Professional Documents

Culture Documents

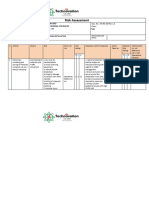

Risk Assessment For

Risk Assessment For

Uploaded by

Herdhiska Pradhiarta AjiprayogaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For

Risk Assessment For

Uploaded by

Herdhiska Pradhiarta AjiprayogaCopyright:

Available Formats

1

2

1

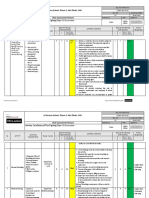

1. Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to

traffic management.

2. Ensure exclusion zone is set up around the

preparation work area and all plant

Plant and movement and checked by supervisor

Traffic 3. Traffic light batons shall be provided for

movement banks man at night

4. All plant to have a fully trained banks man

present all times.

Run over by

5. No plant to reverse without banks man.

vehicles/plants

6. Ensure access route are sufficient and safe to

Delivering, Hit by reversing

use.

unloading and equipment

Operatives 7. Do not take rest in or under vehicles Site Eng.

storing of Light Overhead Staff/visitors

1 Mediu 8. Proper barricade and safety signboard Supervisor,

Fittings Materials obstructions 3 4 12 1 4 4 Low

m provided on open excavation Foreman,

using Pickup and Vehicle break

unloading by 9. All vehicles must be fitted with reverse alarm

down

manual handling / Flashing light.

Property

10.The work place and all access to be well

damage

illuminated.

Collision with

11.Enforce Speed limit

other vehicles

12.Ensure all vehicles entering the site is

Personal injury properly maintained and reported if found

any defect

13.Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

3

4

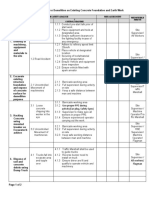

1. Work briefing must be conduct before

starting the activity.

1 Improper 2. Eliminate the need for manual handling by

Manual Handling using mechanical aid.

technique 3. Operatives must be trained for safe manual

2 Wrong posture handling

3 Poor visibility Operatives 4. If unsure of the load weight, check with

4 Lack of access & involved in work supervisor. Supervisor,

Manual Handling egress 5. Ensure proper manual handling procedure Foreman,

2 Med Low

5 Back aches 3 4 12 6. Ensure adherence with sufficient and 1 4 4 Site Eng.

6 Slippery surfaces appropriate PPE.

7. Limit load carrying to 20kg per person

8. Supervisor must make sure while manual

handling loads individual task and

environment to be considered to reduce the

risk of manual handling.

9. Manual Handling assessment will be carried

by SAF 68

3 Material storing 1 Loose & Operatives 3 4 12 Med 1. Ensure accesses are kept clear at all times. 1 4 4 Low Supervisor,

unsecured Staff/storekeeper 2. Housekeeping to be carried out regularly Foreman,

material throughout the day when required Site Eng.

2 smoking at 3. Supervisor to ensure operatives are stacking

storage area material neatly and stacks are stable and in a

3 Incorrect storage safe condition

&improper 4. Provide adequate lighting especially during

materials stacking night hours

4 Fire 5. Appropriate space is allowed around storage

5 Slip, Trip & Fall areas for employees to move around safely

without the risk being trapped between

stacked materials.

6. No smoking signage must be displayed in

storage area and strictly to be followed

smoking policy

7. Fire extinguisher must be available in storage

area in fore point.

8. Emergency number must display in storage

area

9. Fragile materials must be stored in a safe

manner with caution signage.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

5

6

.

1. Trained and authorised personnel to erect

the mobile tower

2. Ensure the PTW in place and task briefing by

supervisor to work force.

3. Ensure proper working platform with

complete fall protection

4. Secure the tools and objects kept on the

Fall of person platform

Falling of 5. Ensure safe access to the working platform.

Installation of 6. Ensure Full body harness with double lanyard Site Eng.

Materials Involved all Mediu

4 Light Fittings using 3 4 12 and 100% tie off 1 4 4 Low Supervisor

Slip, tripping, operatives m

Mobile Tower. 7. Ensure the scaffold platform is properly Foreman

Fall

erected with "Safe to use" tag.

Access & egress

8. Ensure castor wheels are locked and out

Protruding

riggers in place.

9. Hand tools must be secured/tethered

10.Don’t move scaffoldings while personals are

on board.

11. Ensure proper illumination in work place.

12. Ensure all Containment have proper earthing

Ensure STARRT card briefing done before starting

5 Use of Ladder Falling from height Operatives/ 3 4 12 Medi Ladder is not to use daily basis but in certain 1 4 4 Low Site Engr

Staff/ um cases where there is very narrow place and Sup

Working on even podium ladder not possible to fix in that Foreman

Uneven ground cases Ladder can use if permission granted from

McLaren Safety

Falling objects 1) Only light work, off short duration and work in

which the operative can maintain secure hand

and foot hold can be undertaken form a ladder

2) Never try to overreach with any ladders

3) Check the ladder is of suitable quality for

industrial use and is in good condition

4) Maintain a minimum of 3 points of contact

with stepladders at all times (feet/thighs/hands)

If possible avoid the use of stepladders at a

working height of 2 meters and more.

5) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

7

8

step ladder is orientated to provide maximum

stability.

6) Stepladders/ladders has to be used on leveled

ground/firm base

7) Ensure that during using ladder from the top 2

steps is blocked to avoid climb on that.

8) The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

9) Person must hold the ladder while another

operative working on it

8) Materials should not be placed above the

thread of ladders/step ladders

9) Do not carry any materials in one hand while

climbing or getting down from ladder

10) Ensure the area under the ladder is

barricaded especially if it is being used in a public

area.

11) Ensure the ladder is electrical insulated

podium type if working in live services

6 Use of power Damaged Operatives and 3 4 12 Medi 1. All portable electrical equipment must be 1 4 4 Low Supervisor

tools such as Drill Sockets & cable staff um PAT tested and color coded. Make sure the Foreman

machine/Grinder insulation. test dates are visible on the equipment. Site Eng.

Electrocution 2. Ensure all disk shall be appropriate and

Electric shock expiry date is over.

Short circuit & 3. Ensure all power tools are in good condition

Burns and appropriately maintained

Trip/Fall 4. PTW to be obtained, prior to commencing

Noise the task

Hearing loss 5. Damaged industrial sockets and power

Vibration cables must be removed.

Dust 6. Ensure the electrical cable is not damaged

and has not been repaired with insulating

tape or unsuitable connectors.

7. Ensure cables from power tools shall be

organized so as not to present a tripping

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

9

10

hazard

8. Only trained competent operatives to

operate the power tools.

9. Ensure proper and regular maintenance of

equipment that takes account of noise

10.Ensure proper hearing protection always.

11.Make sure people use the right tool for the

job and are trained to use it correctly

12.Ensure defective tools that require

maintenance is reported for repair or

replacement.

13.Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly.

14. Hot work permit should have obtained if

using heat gun.

15.Fire extinguisher/Fire blanket must be in

place

16.Fire watcher must monitor the hot work area

and he will not move until there is any smoke

or heat.

17.Ensure proper earth leakage protection is

provided.

18. power tools must be 110V to be ensured.

7 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be updated and 1 4 4 Low Site Eng.

condition Sand Storm visitors informed to work force if there is any Sup

Fog prediction about adverse weather. Foreman

Slippery surface 2 No activity shall be allowed during adverse

Risk of weather condition on site

electrocution 3 Protect the Power tools/DB from rain

Flying debris, water to avoid short circuit.

Slip, Tripping and 4 Ensure during adverse weather or Foggy

fall weather no lifting operation and no vehicle

movement.

5 After clear the weather make sure all

power tools are safe to use.

6 No work at height during high wind and

rain

7 In case of emergency, call

McLaren/Emergency number

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

11

12

1. Ensure proper night work permit is obtained

2. Proper lighting system should be in place

3. Ensure proper Communication / Coordination

and close supervision

Poor visibility Operatives/staff

4. Industrial safe torches to be available for

due to darkness emergency situations

Working at night 5. High visibility Traffic Vest for personnel’s in

/ poor Medi Supervisor

8 time 3 4 12 night shift 1 4 4 Low

illumination um Foreman

Lone worker 6. Avoid lone working and always ensure buddy

system while working at night

Employees to be trained and understand

McLaren Crises plan.

1. Hand tools should be visually inspected for

Improper defects, prior to use.

selection of 2. Never use damaged, blunt or broken tools to

hand tools. avoid injury.

Damaged and 3. Select right tools for right Job Site Engr

Defective Hand 4. Ensure no Homemade or makeshift tools to Supervisor

tools. be used at site Foreman

Use of Hand tools Operatives/Staff Medi

9 Hand injuries 3 3 9 5. Remove from service any tool that shows 1 3 3 Low

um

Pinch point signs of damage or defect

Ergonomics 6. Ensure Hand tools are Stored in accordance

Repetitive with the manufacturer’s instructions.

strain injury 7. Ensure hands are not in direct line of fire

while working with hand tools

8. Ensure appropriate PPE at all times.

5 Approved By: Name Vishnu Mohan Position __PM_______ Signature _ ________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

6

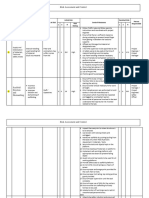

7 RISK ASSESSMENT & CONTROL GUIDELINES

8

9 1. Executing Steps:

0 1.1. Planning

1 a) Construction and HSE team must ensure that hazard identification is complete.

2 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

3 have well established legal requirements, potentially high risks).

4 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

5 potential high risks.

6 1.2. Risk Assessment

7 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

8 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

9 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

0 1.3. Risk Assessment Process

1 The process of carrying out a risk assessment should be as follows.

2 1. Identify the hazards.

3 2. Identify who might be harmed and how.

4 3. Evaluate the risk and implement the control measures.

5 4. Record the significant findings.

6 5. Review the assessment and update if necessary.

7 1.4. Examination of the Hazards and Risk Associated

8 Competent staff must be used in examining the risk associated with the identified hazard.

9 Competent staff should examine following aspect to determine the risk involved:

0 o Examine the existing control measures in place.

1 o Identify employees at risk.

2 o Likelihood of risk.

3 o Severity

4 o Risk level and their tolerability.

5 1.5. Evaluating the risk:

6 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

7 access the risks.

8 1.5.1. Risk Rating Score

9 Risk rating score is a combination of two factors.

0 The severity of the risk that could injure persons or cause damage to plant.

1 The likelihood of the risk that it could happen (Probability).

2

3 RISK RATING = LIKELIHOOD X SEVERITY

4 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

5 the table below. SEVERITY

6

No Injury Minor Moderate Major Catastrophic

7

(1) Injury (2) Injury (3) Injury (4) (5)

8

9 1 2 3 4 5

Rarely (1)

0

1 Unlikely (2) 2 4 6 8 10

2 LIK

ELI Possible (3) 3 6 9 12 15

3

4 HO Likely (4) 4 8 12 16 20

5 OD

Almost

6 5 10 15 20 25

Certain (5)

7 RISK LEVEL:

Low Medium High

8

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

9

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Job Hazard AnalysisDocument10 pagesJob Hazard Analysisnasution22No ratings yet

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- Risk Assessement Fire ProtectionDocument17 pagesRisk Assessement Fire ProtectionJohn Mark MacoyNo ratings yet

- Jha For SMP 2Document7 pagesJha For SMP 2Rohit TharseNo ratings yet

- Job Safety Analysis (JSA) - Earthworks DateDocument1 pageJob Safety Analysis (JSA) - Earthworks DatenabeelNo ratings yet

- MAB For JHADocument8 pagesMAB For JHARohit TharseNo ratings yet

- Risk Assessment and ControlDocument8 pagesRisk Assessment and Controlanand.v4491No ratings yet

- Hazard Identification & Risk AssessmentDocument8 pagesHazard Identification & Risk Assessmentanand.v4491No ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- CHW & LTHW Installation - Risk Assesment.docxDocument21 pagesCHW & LTHW Installation - Risk Assesment.docxMohammad OsmanNo ratings yet

- Risk Assessment For Demolishing of Burnt Ware of Procurement DepartmentDocument10 pagesRisk Assessment For Demolishing of Burnt Ware of Procurement DepartmentEdmund KonoteyNo ratings yet

- Plant and Traffic MovementDocument5 pagesPlant and Traffic MovementALTHAF HUSSAINNo ratings yet

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- I1252-HSE-RAR-008 (00) Concrete Works.Document4 pagesI1252-HSE-RAR-008 (00) Concrete Works.Farman ShaikhNo ratings yet

- 4 - ExcavtionDocument1 page4 - ExcavtionHSE AmlaakNo ratings yet

- JSA - Scaffolding Erection and Dismantling Work.Document3 pagesJSA - Scaffolding Erection and Dismantling Work.hitech.birlacyrNo ratings yet

- 01 Job Hazard Analysis For Piling Works (JHA)Document3 pages01 Job Hazard Analysis For Piling Works (JHA)AmanNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Yanbu Bulk PlantDocument6 pagesYanbu Bulk PlantDarius DsouzaNo ratings yet

- Hazard Identification Plan: Yanbu Refinery Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document6 pagesHazard Identification Plan: Yanbu Refinery Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- JSA For HP and LP Piping ErectionDocument1 pageJSA For HP and LP Piping ErectionAmit SinghNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- Testing Comissioning of Electrical SystemDocument8 pagesTesting Comissioning of Electrical Systemmo7d aliNo ratings yet

- Risk AssessmentsDocument7 pagesRisk Assessmentstareqawad95.taNo ratings yet

- Risk AssessmentDocument5 pagesRisk AssessmentDurga PrasadNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Job Hazard Analysis (Jha) : Equipment Daily Check Sheet To Be Filled Up Prior To DeploymentDocument13 pagesJob Hazard Analysis (Jha) : Equipment Daily Check Sheet To Be Filled Up Prior To DeploymentPuja SawNo ratings yet

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809No ratings yet

- Jsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortDocument7 pagesJsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortSebin VargheseNo ratings yet

- Jsa of Boiler Drum LiftingDocument10 pagesJsa of Boiler Drum LiftingGyanendra Narayan NayakNo ratings yet

- Hazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Risk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Hazard Identification Plan: Abha Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Abha Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Hazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Hazard Identification Plan: Sulayyil Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00612-0001Document7 pagesHazard Identification Plan: Sulayyil Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00612-0001Darius DsouzaNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- JHA PROJECT For BOLTING TORQUINGDocument2 pagesJHA PROJECT For BOLTING TORQUINGHaris MustafaNo ratings yet

- Tool Box Talk Lifting Works of Porta CabinDocument2 pagesTool Box Talk Lifting Works of Porta CabinRyan PertezNo ratings yet

- AHAa RoofingDocument7 pagesAHAa RoofingjunomarsNo ratings yet

- S60370 Nur Ain Farhani Binti Mohamad YazidDocument3 pagesS60370 Nur Ain Farhani Binti Mohamad YazidAin frhnniiiNo ratings yet

- Rsa 3 Project: Title Job Safety Analysis FormDocument3 pagesRsa 3 Project: Title Job Safety Analysis FormKashif RehmanNo ratings yet

- JSA UG Pipe Fabrication and LoweringDocument11 pagesJSA UG Pipe Fabrication and LoweringMuthu AlaguRajNo ratings yet

- JSA For Coating and PaintingDocument7 pagesJSA For Coating and PaintingMuthu AlaguRajNo ratings yet

- CN Montreal Yard Rules en PDFDocument1 pageCN Montreal Yard Rules en PDFsargunam santhanamNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809No ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031100% (1)

- Chapter 2 Hazard and Control MeasuresDocument3 pagesChapter 2 Hazard and Control MeasuresArul PrasaadNo ratings yet

- Master JSA 2052U Blower Removal & Installation Manual LiftingDocument6 pagesMaster JSA 2052U Blower Removal & Installation Manual LiftingOvais FarooqNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- 5.backfilling and CompactionDocument4 pages5.backfilling and CompactionZeeshan Abbasi100% (1)

- Job Safe Procedure Air Quality Monitoring 21-2023Document3 pagesJob Safe Procedure Air Quality Monitoring 21-2023Shah MuzzamilNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting Systemabbas100% (1)

- Cathlyn Joy S. Jandoc BSN 2D Activity 5Document2 pagesCathlyn Joy S. Jandoc BSN 2D Activity 5Aaron ConstantinoNo ratings yet

- Unani Drug Manufacturers 2022-11!10!112507Document6 pagesUnani Drug Manufacturers 2022-11!10!112507Minhaj uddin MilonNo ratings yet

- Safety Officer DutiesDocument5 pagesSafety Officer DutiesAbhijit JanaNo ratings yet

- Principles of Emergency Ultrasound and EchocardiographyDocument7 pagesPrinciples of Emergency Ultrasound and EchocardiographyesmoesNo ratings yet

- Ikigai Worksheet: Passion MissionDocument1 pageIkigai Worksheet: Passion Missiontelpastor100% (1)

- 1 Decc1003 PengenalanDocument26 pages1 Decc1003 PengenalanChen Lee Wan100% (1)

- Certificate of Fetal Death (Municipal Form 103A)Document2 pagesCertificate of Fetal Death (Municipal Form 103A)Carmi Anne Jurado DomingoNo ratings yet

- Module-6: Managing Health and SafetyDocument35 pagesModule-6: Managing Health and Safetyshubham shahNo ratings yet

- g40 - Đề Tham Khảo + Đáp Án - Oanh LeDocument4 pagesg40 - Đề Tham Khảo + Đáp Án - Oanh LetramNo ratings yet

- Cadcor Safety ManualDocument54 pagesCadcor Safety ManualMARY ANN GUEVARRANo ratings yet

- 1 - Stucki - Bickenbach - Defining and Operationalizing HealthDocument9 pages1 - Stucki - Bickenbach - Defining and Operationalizing HealthHealth SciencesNo ratings yet

- 20 - Doddakula2010Document6 pages20 - Doddakula2010TandeanTommyNovenantoNo ratings yet

- Bodyshaming 222Document5 pagesBodyshaming 222Thuỳ NguyễnNo ratings yet

- Preposition Worksheet (With Key Answer)Document4 pagesPreposition Worksheet (With Key Answer)Mathew V SajiNo ratings yet

- Basics of Negotiation Competition For Law Students, HRISHIKESH JAISWAL, NLIU BHOPALDocument4 pagesBasics of Negotiation Competition For Law Students, HRISHIKESH JAISWAL, NLIU BHOPALHRISHIKESH PRAKASH JAISWALNo ratings yet

- Nutritional EpidemiologyDocument26 pagesNutritional EpidemiologyAri Is The Big BossNo ratings yet

- S.Anwar EN 2022Document2 pagesS.Anwar EN 2022hz135874No ratings yet

- E-ISSN: 2347-8640 P-ISSN: 2454-2660, Issue JETIR, (JULY September 2016)Document9 pagesE-ISSN: 2347-8640 P-ISSN: 2454-2660, Issue JETIR, (JULY September 2016)VaishaliNo ratings yet

- G.C.W College Tosham, Bhiwani (Haryana)Document9 pagesG.C.W College Tosham, Bhiwani (Haryana)Monika 13No ratings yet

- Chris Enss - Wicked Women - Notorious, Mischievous, and Wayward Ladies From The Old West (2015, TwoDot)Document225 pagesChris Enss - Wicked Women - Notorious, Mischievous, and Wayward Ladies From The Old West (2015, TwoDot)Ad MinaNo ratings yet

- GAMA-ICTM ProgramBook v3-1Document144 pagesGAMA-ICTM ProgramBook v3-1juanNo ratings yet

- Sameer Ob IaDocument10 pagesSameer Ob IaSameer100% (1)

- Mapeh-Quarter 4Document36 pagesMapeh-Quarter 4Teacher BhingNo ratings yet

- Tests in SyphilisDocument9 pagesTests in SyphilisaditiNo ratings yet

- Lenyo - 2016 - Sports Brochure AngolDocument20 pagesLenyo - 2016 - Sports Brochure AngolSarita YasminNo ratings yet

- Reviewing Harm Reduction For People Who Inject Drugs in Asia - The Necessity For GrowthDocument5 pagesReviewing Harm Reduction For People Who Inject Drugs in Asia - The Necessity For GrowthAura NirwanaNo ratings yet

- MSDS Castrol Alphasyn HTX 1000 PDFDocument9 pagesMSDS Castrol Alphasyn HTX 1000 PDFzaidan hadiNo ratings yet

- MV2000 - MA-15-G001 Marketing PDFDocument33 pagesMV2000 - MA-15-G001 Marketing PDFAndres Riascos EnriquezNo ratings yet

- Wound ManagementDocument3 pagesWound Managementade suhendriNo ratings yet

- NURS-FPX6026 - WhitneyPierre - Assessment 1-2docxDocument9 pagesNURS-FPX6026 - WhitneyPierre - Assessment 1-2docxCaroline AdhiamboNo ratings yet