve arm

R(W). mln-max. gov. push 1' VALVE, metering or 22256

.SLEEVE. thrust 1 RETAINER ASSY., gov. weight

RETAINER ASSY., gov. weight

U/&HER. thrust sleeve

RETAINER, governor weight

YfIIGHT. governor 6l

HUB ASSEMBLY qov. weight

IRfklG, gov. cage retaining 1 RING. flexibfe'retainino

NOTE: Use Sprinn #21266 With Sleeve #22327 Only.

"NKAoli~ov

WASHER,throttle shaft I IASHER, throttle shaft seal

NUT, wx. travel screw I 2173' 21284 IIN,, vacuum module drive

16416 21285 IMy, shaft retaining

!XREY. low idle I 17438 ., throttle shaft

SPRIING. low idle screw I 1358 18021 IOOK ASSY.. gov. linkage

S;HUFr ASSEMELV, throttle 20Ea3 12358 LINKAGE ASSY., governor

f-", 12360 SCREW, gov. linkage hook

1712 12362 WASHER, gov. linkage hook

dIEY. ma. throttle travel 18024 HOOK, governor linkage

1 1~~11926 ,PRXNG. qov. linkaoe hook

E L

3i

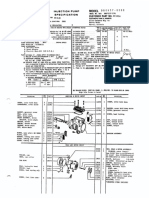

DB2825PC3241 OMATIC ADVANCEGROUP

11611 1 CAP, advance adj. screw

HUT, trimner screw 1 14544 1 SCREW, advance Gdjusting

12040 1 SEAL, advance adj. screw

-1 4941 1 PLUG, piston hole (spring)

SEAL, piston hole plug 1

4940 1 XIDE, advance adj. spring

PISTON, spring 1 : 1602 1 SPRING, outer advance

UASHER. slide 2 2 1788 1 SPRING. inner advance or

21911 Inner Adv. spring

PISTON. dower 1 1227 11507 2 jEAL. head locating screw

SEAL, piston hole plug 1 0113

-; i2241 1 <CREWASSEMBLY, head locating

PLUG,.piston hole 1 1241 OR :REWASSY., 22240 c.025)

. I 2766 1 )EAL. advance screw hole plug

SEAL, piston hole plug ?764

SCREW. cam advdnC@ ; 5438 15719 1 'LUG. advance screw I~ole

E 1131 P a

- i!161E 1 INSULATOR. terminal

211518 TERMINAL. electric shut-off

LOCKNUT. terminal contact 2 4760 12049 : LOCKWASHER, terminal contact

STRAP, terminal grounding 0951 2515 2 NUT, termlnal contact

LOCKWASHER. cover screw ; 8493 ; 8501 WASHER,terminal contact

LOCKUASHER,terminal 2 2049 1250C : WASHER, teninal insulating

ASSEMBLEGROUNDINGSTRAP ON

LEFT SIDE VIEWING END PLATIE

SOLENOID FRAME6 ARM ASSEMBLY 1

!1584 1 SOLENOID FRAME& ARM ASSEMBLY

- ; - -

FOR SERVICE USE ONLY FOR ENGINEERINGUSE ONLY

APPLICAHLESERVICE ASSENBLIES DATE CHC. NO EDITION

GASKETKIT 121921 4-30x - 13335 _ 3

PILOT TUBE #21228 10-8-80 13942 4

SHUT DOWNCOIL A&4 AlD SOLENOIDASSY. Y22149

l-30-81 14044 5

THBOTTLESNAFT BUSHLNG 115093

* MIN/MAX GOVERNORKIT $22726 or #23185

** IDLE SPRING KIT (SB360) 823160

Housing Kit (SB36j) #23274

You might also like

- Valve Clearance - Part 1 0-12Document12 pagesValve Clearance - Part 1 0-12api-327987286100% (1)

- Multizone Receiver: Installation & Operation GuideDocument82 pagesMultizone Receiver: Installation & Operation GuideJuan Manuel BurdetNo ratings yet

- Renr9540renr9540-01 Sis PDFDocument9 pagesRenr9540renr9540-01 Sis PDFJorgeNo ratings yet

- DL B2825PCX272: Customer Part No. 561730Document3 pagesDL B2825PCX272: Customer Part No. 561730Ventas R11No ratings yet

- DB2825PC8271: ModelDocument3 pagesDB2825PC8271: ModelVentas R11No ratings yet

- DB2825PC3059: Customer Part No. 559073 EditlotDocument3 pagesDB2825PC3059: Customer Part No. 559073 EditlotVentas R11No ratings yet

- Injection Pump Specificatiqn: / Imcij Rigst SideDocument2 pagesInjection Pump Specificatiqn: / Imcij Rigst Sidejohnny sabinNo ratings yet

- Customer PART NO. 22500241: 0 SuiersedesDocument3 pagesCustomer PART NO. 22500241: 0 SuiersedesVentas R11No ratings yet

- DB2825PC3743: ModelDocument3 pagesDB2825PC3743: ModelVentas R11No ratings yet

- DB28251PC36 3: (Customer Part No. 2215011177Document3 pagesDB28251PC36 3: (Customer Part No. 2215011177Ventas R11No ratings yet

- Shaft.: ScrewDocument3 pagesShaft.: ScrewVentas R11No ratings yet

- Scxew : 2722 @Cc6 A 9 - 4fjaaDocument2 pagesScxew : 2722 @Cc6 A 9 - 4fjaadieselmotorsbogotasasNo ratings yet

- M O-352 4all: Mobel Ex-Kmx43Document2 pagesM O-352 4all: Mobel Ex-Kmx43johnny sabinNo ratings yet

- Fitvma - DBGF 633 - LDP: Icatalog NO:: 00-3843Document2 pagesFitvma - DBGF 633 - LDP: Icatalog NO:: 00-3843johnny sabinNo ratings yet

- Jnjection Pump Specification MODECCB MA O : Part NoDocument2 pagesJnjection Pump Specification MODECCB MA O : Part Nojohnny sabinNo ratings yet

- The Carbon Brush: ExchangeDocument5 pagesThe Carbon Brush: ExchangeJorge Morejon BuenoNo ratings yet

- Injection Pump Specification Modei.: Licet - . - . - . - . .F.%Document2 pagesInjection Pump Specification Modei.: Licet - . - . - . - . .F.%johnny sabinNo ratings yet

- DBGVCC631-3DL: ModelDocument2 pagesDBGVCC631-3DL: ModeldieselmotorsbogotasasNo ratings yet

- Stanadyne:, Zezt&%ADocument2 pagesStanadyne:, Zezt&%AVentas R11No ratings yet

- Injection Pump JDB431MD2800 Specification: ModelDocument3 pagesInjection Pump JDB431MD2800 Specification: ModelRobert Alexander FrankNo ratings yet

- Pumf SpecificationDocument2 pagesPumf SpecificationdieselmotorsbogotasasNo ratings yet

- DBGFC633-2AF Datos de Prueba StanadyneDocument2 pagesDBGFC633-2AF Datos de Prueba Stanadynemurillo_rodriguez8382No ratings yet

- Model Ibgf 633 - Im: Injection Pump Speci - Fication Supersedes Model Custop Ier Part 9 C"Stomer'SDocument2 pagesModel Ibgf 633 - Im: Injection Pump Speci - Fication Supersedes Model Custop Ier Part 9 C"Stomer'Sjohnny sabinNo ratings yet

- Customer Part No. 4514954: Injection Pump Specification Model Ik) DelDocument2 pagesCustomer Part No. 4514954: Injection Pump Specification Model Ik) DeldieselmotorsbogotasasNo ratings yet

- DBGVC 437 - 8af": Customer Part No. JD403F-206 Z LDocument2 pagesDBGVC 437 - 8af": Customer Part No. JD403F-206 Z LMiguel RojasNo ratings yet

- Date0: Eoltlon No. Snqine Zdt29 5Document2 pagesDate0: Eoltlon No. Snqine Zdt29 5Miguel RojasNo ratings yet

- Catalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4Document2 pagesCatalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4johnny sabinNo ratings yet

- In - Leciloan F'U Specificatio: CoverDocument2 pagesIn - Leciloan F'U Specificatio: Coverjohnny sabinNo ratings yet

- DBGVC231 7BMDocument3 pagesDBGVC231 7BMMiguel RojasNo ratings yet

- ShaftDocument2 pagesShaftdieselmotorsbogotasasNo ratings yet

- 1 Diesel Systems: Injection Pump Specification Customer Part No. Ar50002 EwnonnoDocument3 pages1 Diesel Systems: Injection Pump Specification Customer Part No. Ar50002 EwnonnoRobert Alexander FrankNo ratings yet

- Catalqg PAGE NO:'!$o@: 1., Njectlon LinesDocument2 pagesCatalqg PAGE NO:'!$o@: 1., Njectlon Linesjohnny sabinNo ratings yet

- DBGVC429-5AF Datos de Prueba StanadyneDocument2 pagesDBGVC429-5AF Datos de Prueba Stanadynemurillo_rodriguez8382No ratings yet

- Experiment No-05Document5 pagesExperiment No-05ARNAB KAMILYANo ratings yet

- DBGV (X429 - 3cli: ModelDocument2 pagesDBGV (X429 - 3cli: ModelMiguel RojasNo ratings yet

- Injection Pump: D B 2 8 2 5 S H 3 7 9 9Document3 pagesInjection Pump: D B 2 8 2 5 S H 3 7 9 9Ventas R11No ratings yet

- Dbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3Document2 pagesDbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3dieselmotorsbogotasasNo ratings yet

- Specification: 2.speed Advance 3 DDocument2 pagesSpecification: 2.speed Advance 3 Djohnny sabinNo ratings yet

- B - %iDH: Insjection - DBGFC X31-Speciflcat98NDocument2 pagesB - %iDH: Insjection - DBGFC X31-Speciflcat98Njohnny sabinNo ratings yet

- Diesel Systems: Injection Pump Uooeldb2829Yl4187 1 SpecificationDocument3 pagesDiesel Systems: Injection Pump Uooeldb2829Yl4187 1 Specificationmarco rodNo ratings yet

- BFPT Air Exhust Fan A-ADocument20 pagesBFPT Air Exhust Fan A-AKARTHIKEYANNo ratings yet

- M.E. L.O. Auto Filter Vol 1Document6 pagesM.E. L.O. Auto Filter Vol 1Bhavesh NikamNo ratings yet

- D-2300 IUU Lao Rcy, C T: 7 BATE@ 1a26m66Document2 pagesD-2300 IUU Lao Rcy, C T: 7 BATE@ 1a26m66dieselmotorsbogotasasNo ratings yet

- Specification Customer Fart No. AR35081R: Injection Pump Bdel CZ'CDocument2 pagesSpecification Customer Fart No. AR35081R: Injection Pump Bdel CZ'Cjohnny sabinNo ratings yet

- Dbwcc42Wcm: ModelDocument3 pagesDbwcc42Wcm: ModelMiguel RojasNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- Workshop Injection Pump 05945Document4 pagesWorkshop Injection Pump 05945Kevin Ttito100% (1)

- Ficha Técnica GEDocument10 pagesFicha Técnica GEMaria Hernandez RNo ratings yet

- Model 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationDocument6 pagesModel 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationJavier Fernando Agudelo GómezNo ratings yet

- m0-8 - v6701000 Final DRW & Instruction Manual For LatheDocument69 pagesm0-8 - v6701000 Final DRW & Instruction Manual For Lathewawet10014No ratings yet

- Injection Pump Model I! Specification O'577: BGVC431-3AJDocument2 pagesInjection Pump Model I! Specification O'577: BGVC431-3AJjohnny sabinNo ratings yet

- 35T RT Tadano TR350M-3Document12 pages35T RT Tadano TR350M-3Netty NababanNo ratings yet

- Mewp TL SeriesDocument54 pagesMewp TL SeriesEmanuel FuenzalidaNo ratings yet

- Injection Pump Specification LN3Dyf1500 " - 8A ' 2 'Document2 pagesInjection Pump Specification LN3Dyf1500 " - 8A ' 2 'johnny sabinNo ratings yet

- Diesel Systems Ce/Rnly: Injection Pump SpecificatiqnDocument3 pagesDiesel Systems Ce/Rnly: Injection Pump Specificatiqnmarco rodNo ratings yet

- Injection Pump Specification: CUSTOMER PART NO.: 23500587 Customer'S Name & Address. Model No.: SupersedesDocument3 pagesInjection Pump Specification: CUSTOMER PART NO.: 23500587 Customer'S Name & Address. Model No.: Supersedesmarco rodNo ratings yet

- Model: Injection Pump Specification Customer Part No. 266512Document2 pagesModel: Injection Pump Specification Customer Part No. 266512dieselmotorsbogotasasNo ratings yet

- Modeldbgvc 429-3: Injection Pump Specification DBGVC429-1 J 5Document2 pagesModeldbgvc 429-3: Injection Pump Specification DBGVC429-1 J 5johnny sabinNo ratings yet

- DBGFC 633" 91DL: Customer Part No. 292537Document2 pagesDBGFC 633" 91DL: Customer Part No. 292537dieselmotorsbogotasasNo ratings yet

- Catlai Pa T@: 50 0 - 1226: Model B@ UDocument2 pagesCatlai Pa T@: 50 0 - 1226: Model B@ UdieselmotorsbogotasasNo ratings yet

- Injection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+Document1 pageInjection Pump Specification: D B 2 8 2 9 Ad Em4 2 4 4+johnny sabinNo ratings yet

- 4%7 6l - OG, Page, NO:'!5: MM' PER StrokeDocument2 pages4%7 6l - OG, Page, NO:'!5: MM' PER StrokedieselmotorsbogotasasNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Injection Pump: D B 2 8 2 5 S H 3 7 9 9Document3 pagesInjection Pump: D B 2 8 2 5 S H 3 7 9 9Ventas R11No ratings yet

- Customer PART NO. 22500241: 0 SuiersedesDocument3 pagesCustomer PART NO. 22500241: 0 SuiersedesVentas R11No ratings yet

- Stanadyne:, Zezt&%ADocument2 pagesStanadyne:, Zezt&%AVentas R11No ratings yet

- Injector Specification: Stanadyne"Document2 pagesInjector Specification: Stanadyne"Ventas R11No ratings yet

- A.P Servicio Pesado Rango Medio CATALOGODocument80 pagesA.P Servicio Pesado Rango Medio CATALOGOVentas R11No ratings yet

- Fr-E700 Instruction Manual (Basic)Document155 pagesFr-E700 Instruction Manual (Basic)DeTiEnamoradoNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document6 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Rachmad BuntoroNo ratings yet

- Pressure Switches, Series PM1Document5 pagesPressure Switches, Series PM1fadhlidzilNo ratings yet

- OM. Husqvarna. LC 353 AWD. 2019-11Document49 pagesOM. Husqvarna. LC 353 AWD. 2019-11Erní MüllerNo ratings yet

- Eternity CLSDocument2 pagesEternity CLSfaithnicNo ratings yet

- NI R Series Multifunction RIO User ManualDocument70 pagesNI R Series Multifunction RIO User ManualAlexandru Spike0% (1)

- VD4 ABB - Disj A Vácuo PDFDocument120 pagesVD4 ABB - Disj A Vácuo PDFPaulo RebeloNo ratings yet

- CoolMaster Programmers Reference Manual (PRM)Document19 pagesCoolMaster Programmers Reference Manual (PRM)nassar_aymanNo ratings yet

- Instrument Panel: 1991 Mitsubishi MonteroDocument11 pagesInstrument Panel: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

- CPX-SF34 35 2010-07 570541g1 PDFDocument111 pagesCPX-SF34 35 2010-07 570541g1 PDFwiruNo ratings yet

- Pcs Paddle Shifter User Guide V3.0Document21 pagesPcs Paddle Shifter User Guide V3.0Andreas T P ManurungNo ratings yet

- Controller Installation and Adjustment Procedures For ModelsDocument34 pagesController Installation and Adjustment Procedures For ModelsJonathan RoblesNo ratings yet

- 05 LT - SS1005 - E01 - 1 ZXSDR R8882 L268 Hardware Structure 31Document31 pages05 LT - SS1005 - E01 - 1 ZXSDR R8882 L268 Hardware Structure 31Tharindu WijegoonasekaraNo ratings yet

- BN68-09300D-01 Qrq900a XH L16 181008.0Document356 pagesBN68-09300D-01 Qrq900a XH L16 181008.0Tsamis IoannisNo ratings yet

- Fieldbus ConnectivityDocument122 pagesFieldbus Connectivitysairam2234No ratings yet

- 2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFDocument76 pages2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFTamo NekoNo ratings yet

- BNC Rear TwistDocument1 pageBNC Rear TwistNiki HristovNo ratings yet

- Atc Zat-650 Use en R5Document68 pagesAtc Zat-650 Use en R5blenix66No ratings yet

- PPE CSS9 Week1 PDFDocument20 pagesPPE CSS9 Week1 PDFJoeven PantaleonNo ratings yet

- Deutz Fahr AGROTRON 100 MK3 Tractor Service Repair Manual (SN 6001 and Up)Document20 pagesDeutz Fahr AGROTRON 100 MK3 Tractor Service Repair Manual (SN 6001 and Up)laopaodunNo ratings yet

- BLN 95 8914Document5 pagesBLN 95 8914Dado OgameNo ratings yet

- 261459Document7 pages261459Dick PiñaNo ratings yet

- Cosasco Acme Threaded Access Fitting AssembliesDocument2 pagesCosasco Acme Threaded Access Fitting AssembliesEdgar I RamirezNo ratings yet

- OYO SDLmini UserGuideDocument29 pagesOYO SDLmini UserGuideBi Bol ChiNo ratings yet

- Nitro 07 Ignition ControlDocument41 pagesNitro 07 Ignition Controlorangewedge320% (1)

- Overview On Space Frame Structures: November 2018Document25 pagesOverview On Space Frame Structures: November 2018Intan MustikaNo ratings yet