Professional Documents

Culture Documents

Load Port Specification

Load Port Specification

Uploaded by

waqiuddinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Load Port Specification

Load Port Specification

Uploaded by

waqiuddinCopyright:

Available Formats

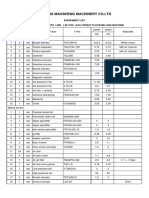

LOADPORT OIL QUALITY SPECIFICATIONS

MEF / POME

Type UCO (flexibag) (flexibag & bulk Discussion

Test Method

shipment)

No. Parameters Proposed

Appearance

Visual Observation. To distinguish between MEF A & MEF B. MEF B is

a) Visual Observation - Color Red/ Orange

Solidified state at room temperature dark in colour.

In-house Method.

To quantify sludge in oil. High sludge will lead to

b) Spin Test (Centrifuge) In 15ml tube at 60 deg C, centrifuge at Sludge level < 2% Sludge level < 2%

1 operational issue (plant operation, disposal)

4000 RPM for 2 minutes.

In-house Method.

100ml sample in 250ml clear bottle. Heat at No permanent No permanent Feedstock with foaming tendency will disrupt vacuum

c) Shake Test

60deg C for 2 minutes. Shake vigorously foam after shake foam after shake system in high temperature, low pressure column.

for 10s and stand for 1 minute.

2 Free Fatty Acid AOCS CA 5a-40 5% max 50% max

3 Iodine Value AOCS CD 1D-92 50 min / 80 min 46 min Basic parameter with standard specifications.

4 Moisture & Impurities AOCS CA 2C-25 2% max 2% max

5 Insoluble Impurities AOCS Ca 3a-46 0.3% max 0.3% max InI >0.3% will definitely fails filtration analysis

6 Mineral Oil AOAC Official Method 945.102 Not present Not present To determine presence of hydrocarbon.

High ester may disrupt vacuum system in plant. A sper

Mod EN 14103.

7 Ester Content 2% max 2% max previous run with average ester at 2.4%, T1 was still

Analyze direct sample

operable with no significant issue.

Elemental Impurities

Based on experience, there is strong correlation

a) Phosphorus MOD ASTM D5185 50 ppm max 50 ppm max between phosphorus and foaming issue. 50 ppm is

8 also standard spec for most trade in the past.

b) Sulfur MOD ASTM D5185 50ppm max 50ppm max To control Sulfur in final product.

Hede Danmark cannot accept high nickel

d) Ni MOD ASTM D5185 < 1ppm < 1ppm

productshould we want to sell to them.

You might also like

- Fineness of Cement by Blaines Air Permeability Method (Is-4031-PART-2)Document6 pagesFineness of Cement by Blaines Air Permeability Method (Is-4031-PART-2)salahromdhani89No ratings yet

- Hvac ToolsDocument12 pagesHvac Toolsavicohvacr100% (2)

- More Production: in Less TimeDocument2 pagesMore Production: in Less TimeDaniel GarciaNo ratings yet

- Power - Plant - Lab Manual MA K11152 KWDocument138 pagesPower - Plant - Lab Manual MA K11152 KWDan MatNo ratings yet

- Selection & Specification Data Substrates & Surface PreparationDocument2 pagesSelection & Specification Data Substrates & Surface PreparationJuanNo ratings yet

- Shell Saraline 185V TDSDocument3 pagesShell Saraline 185V TDSYanu Ismadi100% (2)

- Brochure - DMA-80 Evo - 220309 - 202322Document8 pagesBrochure - DMA-80 Evo - 220309 - 202322Ayman KamounNo ratings yet

- Heavy Metals 1Document6 pagesHeavy Metals 1Axel TuyubNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- Alpha Ef 2100 Technical Data SheetDocument4 pagesAlpha Ef 2100 Technical Data SheetYounes Ben TaherNo ratings yet

- Exxonmobil™ Pp1304E6: Polypropylene HomopolymerDocument2 pagesExxonmobil™ Pp1304E6: Polypropylene Homopolymermohsen_267No ratings yet

- Exxon™ Chlorobutyl 5066: RubberDocument2 pagesExxon™ Chlorobutyl 5066: RubberMaram YasserNo ratings yet

- COA AMLA DRY EXTRACT RevDocument1 pageCOA AMLA DRY EXTRACT RevqalaurelNo ratings yet

- Spec-Shilajit Extract-50%Document1 pageSpec-Shilajit Extract-50%marketing splsgroupNo ratings yet

- Spec-Organic Shilajit Extract-20%Document1 pageSpec-Organic Shilajit Extract-20%marketing splsgroupNo ratings yet

- Interline 399+br+eng PDFDocument2 pagesInterline 399+br+eng PDFMohamed NouzerNo ratings yet

- Lampiran 3 Dan 4 Proposal DisertasiDocument2 pagesLampiran 3 Dan 4 Proposal DisertasioktariyanaNo ratings yet

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- Sorbitol - 70% Process Flow ChartDocument6 pagesSorbitol - 70% Process Flow Chartsachinmittal.nitkNo ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- Astm B 481 - 68 Prepa TitaniumDocument3 pagesAstm B 481 - 68 Prepa Titaniumludovic chantegrelNo ratings yet

- Asi2677 Single Use Film Validation GuideDocument17 pagesAsi2677 Single Use Film Validation GuideCampaign MediaNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Rotolene: Meet The Unbeatable The Resin That Has It AllDocument2 pagesRotolene: Meet The Unbeatable The Resin That Has It Allrosy_hernandez_8No ratings yet

- SDS Natve Tapioca Starch Food GradeDocument1 pageSDS Natve Tapioca Starch Food GradesinarkanakajayaNo ratings yet

- Zeolite Product Data SheetDocument1 pageZeolite Product Data SheetbigdadytexasNo ratings yet

- PCA Ion Exchange Membranes - Technical Data SheetDocument2 pagesPCA Ion Exchange Membranes - Technical Data Sheettestuser010% (1)

- Ethamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyDocument25 pagesEthamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyNikhilNo ratings yet

- Ficha Tecnica Acido SorbicoDocument1 pageFicha Tecnica Acido SorbicoCarlos SiuNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- Swancor 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSwancor 901-3: Epoxy Vinyl Ester Resinswongpengchiong7205No ratings yet

- Pds Luminy l130 20220722Document3 pagesPds Luminy l130 20220722Nguyen HoangNo ratings yet

- Ronovel CMDocument12 pagesRonovel CMtkpeng76No ratings yet

- Intercure 200HS: Rapid Recoat EpoxyDocument4 pagesIntercure 200HS: Rapid Recoat EpoxySubham SahuNo ratings yet

- TDS of SP7154 0002Document2 pagesTDS of SP7154 0002kashyappathak01No ratings yet

- MusaliDocument3 pagesMusalisavithruassociatesNo ratings yet

- QP Report of JetDocument3 pagesQP Report of Jetbj100% (1)

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Ti-ExR04 PDSDocument2 pagesTi-ExR04 PDSBorja AzkargortaNo ratings yet

- Certificate of Analysis - GlucosaminedocxDocument1 pageCertificate of Analysis - Glucosaminedocxiyas salihNo ratings yet

- Ascorbic Acid CoA May 22 (1) - 1Document2 pagesAscorbic Acid CoA May 22 (1) - 1Studley JupiterNo ratings yet

- 7 - Chitosan 90% - 20230714Document1 page7 - Chitosan 90% - 20230714Nguyen HungNo ratings yet

- IP2028 DowpolDocument1 pageIP2028 DowpolRhea TalibNo ratings yet

- Pt. Smart-Lab Indonesia: Manufacturer of Analytical ReagentsDocument1 pagePt. Smart-Lab Indonesia: Manufacturer of Analytical ReagentsibrahimovidNo ratings yet

- Pt. Smart-Lab Indonesia: Manufacturer of Analytical ReagentsDocument1 pagePt. Smart-Lab Indonesia: Manufacturer of Analytical ReagentsibrahimovidNo ratings yet

- Remedi Perf Data-1Document2 pagesRemedi Perf Data-1Nermeen ElmelegaeNo ratings yet

- PP Homo Basell - HP500NDocument2 pagesPP Homo Basell - HP500NJaime222No ratings yet

- Coa LabDocument1 pageCoa Labmagro worldNo ratings yet

- PKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESDocument3 pagesPKI - AN - 2016 - Analysis of Oil Additives Following ASTM D4951 With The Avio 200 ICPOESstrubingeraNo ratings yet

- TDS - Vinyl 901-3 (En)Document2 pagesTDS - Vinyl 901-3 (En)OXY Composite TechNo ratings yet

- TDS-SULFAD®-1710E 硫化极压剂Document3 pagesTDS-SULFAD®-1710E 硫化极压剂ganzhirong8No ratings yet

- Declaration of Food Contact Compliance Nitrile Powder Free Glove (NPT - SD)Document8 pagesDeclaration of Food Contact Compliance Nitrile Powder Free Glove (NPT - SD)vicNo ratings yet

- Guide 2 3Document32 pagesGuide 2 3ArgaNo ratings yet

- MSDS Alpha F-6000Document4 pagesMSDS Alpha F-6000Wassim MansourNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentMohammed NuseirNo ratings yet

- Seabuckthorn Powder COA-WellgreenDocument1 pageSeabuckthorn Powder COA-WellgreenRobiNo ratings yet

- Ak-90le SuezDocument1 pageAk-90le Suezinversiones del peruNo ratings yet

- Carboguard 158 UP PDSDocument4 pagesCarboguard 158 UP PDSvihor94213No ratings yet

- Divyanshu Srivastava@Project - Main DocumentDocument33 pagesDivyanshu Srivastava@Project - Main DocumentAkshay SengarNo ratings yet

- Zinc Oxide 98 White Coa PDFDocument1 pageZinc Oxide 98 White Coa PDFsikkujegnaNo ratings yet

- Specification Hydrate FinalDocument6 pagesSpecification Hydrate FinalSanjayNo ratings yet

- 0618 Thermo Oil VANCEDocument1 page0618 Thermo Oil VANCEwaqiuddinNo ratings yet

- Quotation To Vance Bioenergy - S00117 - Kiryn Pipette and Tips PromotionDocument2 pagesQuotation To Vance Bioenergy - S00117 - Kiryn Pipette and Tips PromotionwaqiuddinNo ratings yet

- MENU Adam's KitchenDocument30 pagesMENU Adam's KitchenwaqiuddinNo ratings yet

- Oil (Uco/Efb/Pome/Mef) Receiving - in Bulk (Loadport) : Responsibilities Process Flow Key Control ProceduresDocument1 pageOil (Uco/Efb/Pome/Mef) Receiving - in Bulk (Loadport) : Responsibilities Process Flow Key Control ProcedureswaqiuddinNo ratings yet

- (Uco Efb Pome Mef) ReceivingDocument1 page(Uco Efb Pome Mef) ReceivingwaqiuddinNo ratings yet

- Revised - Appearance and Quality of Fatty Matter (TK11& TK367)Document2 pagesRevised - Appearance and Quality of Fatty Matter (TK11& TK367)waqiuddinNo ratings yet

- FLASKDocument1 pageFLASKwaqiuddinNo ratings yet

- PT Slamet JayaDocument1 pagePT Slamet JayawaqiuddinNo ratings yet

- Waste Brick and Concrete For Wastewater Treatment by Pilot and Static TestDocument4 pagesWaste Brick and Concrete For Wastewater Treatment by Pilot and Static TestmaizansofiaNo ratings yet

- Substaion DesignDocument6 pagesSubstaion DesignGuru MishraNo ratings yet

- MGB Competition Preparation ManualDocument39 pagesMGB Competition Preparation ManualasrwNo ratings yet

- Jakap Lace Pvt. LTD.: Material Test CertificateDocument1 pageJakap Lace Pvt. LTD.: Material Test Certificatemechtek 20No ratings yet

- Comparison of CT Burden of Protection Relay TypesDocument9 pagesComparison of CT Burden of Protection Relay TypesNeelakandan MasilamaniNo ratings yet

- Engine Manual Rx-8Document326 pagesEngine Manual Rx-8Jose Ignacio Morales Barreda100% (2)

- Vibradores ER para ConcretoDocument32 pagesVibradores ER para ConcretoFelipe FernandesNo ratings yet

- M6 Materials and Hardware PDFDocument495 pagesM6 Materials and Hardware PDFRichard StanleyNo ratings yet

- Rock Blasting For Mining: April 2017Document24 pagesRock Blasting For Mining: April 2017bassir esmatyarNo ratings yet

- Bearing MeasurementDocument7 pagesBearing Measurementhengki wibowoNo ratings yet

- GAPS Guidelines: High Intensity Discharge (Hid) LightingDocument5 pagesGAPS Guidelines: High Intensity Discharge (Hid) LightingAsad KhanNo ratings yet

- Barden/Fag Cronidur® 30 Hybrid Spindle BearingsDocument2 pagesBarden/Fag Cronidur® 30 Hybrid Spindle BearingssgwilliamsNo ratings yet

- 2008 Midea MDV Tropical PDFDocument14 pages2008 Midea MDV Tropical PDFMiraNo ratings yet

- Model Textbook of Chemistry For Senior Secodary Schools: January 2006Document499 pagesModel Textbook of Chemistry For Senior Secodary Schools: January 2006I am SheldonNo ratings yet

- Environmentally Friendly, Phthalate Free, High Performance, Easy To Use MDI Based PUR Injection ResinsDocument6 pagesEnvironmentally Friendly, Phthalate Free, High Performance, Easy To Use MDI Based PUR Injection ResinsAmelaLjNo ratings yet

- Kaifeng Maosheng Machinery Co - LTDDocument2 pagesKaifeng Maosheng Machinery Co - LTDmohamedNo ratings yet

- Chapter 2 PRDocument8 pagesChapter 2 PRKatsuki HashimotoNo ratings yet

- MgO in FLY ASH - ACI Report PDFDocument35 pagesMgO in FLY ASH - ACI Report PDFAYUSH IPNo ratings yet

- Canal DesignDocument34 pagesCanal Designniranjan100% (2)

- Essay Passage Set Plastic TrashDocument8 pagesEssay Passage Set Plastic TrashKaiserKilljoyNo ratings yet

- Liquid Meter Proving TechniquesDocument3 pagesLiquid Meter Proving TechniquesIkhsan ArifNo ratings yet

- Alcomer 750 Types: Technical InformationDocument2 pagesAlcomer 750 Types: Technical InformationPrototypeNo ratings yet

- Owners Manual ACS 50 6410T0008Document36 pagesOwners Manual ACS 50 6410T0008Jose Ramon Chavarria Quintero60% (5)

- ProReact EN Digital Product Brochure PDFDocument2 pagesProReact EN Digital Product Brochure PDFVladimir BukaricaNo ratings yet

- Honeywell Mmi 813.1 Mod 23Document5 pagesHoneywell Mmi 813.1 Mod 23nestor_moNo ratings yet

- FW Delayed-Coking Process: Howard M. Feintuch Kenneth M. NeginDocument58 pagesFW Delayed-Coking Process: Howard M. Feintuch Kenneth M. NeginBharavi K S100% (2)

- Effect On Compressive Strength of Concrete by Partial Replacement of Cement With Fly AshDocument4 pagesEffect On Compressive Strength of Concrete by Partial Replacement of Cement With Fly AshAnonymous CUPykm6DZNo ratings yet

- 775F OhtDocument28 pages775F OhtDavid FortierNo ratings yet