Professional Documents

Culture Documents

Technical Specification: Gear Theoretical Speed (2200rpm) Ratio's (KM/H)

Technical Specification: Gear Theoretical Speed (2200rpm) Ratio's (KM/H)

Uploaded by

shhp567Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification: Gear Theoretical Speed (2200rpm) Ratio's (KM/H)

Technical Specification: Gear Theoretical Speed (2200rpm) Ratio's (KM/H)

Uploaded by

shhp567Copyright:

Available Formats

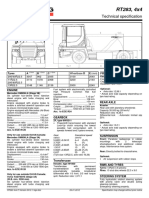

YT182, 4x2

Technical specification

REAR AXLE

Terberg TTA type 70-11

Capacity 30.000 kg (at 20 km/h)*

Hub reduction axle with total reduction

ratio 11.98:1

Optional:

TTA 70-01 9.49:1

D81PL478 9.76:1, 12.73:1 or 16.13:1

D81 PL477 13.2:1 or 16.36:1

* Actual axle load capacity depending on

tyre load rating.

SUSPENSION

Front: Parabolic leaf springs in rubber

mountings with 2 telescopic shock

absorbers.

Maintenance-free system.

Rear: Directly bolted to chassis frame.

Optional:

Air suspension with rubber stops

RIMS AND TYRES

Tyres: 11R22.5 (6 pieces)

GEARBOX Rims: 10 stud disc wheels 22.5 x 8.25

ENGINE

Cummins QSB6.7-190 (Tier 4f/Stage 4) Allison, type 3000

STEERING SYSTEM

Six-cylinder four-stroke direct injection

diesel engine with variable geometry Automatic shift transmission with 5 gears Fully hydrostatic orbitrol steering system

turbo charging and intercooler. forward, 1 gear reverse and torque with priority valve and double acting

Engine equipped with Cummins (AdBlue) converter equipped with Lock-Up clutch. steering cylinder.

system including DOC and SCR-catalyst. Including standard F/R shift protection. Emergency steering property.

Displacement: ............................ 6,7 dm3 Steering wheel diameter 350 mm

Bore: .......................................... 107 mm Gear theoretical speed (2200rpm) Turning circle over front bumper (m)

Stroke: ....................................... 124 mm ratio's [km/h] WB 3100 13,0

Compression ratio: ..................... 17,2 : 1 3.487 8 (F1) WB 3300 13,5

Output:..... 142 kW (193 hp) at 2000 rpm 1.864 19 (F2) WB 3500 14,1

Torque: ................... 809 Nm at 1500 rpm 1.409 25 (F3)

Acc. to ECE R120 1.00 35 (F4) 5th WHEEL

0.75 47 (F5) Terberg 2" cast steel plate

Only for use outside EU/US/Canada: Note: speed is 37km/h@1725 engine rpm Technical capacity 36.000 kg.

5.027 6 (R) Lifting capacity 31.000 kg*.

Cummins QSB6.7-173 (Tier 3/Stage 3A) (Tyre size 11R22.5, axle ratio 11.98:1) Automatic locking of jaw system.

Mercedes OM906LA (Tier 3/Stage 3A) Pneumatic unlocking of 5th wheel,

Optional: operated from cabin.

Cummins ISB6.7E5-205 (Euro 5)

ZF, type 5WG191 with Lock-Up* Indicator light for positive locking inside

Powershift transmission with high the cabin.

efficiency torque converter with Lock-

Up clutch and 5 gears forward and 3 Optional:

gears reverse. 27.000 kg* lifting capacity (for ultra

* Only i.c.w. rear axle ratio >11.90:1 low 5th wheel height)

34.000 kg* lifting capacity

FRONT AXLE * Actual lifting capacity depending on tyre

Terberg TTA type 60-xx load ratings and 5th wheel height.

Non-driven steering axle

Capacity: 10.000 kg (at 20 km/h)* HYDRAULIC SYSTEM

Engine driven hydraulic pump for steering

Optional: and lifting 5th wheel plate, directly

Volvo mounted to the engine, with priority valve

Non-driven steering axle for the steering system.

Capacity 11.000 kg (20 km/h)* Hydraulic oil tank protected mounted to

Terberg TTA62-xx the chassis frame. Tank capacity 50 dm3.

Capacity: 11.000 kg (at 20 km/h)* Hydraulic valve pneumatically operated

* Actual axle load capacity depending on from inside the cab to lift/lower/hold the

tyre load rating. 5th wheel. Working pressure 250 bar.

2 heavy-duty hydraulic single stage lift

rams.

YT182 4x2 E Version 2015-1 15-12-2015 Specification may change without prior notice

ncnielsen Terberg Scandinavia Terberg Scandinavia Ìslyft ehf

Nørregade 66 DK- 7860 Balling Kårebogatan 7 S-418 78 Göteborg Nørregade 66 DK- 7860 Balling Vesturvör 32 IS-200 Kópavogur-simi

tel. +45 99 83 83 83 tel. +46 31 53 64 30 tel. +45 99 83 83 83 tel. +354 564 1600

info@terberg.dk www.terberg.dk info@terberg.se www.terberg.se info@terberg.dk www.terberg.no islyft@islandia.is www.islyft.is

Cab mounted on 3 anti-vibration mounts

in combination with shock absorber.

Entrance to cab by inboard door for safe

and easy entrance/exit to/from driver’s

position.

Horizontal sliding window at driver’s side

Large windows with excellent visibility.

All window panes tinted hardened safety

glass except front window which is

layered.

Noise insulation exceeds international

standards.

Cabin can be tilted with hydraulic hand

pump to 65o

Driver’s seat with air suspension and fully

adjustable, mounted on console with

CHASSIS generous storage space.

Welded construction of rolled steel EXHAUST

channels 200x100x10 mm Vertically mounted silencer with curved Demister/heater with 3-speed blower and

Air reservoirs and fuel tank protected end pipe and protected in critical areas recirculation system.

mounted to the chassis, access steps with stainless steel protection grilles.

with anti-slip surface integrated in Steering column with 1 brake pedal and 1

chassis. accelerator pedal, mounted at right side

ELECTRICAL SYSTEM

Towing pin attachment at front- and rear of column.

24 Volt negative earth.

of chassis. Alternator : 28V/95A (Cummins T4f) Front dashboard switches:

Batteries : 2 x 12 Volt / 140 Ah Ignition

BRAKE SYSTEM Output starter : 4,8 kW (Cummins T4f)

Differential lock

Full air brake system with split front and Fuses and relays mounted in central

electrical box. Work light

rear axle and parking brake circuits.

Wiring with code numbers and easy Hazard lights

Parking brake working on rear axle.

TTA front and rear axles equipped with readable/visible/accessible mounted in Lighting

S-cam brake system with automatic slack central electrical box. 5th wheel unlocking (2x)

adjusters. 7 pin SAE socket at rear of cab for trailer

Kessler rear axles with simplex wedge connection (DIN ISO 1185). Dashboard display:

brake (D81PL478) or single jaw disc Multifunctional full colour CAN-bus

brake (D81PL477). All with auto slack LIGHTING display (DIM) showing vehicle speed ,

adjusters. brake pressure circuit 1+2, diesel and

H4 head lights with dipped and main

Brake pressure: 7,8 – 8,5 bar. AdBlue level and engine rpm.

beam and direction indicators.

Air reservoirs: 2 x 40 dm3 and 1 x 30 dm3 With possibility to read out running

LED rear lights on rear of chassis, with

with standard air dryer. hrs, as well as the following analogue

direction indicators and brake lights.

2 Line trailer brake system mounted on values (all with optical signal and

5th wheel flood light behind cabin.

rear side of cabin, with yellow and red buzzer on critical levels):

Gauge illumination.

spiral hoses with gladhands. * High temperature gearbox

Interior light in cabin.

* Low oil pressure engine

Mounting for rotating beacon light.

* High temperature engine

FUEL TANK

* Low voltage

Capacity 200 dm3 and integrated with CABIN Indicator lights are integrated in the

hydraulic tank. 1 person left-hand or right-hand drive display. It has also integrated

position. diagnostic and vehicle history info

Forward facing driver’s position. which can be shown on the screen

COOLING SYSTEM and downloaded via USB.

Plate and bar type radiator of heavy-duty Dimensions outside:

construction mounted on rubber silent width : 1400 mm Steering column:

blocks with separate air to air length : 1593 mm Combi switch for:

transmission oil cooler and engine height : 1821 mm Direction indicators

intercooler all mounted side by side. Wiper front

High/Low beam

Cabin construction of overdimensioned Horn

strong steel profiles to comply to latest

Rops/Fops regulations. Optional:

Co-driver foldaway seat

YT182 4x2 E Version 2015-1 15-12-2015 Specification may change without prior notice

You might also like

- Dean Moya - SUGGESTED ANSWER (BAR 2022) LECTUREDocument97 pagesDean Moya - SUGGESTED ANSWER (BAR 2022) LECTURELuchie Castro100% (2)

- Lufthansa - Your Booking InformationDocument3 pagesLufthansa - Your Booking InformationMedia PilleNo ratings yet

- Bpharm Myleads 2023 09 12 (All)Document202 pagesBpharm Myleads 2023 09 12 (All)nitingudduNo ratings yet

- Michael Tonry - Punishing Race - A Continuing American Dilemma (2011, Oxford University Press)Document221 pagesMichael Tonry - Punishing Race - A Continuing American Dilemma (2011, Oxford University Press)Par PoundzNo ratings yet

- TERBERG YT180 TechnicalDocument2 pagesTERBERG YT180 Technicalyao nestor100% (1)

- MP4500 6x4 Cursor 13Document4 pagesMP4500 6x4 Cursor 13brayandparavicinoNo ratings yet

- Vesta 1000 01 PDFDocument53 pagesVesta 1000 01 PDFDuta NarendratamaNo ratings yet

- Motivate! 4 Progress Test Standard: Name: - Result: - /100 VocabularyDocument7 pagesMotivate! 4 Progress Test Standard: Name: - Result: - /100 VocabularyDragoș Simică0% (1)

- DT183LE 4x2Document2 pagesDT183LE 4x2shhp567No ratings yet

- Technical Specification: Front AxleDocument2 pagesTechnical Specification: Front AxleFly in the shyNo ratings yet

- Technical Specification: Front AxleDocument2 pagesTechnical Specification: Front Axleshhp567No ratings yet

- CXZ - CXY 240-460 - ARK1408 - v03Document4 pagesCXZ - CXY 240-460 - ARK1408 - v03Yesuf EndrisNo ratings yet

- Giga CXZ 24O-46O 6X4 Giga CXY 24O-46O 6X4: Now With Sat Nav Fitted As StandardDocument8 pagesGiga CXZ 24O-46O 6X4 Giga CXY 24O-46O 6X4: Now With Sat Nav Fitted As StandardLarry Jay TanNo ratings yet

- Giga EXY 24O-46O 6X4: Now With Sat Nav Fitted As StandardDocument4 pagesGiga EXY 24O-46O 6X4: Now With Sat Nav Fitted As StandardjoseriquNo ratings yet

- Terberg RT283 PDFDocument2 pagesTerberg RT283 PDFHemerson FurtadoNo ratings yet

- HS700SS2848-0616 WebDocument4 pagesHS700SS2848-0616 WeberandazarNo ratings yet

- FVM 230-300 - FVL 240-300 - ARK1388 - v02Document4 pagesFVM 230-300 - FVL 240-300 - ARK1388 - v02shane23.chandraNo ratings yet

- FRR 1o7-21o TipperDocument4 pagesFRR 1o7-21o Tipperakash shahNo ratings yet

- Technical Specification: Engine Front AxleDocument2 pagesTechnical Specification: Engine Front AxleÇağrı Fatih AYNo ratings yet

- FRR 1O7-21O Tipper: Now With Sat Nav Fitted As StandardDocument4 pagesFRR 1O7-21O Tipper: Now With Sat Nav Fitted As StandardHugo Rodriguez100% (1)

- Isuzu FXZ240-350 - FXY240-350Document4 pagesIsuzu FXZ240-350 - FXY240-350Hugo RodriguezNo ratings yet

- HD5395TS: Technical SpecificationDocument10 pagesHD5395TS: Technical Specificationdaniel_jorge_10No ratings yet

- EETT eITV - YT203-EV-4x2-EDocument2 pagesEETT eITV - YT203-EV-4x2-ELuis AlonsoNo ratings yet

- Technical Specification: Engine GearboxDocument2 pagesTechnical Specification: Engine Gearboxshhp567No ratings yet

- Condor PK 17 280 Spec SheetDocument4 pagesCondor PK 17 280 Spec SheetJulito Santa CruzNo ratings yet

- Bus Hino Rnk8Document4 pagesBus Hino Rnk8JERZON100% (1)

- Terberg TT223 - 4x2 UKDocument2 pagesTerberg TT223 - 4x2 UKFly in the shyNo ratings yet

- With EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMDocument4 pagesWith EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMSara Sarmiento EcheverryNo ratings yet

- Ficha Tecnica Ak8jrsa NJL Hino PDFDocument5 pagesFicha Tecnica Ak8jrsa NJL Hino PDFChristian Parra OrtegaNo ratings yet

- Sandvik Lh518B: Battery Electric LoaderDocument8 pagesSandvik Lh518B: Battery Electric LoaderHukiro ItachiNo ratings yet

- Hsmy17fm2632fm2635-0921 WebDocument4 pagesHsmy17fm2632fm2635-0921 Webvictor hugoNo ratings yet

- Tata 1109 G LPT BrochureDocument2 pagesTata 1109 G LPT BrochureVishal Karad100% (1)

- Prado: Mechanical SpecificationsDocument3 pagesPrado: Mechanical SpecificationsMark MendozaNo ratings yet

- Compresor Mobil Atlas Copco XAS 37 KDDocument2 pagesCompresor Mobil Atlas Copco XAS 37 KDdiconNo ratings yet

- NQR500 TipperDocument2 pagesNQR500 TipperHugo RodriguezNo ratings yet

- Ficha - Tecnica - Mixer - MK-A12m3Document4 pagesFicha - Tecnica - Mixer - MK-A12m3Ventasde VehiculosNo ratings yet

- FC 1022 Proshift 6 FC 1022 Manual: Key Features Key SpecificationsDocument4 pagesFC 1022 Proshift 6 FC 1022 Manual: Key Features Key SpecificationsRoy AraujoNo ratings yet

- Kenworth AU K200 SpecSheet - 2020 - WEBDocument2 pagesKenworth AU K200 SpecSheet - 2020 - WEBlushnuNo ratings yet

- Croner PKE280 H35 Spec SheetDocument2 pagesCroner PKE280 H35 Spec Sheetvictor hugoNo ratings yet

- AXERA 6-226: Technical Specification 6-9650-B 2004-07-02Document4 pagesAXERA 6-226: Technical Specification 6-9650-B 2004-07-02cristianNo ratings yet

- GHH Fahrzeuge MK-A35Document4 pagesGHH Fahrzeuge MK-A35Ajay SinghNo ratings yet

- Daf FTT 95Document2 pagesDaf FTT 95Bartek GrzybowskiNo ratings yet

- Eurorider 270Document1 pageEurorider 270fatalgamersNo ratings yet

- Atlas Copco Portable Air CompressorsDocument2 pagesAtlas Copco Portable Air CompressorsBane RadovicNo ratings yet

- 2022 Ninja h2r en Us Spec SheetDocument1 page2022 Ninja h2r en Us Spec SheetMiguel PamplonaNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson PhinniNo ratings yet

- TGM 18.240 4x2 BB Freight Carrier Compact CabDocument4 pagesTGM 18.240 4x2 BB Freight Carrier Compact Cabhamza MoussaidNo ratings yet

- SC - 2024 - 48 Introduction of TATA LPT 4225.T 6.7 L BSVI Ph2 10x2Document16 pagesSC - 2024 - 48 Introduction of TATA LPT 4225.T 6.7 L BSVI Ph2 10x2Fstar MakNo ratings yet

- Specifications: Ibratory OIL OmpactorDocument2 pagesSpecifications: Ibratory OIL OmpactorMohamad NuhNo ratings yet

- YT203EV 4x2 Technical Specification Version 2023-9Document2 pagesYT203EV 4x2 Technical Specification Version 2023-9Alessi ReyvenNo ratings yet

- QUESTER COMPACTOR Quester - E44 - Spec - SheetDocument2 pagesQUESTER COMPACTOR Quester - E44 - Spec - SheetAlfred SitholeNo ratings yet

- Volvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetDocument4 pagesVolvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetPandey BoardNo ratings yet

- Volvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetDocument4 pagesVolvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetsandeepkushwahaNo ratings yet

- Automatic Transaxle SystemDocument170 pagesAutomatic Transaxle SystemCesar Giracca100% (1)

- Giga-Cxz415 Giga-Cxy415 Ark0688 PDFDocument4 pagesGiga-Cxz415 Giga-Cxy415 Ark0688 PDFElijah KumbamongNo ratings yet

- ROSA BUS 2015 SpecificationsDocument3 pagesROSA BUS 2015 Specificationsவுதூசனன்சிவபாலன்No ratings yet

- FVL1350 1400Document2 pagesFVL1350 1400Hisham HamdiNo ratings yet

- وظيفةDocument1 pageوظيفةabd alkader100% (1)

- Volksbus 9-150 OD MWM - Euro Ii: BusesDocument4 pagesVolksbus 9-150 OD MWM - Euro Ii: BusesCHAVITA ORTEGANo ratings yet

- hs500fc1022t-0216 WebDocument4 pageshs500fc1022t-0216 WebEstiph Logan Weissy CajacuriNo ratings yet

- Terex TR 45 Spec PDFDocument6 pagesTerex TR 45 Spec PDFarimbi jatisasongkoNo ratings yet

- Road & Track Iconic Cars: CamaroFrom EverandRoad & Track Iconic Cars: CamaroLarry WebsterNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Rules and Procedures in Handling Child Abuse CasesDocument1 pageRules and Procedures in Handling Child Abuse CasesJoyce Carreon50% (2)

- Astrology For Beginners - An Easy Guide To Understanding & Interpreting Your Chart (Hewitt)Document146 pagesAstrology For Beginners - An Easy Guide To Understanding & Interpreting Your Chart (Hewitt)Sabina Serban100% (6)

- Notes On Koine Greek, Pt. 7Document1 pageNotes On Koine Greek, Pt. 7pisteuomenNo ratings yet

- CPN-CSPC Protocol 26nov2014Document136 pagesCPN-CSPC Protocol 26nov2014John J. MacasioNo ratings yet

- Implementing The Weil, Tate and Ate Pairings Using Sage SoftwareDocument19 pagesImplementing The Weil, Tate and Ate Pairings Using Sage SoftwareMuhammad SadnoNo ratings yet

- Lapasan National High SchoolDocument3 pagesLapasan National High SchoolMiss SheemiNo ratings yet

- Business Culture and Etiquettes of BrazilDocument10 pagesBusiness Culture and Etiquettes of BrazilSaloni LohiaNo ratings yet

- Ajit ResumeDocument3 pagesAjit ResumeSreeluNo ratings yet

- Chris McClure's Origami BatDocument6 pagesChris McClure's Origami Batchristopher.t.mcclureNo ratings yet

- PT Bank MandiriDocument2 pagesPT Bank MandiriImanuel Kevin NNo ratings yet

- Soal Uas-1Document4 pagesSoal Uas-1Sri RinjaniNo ratings yet

- LS5 QTR4 - 19. LS5 - SGJ-Likas Na Yaman (Introduction)Document4 pagesLS5 QTR4 - 19. LS5 - SGJ-Likas Na Yaman (Introduction)Roy JarlegoNo ratings yet

- TFWP 2022q4 Pos enDocument1,088 pagesTFWP 2022q4 Pos enMuhammad NaqashNo ratings yet

- Answer Key Review Test Units 1 4Document23 pagesAnswer Key Review Test Units 1 4VICTOR TAPARA SAYANo ratings yet

- The Impact of Social Media On Educational Performance With Reference To College StudentsDocument5 pagesThe Impact of Social Media On Educational Performance With Reference To College StudentsIjcams PublicationNo ratings yet

- EPANET in QGIS Framework: The QEPANET PluginDocument5 pagesEPANET in QGIS Framework: The QEPANET PluginAleksandar PetrovićNo ratings yet

- EagleBurgmann - Fluachem Expansion Joints - ENDocument5 pagesEagleBurgmann - Fluachem Expansion Joints - ENRoberta PugnettiNo ratings yet

- TTL - Lesson Plan - Harvey - IbeDocument12 pagesTTL - Lesson Plan - Harvey - IbeHarvey Kurt IbeNo ratings yet

- Social Media and Political Communication in India: An Analysis of 2017 Legislative Assembly Elections in Himachal PradeshDocument7 pagesSocial Media and Political Communication in India: An Analysis of 2017 Legislative Assembly Elections in Himachal PradeshEditor IJTSRDNo ratings yet

- 17.HB158 Welding Manual301 V30713Document38 pages17.HB158 Welding Manual301 V30713James DickinsonNo ratings yet

- Vizag Srikakulam Vizianagaram Kakinada Rajahmundry Godavari Real Estate PlotDocument9 pagesVizag Srikakulam Vizianagaram Kakinada Rajahmundry Godavari Real Estate Plotwww.hindustanpropertyhub.com Secunderabad Waltair Bezawada East Godavari West Godavari Krishna Prakasam real estate property plotsNo ratings yet

- Powerful Phrases For Customer ServiceDocument16 pagesPowerful Phrases For Customer ServiceArturo GallardoNo ratings yet

- 621Document6 pages621Elia KwanNo ratings yet

- Notice: Comprehensive Conservation Plans Availability, Etc.: Gray Wolf Western Great Lakes Distinct Population Segment Post-Delisting Monitoring PlanDocument2 pagesNotice: Comprehensive Conservation Plans Availability, Etc.: Gray Wolf Western Great Lakes Distinct Population Segment Post-Delisting Monitoring PlanJustia.comNo ratings yet