Professional Documents

Culture Documents

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Uploaded by

elmsm14Copyright:

Available Formats

You might also like

- 700R4 Manual PDFDocument96 pages700R4 Manual PDFK B100% (3)

- T ISS PX01 Instruction Manual Rev.01Document9 pagesT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Case SR200 Service Manual Pgs 1-28Document28 pagesCase SR200 Service Manual Pgs 1-28gregfortkamp43% (14)

- Oracle X86 Server Installation Specialist Online Assessment 2020Document21 pagesOracle X86 Server Installation Specialist Online Assessment 2020Josip BelinaNo ratings yet

- Job Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air CompressorDocument4 pagesJob Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air Compressorlatiplambosi100% (1)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- Aras Simulation Management 12.0R1 - User GuideDocument19 pagesAras Simulation Management 12.0R1 - User GuideHernan GiagnorioNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Mobile Scaffold SafetyDocument1 pageMobile Scaffold SafetyDhiraj ThukralNo ratings yet

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDocument2 pagesRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Safety Campaign-Energy Isolation-April 2022Document7 pagesSafety Campaign-Energy Isolation-April 2022HSE99 BHDCNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Document3 pagesJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21No ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument4 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- JSA - Electrical IsolationDocument1 pageJSA - Electrical IsolationRaju KhalifaNo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Height Pass FormatDocument1 pageHeight Pass Formatamit kumarNo ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- JSA For Manual Excavation Inside The Operation Area (Access Road)Document6 pagesJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Can Get Medical Assistance.: Deyaar Facilities Management LLC First Aid - Basic - TBT-28Document2 pagesCan Get Medical Assistance.: Deyaar Facilities Management LLC First Aid - Basic - TBT-28nIKHILNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- TOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEDocument5 pagesTOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEazerNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Datasheet SQ R 2.41Document2 pagesDatasheet SQ R 2.41Alejandro CarhuacusmaNo ratings yet

- Varispeed-F7 Manual PDFDocument463 pagesVarispeed-F7 Manual PDFIsradani MjNo ratings yet

- CSBS DBMS Lab2 22-23Document12 pagesCSBS DBMS Lab2 22-23VaibhavNo ratings yet

- Mkdir CommandDocument3 pagesMkdir Command11-B ,Niranjan DorageNo ratings yet

- Be Enc 2020Document10 pagesBe Enc 2020Shaikh FarooqNo ratings yet

- SAP FSCM BasicsDocument5 pagesSAP FSCM BasicspaiashokNo ratings yet

- Web-Based Management System With SMS and E-Mail Notification For Binan Tricycle Franchising and Regulatory BoardDocument8 pagesWeb-Based Management System With SMS and E-Mail Notification For Binan Tricycle Franchising and Regulatory Boardsjdmnts3No ratings yet

- Untitled 0Document288 pagesUntitled 0khushiNo ratings yet

- Emk31303 - (Group J) Mini Project ManagementDocument32 pagesEmk31303 - (Group J) Mini Project ManagementAMIRAH BINTI AHMAD FAUZI STUDENTNo ratings yet

- Isuzu Engine Mechanical 4hk1 TC 6a 1Document10 pagesIsuzu Engine Mechanical 4hk1 TC 6a 1Janet100% (66)

- Introduction To SCMDocument38 pagesIntroduction To SCMArif Shan50% (2)

- Hig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29Document2 pagesHig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29isaacsavioNo ratings yet

- DO NOT: SortingDocument4 pagesDO NOT: SortingiGun SkNo ratings yet

- NTDCL Test 2022Document7 pagesNTDCL Test 2022Rafy Info TvNo ratings yet

- Memo To Users IBM I 7.1Document74 pagesMemo To Users IBM I 7.1Anonymous c1oc6LeRNo ratings yet

- C911 / C931 / C941 Maintenance Manual: Downloaded From Manuals Search EngineDocument297 pagesC911 / C931 / C941 Maintenance Manual: Downloaded From Manuals Search Engineemir pestanaNo ratings yet

- Samsung ML-1440 ML-1450 Repair Service ManualDocument96 pagesSamsung ML-1440 ML-1450 Repair Service ManualSteveSherrattNo ratings yet

- Students Thesis DissertatrionDocument3 pagesStudents Thesis Dissertatrionjun del rosarioNo ratings yet

- 57 Ways To Get Traffic To Your WebsiteDocument75 pages57 Ways To Get Traffic To Your WebsiteDeeJNo ratings yet

- 4n25 OptoDocument6 pages4n25 OptoHeber Garcia VazquezNo ratings yet

- Electronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloDocument12 pagesElectronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloengshimaaNo ratings yet

- Grid Automation Webinar Series: Hitachi Abb Power Grids Powering Good For Sustainable EnergyDocument30 pagesGrid Automation Webinar Series: Hitachi Abb Power Grids Powering Good For Sustainable EnergyRidouan HijeNo ratings yet

- ATGB3673 Estimating Buildsoft Assignment BriefDocument5 pagesATGB3673 Estimating Buildsoft Assignment BriefSamantha LiewNo ratings yet

- Parasoft Soatest 9.x TutorialDocument9 pagesParasoft Soatest 9.x Tutorialblunt2vitreNo ratings yet

- DEFCON 22 Lucas Morris Michael McAtee ShareEnum We Wrapped SambaDocument23 pagesDEFCON 22 Lucas Morris Michael McAtee ShareEnum We Wrapped SambaSudhanshu Shekhar SharmaNo ratings yet

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Uploaded by

elmsm14Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007

Uploaded by

elmsm14Copyright:

Available Formats

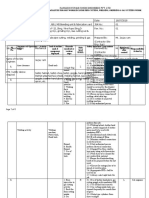

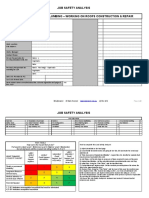

Hawiyah Unayzah Gas Reservoir Storage Project

JSA FOR ACTIVITY JSA CONTROL NO.: PTJ-S-007

JOB SAFETY ANALYSIS DISCIPLINE:

Steel Structure dismantling & Civil/Building Electrical/Instrument

REV. NO.: G Miscellaneous Steel

Mechanical, Steel structure, Piping

REV. DATE: 28 January 2024 LOCATION: Fabrication workshop

Pre-com. Others _ _________

Subcontractor Contractor SAPMT

CONST. SI HSE Mgr. CONST. Mgr. CONST. SI HSE Mgr. HSE Advisor SA-SPM

Date

Signature

EMERGENCY RESPONSE PROCEDURE CONTACT NUMBERS: When reporting an emergency give the clear

information such as:

In an EMERGENCY, or on the hearing of the “Stop □TBM Leader :

Work Alarm”, every supervisor shall ensure the Name: Mohamed Elmslimany 1. Your exact location.

following: Phone No.: 053 945 0211 2. Nature of emergency.

1. All work is stopped at once. 3. Service required and repeats the message.

□ Permit Receiver : 4. Your name & badge number.

2. All equipment is shutdown. Name: Fakrudeen

3. All personnel are evacuated to the pre- Phone No.: 057 107 6155 Stay on the telephone until you are told to hang-up. If

determined assembly area. possible, post a lookout to direct the Ambulance, Fire

□Permit Issuer :

4. A roll call is taken and every man is accounted Truck or EMERGENCY Response to the right location.

Name:

for.

Phone No.:

5. No one is permitted to return until

notification has been received from □Area HSE Number :

operations or from the company Name: shakeel

representative that it is safe to do so. Phone No.: 0534359203

SSA Emergency Contact No 055-360-5083

Page 1 of 30HUGRS JSA Format R1

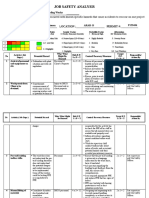

Hawiyah Unayzah Gas Reservoir Storage Project

RISK RATING RESIDUAL RISK

POTENTIAL L S Risk L2 S2 Risk RESPONSIBLE

NO. STEP category PREVENTIVE MEASURES Category

HAZARDS PERSON

after

treatment

1 WPR & ISSUER All personnel must undergo the required

Non-Compliance of

JOINT SITE training such as Site Safety orientation, etc.

Saudi Aramco CSM Broadly

INSPECTION Joint Site Inspection must be conducted by Broadly

and Safety 2 2 Acceptabl 1 2 HSE Samsung

issuer, permit receiver to identify potential Acceptable

Handbook e

hazards and risks and ensure to secure work

permits prior to activity

Site Preparation Unauthoriz 2 2 Broadly Obtain the required work permit in 1 2 Broadly Work

Before Starting the ed work Acceptabl accordance with G.I 2.100. Acceptable Supervisor,

Job execution e Permit Receiver, Issuer and work supervisor Permit

Unidentifie shall conduct site inspection before the Issuer/Receiver

d/Unsafe activity.

work The work permit receiver is certified by SSA

location All safety precautions and controls must be

Improper, implemented prior any work.

damagede Stop work trigger if no permit to work issued.

quipment The work location shall be confirmed that it is

and tools safe and free from any hazards.

Drawing shall be marked with work location.

Prior to start the job all equipment and tools

shall be inspected and make sure that all

equipment and tools are in good condition

and color coded.

Tool Box Talk and pre-job meetings to be held

to ensure all employees are aware about the

job and their roles.

No work before issuing the required permit(S)

to work

Make sure that all equipment is inspected by

trained and certified inspectors

Make sure that all tools are the suitable tool

for the job and the correspondence

Page 2 of 30HUGRS JSA Format R1

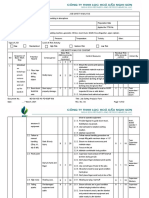

Hawiyah Unayzah Gas Reservoir Storage Project

employee is trained to use it.

Personnel shall not operate any tools unless

they are appropriately trained in their

selection, use, inspection, and storage.

Training records shall be made available

upon request.

Tools constructed of good quality materials

shall be used. Use of “homemade” tools is

prohibited.

Tools shall be kept clean at all times.

Tools shall be inspected before and after use,

as well as before storage.

Provide adequate lightings for proper

illumination.

Ensure access ways shall be provided with

adequate lightings. Broadly Work

Poor Illumination 2 4 ALARP 1 2

Task Lightings shall be installed on strategic Acceptable Supervisor

locations at site.

Conduct Illumination Survey to ensure proper

illumination.

Night Shift activities shall be covered with

Approved Work Permit.

Unauthorized Line Supervision and Permit Receiver to Broadly Work

2 4 ALARP 1 2

Night Shift work execution closely supervise Night Shift activities. Acceptable Supervisor

2

Activities Approval from SSA/SAPMT shall be obtained

prior to conduct Night Lifting.

Elevate cables at least 7 ft in height or

provide protective guarding if to be laid on

Poorly managed the ground.

Damaged lighting fixture shall be replaced

electrical facilities

immediately. Broadly Work

for temporary / 2 4 ALARP 1 2

Outlet shall be protected from direct contact Acceptable Supervisor

Task lighting and labeled with its volt capacity.

Open junction box and panel boards shall be

sealed and protected. Provision of label for

contact person in case of emergency.

3. Structure cleaning Personal injury 2 3 ALARP - Conduct regular housekeeping and ensure 2 Broadly Supervisor

Page 3 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

using Air that the work site is free any debris. Good

Compressor housekeeping shall be maintained to help

(Air blowing) prevent slips, trips and falls.

- Walking surface shall not be obstructed.

- Follow manual lifting procedures; use the

leg not the back.

- Maintain proper back posture and body

position during manual lifting.

- Seek for assistance if the load is too heavy

for a single person.

- Line supervision shall discuss all the

Slip trip & Fall possible hazard during manual handling of 1 Safety Officer

Acceptable

materials. Permit Receiver

- Ensure there are enough crew members

before lifting the load.

- Never positioned on line of fire and/or

where the possibility of caught in between

materials or equipment.

- Ensure to keep the access area free of any

obstruction.

- Ensure to follow 3-point contact ladder

safety procedure.

- Ensure to hold the ladder or tie up firmly.

Ensure to face always to ladder side.

- Ensure to provide drip-tray for mixing.

- Ensure to post CHB or MSDS at work site

and storage area.

Health hazard - Ensure to clean spills promptly and dispose

Chemical spillage properly to approved area. Supervisor

Broadly

Inhalation of 2 3 ALARP - Ensure to store all painting cans in shaded 2 2 Safety Officer

Acceptable

unwanted area under shelter. Permit Receiver

substances - Ensure to provide UL/FM rated Fire

extinguisher at storage and work area.

Ensure to use tarpaulin sheets under pipes

and steel structure to protect ground.

Equipment failure. 2 3 ALARP - All equipment covered under SA GI 7.030 2 Broadly Supervisor

shall have a valid inspection sticker issued 2 Acceptable Safety Officer

by SA or an SA-approved third-party Permit Receiver

Page 4 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

inspection agency.

- Equipment Operator shall conduct a daily

equipment inspection before operation.

- Ensure minimum requirements for safe

operation, inspection and maintenance as

per CSM -III-2 - Mechanical and Heavy

Equipment.

- Regular equipment preventive

maintenance shall be conducted.

- Additional control hazard controls during

Air Compressor use:

- Compressed air systems operating at or

above 30 psig nozzle pressure shall have a

relief device

- Compressed air shall not be used to

remove dust or dirt from clothing or

individuals. Compressed air hoses shall not

be directed towards an individual for any

reason.

- Screw type (Jubillee) hose clamps shall not

be used to secure compressed air hoses to

fittings/couplers.

- Shall be properly designed, inspected,

tested, and maintained. Air receivers shall

have periodic documented inspections.

- Daily checks shall be performed on the

compressor’s pressure relief valve, fuel, oil,

and water levels. The air reservoir shall be

drained of any trapped water prior to use.

- Shall be equipped with an easily accessible

and visible emergency shutdown switch or

button.

- Goggles and a full face shield shall be worn

when compressed air is used during special

cleaning/purging tasks.

- Compressed air hose joints (twist lock

fittings) shall be secured with proper

couplers and safety wires/pins and/or whip

Page 5 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

checks to prevent the tool and hose

couplings from being inadvertently

disconnected per CSM 11.6.3.

Hearing protection is required when the noise

level exceeds 85 dB.

- Hoses shall be secured by providing safety

wire or whip check arrestor in case of

sudden hose detachment.

- Hoses connecting test pumps to manifolds

Accidental release shall be rated for the test pressure and shall

Work

of air hose 4 3 ALARP be fitted with safety chains or equivalent 3 2 ALARP

Supervisor

connection. means strong enough to prevent whipping

in case the coupling becomes disconnected.

Install barricade around the subject for

testing and test manifold and provide

signage

- Work area shall be isolated and provided

with appropriate slgnage. Assign watch

man to monitor the barricaded I discharge

area thus. preventing any unauthorized

entry.

- Blow point shall be provided with barrier so

as to prevent flying debris on the nearby

Flying Debris/ High Work

4 3 ALARP work location. Deflector plate place at open 3 2 ALARP

Air Pressure Supervisor

end to catch flying debris.

- Involved Personnel shall wear proper eye

and face protection e.g. Safety glass, Face

shield.

An audible signal shall be sounded prior to all

blows in order to forewarn all personnel on

the job site.

- Operator shall wear suitable respirator.

Exposure to harm Work

4 3 ALARP Wetting of work location whenever 3 2 ALARP

dust Supervisor

applicable.

High Noise Level 2 2 Broadly - Assigned personnel shall wear proper 1 2 Broadly Supervisor

Acceptabl hearing protection e.g. ear muff / ear plug. Acceptable Safety Officer

e Personnel in affected areas to also wear Permit Receiver

hearing protection.

Page 6 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

- Provide appropriate signage e.g. Hearing

Protection required at the work area.

Use of PPE as per SA CSM 1-3 "PPE"

4. Loading/ Unloading, Improper 3 4 ALARP Position the crane on well compacted and 3 3 ALARP Supervisor

Dismantling of Steel position of level ground. Safety Officer

Structure and other the Keep sufficient distance from any obstacle Permit Receiver

miscellaneous steel crane structures to avoid unexpected occurrence.

materials Using /Manlift. Don’t bypass the crane safety program during

Crane, Boom Truck, Improper lifting.

Forklift. Etc. lifting Lift the load as per approved lifting plan.

practice. The rigging of the load must be done only by

Failure of qualified rigger.

Lifting Riggers and Crane operator shall be

Operation. competent & SA certified.

The outriggers of crane must be fully

extended prior to the lift, and the rubber

tires must be off the ground

Cranes shall have a valid Crane Safety

inspection sticker.

Crane operator must have his certificate in his

own posses

Use audible alarm or whistle to alert around

working personnel

When wind speed is above 32 km/h or

according to crane manufacture, the work

shall be stopped.

Frequent and Periodic inspection for Lifting

gears such as shackles, slings, hooks, pulley,

etc. to be conducted and recorded as per G.I

7.029 -Rigging Hardware Requirements.

lifting zone shall be barricaded by warning

taps and warning signs to prevent

unauthorized personnel from entering lifting

zone

Safe working load and serial number shall be

clearly marked on the sling and the lifting

gear, either by tagging or stamping

Page 7 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Stop Work Trigger because of using defective

lifting tools or un-inspected equipment.

Operators must have valid SAG license and

Saudi Aramco certification.

Saudi Aramco certified Rigger -III shall be

available full-time during crane operation

Ensure to provide dedicated flagman for

heavy equipment moving.

Ensure all heavy equipment equip with

reverse alarm.

Ensure to provide proper refresher training to

all operator, rigger and flagman.

Crane must have a valid third-party

inspection sticker and SSA monthly

inspection sticker

Night time crane lifts should have an

approved Critical Lift Plan on site

prior to each crane lift.

Night time crane lift should have

specific prior written approval from

the Facility Manager for each crane

lift, except during T&I or Shut Down.

Night time crane lift should also have

proper lighting, sufficient to perform

the lift safely.

The Critical Lift Plan form shall be

properly completed, signed, and

approved prior to the lift. It shall first

be signed by the originator; then

signed by the crane operator, rigger,

and USER supervisor. It shall then be

reviewed and approved by a Saudi

Aramco certified Rigger-I.

The Rigger-I shall physically examine

the jobsite and the equipment to be

used prior to giving signature

approval to the Critical Lift Plan. He

Page 8 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

shall be physically present to

supervise all lifts that require a

Rigger-I.

Only a Rigger-I shall execute tandem

lifts, lifts over forty (40) tons, lifts

exceeding eighty-five percent (85%)

of the crane’s rated load capacity,

working beside energized power-

lines, and/or on rubber pick and

carry operations.

While using Manlift:

Barricade off work area and place

warning signs.

Clear all personnel from the area

before raising, lowering or slewing

the Platform.

If working under the overhead

structures, bridge, in a tunnel etc.,

remember the leverage factor and

ensure ample clearance above the

platform to cater for any unexpected

amplified upward platform

movement.

Operator Awareness-never allows

any part of body through, under or

between platform arms.

Ensure load on platform is secure

&evenly distributed, do not exceed

manufacture rated capacity.

When elevated, drive only on ground

capable or supporting its weight.

Do not tie off the platform to any

fixed structure or plant, or use the

platform as an anchor point.

Never allow any person to work

underneath any part of the boom.

Avoid congested work areas.

Never use ladder or boxes to gain

Page 9 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

extra height.

Never stand on handrails to gain

extra height.

Clearly define the work area.

Keep all personnel clear.

Operator shall be trained as per

Aramco requirement.

Standby Certified Manlift operator

must be available on ground during

the operation

Stop Work Trigger because of using

defective non-inspected man lift or

the operator not certified

Use Rope or Lanyard for tools.

Use Designed anchoring point to

hook full body Harness.

Stop work trigger if there are any loose

grating causing falling hazards.

Using 3 4 ALARP Do not exceed the maximum safe working 3 3 ALARP Supervisor

improper load of the crane. Safety Officer

lifting Know the accurate weight of the loads and Permit Receiver

Gears. lifting gears prior to lift.

Position the crane on levelled and compacted

Worker ground.

Moving Use fully extended outriggers with

Under the appropriate float pads and mats.

lifted steel Do not leave the crane unattended while a

structure load is suspended.

No unauthorized entry in the lifting activity

area.

Do not perform crane lifts at wind speed

above 32 km/h unless otherwise specified by

the manufacturer.

Strictly adhere to crane load chart data.

Follow manufacture installation instruction.

Ensure that no oil or hydraulic leakage

Ensure that limit switch is installed and

Page 10 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

working functionary.

Ensure to do preventive maintenance of

crane periodically.

Ensure to barricade swing radius area.

Assign Flagman for heavy equipment for

movement.

Ensure all lifting gears are obvious rated to

the load being lifted.

Avoid sharp bends in slings, protect sling from

sharp edges and abrasion or using the

proper softener.

Do not modify, repair and shorten the sling.

Verify that the manufacturer safe working

load and serial number are clearly marked

on each sling.

While erection/modification/dismantling

activity ongoing to any steel structure be

sure the load secured by using proper lifting

Gears example (chain block, Beam clamp,

Chain puller, Web wire rope, shackles, sharp

edge softener, lifting jacks… etc).

Not allow any body allowed to moving under

the lifted load (line of fire hazards)

Ensure shackle and another connecting

device are completely closed or bolted.

Do not use fasteners or other rigging

hardware handmade or manufactured

All lifting gear must be inspected, and color

coded by Saudi Aramco certified rigger.

All lifting gears shall be certified from 3rd

party.

Incompete 4 3 ALARP All lifting gears shall be stored far from 3 3 ALARP Supervisor

nt crane sunlight and hot activities. Safety Officer

operator All lifting gears shall be inspected visually Permit Receiver

and rigger before use by a competent certified person. Crane operator

Weight of load shall be assed and to be Rigger

Crane tip identified before lifting or handling.

Page 11 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

over and Ensure to use taglines with sufficient number

mechanical only to oriented the load.

failure Ensure nobody under the suspended loads.

Prohibit No unauthorized entries in to the

Failure the lifting area.

lifting S-PCM must be conducted prior to job

object commencement

/Falling CCL must be discussed before job

Objects commencement.

Conduct regular housekeeping and ensure

that the work site is free any debris. Good

housekeeping shall be maintained to help

Slips, trips, prevent slips, trips and falls.

and falls at Walking surface shall not be obstructed.

same level, Provision of wooden dunnage to secure the

Broadly

caught in 2 2 steel structure. 1 2 Broadly Work

Acceptabl

between PTW Receiver should be available for the Acceptable Supervisor

e

moving duration of works.

equipment PPE as per SA CSM 1-3 “PPE”

Daily TBT before starting the daily activities,

conduct job-based TBT and discuss the JSA

for the activity before starting the activities.

Adequate supervision and HSSE coverage.

Working at 3 2 ALARP Toolbox talk regarding work at heights to be 2 2 Broadly Supervisor

height conducted prior star of work. Acceptable Safety Officer

(scaffolding) No person shall be engaged in any work Permit Receiver

Fall of activity where that do not possess the

person technical knowledge and experience, unless

Injuries they are under direct supervision of

Collapse, authorized person or supervisor.

scaffolding Working area to be checked for hazards

failure before works commence. Waste materials to

be removed from scaffolds immediately.

Ensure that scaffold was inspected and

tagged by Aramco approved scaffolding

supervisor / Inspector

Stop Work Trigger because of using defective

Page 12 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

scaffold.

Only work at heights trained personnel to do

the job.

To ensure that full body harness was

inspected and color-coded prior start of

activity.

To ensure that full body harness was 100% tie

off on a proper anchorage point.

Assign standby person to monitor under the

work area.

Stop Work Trigger because of using defective

harness

Scaffold Plan Completeness Checklist shall be

available at site. (IF REQUIIRED), Certified

Scaffold supervisor shall be available,

Scaffold Inspector if required.

Ensure that scaffold was inspected and

tagged by Aramco approved scaffolding

supervisor / Inspector

Scaffold to be correct in size and height for

the task, scaffold to be positioned directly

below work face.

Area barricade and warning signage to be

provided.

Keep the foundation of the scaffold away

from any adjacent excavation by 1.5 of the

depth.

Ensure to conduct proper specific training to

all involved workers prior to activity.

Check the ties point and the outriggers if

needed as per GI. (8.001).

Stop Work Trigger because of using defective

scaffold or not tagged valid.

Physical 2 2 Broadly Follow manual lifting procedures; use the leg 1 2 Broadly Work

Injury due Acceptabl not the back. Acceptable Supervisor

to e Maintain proper back posture and body

improper position during manual lifting.

Page 13 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Seek for assistance if the load is too heavy for

a single person.

manual

Use mechanical aid (e.g. boom truck,

handling

wheelbarrow, pallet truck, cranes, etc.)

while

when the load exceeds on body capacity.

transferrin

Line supervision shall discuss all the possible

g steel

hazard during manual handling of materials.

structure.

Ensure there are enough crew members

Pinch point

before lifting the load.

injury

Never positioned on line of fire and/or where

the possibility of caught in between

materials or equipment.

Ensure to lift the load close to your body as

possible.

Ensure to ask for help from other workers.

Back Pain

Ensure to lift the load in a proper body

Slip, Trip, Supervisor

posture. 2 2 Broadly

Foot Injury, Safety Officer

2 3 Ensure to grab the load properly. Acceptable

Pinch point ALARP Permit Receiver

Ensure to keep the access area free of any

injury.

obstruction.

Ensure to provide specific handling training to

all involved workers prior to work.

Personnel caught in 2 2 Broadly Flagman with reflective or visibility vest shall 1 2 Broadly Work

between or struck Acceptabl be assigned as spotter for equipment Acceptable Supervisor,

by moving e movement. Operator

equipment (crane, Only authorized personnel shall be allowed to

boom truck, trailer enter the work area where mechanical and

truck, forklift etc.). heavy equipment is in operation.

When entering the work area, authorized

personnel shall make direct eye contact with

the equipment operator(s) to ensure their

presence is known.

Operators shall ensure the work area is clear

prior to operating mechanical and heavy

equipment.

Personnel shall not be within the operating

radius of the equipment.

Page 14 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Equipment shall have audible alarms and

lights during operation.

Personnel shall not ride in or work off any

part of the equipment, unless it is specifically

designed for such work.

Personnel shall not rest or sleep (e.g., seek

shade) under or around mechanical or heavy

equipment at any time.

Working radius of equipment shall be

barricaded with appropriate warning signs.

PWAS must be installed on all heavy

equipment and trucks.

Detour / pedestrian lane shall be provided to

prevent unauthorized person from crossing

the equipment work zone.

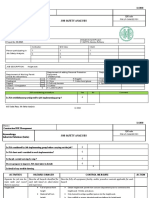

5. Cutting & welding of Lack of Competency 4 3 ALARP Emergency/ incident reporting and touching 3 3 ALARP Supervisor

Steel Structure and skills. of any switches and alarms shall be included Safety Officer

using Hand/ Power and discussed during TBT Permit Receiver

Tools Lack of knowledge S-PCM must be conducted prior to job

(Hot Work) in case of commencement

emergency. CCL must be discussed before job

Work area not commencement

barricaded All personnel shall have adequate training for

their job.

Proper supervision to be ensured throughout.

Wear appropriate PPE according to job

nature.

All personnel within work location must

attend safety induction & provided regular

TBT to educate all and be familiar with

hazards around them.

Emergency/ incident reporting shall be

discussed during TBT.

Work area ground level shall be barricaded

with signage to avoid entry of unauthorized

personnel.

Standby man shall be in place

Page 15 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Use hand tools/equipment’s which inspected

and color coded

Make sure that all tools are the suitable tool

for the job and the correspondence

employee is trained to use it.

Make sure that all equipment is inspected by

trained and certified inspectors

Stop work trigger if the electrical power tools

&equipment not properly grounded &

inspected or not equipped with GFCI.

ALWAYS use shim plate as support to prevent

the grinder being caught between structures

while removing fit up or tack weld supports.

Prior to start the job all equipment and tools

shall be inspected and make sure that all

equipment and tools are in good condition

and color coded.

Uninspected 4 3 ALARP Ensure to check and fill the daily checklist for 3 3 ALARP Supervisor

tools/equipment’s equipment’s and power tools prior to work. Safety Officer

Make sure that all tools are the suitable tool Permit Receiver

Defective welding for the job and the correspondence

machine and no employee is trained to use it.

spark arrestor Make sure that all equipment including

welding machines are inspected by trained

and certified inspectors.

Make sure that spark arrestor is available.

Stop work trigger if welding M/C found with

no spark arrestor in brown field & not

properly grounded & inspected.

Adequate approved FM /UL rated fire

extinguisher available and provide for

equipment in ground level and in the work

location

Ensure the hot work location is covered with

approved fire blanket or fire proof tarpaulin.

Trained Fire watch man available all the time

with approved fire extinguisher within 3

Page 16 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

meters. He shall remain at the work area for

no less than 30 minutes after the work has

finished.

Fire blanket to be laid on wooden plank

and/or to protect electrical/Instrument cable

and/or sensible material around installed.

Use slag containers with welders and

grinders.

Water Spraying (Wetting process) method

should be done after all hot work activities

where there are chances of fire

Stop work trigger if any gas leakage

discovered and plant alarm triggered.

Ensure that heat stress requirements are

available, implemented and training is

obtained.

Providing a good shaded ventilated resting

area.

The chosen working site shall be shaded and

ventilated.

Ensure the supply of drinking water is enough

(cold and hot)

Stop work trigger during the severe weather

based on S.A heat stress matrix/level.

Use water hydration and add rehydration

mixes as per recommendations

Wear (Welding face shield, welding googles,

ear plugs/ proper welding masks, welding

hand gloves, etc.)

Presence of toxic 4 3 ALARP Stop work trigger if no ear protection & noise 3 3 ALARP Supervisor

and flammable level exceed 85 dba. Safety Officer

gases and Fire TBT about the hazards of hot work & sound Permit Receiver

hazards.

Heat Stress The working site to be properly ventilated.

Ensure to manage cables properly over head

Grinding slag not with insulated hangers or under trenches.

contained. Ensure pedestrian access & Egress are clear

Page 17 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

and tidy.

Presence of high SIMOPS activities to be conducted through

noise several dedicated meetings, requiring

participation of all involved parties to avoid

Inhalation of fumes any SIMOPS activities and a proper SIMOPS

risk assessment shall be conducted when

Fire hazard two or more activities are being executed in

the same location at the same time.

Slip, Trip & Fall. TBT meeting is mandatory before work

commencement.

SIMOPS & Interface The combined hazards are to be assessed and

Activities. proper control measures to be implemented,

in order to reduce the related risks to As Low

as Reasonably Practicable (ALARP) level. The

mitigation actions should be continuously

reviewed according to work site progress

and their implementation on the area to be

continuous monitored.

Team leader ensures that all members of the

operational teams duly enforce the

requirements of this SIMOPS procedure

Team Leader is responsible for proper

coordination and safe simultaneous

interfaces between others activities, as well

as identification and resolution of any

potential impact on other operations.

In order to identify potential hazards and to

eliminate, minimize or managed the risk

associated with SIMOPS, dedicated risk

assessment process

Barrier safety signs and safe access / egress

routes for all teams to be set in such manner

not to obstruct the other jobs or not to be

affected by other jobs in progress.

Communication system/signals to be set for

emergency cases.

Controlling and restricting personnel access

to areas where simultaneous activities may

Page 18 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

be taking place.

- Providing specific instruction for securing

(making safe) operations and mustering

personnel in case of emergency.

Personnel injuries 2 4 ALARP Personnel involved in cutting and welding 1 2 ALARP Work

(Eye, hearing, operations, including helpers, shall use Supervisor

respiratory, burns proper PPE (face shields, earplugs, particular

etc) during cutting, respirator etc).

grinding, and Respiratory protection equipment shall be

welding works provided and used as needed.

Leather gloves and leather body protection /

apron shall be worn for protection against

heat, sparks, flying metal particles and

radiation. Gloves shall protect wrists and

forearms.

Safety boots and leggings shall be worn as

needed to provide protection against heat,

sparks and flying metal particles. Pants shall

not be worn inside (i.e., tucked in) safety

boots.

Welding helmet shall be worn during welding

operations to protect the welder’s eyes and

face against the intense radiation

(light/heat), flying particles, etc.

Noncombustible or flameproof welding

screens / fire blanket shall be used to

protect nearby personnel and equipment

from exposure to arc welding/cutting

hazards.

Ensure to select the correct type of disc and

inspect grinding equipment before use.

Grinding wheels shall be free of defects and

must be inspected prior to use.

Grinding wheels shall be balanced & centered

and shall be installed per the wheel

manufacturer’s instructions.

The running speed shall not exceed the

Page 19 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

maximum permissible speed displayed on

the grinding wheel.

Dust control procedure (such spraying of

water) shall be implemented in areas where

dust accumulation is possible

Improper storage 4 3 ALARP Secure protective caps on all cylinders when 3 3 ALARP Supervisor

practices not in use. Safety Officer

(Compressed gas Properly secure the cylinder in an upright Permit Receiver

cylinders) position during movement or use at

worksite.

All cylinders must be label properly.

Unlabeled using gas Do not strike cylinders together.

cylinder on site. Ensure to install flashback arrestor at O2

/acetylene cylinder regulators.

Protect cylinders from direct flame, sunlight

and other heat sources.

Using Damage Use fraction lighter for torches

hoses/gages/ gas Always keep cylinder valve tool locker

Regulators. attached to cylinders

Use approved rated hoses

Use approved connection (Jubilee clips not

allowed)

Ensure cutting area free from wood, papers

or any combustible materials

Provide proper approved FM /UL rated Fire

extinguisher near cylinder storage area

Inspect cylinders and gauges prior to use.

Ensure to use accepted pressure 15psi.

Transfer the cylinders in storage cage.

Ensure to post warning signs at storage area

like No smoking

Do not store cylinders at temperature

exceeding 54 0C.

Properly identify full and empty cylinders and

store separately.

- Keep stored O2 cylinders separated from

fuel gas cylinders by 6.1 m (20 feet) or by

Page 20 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

1.5 m (5ft) high, noncombustible barrier.

Electrical Hazards 2 2 Broadly All electrical tools and cables are maintained 1 2 ALARP Work

(for grinding and Acceptabl in safe condition and checked regularly for Supervisor

welding works using e any defects.

electrical power Frayed, damaged electrical cables and power

sources tools shall be removed and tagged “Do Not

Use”.

All cables shall be protected from sharp

edges.

Only properly insulated or nonconductive

tools shall be used when work is performed

on or near electrical equipment.

All electrical power tools must be properly

grounded unless they are of the double

insulated type.

Ground Fault Circuit Interrupters (GFCIs) shall

be provided where required per NFPA 70.

The frames of all electrical arc welding

machines shall be properly grounded.

Splices are not allowed anywhere in welding

cables.

Welding cables (welding leads) shall be

continuous (i.e., free from repair/joints) for a

minimum distance of 3 m (10 ft) from the

end to which the electrode holder is

connected.

Welding cables shall be regularly inspected

for cuts or abrasions to the insulation.

Damaged cables shall be removed from

service.

When feasible, welding cables shall be

elevated or protected by nonconductive

cable covers.

When the material to be welded or cut is

supported by a crane, the welding/cutting

shall not occur near the rigging or a

shield/screen shall be provided to protect

Page 21 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

the rigging. In such situations, the rigging

shall be nonconductive and outside the heat

affected zone.

Welders shall remove the electrode from the

electrode holder when welding operations

are discontinued for any period of time.

Electrode holders shall be unplugged when

not in use.

Wear appropriate PPE’s such as safety gloves,

shoes and glasses fire retardant clothing.

6. Gasket Installing & Physical Injury due 2 2 Broadly Follow manual lifting procedures; use the leg 1 2 Broadly Work

Bolt tightening to improper manual Acceptabl not the back. Acceptable Supervisor,

handling. e Maintain proper back posture and body Rigger

position during manual lifting.

Seek for assistance if the load is too heavy for

a single person.

Use mechanical aid (e.g. boom truck,

wheelbarrow, pallet truck, cranes, etc.)

when the load exceeds on body capacity.

Additional hazard controls during

manual dragging and alignment of

steel structure:

Web slings shall be protected from

damage by softeners.

The chains or ropes of a chain block and

pullers shall not be used as chokers

Rigging equipment shall be identified

with clear SWL markings.

Chain block and pullers shall not be used

on loads greater than its capacity.

Lifting hooks shall not be used unless

equipped with an appropriate safety

latch.

Loads shall be secured on a permanent,

fixed and sturdy structure.

Install barricade around the lifting zone.

Tools shall be secured with retaining

strings. Secure equipment’s on a

Page 22 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

permanent structure.

Use required personal protective equipment.

Whiplash arrestor is provided on hoses which

are possible to disconnect or where high air

Struck by high pressure is present.

Supervisor

pressure air Allowable rated capacity or pressure of hoses Broadly

2 4 ALARP 1 2 Safety Officer

due to hose or equipment in tightening is not exceeded. Acceptable

Permit Receiver

disconnection. Barricade and warning signs are provided on

the bolt tightening area to restrict

unauthorized person.

Hand and power 2 2 Broadly Ensure a correct size of Torque Wrench has 1 2 Broadly Work

tools failure Acceptabl been selected for the bolt tightening Acceptable Supervisor

e application.

Ensure a correct size of Socket / Insert has

been selected for the nut.

The Torque wrench shall be in the correct

mode for tightening / loosening.

Hydraulic Torque Hoses must be in good

condition and are free from any damage

such as crushing, cuts or kinks.

Hydraulic Torque pump unit reservoir shall

always be filled with hydraulic oil only.

Use a manufacturer’s specified tools required

for cleaning and tensioning the bolts and

nuts.

Always wear the appropriate PPEs for the job.

Precision instrument and special tools

bearsthevalid date of calibration and

inspection stickerfrom the approved Third-

Party CalibrationAgency.

User to conduct pre-operational inspection

andchecking on the parts of the precision

instrumentand special tools prior to use.

Precision instruments and special tools

areinspected/color coded using the color-

codingcalendar.

Defective precision instrument and special

Page 23 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

toolsare removed from the site and returned

to theManufacturer for warranty repair.

7 Touch-up All employees involved in painting works shall

painting be properly trained.

Chemical containers shall be properly marked

and labeled. Only approved containers shall

be used.

Paint mixing shall be conducted within a drip

pan or tray to contain spills.

Eyewash station shall be provided.

Contact with

-Wear appropriate PPEs such as disposable

Chemicals Supervisor

coverall, respirators, rubber gloves, face Broadly

(Inhalation, 2 3 ALARP 1 2 Safety Officer

shield etc. Acceptable

ingestion, eye Permit Receiver

MSDS / CHB for painting materials shall be

irritation, skin

available at the work area.

Only limited amount of paint mixture shall be

brought at site. Painting materials shall not

be stored inside the operating plant.

- Painting works shall not be conducted

simultaneously with hot work activities.

Conduct regular housekeeping and ensure

that the work site is free any debris.

Fall Hazards 2 3 ALARP Provide proper working platform such as 1 2 Broadly Supervisor

(Personnel and scaffold when working at elevated area. Acceptable Safety Officer

materials) PPE’s and related requirements during Permit Receiver

working at heights shall comply in

accordance with CSM-II-5 Fall Protection.

-All employees working at heights must be

trained.

Work area must be barricaded and provided

with appropriate signage.

Use proper access when going to elevated

areas.

Access and egress must be free from any

debris or materials.

Where possible, work shall be performed on

the ground to minimize exposure to falls

Page 24 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

from heights.

Each person who could fall more than 1.8 m

(6 ft) shall be protected from falling by a fall

protection system.

All fall protection equipment shall be in good

working condition before commencing work.

Work supervisors shall closely monitor work

activities to ensure personnel are properly

using fall protection equipment.

Fall protection equipment shall not be used

for any purpose other than its intended use.

Tools or materials used at elevated area must

have retaining string and containment box.

Full body harness shall be equipped with

suspension trauma.

Provision of lifeline.

Erect guardrail systems with toe boards

andedges of floors and cover all floor

openings.

All floor openings (12 inches or more)

areguarded by a secured cover, a guardrail

or equivalent on all sides.

-When using ladders:

Set ladders on a stable ground and

must be secured from the top and at

its base.

Ladders shall not be use inhorizontal

positionas platforms, runways or

scaffolds

Straight ladders shall be used at an

angle of 75degrees.

Top rung of the A-type ladder is not

permittedto use.

An extension of 36” to 42“from the

landing orabove the highest rung

shall be observed inusing ladders.

Ladder shall be secured and

Page 25 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

extended 1m above landing platform

8. General Monitor the weather condition with the local

Requirements weather measurement equipment.

Plan the work according to weather report/

condition

Provide proper shelter at work site to avoid

workers directly expose to wind, storm and

rain.

Provision of proper welfare facilities (drinking

water, cool shelter, toilet) at site.

Adverse weather

Schedule the work to avoid direct and

condition(Heavy

continuous exposure to sunlight during hot Supervisor

Rain, lightning, Broadly

3 3 ALARP season. 2 2 Safety Officer

Storm, hot and Acceptable

Withdraw the worker from high elevation Permit Receiver

cold condition,

during lightning.

heavy wind etc.)

Retract the boom of crane and manlift.

Stop all activity during heavy rain.

De-energize and cover the all-temporary

electrical equipment during heavy rain.

Do not allow crane or any lifting activity if

wind speed more than 32km/h

- Heat stress preventive measure to be

implemented during hot weather

condition.

Environmental 2 2 Broadly Ensure to remove unwanted materials from 1 2 Broadly Supervisor

(Housekeeping and Acceptabl work site. Acceptable Safety Officer

stacking of e Ensure to remove any contaminated soil Permit Receiver

materials) promptly and dispose to approved dumping

area

Ensure to provide designated smoking center.

All materials shall be stacked properly

All access shall be free from any objects

Stack and contain empty bags, container for

rubbish, remove rubbish and dispose in

approved area by SA approved Disposal

Company.

Remove and dispose waste painting cans to

Page 26 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

approved dumping area.

Work trigger if waste and unused

material/painting cans collected and not

removed.

-

All shall be familiar with SA and SECL

emergency contact numbers.

All work permits shall be cancelled in case of

any emergency

All equipment shall shut off, power isolated

Emergency Situation

and secured during emergency.

(Unawareness of

Broadly All personnel shall proceed to the nearest Supervisor

emergency Broadly

2 2 Acceptabl assembly point in upwind / cross wind 1 2 Safety Officer

Response & not Acceptable

e direction during emergency Permit Receiver

familiar of contact

Head count shall conduct at the Assembly

numbers).

point.

All crew shall remain calm at the muster point

till all clear alarm is sounded.

- Stop work trigger if any emergency alarm

trigger or sounded.

Page 27 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Page 28 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

JSA ATTENDANCE SHEET JSA Reference No:

Activity

No: Name Signature No: Name Signature No: Name Signature

Page 29 of 30HUGRS JSA Format R1

Hawiyah Unayzah Gas Reservoir Storage Project

Page 30 of 30HUGRS JSA Format R1

You might also like

- 700R4 Manual PDFDocument96 pages700R4 Manual PDFK B100% (3)

- T ISS PX01 Instruction Manual Rev.01Document9 pagesT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Case SR200 Service Manual Pgs 1-28Document28 pagesCase SR200 Service Manual Pgs 1-28gregfortkamp43% (14)

- Oracle X86 Server Installation Specialist Online Assessment 2020Document21 pagesOracle X86 Server Installation Specialist Online Assessment 2020Josip BelinaNo ratings yet

- Job Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air CompressorDocument4 pagesJob Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air Compressorlatiplambosi100% (1)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- Aras Simulation Management 12.0R1 - User GuideDocument19 pagesAras Simulation Management 12.0R1 - User GuideHernan GiagnorioNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Mobile Scaffold SafetyDocument1 pageMobile Scaffold SafetyDhiraj ThukralNo ratings yet

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDocument2 pagesRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Safety Campaign-Energy Isolation-April 2022Document7 pagesSafety Campaign-Energy Isolation-April 2022HSE99 BHDCNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Document3 pagesJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21No ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument4 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- JSA - Electrical IsolationDocument1 pageJSA - Electrical IsolationRaju KhalifaNo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Height Pass FormatDocument1 pageHeight Pass Formatamit kumarNo ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- JSA For Manual Excavation Inside The Operation Area (Access Road)Document6 pagesJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Can Get Medical Assistance.: Deyaar Facilities Management LLC First Aid - Basic - TBT-28Document2 pagesCan Get Medical Assistance.: Deyaar Facilities Management LLC First Aid - Basic - TBT-28nIKHILNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- TOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEDocument5 pagesTOUAT GAZ Project Job Safety Analysis (Jsa) : Mandatory PPEazerNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Datasheet SQ R 2.41Document2 pagesDatasheet SQ R 2.41Alejandro CarhuacusmaNo ratings yet

- Varispeed-F7 Manual PDFDocument463 pagesVarispeed-F7 Manual PDFIsradani MjNo ratings yet

- CSBS DBMS Lab2 22-23Document12 pagesCSBS DBMS Lab2 22-23VaibhavNo ratings yet

- Mkdir CommandDocument3 pagesMkdir Command11-B ,Niranjan DorageNo ratings yet

- Be Enc 2020Document10 pagesBe Enc 2020Shaikh FarooqNo ratings yet

- SAP FSCM BasicsDocument5 pagesSAP FSCM BasicspaiashokNo ratings yet

- Web-Based Management System With SMS and E-Mail Notification For Binan Tricycle Franchising and Regulatory BoardDocument8 pagesWeb-Based Management System With SMS and E-Mail Notification For Binan Tricycle Franchising and Regulatory Boardsjdmnts3No ratings yet

- Untitled 0Document288 pagesUntitled 0khushiNo ratings yet

- Emk31303 - (Group J) Mini Project ManagementDocument32 pagesEmk31303 - (Group J) Mini Project ManagementAMIRAH BINTI AHMAD FAUZI STUDENTNo ratings yet

- Isuzu Engine Mechanical 4hk1 TC 6a 1Document10 pagesIsuzu Engine Mechanical 4hk1 TC 6a 1Janet100% (66)

- Introduction To SCMDocument38 pagesIntroduction To SCMArif Shan50% (2)

- Hig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29Document2 pagesHig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29isaacsavioNo ratings yet

- DO NOT: SortingDocument4 pagesDO NOT: SortingiGun SkNo ratings yet

- NTDCL Test 2022Document7 pagesNTDCL Test 2022Rafy Info TvNo ratings yet

- Memo To Users IBM I 7.1Document74 pagesMemo To Users IBM I 7.1Anonymous c1oc6LeRNo ratings yet

- C911 / C931 / C941 Maintenance Manual: Downloaded From Manuals Search EngineDocument297 pagesC911 / C931 / C941 Maintenance Manual: Downloaded From Manuals Search Engineemir pestanaNo ratings yet

- Samsung ML-1440 ML-1450 Repair Service ManualDocument96 pagesSamsung ML-1440 ML-1450 Repair Service ManualSteveSherrattNo ratings yet

- Students Thesis DissertatrionDocument3 pagesStudents Thesis Dissertatrionjun del rosarioNo ratings yet

- 57 Ways To Get Traffic To Your WebsiteDocument75 pages57 Ways To Get Traffic To Your WebsiteDeeJNo ratings yet

- 4n25 OptoDocument6 pages4n25 OptoHeber Garcia VazquezNo ratings yet

- Electronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloDocument12 pagesElectronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloengshimaaNo ratings yet

- Grid Automation Webinar Series: Hitachi Abb Power Grids Powering Good For Sustainable EnergyDocument30 pagesGrid Automation Webinar Series: Hitachi Abb Power Grids Powering Good For Sustainable EnergyRidouan HijeNo ratings yet

- ATGB3673 Estimating Buildsoft Assignment BriefDocument5 pagesATGB3673 Estimating Buildsoft Assignment BriefSamantha LiewNo ratings yet

- Parasoft Soatest 9.x TutorialDocument9 pagesParasoft Soatest 9.x Tutorialblunt2vitreNo ratings yet

- DEFCON 22 Lucas Morris Michael McAtee ShareEnum We Wrapped SambaDocument23 pagesDEFCON 22 Lucas Morris Michael McAtee ShareEnum We Wrapped SambaSudhanshu Shekhar SharmaNo ratings yet