Professional Documents

Culture Documents

FMEW

FMEW

Uploaded by

Anthony ChundalCopyright:

Available Formats

You might also like

- Value Chain AnalysisDocument4 pagesValue Chain AnalysisRamy Gaballa0% (1)

- CBLM Backhoe Loader Unit 2 Lo1docx CompressDocument67 pagesCBLM Backhoe Loader Unit 2 Lo1docx CompressCarmen GuevaraNo ratings yet

- NIOSH WPA - GlomaxDocument28 pagesNIOSH WPA - Glomaxyewminyun6098100% (4)

- 2030 Student GuideDocument326 pages2030 Student GuideZach Brownfield100% (1)

- How To Use This Competency-Based Learning MaterialDocument12 pagesHow To Use This Competency-Based Learning MaterialCharis AbadNo ratings yet

- SiwesDocument26 pagesSiwesToheeb AtandaNo ratings yet

- Fatigue Management GuidelineDocument7 pagesFatigue Management GuidelinePramavirsa Wnw100% (1)

- Perform Housekeeping DutiesDocument33 pagesPerform Housekeeping DutiestereveNo ratings yet

- JUK 123a - 2127PL256-W2-en - 07-2010Document4 pagesJUK 123a - 2127PL256-W2-en - 07-2010FabianNo ratings yet

- Instructor Materials: M M P S N - M S N/A O NMS T N/A F M E W Msfmew 5 HDocument42 pagesInstructor Materials: M M P S N - M S N/A O NMS T N/A F M E W Msfmew 5 HMuhammad RizwanNo ratings yet

- Porras - Module No. 2Document5 pagesPorras - Module No. 2Hanna PorrasNo ratings yet

- Excavator-Operator-PH-v2.0 (1) Level 4Document101 pagesExcavator-Operator-PH-v2.0 (1) Level 4kldbin.farooq27No ratings yet

- 2 Using Hand ToolsDocument31 pages2 Using Hand ToolsbrianmongeNo ratings yet

- SCWG GPG Worker Exposure Durations For DBADocument9 pagesSCWG GPG Worker Exposure Durations For DBAEm GerNo ratings yet

- OS Vehicle Body Repairing and P L2Document62 pagesOS Vehicle Body Repairing and P L2Aida Mohammed100% (1)

- Maintenance PlanDocument60 pagesMaintenance PlanScribdTranslationsNo ratings yet

- FG LFSQ0213 Fitter Mechanical 20.07.2018Document270 pagesFG LFSQ0213 Fitter Mechanical 20.07.2018renjithkrishnanNo ratings yet

- Hazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsDocument29 pagesHazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsP Eng Suraj Singh100% (1)

- Lo 3 (LG-3)Document21 pagesLo 3 (LG-3)Alage TekaNo ratings yet

- 01.40.01.701 Personal Protective Equipment (PPE)Document6 pages01.40.01.701 Personal Protective Equipment (PPE)Cris KasongoNo ratings yet

- MPDS Instructor Guide.167183709 PDFDocument180 pagesMPDS Instructor Guide.167183709 PDFMarian TudorNo ratings yet

- PEP MAC 304 No. 2 Week 2Document3 pagesPEP MAC 304 No. 2 Week 2Anj TrinidadNo ratings yet

- FMEA Failure Modes Effects Analysis PDFDocument32 pagesFMEA Failure Modes Effects Analysis PDFVILLANUEVA_DANIEL2064100% (1)

- Instructor Manual (5G-Small Cell Deployment Training)Document258 pagesInstructor Manual (5G-Small Cell Deployment Training)elmoustaphaelNo ratings yet

- Benchmarking ProcessDocument17 pagesBenchmarking ProcessgilangrahadianNo ratings yet

- The University of Faisalabad: Environmental Engineering-IIDocument47 pagesThe University of Faisalabad: Environmental Engineering-IINomi khanNo ratings yet

- Instrument TechnicianDocument4 pagesInstrument TechnicianFathan S0% (1)

- Vibration Analysis and Diagnostic Guide: June 2012Document66 pagesVibration Analysis and Diagnostic Guide: June 2012JOLITO RAMOSNo ratings yet

- 2012 Tinga MBFA BookDocument78 pages2012 Tinga MBFA BookRushil RamroepNo ratings yet

- Plant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliDocument10 pagesPlant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliAdam BukhariNo ratings yet

- Module 8 Apply Quality Standards Converted1Document40 pagesModule 8 Apply Quality Standards Converted1Challe MontemayorNo ratings yet

- Top 5 Safety Activities: Plant WalkaboutDocument31 pagesTop 5 Safety Activities: Plant WalkaboutKieron Ivan M. GutierrezNo ratings yet

- K5-Nota Kuliah OSHADocument9 pagesK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNo ratings yet

- Standard Operating ProdecureDocument13 pagesStandard Operating ProdecureAmanDeep SinghNo ratings yet

- Analisis de RiesgosDocument1 pageAnalisis de RiesgositzelNo ratings yet

- Analytical Troubleshooting Course Number 10306Document2 pagesAnalytical Troubleshooting Course Number 10306MohamedNo ratings yet

- Jawaharlal Nehru Engineering College Aurangabad: Data Warehousing and Data Mining (DWDM)Document37 pagesJawaharlal Nehru Engineering College Aurangabad: Data Warehousing and Data Mining (DWDM)JJ OLATUNJINo ratings yet

- I. Purpose of MaintenanceDocument5 pagesI. Purpose of MaintenanceLa GraciahNo ratings yet

- A GRADE 11 Q1M2 TeacherDocument33 pagesA GRADE 11 Q1M2 TeacherRusty Ugay LumbresNo ratings yet

- 5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalDocument35 pages5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalGlaiza Magistrado MonteNo ratings yet

- LG 35 40Document117 pagesLG 35 40tariku kirosNo ratings yet

- TP - 10 Troubleshooting and Maintenance Techniques: Lecture # 3Document49 pagesTP - 10 Troubleshooting and Maintenance Techniques: Lecture # 3Amer Abd EL-hkimNo ratings yet

- Lab Manual - Drilling EngineeringDocument23 pagesLab Manual - Drilling Engineeringdrake drizzyNo ratings yet

- K To 12 PC Hardware Servicing Learning ModuleDocument114 pagesK To 12 PC Hardware Servicing Learning ModuleJusten AranetaNo ratings yet

- Pooji MGT FinalDocument8 pagesPooji MGT FinalRohi shewalkarNo ratings yet

- TEEE 4204 Part 3 Installation PracticesDocument12 pagesTEEE 4204 Part 3 Installation Practiceswakolesha TadeoNo ratings yet

- Facilitator Guide Module 1 Task 1 PDFDocument31 pagesFacilitator Guide Module 1 Task 1 PDFfazadoNo ratings yet

- Wireless Communication Equipment Repair - Course - Outline - Spring - 2018Document17 pagesWireless Communication Equipment Repair - Course - Outline - Spring - 2018Geoffrey AlleyneNo ratings yet

- MO3 - Preparing Raw MaterialDocument81 pagesMO3 - Preparing Raw MaterialGadisaNo ratings yet

- Bi 127Document19 pagesBi 127Nisha BhattNo ratings yet

- 14 IshmDocument129 pages14 IshmNIKHIL SUNDARNo ratings yet

- INSPECTION REPORT - Group CDocument8 pagesINSPECTION REPORT - Group C205695 Onyeukwu Stephen Gift IndustrialNo ratings yet

- Group 3 Causes of Accidents in Process PlantsDocument12 pagesGroup 3 Causes of Accidents in Process PlantsFortuneNo ratings yet

- Learner GuideDocument38 pagesLearner GuidehyagiyahNo ratings yet

- 05 Ch1.2 Engineers Survival Guide PT 1 v20210831 SVDocument23 pages05 Ch1.2 Engineers Survival Guide PT 1 v20210831 SVRicco metalNo ratings yet

- A GRADE 11 Q1M2 StudentDocument30 pagesA GRADE 11 Q1M2 StudentRusty Ugay LumbresNo ratings yet

- HAZOP ReportDocument15 pagesHAZOP ReportDIBAKOANE KARABONo ratings yet

- NDT Assignment 4Document3 pagesNDT Assignment 4lovepreetsk0465No ratings yet

- K To 12 PC Hardware Servicing Learning ModuleDocument114 pagesK To 12 PC Hardware Servicing Learning Modulelourdes estopaciaNo ratings yet

- Guidelines to make your own SOP (Standard Operating Procedure)): 1, #1From EverandGuidelines to make your own SOP (Standard Operating Procedure)): 1, #1No ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- On the process of maintenance decision-making in the offshore operational environment of the oil and gas industry: a systems approachFrom EverandOn the process of maintenance decision-making in the offshore operational environment of the oil and gas industry: a systems approachNo ratings yet

- Dela Cruz Written Report Group SpeakingDocument2 pagesDela Cruz Written Report Group SpeakingShenna LimNo ratings yet

- Naukri Priya.E 1718796 - 04 08 - 1Document4 pagesNaukri Priya.E 1718796 - 04 08 - 1VIJAY VAITNo ratings yet

- UntitledDocument57 pagesUntitledRajendra PuranNo ratings yet

- Ambulance Inspection FormDocument6 pagesAmbulance Inspection FormShejil BalakrishnanNo ratings yet

- Unrestricted File Download V1.0Document7 pagesUnrestricted File Download V1.0Leet OptimizerNo ratings yet

- Bill of Quantity Schedule For Boiler SystemDocument4 pagesBill of Quantity Schedule For Boiler SystemshakibNo ratings yet

- Week 8Document73 pagesWeek 8sakshampe642No ratings yet

- NO Item QTY Unit Price/Unit Total Price: I Preliminary Works PreparatoriesDocument5 pagesNO Item QTY Unit Price/Unit Total Price: I Preliminary Works Preparatoriesrobert peter rajiminNo ratings yet

- Heli 2000-3500Document6 pagesHeli 2000-3500Hector Emiliano GarciaNo ratings yet

- 106 1 CompletedDocument323 pages106 1 CompletedAnonymous l5GLwMAE5No ratings yet

- Installations Us Prog 3 DDocument5 pagesInstallations Us Prog 3 DAmanNo ratings yet

- TN15 SPI Interface SpecificationDocument5 pagesTN15 SPI Interface Specificationapi-26279731No ratings yet

- Edu 534 BakalingDocument9 pagesEdu 534 BakalingArnel Navarro AsumbradoNo ratings yet

- The Full Cinematic Sound Experience: Philips DVD Home Theater SystemDocument2 pagesThe Full Cinematic Sound Experience: Philips DVD Home Theater Systemjbsp56No ratings yet

- Problems Faced by StudentsDocument3 pagesProblems Faced by Studentskarishma mannarNo ratings yet

- Complaint LetterDocument1 pageComplaint Letterapi-515409227No ratings yet

- Case Based Reasoning PDFDocument27 pagesCase Based Reasoning PDFMohammad MohibullahNo ratings yet

- Pong GameDocument3 pagesPong GameJustin James Mortel MacapiliNo ratings yet

- Tugas Destructive Test Welding UNY 2017Document10 pagesTugas Destructive Test Welding UNY 2017G. YUDHA FATRIA EGIANSYAH gyudha.2019No ratings yet

- SP-P60 Series 255 W - 290 W Key Features: 20 % 1500 V 10 Year 25 YearDocument2 pagesSP-P60 Series 255 W - 290 W Key Features: 20 % 1500 V 10 Year 25 YearscribdgineerNo ratings yet

- 1-Introduction To Information and Communication TechnologyDocument6 pages1-Introduction To Information and Communication TechnologyMica Angela Dela CruzNo ratings yet

- RFQ SBP TMPVL 4231 Software Update and Maintenance Operations V6 09 MAY 23Document65 pagesRFQ SBP TMPVL 4231 Software Update and Maintenance Operations V6 09 MAY 23annikul01No ratings yet

- Couplings, Adaptors and SleevesDocument28 pagesCouplings, Adaptors and Sleeveswael72No ratings yet

- Hadoop Tutorials: Daniel Lanza Zbigniew BaranowskiDocument49 pagesHadoop Tutorials: Daniel Lanza Zbigniew BaranowskiRavi KumarNo ratings yet

- T-II BLOCK 2 StructureDocument15 pagesT-II BLOCK 2 StructureSarab JoharNo ratings yet

- Film City ChandigarhDocument8 pagesFilm City ChandigarhSourav KNo ratings yet

- Manual Chem Well T: Document Manual-de-Automacao..Document3 pagesManual Chem Well T: Document Manual-de-Automacao..Scribd ScribdNo ratings yet

- BC Film & TV Producers Contact List 2007Document13 pagesBC Film & TV Producers Contact List 2007showbc100% (4)

FMEW

FMEW

Uploaded by

Anthony ChundalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FMEW

FMEW

Uploaded by

Anthony ChundalCopyright:

Available Formats

NUCLEAR POWER GENERATION

DIABLO CANYON POWER PLANT

SELF PACED (WBT) GUIDE AND STUDENT HANDOUT

PROGRAM: MECHANICAL MAINTENANCE PERSONNEL AND SUPERVISOR

COURSE: NON-MECHANICAL SPECIFIC COURSE NO.: N/A

TOPIC: OTHER NMS TRAINING TOPIC NO.: N/A

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

APPROXIMATE TIME FOR INSTRUCTION: 5 HOURS

Instructor Materials

1. Lesson guide

2. AD4.ID6, Foreign Material Exclusion Program

Student Materials

1. Lesson Guide/Student Handout

2. Current Revision of AD4.ID6, Foreign Material Exclusion Program

Lesson References

1. Lesson MS0059, Foreign Material Exclusion Program (FME Monitor Training)

Remarks

1. This lesson covers worker responsibilities in regards to the DCPP FME program.

This lesson also contains a “Current Issues” section.

This lesson is to be presented as CBT.

2. This revision is tracked by TIP #21233 that documents editorial corrections based on

CBT feedback, and AD4.ID6 revision. See revision bars.

3. “SOER 95-1, Reducing Events Resulting from Foreign Material Intrusion”, applicable

philosophy of this SOER has been incorporated into IDAP AD4.ID6, “Foreign Material

Exclusion Program”.

4. TIP #18200, OE23463 - Failed Dead Blow Hammer and Loss of FME Integrity (Wolf

Creek), incorporated into Current Issues segment of lesson.

5. This lesson is intended to assist personnel assigned to work on plant equipment to

recognize management FME program expectations, use of Human Performance Error

Prevention Tools, and their responsibilities as a FME Worker. This lesson is not

intended to allow personnel to perform work as a FME Monitor. Before working as a

FME Monitor personnel must satisfactorily complete the FME Program training

(MS0059).

AUTHOR: WOODY WHITE DATE: 11/2/11

REVIEWED BY: HOWARD W. LEWIS DATE: 11/22/11

TRAINING SUPERVISOR

APPROVED BY: KEITH WHITTEN FOR MJG1 DATE: 11/23/11

MECHANICAL MAINTENANCE MANAGER REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Objectives

Terminal Upon completion of this lesson, the student will serve as a Foreign

Objective Material Exclusion (FME) worker and take appropriate preventive

measures to preclude the potential for inadvertent introduction of

foreign material into plant systems or components in accordance with

AD4.ID6, Foreign Material Exclusion Program.

Enabling

Objectives

Number Enabling Objective Description

1 State the objective and goal of the Foreign Material

Exclusion Program.

2 Define terms associated with FME.

3 Identify the FME Worker and other FME personnel

responsibilities.

4 Discuss the DCPP Site Standards Handbook expectations

for FME.

5 Describe the implementation requirements for an FME

plan.

6 Describe the guidelines for FME area covering and

posting.

7 Discuss requirements for loss of integrity actions.

8 Describe the “Material Accountability Control”

requirements that apply to all High Risk FME areas.

9 Identify items and activities that require special controls in

or near High Risk FME areas.

N/A Current Issues

End of Objectives

MSFMEW PAGE 2 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Introduction

Purpose The purpose of this lesson is to identify practices and procedures used to

prevent introduction of foreign materials into systems and equipment

when performing FME “Worker” duties.

Applicability This lesson is not intended to allow personnel to perform work as a

FME “Monitor”. Before working as a FME “Monitor” personnel must

satisfactorily complete additional training.

End of Introduction

MSFMEW PAGE 3 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Foreign Material Exclusion Worker

Objective & Goal of the FME Program

Objective 1 State the objective and goal of the Foreign Material Exclusion

Program.

Need to Know The objective of the FME program is to take appropriate precautions

FME to minimize the potential for inadvertent introduction of foreign material

OBJECTIVE & into plant systems or components.

Goals

We want you to have a “Focus on Prevention”.

You need to:

RECOGNIZE when you are about to perform an activity that

can generate foreign material.

Use a CAREFUL, THOUGHTFUL, PROFESSIONAL

APPROACH and think through the activities you intend to

perform.

Take adequate precautions to prevent an introduction of foreign

material into any system or component.

All foreign material that is created shall be CAPTURED/CONTAINED.

The approach of “CLEANING UP AFTERWARDS” is not acceptable

Procedure The plant procedure for FME controls that we will be referring to

throughout this lesson is AD4.ID6.

Nice to Know Good Housekeeping is our first line of defense for preventing the

intrusion of foreign materials in or on our equipment and systems.

Housekeeping Housekeeping is the responsibility of all station organizations.

You must “CLEAN AS YOU GO” to prevent poor housekeeping.

Clean As You Go: Includes cleaning up foreign material such as machining,

grinding, welding, or cutting, while those activities are in progress in addition

to at the end of the task

Continued on next page

MSFMEW PAGE 4 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Objective & Goal of the FME Program, Continued

Nice to Know

Foreign material in plant systems and components can cause:

Effect On Fuel damage.

Plant Component malfunction or failure.

Increased radiation levels.

Increased radioactive waste.

Changes in system performance characteristics.

The net result could be:

Decreased plant safety and reliability.

Unnecessary work.

Increased maintenance costs.

Unwarranted radiation exposure.

Example of poor FME management: Fuel assembly during DCPP

2R14 showing failed fuel rod caused by debris induced fretting (wear).

Continued on next page

MSFMEW PAGE 5 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Common Industry FME Errors (SOER 95-1)

Introduction The following material comes from a nuclear industry event report that

covers common FME problems found at Nuclear stations.

Common Most events involving foreign material intrusion result from

Problems weaknesses in the following areas:

Using band saws to cut into piping systems. They can

introduce a large amount of small metal particles not easily

removed from the system.

Using tools that are not in good repair that can have pieces fall

into open systems. Examples:

o wire brushes with loose bristles

o chisels with mushroomed heads

o tools with loose parts

Not installing plugs in piping and components during machining

and grinding activities.

Not installing temporary covers on openings in equipment and

systems during periods when no work is in progress.

Not removing debris, tools, and material from the work area

prior to reassembling equipment or closing systems

Insufficient Workers sometimes receive insufficient guidance for implementing the

Guidance FME program due to the following:

The work plan does not address the need for FME controls.

Work plans provide insufficient direction for when and how to

establish FME boundaries or zones.

Work plans do not adequately define the work practices to be

used

Work plans lack inspection and accountability requirements

Post-work inspection requirements for system cleanliness are not

thorough.

Continued on next page

MSFMEW PAGE 6 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Common Industry FME Errors (SOER 95-1), Continued

Not Familiar Workers performing a task were not familiar with the station

with requirements for FME controls which include.

requirement Failure to implement tool inventory controls.

Contractors not familiar with station FME requirements or good

industry practices.

Personnel, aware of foreign materials having been introduced

into a system or component fail to notify their Supervisor.

Expectations are typically not sufficiently reinforced in training

and during work activities

SOER 95-1 The most common causes of foreign material intrusion events are:

continued

Insufficiently established and communicated management

expectations for the implementation of FME controls.

In Summary Limited supervisory emphasis on FME considerations and

practices during pre-job briefings and monitoring of work

activities.

Insufficient training of workers in basic FME practices and lack

of specific FME training for work activities involving specialized

activities or key plant systems.

Practice / The objective of the FME program is to take the approach of

Feedback “CLEANING UP AFTERWARDS” to prevent the potential for

inadvertent introduction of foreign material into plant systems or

components.

A. True

B. False

End of Objective 1

MSFMEW PAGE 7 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions

Objective 2 Define the terms associated with FME.

Need to Know The following terms and their definitions are used in the FME program.

Term Definition Example or Condition

Foreign Material that IS NOT part of the plant Dirt

Material equipment as designed. Debris

(“Material” may be solid/liquid/gas) Broken or loose parts.

Oil or lubricant

Rags

Machine tailings.

Grinding particles.

Tools

Paint chips.

Weld Slag

Lapping compound.

Other items that could affect

equipment operation or

system chemistry.

FME Area An equipment breach or work area Open Valves

requiring special controls to prevent Open piping

inadvertent entry of foreign material

Removed pipe spools

into plant equipment.

Reactor cavity during

refueling

Turbines

Spent fuel pools

Panels

Relays

Handholes and manways.

Containment Recirc Sumps

Rx head instrument port gaps.

Generators

Switchgear

Computers

Instrument Transformers

Continued on next page

MSFMEW PAGE 8 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Term Definition Example or Condition

FME Barrier An internal or external device, cover, FME barriers include:

or shield installed to prevent foreign Component parts, such as

material entry into equipment. valve bonnets, diaphragms,

manway covers.

Temporary covers, such as

tents, glove bags, pipe dams,

fabricated covers.

Temporary Curtains or Walls.

FME A physical or imaginary boundary The FME boundary MAY

Boundary around a job or area include a barrier to prevent

entry of foreign material into

the area.

FME boundaries MAY consist

of rope, curtains, tents,

temporary walls, fencing,

FME tape markers, or other

similar materials.

Disposable Items that enter the FME area as bulk Disposable gloves

Items consumables, are used inside the FME Wipe-alls

area, and are disposed of at the work

Rags

site.

Ty-Wraps

Buffer Zone An area established immediately adjacent

to critical or sensitive Foreign

Material Exclusion Areas (FMEA) as

appropriate or practicable. This zone is

maintained free

from material having a potential of being

tracked, blown, or falling into the Foreign

Material Exclusion Area (FMEA).

Lanyard A device used to hold or fasten a tool, Lanyards are generally made from

material, or other item thus preventing rope, cord, or some other suitable

its loss. restraint and can be used to attach

an item to a secure attachment

point.

Continued on next page

MSFMEW PAGE 9 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Term Definition Example or Condition

Equipment Plant systems or components Piping

Tubing

Pumps

Valves

Instruments

Pools

Vessels

Electrical panels or cabinets

Cavities

Heat Exchangers

Equipment An opening through which foreign material Examples include, switchgear

Breach can enter equipment. Breaches include cabinet door opened, cover to an

physical openings in mechanical systems electrical enclosure removed.

and cases where the interior of

instrumentation, including Measuring and

Testing Equipment (M&TE) or electrical

equipment is exposed.

Fail-safe A condition that ensures foreign Enter equipment OR

material cannot: Be inadvertently left in

equipment.

Fail-safe An item that meets one of the Is too large to fit through the

Item following criteria: equipment breach.

Is securely attached to the

person or to a secure object

external to the FME area, such

that it cannot be lost in the FME

area.

Is contained in a container, such

as a bag or box that is fail-safe.

For the Reactor Cavity and

Spent Fuel Pool FME areas, is

NOTE: Logging of some items determined to be fail-safe by

meeting this definition may be comparison to an authorized "fail

required. safe gauge”.

Clear Plastic Plastic material that is not color tinted Plastic sheeting.

or opaque. Plastic Sleeving.

Plastic Wrappers.

Plastic bags.

Clear plastic Hose.

Continued on next page

MSFMEW PAGE 10 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Practice / Connect the term in the left column to the correct description in the

Feedback right column. (answer on next page)

Term Description

FME Boundary Opening through which

foreign material can enter

equipment.

Fail Safe Item A condition that ensures

foreign material cannot enter

or be left.

FME Barrier An item is too large to fit

through the equipment

breach.

Equipment Breach An equipment breach or work

area requiring special

controls.

FME Area An internal or external device,

cover, or shield installed.

Fail Safe A physical or imaginary

boundary around a job or

area.

Continued on next page

MSFMEW PAGE 11 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Answer to Practice / Feedback

Term Description

FME Boundary Opening through which

foreign material can enter

equipment.

Fail Safe Item A condition that ensures

foreign material cannot enter

or be left.

FME Barrier An item is too large to fit

through the equipment

breach.

Equipment Breach An equipment breach or work

area requiring special

controls.

FME Area An internal or external device,

cover, or shield installed.

Fail Safe A physical or imaginary

boundary around a job or

area.

Continued on next page

MSFMEW PAGE 12 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Term Definition Example or Condition

FME Level Either Standard Risk or High Risk FME

controls.

FME Plan A detailed plan included in the work

package for projects requiring High Risk

FME controls.

Standard An equipment breach or work area where

FME Area foreign material is not easily identifiable

and retrievable.

High Risk An equipment breach or work area in Motors

FME Area which: Spent fuel pools.

A closeout inspection may not identify Main generators.

all foreign material Steam generators.

OR Turbine stop valves.

Foreign material retrieval is impossible RCS first off check valves.

or very difficult Rx Cavity during refueling.

Containment Recirc sumps.

NOTE: This type of FME area requires Piping system breach, in or

“Material Accountability Controls” close to a downward

vertical piping run, if an

effective internal inspection

cannot be performed.

Material Physical or administrative controls taken Account for items entering or

Account- to: exiting an FME area.

ability Prevent introducing foreign

Controls material into plant equipment.

Material A listing of items brought into an FME Personnel Entry Log (PEL)

Account- area. The types of logs used are: Material Accountability Log

ability Log (MAL)

Continued on next page

MSFMEW PAGE 13 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Practice / Connect the term in the left column to the correct description in the

Feedback right column. (answer on next page)

Term Description

Material Accountability Either Standard Risk or High

Log Risk FME controls.

High Risk FME area A detailed plan included in

the work package for projects

requiring High Risk FME

controls.

Material Accountability A list of items brought into an

Controls FME Area.

FME Level An area where foreign

material is not easily

identifiable and retrievable.

Personnel Entry Log An inspection won’t identify

all foreign material or retrieval

is impossible.

FME Plan A list of people who enter an

FME Area.

Standard FME Area Physical or administrative

controls taken to account for

items.

Continued on next page

MSFMEW PAGE 14 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Definitions, Continued

Answer to Practice / Feedback

Term Description

Material Accountability Either Standard Risk or High

Log Risk FME controls.

High Risk FME area A detailed plan included in

the work package for projects

requiring High Risk FME

controls.

Material Accountability A list of items brought into an

Controls FME Area.

FME Level An area where foreign

material is not easily

identifiable and retrievable.

Personnel Entry Log An inspection won’t identify

all foreign material or retrieval

is impossible.

FME Plan A list of people who enter an

FME Area.

Standard FME Area Physical or administrative

controls taken to account for

items.

End of Objective 2

MSFMEW PAGE 15 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Personnel Responsibility

Objective 3 Identify the FME worker and other FME personnel responsibilities.

Need to Know All personnel share a common responsibility for Foreign Material

Responsibility Exclusion.

Any person may have work stopped if FME integrity becomes, or is in

danger of becoming, compromised (notify supervision immediately).

Personnel Responsibility

FME Worker Qualified worker responsible for implementing FME

activities in the field per plant procedure..

FME Monitor Controls access to the FME Area using material

accountability controls and has the authority to prevent

access or stop work when appropriate.

FME Supervisor Establishes, maintains and closes out FME areas and

notifies the appropriate personnel of a loss of FME

integrity.

Performs pre job briefs on the specific FME

requirements before start of work and ensures you are

qualified for FME work assigned.

FME Coordinator Assists organizations with implementation of FME

Program and evaluates FME Program effectiveness.

Practice / As an FME Worker, if you suspect a loss of FME integrity who should

Feedback you inform?

A. The FME Coordinator

B. The Plant Manager

C. The FME Supervisor for the FME

D. The Maintenance Manager

.

End of Objective 3

MSFMEW PAGE 16 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Program Requirements

Objective 4 Discuss the DCPP Site Standards Handbook expectations for FME.

Need to Know You shall take appropriate actions to prevent the introduction of foreign

material into plant systems and components. The principles of FME is a

DCPP Site behavior that focuses on prevention. Your responsibilites include:

Standards Know whether your job requires FME controls.

Handbook Understand the FME plan.

(Red Book) Perform, or notify the appropriate personnel to perform, FME

inspections.

Set up, maintain and/or adhere to FME boundaries and barriers.

Document results of FME inspections.

Notify the appropriate supervisory personnel if a loss of FME

integrity occurs.

Label and/or post FME areas and barriers.

Personnel entering an FME area shall:

Empty outer pockets on clothing or seal with tape, Velcro, etc.

Secure eyeglasses, earplugs, badges, and dosimetry using

lanyards.

Log into the FME area as required.

Re-assess FME plan when conditions change.

Human The following list of Human Performance Error Prevention Tools are

Performance not all inclusive, but they give you a good starting point:

and FME • Task Preview – prior to the Pre-job brief and starting the job identify

FME intrusion concerns.

• Pre-job brief – participate in the Pre-job brief and discuss solutions

to prevent any identified FME intrusion possibilities.

• Questioning Attitude – utilize this when there is any confusion or

doubts. Stop all activities if unsure and contact supervision.

• Two Minute Rule and Job Hazard Analysis – These tools can help

you identify and prevent FME intrusion concerns on the job.

• Maintain situational awareness for job duration – unexpected or

unplanned issues can happen. Maintain focus & prevent FME

intrusion concerns.

• Self-Checking – continually use this technique to ensure you are not

challenging your FME plan.

Continued on next page

MSFMEW PAGE 17 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Program Requirements, Continued

Practice / The DCPP Site Standards Handbook includes expectations for

Feedback personnel working in and around FME areas. All of the following are

included "EXCEPT":

A. Set up, maintain and/or adhere to FME boundaries.

B. Know who the FME planner for the job is.

C. Know whether your job requires FME controls.

D. Understand the FME plan.

End of Objective 4

MSFMEW PAGE 18 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Program Requirements

Objective 5 Describe the implementation requirements for an FME plan.

Introduction Responsibilities for a successful FME plan rests with planners,

supervisors and workers. Each of us has specific duties to perform.

Need to Know The work planner evaluates maintenance work and writes FME

requirements into work packages.

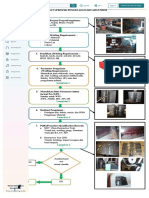

Nice to Know The following decision making flowchart demonstrates the process

used in selecting the appropriate FME level:

Implementation

Process Can foreign material degrade the

equipment?

Yes

No

Will an equipment closeout inspection

locate all foreign material?

No

Implement High

Yes

Risk FME Plan.**

No

Is foreign material retrieval possible?

Yes

Can foreign material be easily Implement Standard

No

identified and retrieved? FME Plan.**

FME controls not required.

Implement Zone 3

Housekeeping in

Yes accordance with AD4.ID1.

Inspect equipment internals

for foreign material prior to

** Some exceptions may apply.

equipment closure.

Continued on next page

MSFMEW PAGE 19 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Program Requirements, Continued

Need to Know During refueling, use the reactor cavity FME plan for all activities in the

reactor cavity FME area per an attachment in the FME procedure.

Specific

Procedural Use the Spent Fuel pool FME plan for all activities in the Spent Fuel

Guidance

Pool FME area per an attachment in the FME procedure.

FME Prior to breaching (opening) the equipment, the FME supervisor shall

Supervisor ensure:

Duties 1. Areas above and around the breach are clean.

2. The FME area boundary is established and posted

High Risk

3. A qualified FME monitor is assigned.

FME Controls

4. A material accountability log is established.

Standard Risk Maintaining the Standard FME Area

FME Controls 1. Conduct Pre-job briefs for workers discussing FME controls.

2. Ensure workers review the FME procedure for items and

activities requiring special controls, near or above the FME

boundary.

3. Ensure FME barriers are installed over equipment openings

when required.

4. Workers shall immediately report any dropped, lost, or otherwise

unaccounted for material to the FME supervisor.

5. If FME integrity is lost, as reported by employees, implement

loss of FME integrity actions per the FME procedure.

FME 1. FME supervisors may change the FME level or revise the FME

Supervisor controls (unless controlled by another procedure.)

Duties 2. If the FME plan or controls are described in the (work) order,

the order will need to be revised.

Modifying

Controls or

Following installation of FME barriers in equipment

Plans openings, a high risk FME area may be downgraded to a

standard FME area.

3. If a high risk FME area is downgraded to a standard FME area

because of installing FME barriers, the high risk FME area

controls shall be reestablished prior to removing the FME

barriers from the openings.

Continued on next page

MSFMEW PAGE 20 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Program Requirements, Continued

FME If FME barriers are installed and the area meets the requirements of a

Supervisor standard FME area, the FME supervisor may downgrade the FME

Duties area and implement a standard FME plan.

Downgrading • Except for accountability of the FME barriers, maintaining

or Upgrading material accountability logs is not required.

an FME Plan • An FME monitor is not required.

Prior to removing the FME barriers, the FME supervisor shall upgrade

the FME area and implement a high risk FME plan.

• An FME monitor shall be in place.

• Material accountability shall be implemented.

Need to Know You need to follow FME standards/requirements during the work

activities on an open system or component by performing the following:

FME Workers installing temporary covers when work is not in progress

Responsiibilit using fail-safe tools if required

ies installing pipe dams if required and/or practical

cleaning the internals of the system/component

maintaining the FME Area to the required housekeeping condition

complying with material control as required

complying with personnel control as required

complying with the information provided by the FME monitor

stopping work and notifying supervision if FME control is lost

reestablishing the FME Area, if required

accounting for all materials prior to system or component closure

checking all tools for missing parts or damage that may have been

introduced into the plant system

using approved solvents and chemicals

using correct tools and materials

Practice/ If the work being performed on a job cannot degrade the equipment,

Feedback the following FME requirements are needed:

A. None, only good housekeeping practices

B. Standard FME Area

C. High Risk FME Area

If Foreign Material cannot be identified by inspection or is not easily

retrievable, the following FME requirements are needed:

A. None, only good housekeeping practices

B. Standard FME Area

C. High Risk FME Area

End of Objective 5

MSFMEW PAGE 21 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting

Objective 6 Describe the guidelines for FME area covering and posting.

Need to Know Boundaries

FME 1. The FME area boundary and the equipment breach (opening) may

Boundaries be the same. In other words, the opening in the pipe might also

be the boundary of the FME Area and no other boundaries are

erected. In this situation marking and posting the FME area

boundary is not required. However, if the FME area boundary is

marked, it shall be posted as described below.

2. IF the FME area boundary and equipment breach are not the

same, then the FME area boundary:

Shall be clearly marked.

Shall be posted with warning signs. Use FME AREA sign

provided in the procedure, or equivalent. (See example below.)

WARNING !

This is an FME area

Entry by AUTHORIZED PERSONNEL

Only

Contact FME Supervisor

for Entry Requirements

FME Supervisor _________________________ Phone ________

W/O # _________________________

Shall be as close to the equipment breach as possible.

Should provide a controlled access point for personnel entry into

the FME area.

Continued on next page

MSFMEW PAGE 22 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

FME Below is an example of a FME Area with warning sign posted

Boundaries,

continued

Continued on next page

MSFMEW PAGE 23 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

Need to Know Barriers

FME A FME Boundary is a roped off area; a FME barrier is talking about

Barriers what is done to actually close off the breach (opening) in the piping

system. (Note: FME areas are not limited to just piping systems.)

1. An FME barrier shall be installed over the equipment breach

whenever the breach is unattended or is not required to be open.

2. FME barriers placed over equipment breaches shall be posted

with warning signs. Use the FME Cover sign, provided in the

procedure, or equivalent. (See example below.)

KEEP OUT !

Do Not Remove

*FME Cover*

Removal By

AUTHORIZED PERSONNEL ONLY

FME Supervisor ________________________ Phone ______________________

W/O # _________________________________

Continued on next page

MSFMEW PAGE 24 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

FME Below is an example of a posted FME Cover Sign on an opened

Barriers, breach in system.

continued

Need to 3. To prevent introducing foreign material into equipment, internal

Know FME barriers should be used whenever possible to isolate

FME Barrier, equipment internal openings. (For example “Pipe Dams”.)

continued 4. Internal FME barriers that can fit through the equipment breach

shall be tethered externally to the equipment and logged on the

Material Accountability Log.

5. Prior to removing any FME barrier, the person removing the barrier

shall:

Obtain approval from the FME Supervisor

Inspect the area around the barrier and clean if needed.

If necessary, check system pressure behind the barrier.

NOTE: Isolation valve leakage may cause pressure build-up behind

FME barriers.

Continued on next page

MSFMEW PAGE 25 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

Need to Know 5. Paper pipe dams used for gas purges SHALL NOT be used as

FME barriers.

FME Barriers, 6. FME barriers shall:

continued Not introduce foreign material into plant equipment during

installation or removal.

Prevent dropped material from entering plant equipment.

Allow inspection of the barrier for trapped debris prior to

removal.

Either allow removal of trapped debris from the barrier or allow

removal of the barrier without loss of any trapped debris.

Resist tearing, splitting or melting.

Be fire retardant or fire resistant.

Be chemically and physically compatible with the equipment.

If required, allow airflow to provide confined space ventilation

or provide a system vent path.

Examples of Barriers below:

Continued on next page

MSFMEW PAGE 26 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

Examples of No FME Barriers in place to prevent foreign material intrusion

Inadequate

and

Adequate

FME Barriers

Adequate FME Barrier to prevent foreign material intrusion

Continued on next page

MSFMEW PAGE 27 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

FME Covers and Posting, Continued

Practice / When an FME barrier is constructed it should meet the following

Feedback requirements, EXCEPT…

A. Not introduce foreign material into plant equipment during

installation or removal.

B. Resist tearing, splitting or melting.

C. Water / air tight to prevent liquids from escaping.

D. Be fire retardant or fire resistant.

End of Objective 6

MSFMEW PAGE 28 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Loss of Integrity Actions

Objective 7 Discuss requirements for loss of integrity actions.

Need to Know A loss of FME integrity occurs when:

Foreign material is found inside equipment upon initial opening.

Loss of FME

Material that is logged into a High Risk FME area cannot be

integrity

accounted for during log reviews or closure activities.

Non-failsafe material is found inside a High Risk FME area that

is not logged into the area.

Non-failsafe items become detached from lanyards inside the

FME area.

Material that is dropped into equipment cannot be immediately

retrieved.

Material that cannot float is dropped into or found in the reactor

cavity or spent fuel pool.

FME barrier integrity is lost.

For example:

Pipe dams are deflated or damaged

Covers are found damaged or missing when the area

has been left unattended.

Continued on next page

MSFMEW PAGE 29 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Loss of Integrity Actions, Continued

Nice to Know Recovery actions will only take place after you have notified the FME

Supervisor of a problem and plan is developed to recover.

Recovery from There are many methods available for locating material, refer to

loss of the procedure for specific methods.

Integrity,

If the foreign material cannot be retrieved, engineering assistance

continued

should be obtained to determine alternate retrieval methods or to

determine the effects of the foreign material on the system.

Practice /

Feedback The following are indications of a loss of FME Integrity, EXCEPT for…

A. Foreign material is found inside equipment upon initial opening.

B. Non-failsafe material is found inside a High Risk FME area that is

not logged into the area.

C. Non-failsafe items become detached from lanyards inside the

FME area.

D. A yellow plastic bag that does float is dropped into spent fuel

pool.

End of Objective 7

MSFMEW PAGE 30 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Material Accountability

Objective 8 DESCRIBE the "Material Accountability Controls" requirements

that apply to all High Risk FME areas.

Logging The FME worker and/or FME monitor shall inspect all items entering

Material and leaving the FME area.

Fail-safe items do not require logging, unless specified

otherwise.

Nonfail-safe items, including dosimetry and personal items shall

be logged into and/or out of the FME area.

Any items exempt from logging should be listed in the specific

FME plan.

Internal (such as a pipe plug) FME barriers shall be logged, except:

• When installation and removal of the FME barrier is controlled by a

procedure.

• The procedure provides signoffs for documenting installation and

removal of the FME barrier.

Items with missing parts or fasteners shall be logged, and the location

of the missing part or fastener noted in remarks or marked or indicated

on the item.

Disposable items may be brought into an FME area without logging

• The FME supervisor may authorize relief from requirements to log

certain disposable items entering the FME area.

• Disposable items shall be:

• Brought into the FME area in a container that is fail-safe

• Used at one job-site only

• Controlled by workers at the job-site

• Disposed of in a fail-safe container at the job-site

Continued on next page

MSFMEW PAGE 31 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Material Accountability Controls, continued

NOTE: The Personnel Entry Log (PEL) should be completed by the individual

FME worker and the Material Accountability Log (MAL) should be

completed by the FME Monitor

Logging Print all information completely and accurately.

Instructions

Record time in 24 hour format. For example: 0630, 1425,

0050, and 2310.

Record the FME worker or monitor’s user ID or keycard number

on each FME area entry and exit.

Amplifying information associated with the entry may be entered

in the Remarks section and cross-referenced to a reference

number in the Remarks column.

The MAL may be used to log all items entering the FME area

when a qualified FME monitor is provided. To help find an item

in the FME area, enter its location on the PEL or MAL.

If an item is moved to a new location inside the FME area, a

new entry using the revised location information should be

made on the PEL or MAL.

Upon final exit from the FME area, account for all items logged

into the area.

If a Personnel Entry Log is being closed out and an item is to

remain in the FME area then the item must be transferred to the

Material Accountability Log by a qualified FME monitor.

Continued on next page

MSFMEW PAGE 32 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Material Accountability Controls, continued

Personnel The PEL may be used for entries into high risk FME areas, including

Entry Log the Reactor Cavity and the Spent Fuel Pool FME areas.

(PEL)

The PEL is valid for one shift and may be used for several entries into

the FME area. If the FME area will last less then one shift then a MAL

is not required to be used.

Upon final exit from the FME area the PEL should be placed in an

INACTIVE file.

Until final area closeout, inactive PELs:

• May be retained at the FME area or at another location, as

desired by the FME supervisor.

• Shall be available for accuracy and reconciliation reviews.

Following FME area closeout, PELs shall be forwarded to the

responsible group or individual for retention.

Practice If an FME is in place for less then one shift do you need to use a

Material Accountability Log?

A. Yes

B. No

The Personnel Entry Log can be filled out & maintained only by a

qualified FME Monitor.

A. True

B. False

When entering the time on a log, how would 2:15 PM be written?

A. 2:15 PM

B. 0215

C. 1415

Continued on next page

MSFMEW PAGE 33 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Material Accountability, Continued

Page 1 of 2

PRINT — USE INK

Enter time in 24 hour format

** THIS PEL IS VALID FOR ONE SHIFT **

COMPLETE THE FOLLOWING: UNIT No.: DATE:

Name: Dept / Team:

Phone: Keycard: Order or RWP:

Supervisor:

Work Area: Rx Head — Rx Cavity - Edge Lower Upper — Stm Gen 1 2 3 4

(check one)

SFP — Other (describe)________________________________________________

ENTRY Checklist PROHIBITED ITEMS

1. Log in nonfail-safe dosimetry or personal items for DO NOT take into any high risk FME area:

each entry. Easily breakable items.

2. Log in nonfail-safe items for each entry. Staples or paperclips.

3. Inspect all items entering the FME area. Safety glasses that might fall apart. Such

No visible foreign material. as Wilson Spectra II.

No loose or missing parts or fasteners. DO NOT take into Rx or SFP FME area:

4. Lanyard items that could fall into equipment. Ty-wraps with metal clips

5. Empty outer pockets or seal shut. Clear plastic sheeting, sleeving, wrappers

6. Minimize consumables taken into the FME area. or bags. Marked twirl packs are exempt.

Fill in all spaces Enter: Y-Yes, N-None or number if more than one

ENTRY DOSIMETRY PERSONAL ITEMS EXIT

1

Time Monitor TLD PED PIC Glasses Badge Pager Time Monitor1

1

Monitor — Use PIMS ID or keycard number

EXIT Checklist:

1. Log out nonfail-safe dosimetry or personal items upon each exit.

2. Log out or transfer nonfail-safe items upon final exit.

3. Inspect all items removed from the FME area.

No undocumented missing parts or fasteners.

4. Remove all consumable material upon final exit.

5. Report unretrievable or lost items to the FME supervisor.

6. Ensure all fail-safe items are removed.

MSFMEW PAGE 34 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Page 2 of 2

Material description, quantity,

Remarks Entry Exit Disposition

and location in the FME area

(Detail individual items/assemblies) Remarks Time Monitor1 Time Monitor1 Code3 MAL &

(Use additional lines as necessary) Number Page# 2

1.

2.

3.

4.

5.

6.

7.

8.

Remarks:

1

Monitor — Use PIMS ID or keycard number

2

MAL & Page # — Examples: C- 3 or D - 4

3

Disposition Codes:

R – Removed from the area.

I – Installed and will remain in the area.

E – Exchanged for a like item in the area. Reviewed By: ___________________________________

M – Moved to a new location inside the area.

L – Found or dropped in the area and left in the area.

V – Verified in the FME area during closeout.

T – Transferred to the MAL.

Date: _________________________________________

End of Objective 8

MSFMEW PAGE 35 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Special Controls

Objective 9 Identify items and activities that require special controls in or

near High Risk FME areas.

Need to Know The following items are not permitted in a high risk FME area, including

Restricted Items the Reactor Cavity and Spent Fuel Pool FME Areas.

1 Wire brushes and wire wheels.

2 Metal staples and paper clips.

3 Items with visible foreign material.

4 Items with loose parts or fasteners.

5 Easily breakable items, except glass light bulbs are exempt.

6 Safety glasses that can fall apart (lens may pop out, etc.).Such as Wilson

Spectra II

Need to Know In addition to the first list the following items shall not be allowed into

Restricted Items the Reactor Cavity and Spent Fuel Pool FME Areas.

1 Ty-wraps with metal clips. For acceptable metal free ty-wraps, see the

approved consumable materials list.

2 Wire brushes and wire wheels.

3 Clear plastic sheeting, sleeving, bags, or clear plastic hose. The following

clear plastic items are exempt:

Clear plastic face on a bubble suit

Bags having colored stripes (twirl packs)

Need to Know Prior to starting work above or adjacent to an FME area or FME

Special boundary, You must:

Controls Inform the FME Supervisor/Monitor of any activities that may

release material in an uncontrolled manner.

The FME Supervisor shall evaluate the acceptability of any

special controls required to contain the material or prevent its entry

into plant equipment.

Continued on next page

MSFMEW PAGE 36 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Special Controls, Continued

Special The following are examples of activities that may require special

Controls, controls to prevent introduction of foreign material into an FME area.

continued Working above or adjacent to the FME boundary. (Example:

Steam Generator catwalk around Reactor Cavity)

Working over the FME area, such as on a crane. (Example: over

or near the Spent Fuel Pool or Reactor Cavity)

Using wire wheels or brushes

Welding or burning that produces hot slag

Using grinding wheels

Need to Know Prior to moving a crane over or into a high risk FME area. The crane

shall be inspected for foreign material.

Cranes 1. The crane shall be free of debris, excess lubricant, and loose

fasteners or components.

a) All no-fail safe foreign materials shall be removed from the

crane or logged in the material accountability log.

b) The inspection can be performed by the FME Supervisor,

crane operator, or other individual familiar with the FME

requirements for the area.

c) Documentation of inspection results is not required.

d) The FME Supervisor shall authorize moving the crane into the

FME area.

2. If access to the crane and introduction of foreign material onto the

crane are controlled following the initial crane inspection, additional

crane inspections and entry authorizations are not required when

moving the crane over or into a high risk FME area.

Continued on next page

MSFMEW PAGE 37 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Special Controls, Continued

Practice / Are the following statements true or false?

Feedback

Cranes can be moved over a high risk FME if the crane is inspected

for foreign material first.

A. True

B. False

Only the FME Supervisor can perform the inspection of a crane prior to

moving it over a high risk FME area.

A. True

B. False

End of Objective 9

MSFMEW PAGE 38 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

CURRENT ISSUES

Introduction The following information regarding the Foreign Material Exclusion Area

program is new or important issues that effect the way we as workers

prevent Foreign Material intrusion into plant equipment or components.

FME Store FME Store cabinets are located in various areas of the plant as shown below.

The FME Store has the most popular items that you may need to meet the needs

of the DCPP FME program.

FME Store Locations

Unit 1 MRF 85’ Turbine Bldg

Unit 2 MRF 85’ South of Admin

Bldg

Unit 2 RV Shop 85’ South of

Admin Bldg

I&C Hot Shop 85’ Aux Bldg

Hot Shop 140’ Fuel Handling

Bldg

Intake (South annex)

Maintenance Shop Training

Bldg

U-1/U-2 85’ 12 KV breaker

rooms

OST U-1 140’ Turbine Bldg

Main Warehouse

FME Warehouse, U-1 100’ East

Buttress

Continued on next page

MSFMEW PAGE 39 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

CURRENT ISSUES, Continued

FME Stores Located in the cabinets are FME cover and barrier signs, and FME cover

will look like bags from 4" to 24".

this There are (will be) pipe caps and plugs for 1/4" up to 2" pipe.

Tubing caps and plugs are also available.

The most common tubing size is 3/8".

Blind flange covers in various sizes and materials are also available.

Don't see what you need? Call or page x4071 for additional information.

Visit the FME Store today

Continued on next page

MSFMEW PAGE 40 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

CURRENT ISSUES, Continued

DCPP Event Adverse trend in FME events during 2R13 Refueling outage.

An adverse trend in FME events during the 2R13 refueling outage (May of

2006) led to initiation of this Non Conformance Report (NCR). The

analysis showed at DCPP over the last several years that the focus was

aimed towards correcting FME problems instead of preventing problems.

Identified problems were:

Equipment damage from foreign material was identified as:

Dented fuel bundle grid strap in Unit 2

Minor deformation on a Unit 2 fuel bundle flow nozzle

Inhibited movement of a Unit 2 reactor coolant pump over current

relay

A fret mark on a Unit 1 fuel rod (1R13), and other historical

equipment damage.

The corrective actions to prevent recurrence and improve performance

include:

Strengthen line ownership of the FME program to foster

stewardship of FME fundamentals.

Revise the FME program procedure to enhance management

expectation communication.

Implement a separate level of FME worker training to improve

understanding of FME requirements. (The reason for this lesson.)

Continued on next page

MSFMEW PAGE 41 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

CURRENT ISSUES, Continued

Industry Failed Dead Blow Hammer and Loss of FME Integrity (Wolf Creek)

FME Event Misapplication of dead blow hammers containing BB type shot can

cause foreign material exclusion (FME) events.

Short description of event:

An electrician used a dead blow hammer on a knocker wrench to

tighten a jam nut on a bolt used to apply a torque wrench to a

reactor coolant pump motor rotor.

The dead blow hammer split/shattered causing a loss of foreign

material exclusion (FME) integrity.

The electrician did not select the best tool for the job and was

unaware dead blow hammers were filled with BB type shot that

could potentially be an FME concern.

Lessons Learned:

Ensure that when selecting a tool to perform work inside or near FME

areas that you inspect it for any visible damage or missing/loose

components and determine that no unforeseen events will occur

because of its use.

End of Current Issues

MSFMEW PAGE 42 OF 43 REV. 4

LESSON: FOREIGN MATERIAL EXCLUSION WORKER LESSON NO.: MSFMEW

Summary

Review of the Lesson

Terminal Upon completion of this lesson, the student will serve as a FME worker

Objective and take appropriate preventive measures to preclude the potential for

inadvertent introduction of foreign material into plant systems or

components in accordance with AD4.ID6, Foreign Material Exclusion

Program.

Enabling Objectives

Number Enabling Objective Description

1 State the objective and goal of the Foreign Material

Exclusion Program.

2 Define terms associated with FME.

3 Identify the FME Worker and other FME personnel

responsibilities.

4 Discuss the DCPP Site Standards Handbook expectations

for FME.

5 Describe the implementation requirements for an FME

plan.

6 Describe the guidelines for FME area covering and

posting.

7 Discuss requirements for loss of integrity actions.

8 Describe the “Material Accountability Control”

requirements that apply to all High Risk FME areas.

9 Identify items and activities that require special controls in

or near High Risk FME areas.

Summary Once again the plant procedure for FME controls that we have been

referring to throughout this lesson is AD4.ID6. Following procedural

requirements is necessary to keep foreign material out of plant

systems and components.

Learning Assessment of the student’s comprehension will be evaluated by

Assessment written exam.

End of Lesson Guide

MSFMEW PAGE 43 OF 43 REV. 4

You might also like

- Value Chain AnalysisDocument4 pagesValue Chain AnalysisRamy Gaballa0% (1)

- CBLM Backhoe Loader Unit 2 Lo1docx CompressDocument67 pagesCBLM Backhoe Loader Unit 2 Lo1docx CompressCarmen GuevaraNo ratings yet

- NIOSH WPA - GlomaxDocument28 pagesNIOSH WPA - Glomaxyewminyun6098100% (4)

- 2030 Student GuideDocument326 pages2030 Student GuideZach Brownfield100% (1)

- How To Use This Competency-Based Learning MaterialDocument12 pagesHow To Use This Competency-Based Learning MaterialCharis AbadNo ratings yet

- SiwesDocument26 pagesSiwesToheeb AtandaNo ratings yet

- Fatigue Management GuidelineDocument7 pagesFatigue Management GuidelinePramavirsa Wnw100% (1)

- Perform Housekeeping DutiesDocument33 pagesPerform Housekeeping DutiestereveNo ratings yet

- JUK 123a - 2127PL256-W2-en - 07-2010Document4 pagesJUK 123a - 2127PL256-W2-en - 07-2010FabianNo ratings yet

- Instructor Materials: M M P S N - M S N/A O NMS T N/A F M E W Msfmew 5 HDocument42 pagesInstructor Materials: M M P S N - M S N/A O NMS T N/A F M E W Msfmew 5 HMuhammad RizwanNo ratings yet

- Porras - Module No. 2Document5 pagesPorras - Module No. 2Hanna PorrasNo ratings yet

- Excavator-Operator-PH-v2.0 (1) Level 4Document101 pagesExcavator-Operator-PH-v2.0 (1) Level 4kldbin.farooq27No ratings yet

- 2 Using Hand ToolsDocument31 pages2 Using Hand ToolsbrianmongeNo ratings yet

- SCWG GPG Worker Exposure Durations For DBADocument9 pagesSCWG GPG Worker Exposure Durations For DBAEm GerNo ratings yet

- OS Vehicle Body Repairing and P L2Document62 pagesOS Vehicle Body Repairing and P L2Aida Mohammed100% (1)

- Maintenance PlanDocument60 pagesMaintenance PlanScribdTranslationsNo ratings yet

- FG LFSQ0213 Fitter Mechanical 20.07.2018Document270 pagesFG LFSQ0213 Fitter Mechanical 20.07.2018renjithkrishnanNo ratings yet

- Hazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsDocument29 pagesHazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsP Eng Suraj Singh100% (1)

- Lo 3 (LG-3)Document21 pagesLo 3 (LG-3)Alage TekaNo ratings yet

- 01.40.01.701 Personal Protective Equipment (PPE)Document6 pages01.40.01.701 Personal Protective Equipment (PPE)Cris KasongoNo ratings yet

- MPDS Instructor Guide.167183709 PDFDocument180 pagesMPDS Instructor Guide.167183709 PDFMarian TudorNo ratings yet

- PEP MAC 304 No. 2 Week 2Document3 pagesPEP MAC 304 No. 2 Week 2Anj TrinidadNo ratings yet

- FMEA Failure Modes Effects Analysis PDFDocument32 pagesFMEA Failure Modes Effects Analysis PDFVILLANUEVA_DANIEL2064100% (1)

- Instructor Manual (5G-Small Cell Deployment Training)Document258 pagesInstructor Manual (5G-Small Cell Deployment Training)elmoustaphaelNo ratings yet

- Benchmarking ProcessDocument17 pagesBenchmarking ProcessgilangrahadianNo ratings yet

- The University of Faisalabad: Environmental Engineering-IIDocument47 pagesThe University of Faisalabad: Environmental Engineering-IINomi khanNo ratings yet

- Instrument TechnicianDocument4 pagesInstrument TechnicianFathan S0% (1)

- Vibration Analysis and Diagnostic Guide: June 2012Document66 pagesVibration Analysis and Diagnostic Guide: June 2012JOLITO RAMOSNo ratings yet

- 2012 Tinga MBFA BookDocument78 pages2012 Tinga MBFA BookRushil RamroepNo ratings yet

- Plant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliDocument10 pagesPlant Utilities and Maintenance CPB 20004 Prolog. Karte 00: Mohd Syazwan B Mohd GhazaliAdam BukhariNo ratings yet

- Module 8 Apply Quality Standards Converted1Document40 pagesModule 8 Apply Quality Standards Converted1Challe MontemayorNo ratings yet

- Top 5 Safety Activities: Plant WalkaboutDocument31 pagesTop 5 Safety Activities: Plant WalkaboutKieron Ivan M. GutierrezNo ratings yet

- K5-Nota Kuliah OSHADocument9 pagesK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNo ratings yet

- Standard Operating ProdecureDocument13 pagesStandard Operating ProdecureAmanDeep SinghNo ratings yet

- Analisis de RiesgosDocument1 pageAnalisis de RiesgositzelNo ratings yet

- Analytical Troubleshooting Course Number 10306Document2 pagesAnalytical Troubleshooting Course Number 10306MohamedNo ratings yet

- Jawaharlal Nehru Engineering College Aurangabad: Data Warehousing and Data Mining (DWDM)Document37 pagesJawaharlal Nehru Engineering College Aurangabad: Data Warehousing and Data Mining (DWDM)JJ OLATUNJINo ratings yet

- I. Purpose of MaintenanceDocument5 pagesI. Purpose of MaintenanceLa GraciahNo ratings yet

- A GRADE 11 Q1M2 TeacherDocument33 pagesA GRADE 11 Q1M2 TeacherRusty Ugay LumbresNo ratings yet

- 5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalDocument35 pages5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalGlaiza Magistrado MonteNo ratings yet

- LG 35 40Document117 pagesLG 35 40tariku kirosNo ratings yet

- TP - 10 Troubleshooting and Maintenance Techniques: Lecture # 3Document49 pagesTP - 10 Troubleshooting and Maintenance Techniques: Lecture # 3Amer Abd EL-hkimNo ratings yet

- Lab Manual - Drilling EngineeringDocument23 pagesLab Manual - Drilling Engineeringdrake drizzyNo ratings yet

- K To 12 PC Hardware Servicing Learning ModuleDocument114 pagesK To 12 PC Hardware Servicing Learning ModuleJusten AranetaNo ratings yet

- Pooji MGT FinalDocument8 pagesPooji MGT FinalRohi shewalkarNo ratings yet

- TEEE 4204 Part 3 Installation PracticesDocument12 pagesTEEE 4204 Part 3 Installation Practiceswakolesha TadeoNo ratings yet

- Facilitator Guide Module 1 Task 1 PDFDocument31 pagesFacilitator Guide Module 1 Task 1 PDFfazadoNo ratings yet

- Wireless Communication Equipment Repair - Course - Outline - Spring - 2018Document17 pagesWireless Communication Equipment Repair - Course - Outline - Spring - 2018Geoffrey AlleyneNo ratings yet

- MO3 - Preparing Raw MaterialDocument81 pagesMO3 - Preparing Raw MaterialGadisaNo ratings yet

- Bi 127Document19 pagesBi 127Nisha BhattNo ratings yet

- 14 IshmDocument129 pages14 IshmNIKHIL SUNDARNo ratings yet

- INSPECTION REPORT - Group CDocument8 pagesINSPECTION REPORT - Group C205695 Onyeukwu Stephen Gift IndustrialNo ratings yet

- Group 3 Causes of Accidents in Process PlantsDocument12 pagesGroup 3 Causes of Accidents in Process PlantsFortuneNo ratings yet

- Learner GuideDocument38 pagesLearner GuidehyagiyahNo ratings yet

- 05 Ch1.2 Engineers Survival Guide PT 1 v20210831 SVDocument23 pages05 Ch1.2 Engineers Survival Guide PT 1 v20210831 SVRicco metalNo ratings yet

- A GRADE 11 Q1M2 StudentDocument30 pagesA GRADE 11 Q1M2 StudentRusty Ugay LumbresNo ratings yet

- HAZOP ReportDocument15 pagesHAZOP ReportDIBAKOANE KARABONo ratings yet

- NDT Assignment 4Document3 pagesNDT Assignment 4lovepreetsk0465No ratings yet

- K To 12 PC Hardware Servicing Learning ModuleDocument114 pagesK To 12 PC Hardware Servicing Learning Modulelourdes estopaciaNo ratings yet

- Guidelines to make your own SOP (Standard Operating Procedure)): 1, #1From EverandGuidelines to make your own SOP (Standard Operating Procedure)): 1, #1No ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- On the process of maintenance decision-making in the offshore operational environment of the oil and gas industry: a systems approachFrom EverandOn the process of maintenance decision-making in the offshore operational environment of the oil and gas industry: a systems approachNo ratings yet

- Dela Cruz Written Report Group SpeakingDocument2 pagesDela Cruz Written Report Group SpeakingShenna LimNo ratings yet

- Naukri Priya.E 1718796 - 04 08 - 1Document4 pagesNaukri Priya.E 1718796 - 04 08 - 1VIJAY VAITNo ratings yet

- UntitledDocument57 pagesUntitledRajendra PuranNo ratings yet

- Ambulance Inspection FormDocument6 pagesAmbulance Inspection FormShejil BalakrishnanNo ratings yet

- Unrestricted File Download V1.0Document7 pagesUnrestricted File Download V1.0Leet OptimizerNo ratings yet

- Bill of Quantity Schedule For Boiler SystemDocument4 pagesBill of Quantity Schedule For Boiler SystemshakibNo ratings yet

- Week 8Document73 pagesWeek 8sakshampe642No ratings yet

- NO Item QTY Unit Price/Unit Total Price: I Preliminary Works PreparatoriesDocument5 pagesNO Item QTY Unit Price/Unit Total Price: I Preliminary Works Preparatoriesrobert peter rajiminNo ratings yet

- Heli 2000-3500Document6 pagesHeli 2000-3500Hector Emiliano GarciaNo ratings yet

- 106 1 CompletedDocument323 pages106 1 CompletedAnonymous l5GLwMAE5No ratings yet

- Installations Us Prog 3 DDocument5 pagesInstallations Us Prog 3 DAmanNo ratings yet

- TN15 SPI Interface SpecificationDocument5 pagesTN15 SPI Interface Specificationapi-26279731No ratings yet

- Edu 534 BakalingDocument9 pagesEdu 534 BakalingArnel Navarro AsumbradoNo ratings yet

- The Full Cinematic Sound Experience: Philips DVD Home Theater SystemDocument2 pagesThe Full Cinematic Sound Experience: Philips DVD Home Theater Systemjbsp56No ratings yet

- Problems Faced by StudentsDocument3 pagesProblems Faced by Studentskarishma mannarNo ratings yet

- Complaint LetterDocument1 pageComplaint Letterapi-515409227No ratings yet

- Case Based Reasoning PDFDocument27 pagesCase Based Reasoning PDFMohammad MohibullahNo ratings yet

- Pong GameDocument3 pagesPong GameJustin James Mortel MacapiliNo ratings yet

- Tugas Destructive Test Welding UNY 2017Document10 pagesTugas Destructive Test Welding UNY 2017G. YUDHA FATRIA EGIANSYAH gyudha.2019No ratings yet

- SP-P60 Series 255 W - 290 W Key Features: 20 % 1500 V 10 Year 25 YearDocument2 pagesSP-P60 Series 255 W - 290 W Key Features: 20 % 1500 V 10 Year 25 YearscribdgineerNo ratings yet

- 1-Introduction To Information and Communication TechnologyDocument6 pages1-Introduction To Information and Communication TechnologyMica Angela Dela CruzNo ratings yet

- RFQ SBP TMPVL 4231 Software Update and Maintenance Operations V6 09 MAY 23Document65 pagesRFQ SBP TMPVL 4231 Software Update and Maintenance Operations V6 09 MAY 23annikul01No ratings yet

- Couplings, Adaptors and SleevesDocument28 pagesCouplings, Adaptors and Sleeveswael72No ratings yet

- Hadoop Tutorials: Daniel Lanza Zbigniew BaranowskiDocument49 pagesHadoop Tutorials: Daniel Lanza Zbigniew BaranowskiRavi KumarNo ratings yet

- T-II BLOCK 2 StructureDocument15 pagesT-II BLOCK 2 StructureSarab JoharNo ratings yet

- Film City ChandigarhDocument8 pagesFilm City ChandigarhSourav KNo ratings yet

- Manual Chem Well T: Document Manual-de-Automacao..Document3 pagesManual Chem Well T: Document Manual-de-Automacao..Scribd ScribdNo ratings yet

- BC Film & TV Producers Contact List 2007Document13 pagesBC Film & TV Producers Contact List 2007showbc100% (4)