Professional Documents

Culture Documents

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

Uploaded by

ekhgtiCopyright:

Available Formats

You might also like

- How Does Purinject 1C 55 LV Work?Document3 pagesHow Does Purinject 1C 55 LV Work?Abdou BidaouiNo ratings yet

- Advanced Reinforced Concrete DesignDocument1 pageAdvanced Reinforced Concrete Designdrp100% (1)

- Creep and Failure of Lead-Free Solder AlloysDocument77 pagesCreep and Failure of Lead-Free Solder AlloysTamara KhasimaNo ratings yet

- Piping Systems PDFDocument81 pagesPiping Systems PDFFox Alpha DeltaNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareRodrigo Fuente GarcíaNo ratings yet

- RS/2/C/003MR - 2016: Rigid Metallic Ductwork Systems With Rectangular Cross-SectionDocument12 pagesRS/2/C/003MR - 2016: Rigid Metallic Ductwork Systems With Rectangular Cross-SectionshahNo ratings yet

- MC-Injekt 1264 Compact EN EN TDSDocument3 pagesMC-Injekt 1264 Compact EN EN TDSEvgeny ZakharinNo ratings yet

- MC Injekt2033 PDFDocument2 pagesMC Injekt2033 PDFhemantrulzNo ratings yet

- Rebisco & RL Graphics BillingDocument12 pagesRebisco & RL Graphics Billingjulius fampulmeNo ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- Interzinc 22Document4 pagesInterzinc 22dexterisNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- l011663 Hmi PLC Hp043 20dt User ManualDocument56 pagesl011663 Hmi PLC Hp043 20dt User ManualAcisac Autocontrol100% (1)

- Material Submission RebarprimerRevApdfDocument9 pagesMaterial Submission RebarprimerRevApdfAndrew LeeNo ratings yet

- MC-DUR 111 Eco: Water-Based, Epoxy Resin DispersionDocument2 pagesMC-DUR 111 Eco: Water-Based, Epoxy Resin DispersionParinex SRLNo ratings yet

- Interzinc 2265: Product DescriptionDocument4 pagesInterzinc 2265: Product DescriptionIsabelo AbaoNo ratings yet

- Interzinc 22: Inorganic Zinc-Rich SilicateDocument4 pagesInterzinc 22: Inorganic Zinc-Rich SilicateKristi FoxNo ratings yet

- X-Therm PU40 Foam: Technical Data SheetDocument2 pagesX-Therm PU40 Foam: Technical Data SheetAmr RagabNo ratings yet

- Instruction Manual: 5COR469100 - BR25AT - REV00Document8 pagesInstruction Manual: 5COR469100 - BR25AT - REV00Javier SalaNo ratings yet

- Polyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinDocument2 pagesPolyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinVaittianathan MahavapillaiNo ratings yet

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven PatleNo ratings yet

- Interline 921+ds+eng PDFDocument4 pagesInterline 921+ds+eng PDFMohamed NouzerNo ratings yet

- K2 User Manual 1509Document39 pagesK2 User Manual 1509Ghofur Al MusthofaNo ratings yet

- MS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Document7 pagesMS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Dipak VaghelaNo ratings yet

- Centrament VMA 2: Viscosity Modifying AgentDocument2 pagesCentrament VMA 2: Viscosity Modifying AgentvmoderahNo ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- Interfine 691: Isocyanate-Free FinishDocument4 pagesInterfine 691: Isocyanate-Free FinishTrịnh Minh KhoaNo ratings yet

- Ob2 mc161 High Solids Urethane Clear 04 15Document3 pagesOb2 mc161 High Solids Urethane Clear 04 15Jerry ForalNo ratings yet

- Offshore Painting Cycle C5M - HDocument13 pagesOffshore Painting Cycle C5M - HhohnzimhlnrftumftrNo ratings yet

- Sabic® Ppcompound 31T1010: PP Compound Mineral FilledDocument2 pagesSabic® Ppcompound 31T1010: PP Compound Mineral Filledmohamed sabryNo ratings yet

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDocument4 pagesIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009No ratings yet

- Mos Pu Foam CompleteDocument4 pagesMos Pu Foam Completeyusnan yazidNo ratings yet

- TDS MasterRheobuild 2000 PF PDFDocument3 pagesTDS MasterRheobuild 2000 PF PDFRogerNo ratings yet

- BA WNB English D10329Document20 pagesBA WNB English D10329Abi SuryonoNo ratings yet

- Mc-Dur 1077 FGDocument2 pagesMc-Dur 1077 FGTibelu'No ratings yet

- Celcote 242Document4 pagesCelcote 242Anwar MdNo ratings yet

- Qu Ick C BS Ys Te M 1: Mapequick CBS System 1Document2 pagesQu Ick C BS Ys Te M 1: Mapequick CBS System 1Radu JuneNo ratings yet

- 697 UkDocument4 pages697 UkAhmed IbrahimNo ratings yet

- TDS PDF Intercept - 7000Document4 pagesTDS PDF Intercept - 7000PastiDjadi PastiDjadiNo ratings yet

- Manuals W WAT3667 ADocument5 pagesManuals W WAT3667 AYacine BenchikhNo ratings yet

- Bauder LiquiFINISH Product Data SheetDocument2 pagesBauder LiquiFINISH Product Data Sheetshivarajs12340987No ratings yet

- Ceilcote 2000 FlakelineDocument4 pagesCeilcote 2000 FlakelineAhmet GözübüyükNo ratings yet

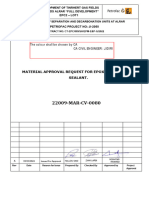

- 22009-Mar-Cv-080 (Epoxy Resing Based Sealant)Document17 pages22009-Mar-Cv-080 (Epoxy Resing Based Sealant)ADNAN ZIADNo ratings yet

- Sikasil® IG-25 HM Plus: Product Data SheetDocument2 pagesSikasil® IG-25 HM Plus: Product Data SheetKhin Sandi KoNo ratings yet

- 03.MasterRoc MP 755 TDS ENDocument2 pages03.MasterRoc MP 755 TDS ENVandi SetiawanNo ratings yet

- Masterroc MP 355 TdsDocument2 pagesMasterroc MP 355 TdsShesh ManiNo ratings yet

- Contite Slab Lift: Description Mix Ratio ApplicationDocument2 pagesContite Slab Lift: Description Mix Ratio ApplicationRahmat DwiNo ratings yet

- CIPP Liner Systems GAADocument2 pagesCIPP Liner Systems GAASlagalicaSlagalicaNo ratings yet

- Product Manual: Bracton Sub Zero Glycol ChillerDocument5 pagesProduct Manual: Bracton Sub Zero Glycol ChillerCezar BarretoNo ratings yet

- Water Valve Update On Wheeled Loaders JCBDocument2 pagesWater Valve Update On Wheeled Loaders JCBJunaid RehmanNo ratings yet

- Mc-Dur 111 D en en TDSDocument2 pagesMc-Dur 111 D en en TDSEvgeny ZakharinNo ratings yet

- Pentaline 2000 F17Document4 pagesPentaline 2000 F17Vineet KhanduriNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinNo ratings yet

- CVP 2200A Manual E09Document17 pagesCVP 2200A Manual E09minhNo ratings yet

- Injection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Document3 pagesInjection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Abdou BidaouiNo ratings yet

- Ceilcote - 2000 InternationalDocument4 pagesCeilcote - 2000 InternationalAjay RanganathanNo ratings yet

- Painting Procedure (Repainting Flow Indicator)Document6 pagesPainting Procedure (Repainting Flow Indicator)nds setyawanNo ratings yet

- Scope of WorkDocument31 pagesScope of WorkChandrakant BagulNo ratings yet

- ENVPEP1412003Document5 pagesENVPEP1412003south adventureNo ratings yet

- ICT GTsTanda &bongaigaon-1Document24 pagesICT GTsTanda &bongaigaon-1Darwin AlphonseNo ratings yet

- Colusal MK: Mineral Corrosion Protection CoatDocument2 pagesColusal MK: Mineral Corrosion Protection CoatHeru PrasetyoNo ratings yet

- MC-Entöler: Cleaning Agent For Oil ContaminationDocument2 pagesMC-Entöler: Cleaning Agent For Oil ContaminationhemantrulzNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Structural EngineeringDocument15 pagesStructural EngineeringSurender Reddy100% (1)

- Physics ProjectDocument8 pagesPhysics ProjectIVAN TIONG WEI JUN MoeNo ratings yet

- Kerto Manual LVL Mechanical PropertiesDocument6 pagesKerto Manual LVL Mechanical PropertiesTiago GonçalvesNo ratings yet

- Dr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaDocument23 pagesDr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaMaheenNo ratings yet

- 1BO16CSE05Document37 pages1BO16CSE05Dinesh GowdaNo ratings yet

- Sewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDocument1 pageSewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDanica Mae AmicayNo ratings yet

- Comp SteelsDocument8 pagesComp Steelskgupta27No ratings yet

- 804-Hermetic Refrigeration System Training Program - 5 FaultsDocument2 pages804-Hermetic Refrigeration System Training Program - 5 FaultsDaud Simon ANo ratings yet

- Is.7634.2.2012 0Document26 pagesIs.7634.2.2012 0Jagadeesh PuppalaNo ratings yet

- ds83001 Repair Materials For Glasteel Nucerite EquipmentDocument2 pagesds83001 Repair Materials For Glasteel Nucerite EquipmentGerman Tonino LópezNo ratings yet

- Mercet BoilerDocument7 pagesMercet BoilerDafiMaboNo ratings yet

- Factored Reaction (W) Factored Tensile Force On The Plate W/2Document9 pagesFactored Reaction (W) Factored Tensile Force On The Plate W/2Sudhanshu Shekhar SinglaNo ratings yet

- ADocument22 pagesAAntonio LoretoCortesNo ratings yet

- Conveyor Design PDFDocument73 pagesConveyor Design PDFRamesh Subramani RamachandranNo ratings yet

- Mini Project Brief For Steel Design & Cad - AY2023 - 2024Document8 pagesMini Project Brief For Steel Design & Cad - AY2023 - 2024krugan652No ratings yet

- Cold Box Resin: Ceracold RDocument3 pagesCold Box Resin: Ceracold RskNo ratings yet

- Case Study A2bDocument16 pagesCase Study A2bvasNo ratings yet

- Preventive MaintenanceDocument3 pagesPreventive MaintenanceTrilok Singh TakuliNo ratings yet

- NJ Brochure-2Document3 pagesNJ Brochure-2JhishnuNo ratings yet

- Material Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/MDocument5 pagesMaterial Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/Mjmarkunongo_69397286No ratings yet

- AnchorDocument5 pagesAnchorpadalakirankumarNo ratings yet

- Tds 1323203 enDocument2 pagesTds 1323203 enMartín BaezaNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlDocument6 pagesEurope Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlOsvaldo Meza100% (1)

- Aisc - Open Deck Parking SolutionsDocument29 pagesAisc - Open Deck Parking Solutionscalaud67% (3)

- 16Mncr5: Quality 16Mncr5 Case Hardening SteelDocument2 pages16Mncr5: Quality 16Mncr5 Case Hardening SteelShubhangi ShindeNo ratings yet

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

Uploaded by

ekhgtiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

MC-BAUCHEMIE - MC-Injekt GL 95 TX - TDS

Uploaded by

ekhgtiCopyright:

Available Formats

MC-Injekt GL-95 TX

Swelling, flexible, waterproofing acrylate gel sealant for injection in concrete,

masonry and foundation soil

PRODUCT PROPERTIES ■ Low-viscosity, high-solids acrylic-based hydrogel

■ Very good injectability

■ Readily controllable injection path propagation thanks to controllable reaction time

■ Very low application temperature

■ Reliable sealing/waterproofing due to high elasticity and good swelling capacity

■ Durably water-impermeable in moist media

■ Corresponds to fire class B2 according to DIN 4102 in the injection medium

■ Fulfils the UBA (German environmental agency) guidelines for sealants in contact with potable water

■ Meets the KTW-BWGL guideline for seals in contact with drinking water

■ High chemical resistance especially in highly alkaline environments

■ CE conformity according to EN 1504-5: CE U(S2) W(2/3/4) (1/40)

■ REACH exposure: water contact permanent, inhalation periodic, processing and application

■ Environmental Product Declaration EPD

AREAS OF APPLICATION ■ Swelling flexible filling sealant for cracks, construction joints, expansion joints and cavities in perma-

nently damp concrete and masonry

■ Subsequent vertical sealing of masonry

■ Subsequent formation of a horizontal barrier/DPC in masonry

■ Injection of waterproofing membrane into interstitial spaces between buildings

■ Injection of waterproofing membrane into foundation soil (curtain injection)

■ Injection of construction joints via injection tubes/hoses

APPLICATION ADVICE Preparatory measures: Prior to injection, an investigation of the structure and of any leaks must be car-

ried out according to the state of the art and the rules of technology, and an injection concept must be

planned. Packers must be set before injection. A trial injection is recommended.

Mixing the components: Components A and B of MC-Injekt GL-95 TX are prepared from their respec-

tive subcomponents in the specified mixing ratio. Component A is mixed from subcomponents A1, A2

and A3. To do this, pour component A2 and A3 into the container of component A1 and stir energetically

with a wooden paddle. Component B is dissolved in B1 and mixed with a wooden paddle. The reaction

times of MC-Injekt GL-95 TX depend on the volume of component B added to B1.

Mixing of the components A and B thus prepared takes place during injection: The components are

mixed as they pass through the mixing head of the MC-I 710 injection pump (mixing distance > 10 cm

inline static mixer).

Reaction time with addition of component B in 25,8 kg or 103,2 kg of B1

% 25,8 kg B1 103,2 kg B1 reaction time

approx. 0,2 % 0,05 kg 0,2 kg approx. 125 s

approx. 0,5 % 0,129 kg 0,5 kg approx. 65 s

approx. 1 % 0,25 kg 1,0 kg approx. 40 s

approx. 2 % 0,5 kg 2,0 kg approx. 25 s

approx. 4 % 1,0 kg 4,1 kg approx. 14 s

Delayed reaction: The reaction time of MC-Injekt GL-95 TX can be extended with MC-Injekt Retarder

GL. The retarder is added to the ready-mixed component A. The amount added determines the delayed

reaction time. This mixture can be used within 2 hours. When using the retarder, the concentration of

component B of 0.5% in component B1 must be adhered to.

MC-Bauchemie Müller GmbH & Co. KG technical datasheet

Am Kruppwald 1-8 · 46238 Bottrop MC-Injekt GL-95 TX

Tel. +49 (0) 2041-101 0 · Fax: +49 (0) 2041-101 400

info@mc-bauchemie.de · www.mc-bauchemie.de 11.10.2023 1|3

APPLICATION ADVICE MC-Injekt Retarder GL in 120 kg component A reaction time at 20 °C

1 kg approx. 80 s

2 kg approx. 3 min

3 kg approx. 15 min

4 kg approx. 28 min

Injection: Injection is performed with the two components being mixed as they are dispensed by the MC-

I 710 injection pump.

MC-Hammer Packer LP 18 or MC-Hammer Packer LP 12 packers are recommended for injection into

building components.

MC-Bore Packer LS 18 packers or injection lances are recommended for injection into foundation soil.

Application work should cease once component/subsoil temperatures fall below 1 °C.

Ensure compliance with the information given in the specifications and the Safety Data Sheets.

Equipment cleaning: Within the working time of the resin, all tools can be cleaned with water or air.

Material that has reacted or set will need to be removed mechanically.

MC-Bauchemie Müller GmbH & Co. KG technical datasheet

Am Kruppwald 1-8 · 46238 Bottrop MC-Injekt GL-95 TX

Tel. +49 (0) 2041-101 0 · Fax: +49 (0) 2041-101 400

info@mc-bauchemie.de · www.mc-bauchemie.de 11.10.2023 2|3

TECHNICAL VALUES & PRODUCT CHARACTERISTICS

Characteristic Unit Value Comments

Mixing ratio parts by vol- 1 : 1 comp. A : comp. B in solution

ume

mass frac-

tions

Canister 27.6 : 0.5 : 2 comp. A1 : comp. A2 : comp. A3

Comp. B1 : Comp. B (0.05 – 1.0 kg)

Drum 110 : 2 : 8 comp. A1 : comp. A2 : comp. A3

comp. B1 : comp. B (0.2 – 4.1 kg)

Density kg/dm³ DIN 53479

approx. 1.1 mixture

approx. 1.2 component A1

approx. 0.97 component A2

approx. 1.06 Component A3

approx. 1.2 - 1.5 comp. B (bulk density)

approx. 1.04 component B1

Viscosity mPa·s approx. 40 EN ISO 3219

Working time seconds 14 - 125

Application conditions °C 1 - 40 component and subsoil temperature

Strain % approx. 150 EN ISO 527-4

PH value approx. 9 cured product

Swelling dimension % approx. 40 water storage at 20 °C

Ultimate elongation % approx. 300 DIN 52 455-1

All technical values are laboratory results determined at 21°C ±2°C and 50% relative humidity.

Colour light blue

Equipment cleaning agent water

Delivery form MC-Injekt GL-95, component A1, 27.6 kg and 110 kg containers

MC-Injekt GL-95, component A2, box of 4 x 0.5 kg containers

MC-Injekt GL-95, component A3, 2 kg and 8 kg containers

MC-Injekt GL-B, component B, box of 4 x 0.5 kg containers

MC-Injekt GL-95 TX, component B1, 25.8 kg and 103.2 kg containers

MC-Injekt Retarder GL, 5 kg container

Storage Can be stored in original sealed packages at temperatures between 5°C and 25°C in dry conditions for

at least 12 months.

Packaging disposal Make sure single-use containers are completely empty.

Safety instructions

Please note the safety information and advice given on the packaging labels and safety data sheets.

Note: The information contained in this data sheet is based on our experience and is correct to the best of our knowledge. It is, however, not binding. It will need to be

adapted to the requirements of the individual structure, to the specific application and to non-standard local conditions. Application-specific conditions must be checked in

advance by the planning engineer/specifier and, where different from the standard conditions indicated, will require individual approval. Technical advice provided by MC’s

specialist consultants does not replace the need for a planning review by the client or its agents in respect of the history of the building or structure. Subject to this prerequi-

site, we are liable for the correctness of this information within the framework of our terms and conditions of sale and delivery. Recommendations of our employees deviating

from the information given in our data sheets are only binding for us if they are confirmed in writing. In all cases, the generally accepted rules and practices reflecting the

current state of the art must be observed. The information given in this technical data sheet is valid for the product supplied by the country company listed in the footer. It

should be noted that data in other countries may differ. The product data sheets valid for the relevant foreign country must be observed. The latest technical data sheet shall

apply to the exclusion of previous, duly superseded versions; the date of issue in the footer must be observed. The latest version is available from us on request or may be

downloaded from our website. [2300018164]

MC-Bauchemie Müller GmbH & Co. KG technical datasheet

Am Kruppwald 1-8 · 46238 Bottrop MC-Injekt GL-95 TX

Tel. +49 (0) 2041-101 0 · Fax: +49 (0) 2041-101 400

info@mc-bauchemie.de · www.mc-bauchemie.de 11.10.2023 3|3

You might also like

- How Does Purinject 1C 55 LV Work?Document3 pagesHow Does Purinject 1C 55 LV Work?Abdou BidaouiNo ratings yet

- Advanced Reinforced Concrete DesignDocument1 pageAdvanced Reinforced Concrete Designdrp100% (1)

- Creep and Failure of Lead-Free Solder AlloysDocument77 pagesCreep and Failure of Lead-Free Solder AlloysTamara KhasimaNo ratings yet

- Piping Systems PDFDocument81 pagesPiping Systems PDFFox Alpha DeltaNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareRodrigo Fuente GarcíaNo ratings yet

- RS/2/C/003MR - 2016: Rigid Metallic Ductwork Systems With Rectangular Cross-SectionDocument12 pagesRS/2/C/003MR - 2016: Rigid Metallic Ductwork Systems With Rectangular Cross-SectionshahNo ratings yet

- MC-Injekt 1264 Compact EN EN TDSDocument3 pagesMC-Injekt 1264 Compact EN EN TDSEvgeny ZakharinNo ratings yet

- MC Injekt2033 PDFDocument2 pagesMC Injekt2033 PDFhemantrulzNo ratings yet

- Rebisco & RL Graphics BillingDocument12 pagesRebisco & RL Graphics Billingjulius fampulmeNo ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- Interzinc 22Document4 pagesInterzinc 22dexterisNo ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- l011663 Hmi PLC Hp043 20dt User ManualDocument56 pagesl011663 Hmi PLC Hp043 20dt User ManualAcisac Autocontrol100% (1)

- Material Submission RebarprimerRevApdfDocument9 pagesMaterial Submission RebarprimerRevApdfAndrew LeeNo ratings yet

- MC-DUR 111 Eco: Water-Based, Epoxy Resin DispersionDocument2 pagesMC-DUR 111 Eco: Water-Based, Epoxy Resin DispersionParinex SRLNo ratings yet

- Interzinc 2265: Product DescriptionDocument4 pagesInterzinc 2265: Product DescriptionIsabelo AbaoNo ratings yet

- Interzinc 22: Inorganic Zinc-Rich SilicateDocument4 pagesInterzinc 22: Inorganic Zinc-Rich SilicateKristi FoxNo ratings yet

- X-Therm PU40 Foam: Technical Data SheetDocument2 pagesX-Therm PU40 Foam: Technical Data SheetAmr RagabNo ratings yet

- Instruction Manual: 5COR469100 - BR25AT - REV00Document8 pagesInstruction Manual: 5COR469100 - BR25AT - REV00Javier SalaNo ratings yet

- Polyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinDocument2 pagesPolyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinVaittianathan MahavapillaiNo ratings yet

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven PatleNo ratings yet

- Interline 921+ds+eng PDFDocument4 pagesInterline 921+ds+eng PDFMohamed NouzerNo ratings yet

- K2 User Manual 1509Document39 pagesK2 User Manual 1509Ghofur Al MusthofaNo ratings yet

- MS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Document7 pagesMS 213 Method Statement For The Chlorination of Drinking Water Network Area 01 Package 5Dipak VaghelaNo ratings yet

- Centrament VMA 2: Viscosity Modifying AgentDocument2 pagesCentrament VMA 2: Viscosity Modifying AgentvmoderahNo ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- Interfine 691: Isocyanate-Free FinishDocument4 pagesInterfine 691: Isocyanate-Free FinishTrịnh Minh KhoaNo ratings yet

- Ob2 mc161 High Solids Urethane Clear 04 15Document3 pagesOb2 mc161 High Solids Urethane Clear 04 15Jerry ForalNo ratings yet

- Offshore Painting Cycle C5M - HDocument13 pagesOffshore Painting Cycle C5M - HhohnzimhlnrftumftrNo ratings yet

- Sabic® Ppcompound 31T1010: PP Compound Mineral FilledDocument2 pagesSabic® Ppcompound 31T1010: PP Compound Mineral Filledmohamed sabryNo ratings yet

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDocument4 pagesIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009No ratings yet

- Mos Pu Foam CompleteDocument4 pagesMos Pu Foam Completeyusnan yazidNo ratings yet

- TDS MasterRheobuild 2000 PF PDFDocument3 pagesTDS MasterRheobuild 2000 PF PDFRogerNo ratings yet

- BA WNB English D10329Document20 pagesBA WNB English D10329Abi SuryonoNo ratings yet

- Mc-Dur 1077 FGDocument2 pagesMc-Dur 1077 FGTibelu'No ratings yet

- Celcote 242Document4 pagesCelcote 242Anwar MdNo ratings yet

- Qu Ick C BS Ys Te M 1: Mapequick CBS System 1Document2 pagesQu Ick C BS Ys Te M 1: Mapequick CBS System 1Radu JuneNo ratings yet

- 697 UkDocument4 pages697 UkAhmed IbrahimNo ratings yet

- TDS PDF Intercept - 7000Document4 pagesTDS PDF Intercept - 7000PastiDjadi PastiDjadiNo ratings yet

- Manuals W WAT3667 ADocument5 pagesManuals W WAT3667 AYacine BenchikhNo ratings yet

- Bauder LiquiFINISH Product Data SheetDocument2 pagesBauder LiquiFINISH Product Data Sheetshivarajs12340987No ratings yet

- Ceilcote 2000 FlakelineDocument4 pagesCeilcote 2000 FlakelineAhmet GözübüyükNo ratings yet

- 22009-Mar-Cv-080 (Epoxy Resing Based Sealant)Document17 pages22009-Mar-Cv-080 (Epoxy Resing Based Sealant)ADNAN ZIADNo ratings yet

- Sikasil® IG-25 HM Plus: Product Data SheetDocument2 pagesSikasil® IG-25 HM Plus: Product Data SheetKhin Sandi KoNo ratings yet

- 03.MasterRoc MP 755 TDS ENDocument2 pages03.MasterRoc MP 755 TDS ENVandi SetiawanNo ratings yet

- Masterroc MP 355 TdsDocument2 pagesMasterroc MP 355 TdsShesh ManiNo ratings yet

- Contite Slab Lift: Description Mix Ratio ApplicationDocument2 pagesContite Slab Lift: Description Mix Ratio ApplicationRahmat DwiNo ratings yet

- CIPP Liner Systems GAADocument2 pagesCIPP Liner Systems GAASlagalicaSlagalicaNo ratings yet

- Product Manual: Bracton Sub Zero Glycol ChillerDocument5 pagesProduct Manual: Bracton Sub Zero Glycol ChillerCezar BarretoNo ratings yet

- Water Valve Update On Wheeled Loaders JCBDocument2 pagesWater Valve Update On Wheeled Loaders JCBJunaid RehmanNo ratings yet

- Mc-Dur 111 D en en TDSDocument2 pagesMc-Dur 111 D en en TDSEvgeny ZakharinNo ratings yet

- Pentaline 2000 F17Document4 pagesPentaline 2000 F17Vineet KhanduriNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinNo ratings yet

- CVP 2200A Manual E09Document17 pagesCVP 2200A Manual E09minhNo ratings yet

- Injection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Document3 pagesInjection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Abdou BidaouiNo ratings yet

- Ceilcote - 2000 InternationalDocument4 pagesCeilcote - 2000 InternationalAjay RanganathanNo ratings yet

- Painting Procedure (Repainting Flow Indicator)Document6 pagesPainting Procedure (Repainting Flow Indicator)nds setyawanNo ratings yet

- Scope of WorkDocument31 pagesScope of WorkChandrakant BagulNo ratings yet

- ENVPEP1412003Document5 pagesENVPEP1412003south adventureNo ratings yet

- ICT GTsTanda &bongaigaon-1Document24 pagesICT GTsTanda &bongaigaon-1Darwin AlphonseNo ratings yet

- Colusal MK: Mineral Corrosion Protection CoatDocument2 pagesColusal MK: Mineral Corrosion Protection CoatHeru PrasetyoNo ratings yet

- MC-Entöler: Cleaning Agent For Oil ContaminationDocument2 pagesMC-Entöler: Cleaning Agent For Oil ContaminationhemantrulzNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Structural EngineeringDocument15 pagesStructural EngineeringSurender Reddy100% (1)

- Physics ProjectDocument8 pagesPhysics ProjectIVAN TIONG WEI JUN MoeNo ratings yet

- Kerto Manual LVL Mechanical PropertiesDocument6 pagesKerto Manual LVL Mechanical PropertiesTiago GonçalvesNo ratings yet

- Dr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaDocument23 pagesDr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaMaheenNo ratings yet

- 1BO16CSE05Document37 pages1BO16CSE05Dinesh GowdaNo ratings yet

- Sewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDocument1 pageSewer & Drainage Layout Sewer & Drainage Layout: Franklin M. CaleDanica Mae AmicayNo ratings yet

- Comp SteelsDocument8 pagesComp Steelskgupta27No ratings yet

- 804-Hermetic Refrigeration System Training Program - 5 FaultsDocument2 pages804-Hermetic Refrigeration System Training Program - 5 FaultsDaud Simon ANo ratings yet

- Is.7634.2.2012 0Document26 pagesIs.7634.2.2012 0Jagadeesh PuppalaNo ratings yet

- ds83001 Repair Materials For Glasteel Nucerite EquipmentDocument2 pagesds83001 Repair Materials For Glasteel Nucerite EquipmentGerman Tonino LópezNo ratings yet

- Mercet BoilerDocument7 pagesMercet BoilerDafiMaboNo ratings yet

- Factored Reaction (W) Factored Tensile Force On The Plate W/2Document9 pagesFactored Reaction (W) Factored Tensile Force On The Plate W/2Sudhanshu Shekhar SinglaNo ratings yet

- ADocument22 pagesAAntonio LoretoCortesNo ratings yet

- Conveyor Design PDFDocument73 pagesConveyor Design PDFRamesh Subramani RamachandranNo ratings yet

- Mini Project Brief For Steel Design & Cad - AY2023 - 2024Document8 pagesMini Project Brief For Steel Design & Cad - AY2023 - 2024krugan652No ratings yet

- Cold Box Resin: Ceracold RDocument3 pagesCold Box Resin: Ceracold RskNo ratings yet

- Case Study A2bDocument16 pagesCase Study A2bvasNo ratings yet

- Preventive MaintenanceDocument3 pagesPreventive MaintenanceTrilok Singh TakuliNo ratings yet

- NJ Brochure-2Document3 pagesNJ Brochure-2JhishnuNo ratings yet

- Material Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/MDocument5 pagesMaterial Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/Mjmarkunongo_69397286No ratings yet

- AnchorDocument5 pagesAnchorpadalakirankumarNo ratings yet

- Tds 1323203 enDocument2 pagesTds 1323203 enMartín BaezaNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlDocument6 pagesEurope Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlOsvaldo Meza100% (1)

- Aisc - Open Deck Parking SolutionsDocument29 pagesAisc - Open Deck Parking Solutionscalaud67% (3)

- 16Mncr5: Quality 16Mncr5 Case Hardening SteelDocument2 pages16Mncr5: Quality 16Mncr5 Case Hardening SteelShubhangi ShindeNo ratings yet