Professional Documents

Culture Documents

BMR Calamine Cream

BMR Calamine Cream

Uploaded by

zaraorganics99Copyright:

Available Formats

You might also like

- Batch Manufacturing Record SAMPLEDocument8 pagesBatch Manufacturing Record SAMPLETrilochan Ayurveda71% (7)

- Sample BMRDocument16 pagesSample BMRspp94% (18)

- MZO03Document533 pagesMZO03Suchitra SharmaNo ratings yet

- Batch Manufacturing RecordDocument7 pagesBatch Manufacturing RecordAnu Joshi100% (1)

- Acitral Syrup 1000litDocument4 pagesAcitral Syrup 1000litAhmad HussainNo ratings yet

- Defence Standard 80-124Document14 pagesDefence Standard 80-124LjubomirSinđelić100% (1)

- Filename: NW Salicylic Acid 2% Cream BMR 50 KG Confidential and Proprietary - 1Document5 pagesFilename: NW Salicylic Acid 2% Cream BMR 50 KG Confidential and Proprietary - 1zaraorganics99No ratings yet

- Manufacturing Formula: Product: Ctzine SyrupDocument6 pagesManufacturing Formula: Product: Ctzine SyrupMohammed Zubair100% (1)

- BMR Dashmool TailaDocument12 pagesBMR Dashmool Tailabibhakar123No ratings yet

- Glimipiride Tablets 2mg BPRDocument41 pagesGlimipiride Tablets 2mg BPRTawonga MachemedzeNo ratings yet

- Manufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Document6 pagesManufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Mohammed ZubairNo ratings yet

- BMR - Reference - Moisturizing CreamDocument6 pagesBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- PQ TabsDocument24 pagesPQ Tabsqadgm.spiNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- UntitledDocument7 pagesUntitledpralexprajapatiNo ratings yet

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDocument23 pagesBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (2)

- ID Card Generate For Visitor SOPDocument2 pagesID Card Generate For Visitor SOPJaydeep PurohitNo ratings yet

- CWPF-PB-QA8 Meal Checks 1.4Document2 pagesCWPF-PB-QA8 Meal Checks 1.4honey loveNo ratings yet

- 22 Specs BTCDocument1 page22 Specs BTCDrBipin DevaniNo ratings yet

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- 17 04 2023Document34 pages17 04 2023BIONIAL HEALTHCARENo ratings yet

- COA Fontera MilkDocument2 pagesCOA Fontera Milkqureshi123456No ratings yet

- SOP For Bubble Point TestDocument4 pagesSOP For Bubble Point TestBejoy KarimNo ratings yet

- Attak Toilet Cleaner BMRDocument1 pageAttak Toilet Cleaner BMRMuntasir RakinNo ratings yet

- Surat JalanDocument2 pagesSurat JalanHSE SuryaSegaraNo ratings yet

- BMR Gandhak RasayanDocument10 pagesBMR Gandhak Rasayanbibhakar123No ratings yet

- Process Validation Protocol For Gliclazide Modified Release TabletsDocument32 pagesProcess Validation Protocol For Gliclazide Modified Release Tabletsreflectprakash3610100% (3)

- Tablet BMR Wenovo (New)Document30 pagesTablet BMR Wenovo (New)Muhammad ImranNo ratings yet

- FEET Grade B - LEVODocument4 pagesFEET Grade B - LEVOcid ribeiroNo ratings yet

- Manufacturing Formula: Product: Univit SyrupDocument6 pagesManufacturing Formula: Product: Univit SyrupMohammed ZubairNo ratings yet

- Medidol TabletDocument6 pagesMedidol TabletMohammed ZubairNo ratings yet

- COCCYX CUSHION - SOFT - HARD-4Document2 pagesCOCCYX CUSHION - SOFT - HARD-4amldc.qualityNo ratings yet

- Tablet BMR Ampsar 5 by 160Document31 pagesTablet BMR Ampsar 5 by 160Muhammad ImranNo ratings yet

- Cwpf-Pb-Qa2: Hourly ChecksDocument1 pageCwpf-Pb-Qa2: Hourly Checkshoney loveNo ratings yet

- MFRDocument9 pagesMFRHarshal PawarNo ratings yet

- VAL-EV - PQR.OC.048.R00 IncubatorDocument10 pagesVAL-EV - PQR.OC.048.R00 IncubatorBily PutraNo ratings yet

- Section 2.4 - Production Process Control FormDocument1 pageSection 2.4 - Production Process Control FormCHRISTOPHER WEALTHNo ratings yet

- Autoclave Validation ProtocolDocument23 pagesAutoclave Validation ProtocolErum Manzoor100% (3)

- AC 10 18 Scope of Accreditation - v1 1 - Halal Accreditation 31Document4 pagesAC 10 18 Scope of Accreditation - v1 1 - Halal Accreditation 31iscscoloaNo ratings yet

- Batch ReleaseDocument12 pagesBatch Releasemarkandey gupta50% (2)

- Mega Iron 1200.Document6 pagesMega Iron 1200.Muhammad ZubairNo ratings yet

- GLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10Document14 pagesGLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10RiyanNo ratings yet

- Dci-Dax-0500 - PT IndoramaDocument5 pagesDci-Dax-0500 - PT Indoramasyarif7ahmadNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alvi100% (1)

- Danical Sachet: Application For Enlistment of Locally Manufactured ProductDocument23 pagesDanical Sachet: Application For Enlistment of Locally Manufactured Productifsha akhlaqNo ratings yet

- 8.cezaf 250mg Injection Im IVDocument3 pages8.cezaf 250mg Injection Im IVSehrish AslamNo ratings yet

- BK Wings at Jan-24Document1 pageBK Wings at Jan-24Dipak DharaNo ratings yet

- Packaging & ProcessingDocument5 pagesPackaging & ProcessingChristianNo ratings yet

- Certificate of AnalysisDocument2 pagesCertificate of AnalysisdhairyasheelNo ratings yet

- Sanfuliq PVP RegistrasiDocument25 pagesSanfuliq PVP RegistrasiFajarRachmadiNo ratings yet

- 750mg CBD Full-Spectrum TinctureDocument6 pages750mg CBD Full-Spectrum TinctureHigh Falls HempNo ratings yet

- Mega Iron Syrup (Elemental Iron-50 MG) : ProductDocument7 pagesMega Iron Syrup (Elemental Iron-50 MG) : ProductMohammed ZubairNo ratings yet

- SOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Document3 pagesSOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Bejoy Karim100% (1)

- Draft Master Batch FarindusDocument33 pagesDraft Master Batch Farindusadite_alifaNo ratings yet

- Dispensed: SampledDocument3 pagesDispensed: Sampledziaurjewel92No ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- SOP Muff FurnaceDocument2 pagesSOP Muff FurnaceDeepakKumarNo ratings yet

- Capsule Process ValidationDocument28 pagesCapsule Process ValidationNavdeep ChaudharyNo ratings yet

- STP of Bactidin BolusDocument5 pagesSTP of Bactidin BolusBejoy KarimNo ratings yet

- XXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Document25 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Navdeep ChaudharyNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- 44 - 1004 - SDS10062Document15 pages44 - 1004 - SDS10062kokoNo ratings yet

- (PDF) Chemistry IJSO Stage-1 - CompressDocument8 pages(PDF) Chemistry IJSO Stage-1 - Compressankit aryaNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersnicholaus alfargoNo ratings yet

- Chemical Bond 21Document16 pagesChemical Bond 21Thanks OdoiNo ratings yet

- CHM138 Lab Report Experiment 1Document8 pagesCHM138 Lab Report Experiment 1Muhammad Asyraaf Haqimi bin BaharinNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- Neet SyllabusDocument2 pagesNeet SyllabusHiranmoy KakotiNo ratings yet

- Experiment 3 Chemical Test For MARIJUANA-1Document3 pagesExperiment 3 Chemical Test For MARIJUANA-1HK FreeNo ratings yet

- Dokumen - Tips Novel Waterborne Uvahals Blend For High Performance Waterborne CoatingsDocument18 pagesDokumen - Tips Novel Waterborne Uvahals Blend For High Performance Waterborne CoatingsLong An ĐỗNo ratings yet

- Experiment 4Document20 pagesExperiment 4William Allan Arcilla100% (3)

- Chemical KineticsDocument11 pagesChemical KineticssamarthNo ratings yet

- Coursebook Answers Chapter 9 Asal ChemistryDocument5 pagesCoursebook Answers Chapter 9 Asal ChemistryStelio GuimarãesNo ratings yet

- Industrial Crops & Products: Didem Sutay Kocabas, Merve Erkoç Akçelik, Erinç Bahçegül, Hatice Neval OzbekDocument13 pagesIndustrial Crops & Products: Didem Sutay Kocabas, Merve Erkoç Akçelik, Erinç Bahçegül, Hatice Neval Ozbekjans carlosNo ratings yet

- Module 1: FireDocument13 pagesModule 1: FireMarielle CaralipioNo ratings yet

- B 4 Revision PackDocument64 pagesB 4 Revision PackKrish SharmaNo ratings yet

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- 183 - Viva Questions Shared by Candidates of Gujarat BOE 2017Document4 pages183 - Viva Questions Shared by Candidates of Gujarat BOE 2017yousufali56100% (1)

- Katalog Almega SejahteraDocument35 pagesKatalog Almega SejahteraRuri YuliantiNo ratings yet

- FYSMENA4111 Computer Lab 5 SurfacesDocument5 pagesFYSMENA4111 Computer Lab 5 Surfaceswer809No ratings yet

- FOC CH 3Document6 pagesFOC CH 3tanmay sharmaNo ratings yet

- Mock Test Code-CDocument19 pagesMock Test Code-CKomal VermaNo ratings yet

- LYNX 40 Drilling Mud DecanterDocument2 pagesLYNX 40 Drilling Mud DecanterPierluigi Ciampiconi0% (1)

- Exelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingDocument1 pageExelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingOctavio DavidNo ratings yet

- Ions and Radicals Lesson PlanDocument5 pagesIons and Radicals Lesson Planameerfati76No ratings yet

- 533EDocument2 pages533EAlma RujanacNo ratings yet

- Aji 14Document2 pagesAji 14kumarswamyk1981No ratings yet

- Marco Material Datasheet Kalrez 6375Document2 pagesMarco Material Datasheet Kalrez 6375prasanna kumarNo ratings yet

- 4th Quarter PPT LESSON 4 Science 8Document60 pages4th Quarter PPT LESSON 4 Science 8Sir Josh100% (1)

BMR Calamine Cream

BMR Calamine Cream

Uploaded by

zaraorganics99Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMR Calamine Cream

BMR Calamine Cream

Uploaded by

zaraorganics99Copyright:

Available Formats

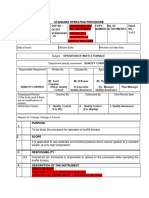

NATURAL WELLNESS INDUSTRIES SDN.

BHD

BATCH MANUFACTURING RECORD

Page 1 of 5 PRODUCT: CALAMINE CREAM Batch no:

Pack size: 30g/ 60g/ 120g

Mfg Date : Batch size: 200 KG Doc no:

Expiry Date : Product Code: Effective date:

Doc. Issued Date : Reg No: Supercedes: NIL

Issued By: Shelf life: 2 YEARS Review Due:

Prepared by: Verified by: Approved by:

QA Executive Production Executive QC HOD

Precaution: Before dispensing complete the checklist in page 3 and follow all the instruction

Percenta

Actual

ge

Qty Quantit Checke Receive

S/ Batch No/ weight Dispense

Materials Name Unit Require y d d

n Lab Series for d By/date

d Receive By/date By/date

weight

d

(%w/w)

1 Calamine Kg 10 5%

2 Zinc Oxide Kg 10 5%

3 Glycerin Kg 20 10%

4 Purified Water Kg 130.60 65.3%

5 Cetyl Alcohol Kg 5 2.5%

6 Glyceril Stearate (Peg

Kg 20 10%

100 Stearate)

7 Methyl Paraben Kg 0.36 0.18%

8 Propyl Paraben Kg 0.04 0.02%

9 Cellulose

Kg 4 2%

Microcrystalline

Filename: CALAMINE CREAM BMR 200Kg CONFIDENTIAL AND PROPRIETARY -1-

NATURAL WELLNESS INDUSTRIES SDN. BHD

BATCH MANUFACTURING RECORD

Page 2 of 5 PRODUCT: CALAMINE CREAM Batch no:

Pack size: 30g/ 60g/ 120g

Mfg Date : Batch size: 200 Kg Doc no:

Expiry Date : Product Code: Effective date:

Doc. Issued Date : Reg No: Supercedes: NIL

Issued By: Shelf life: 2 YEARS Review Due:

Prepared by: Verified by: Approved by:

QA Executive Production Executive QC HOD

MANUFACTURING INSTRUCTION –DISPENSING

Previous Product: Batch No: Room ID: Equipment ID:

RH Temp Sign /Date Sign/Date Sign/

Step Procedures

(%) (oC) Operator Line Leader Date QC

1 Performed line clearance: (please below & sign)

No other material in the vicinity Personnel with gloves, mask & uniform clean

Equipment cleaned All utensils are cleaned

Room is cleared of previous material Room cleaned

2 Remove status labels from room and equipment and

affix them into the BMR.

3 Place materials in Raw Material Buffer Room and

checked.

Name, code number and GRIS number are correct

4 Dispense items one by one in the dispensing page.

Counter checked by another person.

5 At the end of dispensing, perform end clearance

Room is been cleared of present batch material

Room is been cleared of present batch record

6 Send dispensed material to staging area, well placed on

one pallet.

Filename: CALAMINE CREAM BMR 200Kg CONFIDENTIAL AND PROPRIETARY -2-

NATURAL WELLNESS INDUSTRIES SDN. BHD

BATCH MANUFACTURING RECORD

Page 3 of 5 PRODUCT: CALAMINE CREAM Batch no:

Pack size: 30g / 60g/ 120g

Mfg Date : Batch size: 200 Kg Doc no:

Expiry Date : Product Code: Effective date:

Doc. Issued Date : Reg No: Supercedes: NIL

Issued By: Shelf life: 2 YEARS Review Due:

Prepared by: Verified by: Approved by:

QA Executive Production Executive QC HOD

MANUFACTURING INSTRUCTION - MIXING

Previous Product: Batch No: Room ID: Equipment ID:

RH Temp Sign /Date Sign/Date Sign/

Step Procedures

(%) (oC) Operator Line Leader Date QC

1 Perform line clearance by ensuring (please if

complies, below)

Room is cleared of previous batch material Room is cleaned

All utensils are cleaned All personnel are with clean gloves and mask

Uniform clean Jacketed vessel cleaned and assembly correctly

Stainless steel stirrer cleaned and assembly correctly Homogenizer cleaned and assembly correctly

2 Record of equipment used in: (please if complies,

below)

Activity in Previous

Equipment Used Equipment ID Room Remarks

progress Product/ Batch

Heater

Jacketed Vessel Tank

100 L

Jacketed Vessel Tank

200 L

Stainless Steel Stirrer

Homogenizer

Automatic Liquid

Filling Machine

Shrink Tunnel

Machine

Digital Weighing

Scale

Comment:

Filename: CALAMINE CREAM BMR 200Kg CONFIDENTIAL AND PROPRIETARY -3-

NATURAL WELLNESS INDUSTRIES SDN. BHD

BATCH MANUFACTURING RECORD

Page 4 of 5 PRODUCT: CALAMINE CREAM Batch no:

Pack size: 30g / 60g/ 120g

Mfg Date : Batch size: 200 Kg Doc no:

Expiry Date : Product Code: Effective date:

Doc. Issued Date : Reg No: Supercedes: NIL

Issued By: Shelf life: 2 YEARS Review Due:

Prepared by: Verified by: Approved by:

QA Executive Production Executive QC HOD

RH Temp Sign /Date Sign/Date Sign/

Step Procedures

(%) (oC) Operator Line Leader Date QC

3 Bring in the complete dispensed material to External

Liquid Blending Room and check for (please if

complies, below):

Correct name

Correct batch number (or A.R. No)

Correct quantity

4 Affix to BMR, the labels from all dispensed materials as

they are being utilized.

5 Transfer the following into TANK A (JACKETED

TANK)

►PURIFIED WATER 130.60 KG

o

Heat up the water until 70 C.

0

6 Transfer the following into TANK B

► GLYCERIN 20.00 KG

► CETYL ALCOHOL 5.00 KG

► GLYCERYL STEARATE 20.00 KG

► CELLULOSE MICROCRYSTALLINE

4.00 KG

Stir for 30 minutes.

Time Start _____________ Time Stop _____________

7 Reduce the temperature to 45oC, and add the following

into TANK B.

► CALAMINE 10.00 KG

► ZINC OXIDE 10.00 KG

► METHYL PARABEN 0.36 KG

► PROPYL PARABEN 0.04 KG

Stir for 40 minutes.

Allow to cool.

Filename: CALAMINE CREAM BMR 200Kg CONFIDENTIAL AND PROPRIETARY -4-

NATURAL WELLNESS INDUSTRIES SDN. BHD

BATCH MANUFACTURING RECORD

Page 5 of 5 PRODUCT: CALAMINE CREAM Batch no:

Pack size: 30g / 60g/ 120g

Mfg Date : Batch size: 200 Kg Doc no:

Expiry Date : Product Code: Effective date:

Doc. Issued Date : Reg No: Supercedes: NIL

Issued By: Shelf life: 2 YEARS Review Due:

Prepared by: Verified by: Approved by:

QA Executive Production Executive QC HOD

8 Collect about 0.5 L of the bulk liquid from the

outlet valve in a stainless steel container and

transfer back to the main bulk. Stir for 30

minutes.

Time Start __________ Time Stop __________

9 Remove from the outlet valve about 0.2 L of the

bulk liquid and keep it aside in a stainless steel

container. Measure the volume of the liquid.

Volume of bulk liquid _________ L

10

Rinse the silicone transfer hose with the 0.2 L of

the bulk liquid from process 9. Reject the liquid at

the end of the procedure.

11 Submit sample (100 mL) to Q.C Laboratory.

12 Check the External Liquid Filling room is ready

for transfer of Liquid with Line Clearance

completed.

13 Transfer the bulk to the holding tank on the

ground floor by filtering through filter press.

14 Perform end clearance

Room is been cleared of present batch material

Room is been cleared of present batch record

15 Submit Batch Manufacturing Record to

Production Executive/Manager.

PRODUCTION SECTION HEAD:

Filename: CALAMINE CREAM BMR 200Kg CONFIDENTIAL AND PROPRIETARY -5-

You might also like

- Batch Manufacturing Record SAMPLEDocument8 pagesBatch Manufacturing Record SAMPLETrilochan Ayurveda71% (7)

- Sample BMRDocument16 pagesSample BMRspp94% (18)

- MZO03Document533 pagesMZO03Suchitra SharmaNo ratings yet

- Batch Manufacturing RecordDocument7 pagesBatch Manufacturing RecordAnu Joshi100% (1)

- Acitral Syrup 1000litDocument4 pagesAcitral Syrup 1000litAhmad HussainNo ratings yet

- Defence Standard 80-124Document14 pagesDefence Standard 80-124LjubomirSinđelić100% (1)

- Filename: NW Salicylic Acid 2% Cream BMR 50 KG Confidential and Proprietary - 1Document5 pagesFilename: NW Salicylic Acid 2% Cream BMR 50 KG Confidential and Proprietary - 1zaraorganics99No ratings yet

- Manufacturing Formula: Product: Ctzine SyrupDocument6 pagesManufacturing Formula: Product: Ctzine SyrupMohammed Zubair100% (1)

- BMR Dashmool TailaDocument12 pagesBMR Dashmool Tailabibhakar123No ratings yet

- Glimipiride Tablets 2mg BPRDocument41 pagesGlimipiride Tablets 2mg BPRTawonga MachemedzeNo ratings yet

- Manufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Document6 pagesManufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Mohammed ZubairNo ratings yet

- BMR - Reference - Moisturizing CreamDocument6 pagesBMR - Reference - Moisturizing CreamNIKHIL YEMUL100% (1)

- PQ TabsDocument24 pagesPQ Tabsqadgm.spiNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- UntitledDocument7 pagesUntitledpralexprajapatiNo ratings yet

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDocument23 pagesBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (2)

- ID Card Generate For Visitor SOPDocument2 pagesID Card Generate For Visitor SOPJaydeep PurohitNo ratings yet

- CWPF-PB-QA8 Meal Checks 1.4Document2 pagesCWPF-PB-QA8 Meal Checks 1.4honey loveNo ratings yet

- 22 Specs BTCDocument1 page22 Specs BTCDrBipin DevaniNo ratings yet

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- 17 04 2023Document34 pages17 04 2023BIONIAL HEALTHCARENo ratings yet

- COA Fontera MilkDocument2 pagesCOA Fontera Milkqureshi123456No ratings yet

- SOP For Bubble Point TestDocument4 pagesSOP For Bubble Point TestBejoy KarimNo ratings yet

- Attak Toilet Cleaner BMRDocument1 pageAttak Toilet Cleaner BMRMuntasir RakinNo ratings yet

- Surat JalanDocument2 pagesSurat JalanHSE SuryaSegaraNo ratings yet

- BMR Gandhak RasayanDocument10 pagesBMR Gandhak Rasayanbibhakar123No ratings yet

- Process Validation Protocol For Gliclazide Modified Release TabletsDocument32 pagesProcess Validation Protocol For Gliclazide Modified Release Tabletsreflectprakash3610100% (3)

- Tablet BMR Wenovo (New)Document30 pagesTablet BMR Wenovo (New)Muhammad ImranNo ratings yet

- FEET Grade B - LEVODocument4 pagesFEET Grade B - LEVOcid ribeiroNo ratings yet

- Manufacturing Formula: Product: Univit SyrupDocument6 pagesManufacturing Formula: Product: Univit SyrupMohammed ZubairNo ratings yet

- Medidol TabletDocument6 pagesMedidol TabletMohammed ZubairNo ratings yet

- COCCYX CUSHION - SOFT - HARD-4Document2 pagesCOCCYX CUSHION - SOFT - HARD-4amldc.qualityNo ratings yet

- Tablet BMR Ampsar 5 by 160Document31 pagesTablet BMR Ampsar 5 by 160Muhammad ImranNo ratings yet

- Cwpf-Pb-Qa2: Hourly ChecksDocument1 pageCwpf-Pb-Qa2: Hourly Checkshoney loveNo ratings yet

- MFRDocument9 pagesMFRHarshal PawarNo ratings yet

- VAL-EV - PQR.OC.048.R00 IncubatorDocument10 pagesVAL-EV - PQR.OC.048.R00 IncubatorBily PutraNo ratings yet

- Section 2.4 - Production Process Control FormDocument1 pageSection 2.4 - Production Process Control FormCHRISTOPHER WEALTHNo ratings yet

- Autoclave Validation ProtocolDocument23 pagesAutoclave Validation ProtocolErum Manzoor100% (3)

- AC 10 18 Scope of Accreditation - v1 1 - Halal Accreditation 31Document4 pagesAC 10 18 Scope of Accreditation - v1 1 - Halal Accreditation 31iscscoloaNo ratings yet

- Batch ReleaseDocument12 pagesBatch Releasemarkandey gupta50% (2)

- Mega Iron 1200.Document6 pagesMega Iron 1200.Muhammad ZubairNo ratings yet

- GLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10Document14 pagesGLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10RiyanNo ratings yet

- Dci-Dax-0500 - PT IndoramaDocument5 pagesDci-Dax-0500 - PT Indoramasyarif7ahmadNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alvi100% (1)

- Danical Sachet: Application For Enlistment of Locally Manufactured ProductDocument23 pagesDanical Sachet: Application For Enlistment of Locally Manufactured Productifsha akhlaqNo ratings yet

- 8.cezaf 250mg Injection Im IVDocument3 pages8.cezaf 250mg Injection Im IVSehrish AslamNo ratings yet

- BK Wings at Jan-24Document1 pageBK Wings at Jan-24Dipak DharaNo ratings yet

- Packaging & ProcessingDocument5 pagesPackaging & ProcessingChristianNo ratings yet

- Certificate of AnalysisDocument2 pagesCertificate of AnalysisdhairyasheelNo ratings yet

- Sanfuliq PVP RegistrasiDocument25 pagesSanfuliq PVP RegistrasiFajarRachmadiNo ratings yet

- 750mg CBD Full-Spectrum TinctureDocument6 pages750mg CBD Full-Spectrum TinctureHigh Falls HempNo ratings yet

- Mega Iron Syrup (Elemental Iron-50 MG) : ProductDocument7 pagesMega Iron Syrup (Elemental Iron-50 MG) : ProductMohammed ZubairNo ratings yet

- SOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Document3 pagesSOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Bejoy Karim100% (1)

- Draft Master Batch FarindusDocument33 pagesDraft Master Batch Farindusadite_alifaNo ratings yet

- Dispensed: SampledDocument3 pagesDispensed: Sampledziaurjewel92No ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- SOP Muff FurnaceDocument2 pagesSOP Muff FurnaceDeepakKumarNo ratings yet

- Capsule Process ValidationDocument28 pagesCapsule Process ValidationNavdeep ChaudharyNo ratings yet

- STP of Bactidin BolusDocument5 pagesSTP of Bactidin BolusBejoy KarimNo ratings yet

- XXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Document25 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXX Process Validation Protocol (Capsule)Navdeep ChaudharyNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- 44 - 1004 - SDS10062Document15 pages44 - 1004 - SDS10062kokoNo ratings yet

- (PDF) Chemistry IJSO Stage-1 - CompressDocument8 pages(PDF) Chemistry IJSO Stage-1 - Compressankit aryaNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersnicholaus alfargoNo ratings yet

- Chemical Bond 21Document16 pagesChemical Bond 21Thanks OdoiNo ratings yet

- CHM138 Lab Report Experiment 1Document8 pagesCHM138 Lab Report Experiment 1Muhammad Asyraaf Haqimi bin BaharinNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- Neet SyllabusDocument2 pagesNeet SyllabusHiranmoy KakotiNo ratings yet

- Experiment 3 Chemical Test For MARIJUANA-1Document3 pagesExperiment 3 Chemical Test For MARIJUANA-1HK FreeNo ratings yet

- Dokumen - Tips Novel Waterborne Uvahals Blend For High Performance Waterborne CoatingsDocument18 pagesDokumen - Tips Novel Waterborne Uvahals Blend For High Performance Waterborne CoatingsLong An ĐỗNo ratings yet

- Experiment 4Document20 pagesExperiment 4William Allan Arcilla100% (3)

- Chemical KineticsDocument11 pagesChemical KineticssamarthNo ratings yet

- Coursebook Answers Chapter 9 Asal ChemistryDocument5 pagesCoursebook Answers Chapter 9 Asal ChemistryStelio GuimarãesNo ratings yet

- Industrial Crops & Products: Didem Sutay Kocabas, Merve Erkoç Akçelik, Erinç Bahçegül, Hatice Neval OzbekDocument13 pagesIndustrial Crops & Products: Didem Sutay Kocabas, Merve Erkoç Akçelik, Erinç Bahçegül, Hatice Neval Ozbekjans carlosNo ratings yet

- Module 1: FireDocument13 pagesModule 1: FireMarielle CaralipioNo ratings yet

- B 4 Revision PackDocument64 pagesB 4 Revision PackKrish SharmaNo ratings yet

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- 183 - Viva Questions Shared by Candidates of Gujarat BOE 2017Document4 pages183 - Viva Questions Shared by Candidates of Gujarat BOE 2017yousufali56100% (1)

- Katalog Almega SejahteraDocument35 pagesKatalog Almega SejahteraRuri YuliantiNo ratings yet

- FYSMENA4111 Computer Lab 5 SurfacesDocument5 pagesFYSMENA4111 Computer Lab 5 Surfaceswer809No ratings yet

- FOC CH 3Document6 pagesFOC CH 3tanmay sharmaNo ratings yet

- Mock Test Code-CDocument19 pagesMock Test Code-CKomal VermaNo ratings yet

- LYNX 40 Drilling Mud DecanterDocument2 pagesLYNX 40 Drilling Mud DecanterPierluigi Ciampiconi0% (1)

- Exelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingDocument1 pageExelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingOctavio DavidNo ratings yet

- Ions and Radicals Lesson PlanDocument5 pagesIons and Radicals Lesson Planameerfati76No ratings yet

- 533EDocument2 pages533EAlma RujanacNo ratings yet

- Aji 14Document2 pagesAji 14kumarswamyk1981No ratings yet

- Marco Material Datasheet Kalrez 6375Document2 pagesMarco Material Datasheet Kalrez 6375prasanna kumarNo ratings yet

- 4th Quarter PPT LESSON 4 Science 8Document60 pages4th Quarter PPT LESSON 4 Science 8Sir Josh100% (1)