Professional Documents

Culture Documents

SWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenance

SWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenance

Uploaded by

tilet26128Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenance

SWMS Safe-Wrk-Mthd-Statement-Sample-Pump Maintenance

Uploaded by

tilet26128Copyright:

Available Formats

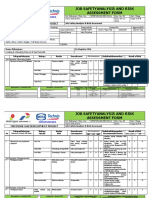

Safe Work Method Statement

ORGANISATION NAME:

PHONE: 02 9688 6444

Premo Fuel Maintenance Pty Ltd

ADDRESS: PO Box 825 Baulkham Hills Email: simon.newman@premofuelmaintenance.com.au

ABN NUMBER: 79 117 273 588 DATE:

Project Details: Take sample from bulk diesel tank/ admix treatment.

Site: Site contact Name:

Area Site Contact Phone No:

This SWMS has been developed in consultation with: Simon Newman

Resources / Trades Involved: NIL Reviewed by: Simon Newman

Position: Director Date:

Equipment Used: Sample kit, spill kit

Maintenance checks: N/A

Materials Used: N/A

OHS or environmental Legislation: Work

Codes or standards applicable to the work: NIL

Health & Safety Act 2011

1 This SWMS was prepared by: Simon Newman

2 NAME 3 POSITION 4 SIGNATURE 5 DATE

7 Director

6 Simon Newman 9

8

10 This SWMS was approved by: Simon Newman

11 NAME 12 POSITION 13 SIGNATURE 14 DATE

15 Simon Newman 16 Director 18

17

19 The names and positions of personnel assigned the responsibility for supervising this work and their qualifications are as follows:

20 NAME 21 POSITION 22 QUALIFICATIONS 23 DATE

24 Simon Newman 25 Director 26 NIL 27

28 The names of workers or their nominated safety representatives who were consulted and involved in the development of this

SWMS are as follows:

29 Simon Newman 30

31 32

33 NSW and National Occupational Health & Safety Commission – Hierarchy of Control Definitions

Controlling the health and safety risks in a workplace is necessary to prevent injury and illness. First, identify and assess the risks,

then decide on the best way to control them by applying the Hierarchy of Controls as follows:

1. Elimination - controlling the hazard at source

2. Substitution - replacing one substance or activity with a less hazardous one

3. Isolation – separating the hazard from the person

4. Engineering - installing guards on machinery

5. Administration - implementing policies and procedures for safe work practices

6. Personal Protective Equipment - use of goggles, respirators, and ear plugs etc.

When deciding on the best way to control a risk, start at the top of the hierarchy of controls, i.e. investigate if the risk can be

eliminated first, for example by changing the way the work is done, or by using safer substances or equipment. This is the most

effective way to control a hazard. If these methods are not possible, use engineering, isolation or administrative controls to reduce

or minimise the risk.

Premo Fuel Maintenance Rev 1.0 2017

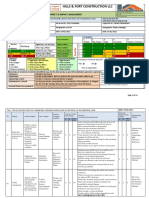

Risk Assessment Matrix Risk Class

Likelihood Those risks with a relatively

High /

Almost high likelihood and large

Likely Possible Unlikely Rare 1-6

certain impact

Extraordinary 1 2 4 7 11

Consequence

Medium Risks with a medium

Major 3 5 8 12 16 / 7-15 likelihood or impact.

Moderate 6 9 13 17 20

Minor 10 14 18 21 23 Low / Those risks with a relatively

16-25 low likelihood and impact.

Insignificant 15 19 22 24 25

Consequence Description Likelihood Description

Extraordinary Catastrophic impact on project. Major Almost The event/impact is common and expected to

incident involving fatalities or permanent Certain occur in most circumstances (will occur regularly /

disability. 10 times for year)

Major Major negative impact on project. Likely The event/impact has happened before and will

Serious injury or disease to staff or probably occur again (will occur often / 5-10 times

subcontractors or the general public. per year)

Moderate Significant negative impact on project. Possible This event/impact could occur at some time (is

Medical treatment required loss of likely to occur few / 2-3 times per year)

production capability.

Minor Minor negative impact on project. First Unlikely This event/impact is not likely to occur (is unlikely

aid treatment required. to occur more than once per year)

Insignificant Insignificant negative impact on project. Rare This event/impact may occur in exceptional

No injuries. circumstances only (is unlikely to occur during a

year)

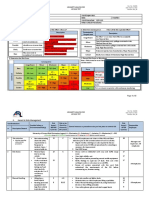

WORK

HEALTH &

ACTIVITY

SAFETY RISK CONTROL PERSON

SEQUENCE HAZARDS

ENVIRONMENT RANK MEASURES RESPONSIBLE

(STEP BY

RISKS

STEP)

Site

Induction

Sign in

Gain access Trip, car park Falling over, 25 High Vis clothing Simon Newman

to tank traffic injured by car watching where you

are going

Open dip Fuel spilling Diesel stain on 24 Use spill kits to mop Simon Newman

stick and take concrete up any spills. Wear

fuel reading gloves, safety glasses.

Perform dip Fuel spilling Diesel stain on 24 Use spill kits to mop Simon Newman

test for water concrete up any spills

Extract Fuel spilling Diesel stain on 24 Use spill kits to mop Simon Newman

sample concrete up any spills

Admix Chemical spill Chemical stain on 24 Use spill kits to mop Simon Newman

treatment Splash to body concrete up any spills, gloves,

safety glasses, msds

Return dip Fuel spilling Diesel stain on 24 Use spill kits to mop Simon Newman

stick concrete up any spills Wear

gloves, safety glasses.

Re-seal dip Fuel spilling Diesel stain on 24 Use spill kits to mop Simon Newman

stick cover concrete up any spills

Premo Fuel Maintenance Rev 1.0 2017

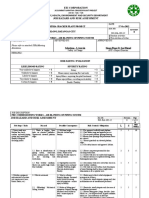

Personnel competency and training:

Simon Newman: Safe handling of 500mL sample bottle of diesel fuel

NOHSC 1015-2001 Storage and Handling of workplace

Trained on the job

dangerous goods.

Company induction Model WHS Regulations Jan 2014

List of PPE:

Gloves High Vis clothing

Steel cap boots Safety glasses

Plant and Equipment:

Sample kit: 1 x small foot pump, 1 x 4mtr hose, 1 x

500mL empty sample bottle

Hazardous chemicals used:

Emergency procedure or rescue plans relevant to the activity:

Walk back to security office or call site contact.

Call 000 for ambulance

Work health and safety legislation:

Work Health & Safety Act 2011

Applicable Australian Standards:

N/A

Applicable industry codes of practise:

N/A

Manufacturers / suppliers specifications:

N/A

Name and signature of person completing the work:

Name: Simon Newman Signature:

SWMS induction statement- The following persons have been inducted into the work activities described in this

SWMS

I have read and understood the content of this SWMS

I will work in accordance with this SWMS

If deemed necessary to amend this SWMS I will consult with my immediate supervisor and assist where

required in reviewing this SWMS

Name: Signature Date

Simon Newman

Premo Fuel Maintenance Rev 1.0 2017

You might also like

- Koh Kiar Sing Wpa (Paper 4)Document32 pagesKoh Kiar Sing Wpa (Paper 4)Muhamad HarizNo ratings yet

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Waste Treatment Plant HiraDocument5 pagesWaste Treatment Plant HiraBharath KumarNo ratings yet

- KENTEX Factory Accident Investigation ReportDocument22 pagesKENTEX Factory Accident Investigation ReportKrizzia Anne Sheng100% (4)

- 69.JSA Loading & Unloading MaterialDocument9 pages69.JSA Loading & Unloading MaterialKidung pamungkas Pamungkas100% (2)

- GS - RA Gulfstar - Environmental Aspect and ImpactDocument6 pagesGS - RA Gulfstar - Environmental Aspect and Impactsajin100% (1)

- EHS Risk AssesmentDocument6 pagesEHS Risk AssesmentSuci Kusuma NingsihNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- Safe Work Method Statement: Collbrook Pty LTD Atfmarschall Family Trust Trading AsDocument15 pagesSafe Work Method Statement: Collbrook Pty LTD Atfmarschall Family Trust Trading AsAvinash100% (2)

- Safety Induction Training Module - EMP4Document59 pagesSafety Induction Training Module - EMP4sahoobd100% (2)

- SWMS No1 V1.0Document11 pagesSWMS No1 V1.0Lachlan MackenzieNo ratings yet

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- AWQMS Plant Risk AssesmentDocument4 pagesAWQMS Plant Risk AssesmenthafizNo ratings yet

- Constuction of RCC Telecom Chamber For Telecom WorksDocument14 pagesConstuction of RCC Telecom Chamber For Telecom WorkssajinNo ratings yet

- SWMS 01 - Container 5 AssemblyDocument23 pagesSWMS 01 - Container 5 AssemblyAsfin HaqueNo ratings yet

- HIP CPP for NGCP PipelinesDocument15 pagesHIP CPP for NGCP PipelinesSajjad AfzalNo ratings yet

- Example Industry Hazard Register 2022Document5 pagesExample Industry Hazard Register 2022She-Ra Sha-Ju LaNo ratings yet

- HAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Document12 pagesHAZARD IDENTIFICATION PLAN (HIP) BASE ON TWO WEEKS LOOK AHEAD PLAN Mar 01st to Mar 15th, 2024Sajjad AfzalNo ratings yet

- PSM 3.2 - Managing Risk (v3)Document59 pagesPSM 3.2 - Managing Risk (v3)Ahmed Hamad100% (1)

- RA-IM-12A - Launching Girder - Marine-Rev-02Document52 pagesRA-IM-12A - Launching Girder - Marine-Rev-02Planning C7No ratings yet

- Enforce Safety WITDocument30 pagesEnforce Safety WITCTaida Aidah BTe WardiNo ratings yet

- SAF-6-1 Identification & Mitigation of Critical HazardsDocument7 pagesSAF-6-1 Identification & Mitigation of Critical HazardsCyprian AendeNo ratings yet

- M-011 Health Safety & Environment Risk Anticipation ManagmentDocument9 pagesM-011 Health Safety & Environment Risk Anticipation Managmentshazeb aliNo ratings yet

- SWMS 01 - Container 1 AssemblyDocument14 pagesSWMS 01 - Container 1 AssemblyAsfin HaqueNo ratings yet

- HIP-TWLA (October 1st October 15th ,2021)Document46 pagesHIP-TWLA (October 1st October 15th ,2021)Sajjad AfzalNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- SWMS 24 - Tractile InstallationDocument16 pagesSWMS 24 - Tractile InstallationAsfin HaqueNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- HIRADC Erection Steel FrameDocument7 pagesHIRADC Erection Steel FrameCrystin Rotua Hasmi PanjaitanNo ratings yet

- CPCCCA3003 - Appendix 4Document14 pagesCPCCCA3003 - Appendix 4Aditya Sharma100% (1)

- Safe Work Method Statement: Solar PV System InstallationDocument13 pagesSafe Work Method Statement: Solar PV System Installationم.عبدالرحيم سلمان100% (5)

- SWMS 27 - Second Skin Wall InstallationDocument20 pagesSWMS 27 - Second Skin Wall InstallationAsfin HaqueNo ratings yet

- Risk Assessment FormDocument4 pagesRisk Assessment Formbeshoy100% (2)

- A Guide To Risk Assessment in Ship OperationsDocument6 pagesA Guide To Risk Assessment in Ship OperationsDmytro OparivskyNo ratings yet

- Risk Assessment CURRTAIN WALL FIXINGDocument4 pagesRisk Assessment CURRTAIN WALL FIXINGmkk42781No ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- Risk AssesmentDocument3 pagesRisk AssesmentYogesh bhatNo ratings yet

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- SWMS #8 Angle Grinders Safe Work Method StatementDocument5 pagesSWMS #8 Angle Grinders Safe Work Method Statementcontrax8No ratings yet

- Training On HIRADocument26 pagesTraining On HIRAparvezblogNo ratings yet

- Risk Assesment - Fire HazardDocument14 pagesRisk Assesment - Fire HazardMohammed Amer PashaNo ratings yet

- Safe Work Method Statement System Scaffold and Mobile Scaffold (0006)Document8 pagesSafe Work Method Statement System Scaffold and Mobile Scaffold (0006)mani narayananNo ratings yet

- Risk Assessment / Job Hazard Analysis (Jha) FormDocument7 pagesRisk Assessment / Job Hazard Analysis (Jha) FormZameel KhanNo ratings yet

- Risk Asessment For Rawlplug TestingDocument9 pagesRisk Asessment For Rawlplug Testingadeoye AdeyemiNo ratings yet

- Lass-Ra 23Document14 pagesLass-Ra 23api-84174556No ratings yet

- HSEQ-FR-004-Risico Analyse - Job Hazard Analysis - 3Document3 pagesHSEQ-FR-004-Risico Analyse - Job Hazard Analysis - 3Beverly BakkerNo ratings yet

- JSA006 - Vacuum Box TestingDocument5 pagesJSA006 - Vacuum Box TestingLaohan LiuNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- 4 5.site Specific Assessment ExampleDocument2 pages4 5.site Specific Assessment ExampleTrustEmmaNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Presentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthDocument16 pagesPresentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthmarinaNo ratings yet

- NOAA Risk Management MasterDocument61 pagesNOAA Risk Management MasterDennis ChenNo ratings yet

- Master Risk Assessment FormDocument4 pagesMaster Risk Assessment FormKirana RoonnaphaiNo ratings yet

- Jgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping SystemsDocument6 pagesJgs-Ra-102-12 Pre-Commissioning Works - Air Blowing of Piping Systemsarnel sungkip100% (2)

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- Risk MatrixDocument3 pagesRisk MatrixyounasNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- MemInspection Process 01.06Document4 pagesMemInspection Process 01.06rondunn.coNo ratings yet

- Dasar Audit 2Document16 pagesDasar Audit 2ekindrinoviaNo ratings yet

- IN-SITE: Keys to an Effective Site Safety and Security ProgramFrom EverandIN-SITE: Keys to an Effective Site Safety and Security ProgramNo ratings yet

- JSA - Bore Pile - Marina CityDocument5 pagesJSA - Bore Pile - Marina CityRomaryo Andi100% (1)

- Occupational HealthDocument6 pagesOccupational HealthkopanohthomasNo ratings yet

- Research Paper OshaDocument7 pagesResearch Paper Oshauylijwznd100% (1)

- 3M Facial ProtectionDocument7 pages3M Facial ProtectionEduleofNo ratings yet

- Topic 01 - IntroductionDocument42 pagesTopic 01 - Introductionimran_chaudhry100% (1)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingeadriesNo ratings yet

- NadoopodDocument2 pagesNadoopodKhairul AzamNo ratings yet

- DA Reckoner 010109Document1 pageDA Reckoner 010109navn76100% (1)

- Ppe Recommended StepsDocument2 pagesPpe Recommended StepsNidhiNo ratings yet

- PP HRAC-111 Week1Document92 pagesPP HRAC-111 Week1Yuk man LawNo ratings yet

- Employees Demand Letter For BangladeshDocument1 pageEmployees Demand Letter For BangladeshNoman HossainNo ratings yet

- Annexure A Study On Quality of Work Life Balance of The Employee in J.Q Trye Manufacturing Industry at CoimbatoreDocument5 pagesAnnexure A Study On Quality of Work Life Balance of The Employee in J.Q Trye Manufacturing Industry at Coimbatorek eswariNo ratings yet

- Foster 30 65 SDSDocument7 pagesFoster 30 65 SDSsheetalnathNo ratings yet

- Puropack® PFA400MB MSDSDocument10 pagesPuropack® PFA400MB MSDSSayed SalahNo ratings yet

- Causes of Construction Accidents and TheDocument6 pagesCauses of Construction Accidents and ThepisalNo ratings yet

- 22-RA-Paint WorkDocument2 pages22-RA-Paint Workravindra100% (1)

- Hierarchy of ControlsDocument2 pagesHierarchy of ControlsFrancine NaickerNo ratings yet

- Case Study 1 (ENGINEERING OF SOSITY)Document22 pagesCase Study 1 (ENGINEERING OF SOSITY)mohd irfanNo ratings yet

- OSHA Lockout Tagout InspectionDocument3 pagesOSHA Lockout Tagout InspectionHariasan RNo ratings yet

- 6.3 Ergonomics For General Industry & OshaDocument33 pages6.3 Ergonomics For General Industry & Osharazlan ghazaliNo ratings yet

- Sample Reports For OfficeDocument9 pagesSample Reports For OfficeAdnan DiampuanNo ratings yet

- Grade-8 Week-5 Caregiving BIS Sheryl-Sunga5Document12 pagesGrade-8 Week-5 Caregiving BIS Sheryl-Sunga5Gianne FigueroaNo ratings yet

- Sds Water-ConditionerDocument7 pagesSds Water-ConditionerFranNo ratings yet

- GOJ Salary Scale WeeklyDocument4 pagesGOJ Salary Scale WeeklylikameleNo ratings yet

- Grey Blue Corporate Recruitment and Selection Policy PresentationDocument9 pagesGrey Blue Corporate Recruitment and Selection Policy PresentationLorena HoffmannNo ratings yet

- Job Safety Analysis FormDocument3 pagesJob Safety Analysis FormDamalieNo ratings yet

- Checklist4 - Industrial Hygiene InspectionDocument4 pagesChecklist4 - Industrial Hygiene InspectioncpborneoNo ratings yet

- Jsa Disconnect and Run CablesDocument4 pagesJsa Disconnect and Run CablesAriffZakariaNo ratings yet