Professional Documents

Culture Documents

Overhaul: 1. Remove Starter Yoke Assy

Overhaul: 1. Remove Starter Yoke Assy

Uploaded by

Islam AttiaCopyright:

Available Formats

You might also like

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn Martin100% (1)

- Eaton Orbital Motors SteeringDocument20 pagesEaton Orbital Motors SteeringIslam Attia0% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Overhaul: Manual Transmission/TransaxleDocument9 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitIslam AttiaNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Magnetic Switch AssyDocument6 pagesOverhaul: 1. Remove Magnetic Switch AssyichamoNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitKolela DjibrilNo ratings yet

- StarterDocument16 pagesStarterswap2gzNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- ដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យDocument9 pagesដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យSopharith YimNo ratings yet

- Generator: Removal of Generator (4A-Fe)Document20 pagesGenerator: Removal of Generator (4A-Fe)henysNo ratings yet

- 13 - Starting TOYOTA PDFDocument19 pages13 - Starting TOYOTA PDFAngello Esquerre RojasNo ratings yet

- Overhaul: Manual Transmission/TransaxleDocument10 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- ST 6Document2 pagesST 6Mega VentasNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- InspectionDocument2 pagesInspectionRacing GarageNo ratings yet

- Automatic Transaxle2 PDFDocument11 pagesAutomatic Transaxle2 PDFluisNo ratings yet

- 19 - Starting Hal 1-12Document12 pages19 - Starting Hal 1-12Fahmi NurinNo ratings yet

- Removal: Torx Screw Screw CaseDocument2 pagesRemoval: Torx Screw Screw CasejuanNo ratings yet

- 19 - Starting and Charging PDFDocument22 pages19 - Starting and Charging PDFJen-Yung ChangNo ratings yet

- Automatic Transmission & TransDocument50 pagesAutomatic Transmission & TransminaryNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Removal: Automatic Transmission (A750F)Document5 pagesRemoval: Automatic Transmission (A750F)joe nathanNo ratings yet

- Automatic Transaxle's DisassemblyDocument32 pagesAutomatic Transaxle's Disassemblymohamed A.abdeltwabNo ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotors100% (1)

- Main Shaft AssemblyDocument6 pagesMain Shaft AssemblyFrancis MartinezNo ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- Cylinder Block (1Az-Fe) : OverhaulDocument17 pagesCylinder Block (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Front Strut: A: RemovalDocument4 pagesFront Strut: A: RemovalmiguelNo ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- TestDocument2 pagesTestsalusfrankNo ratings yet

- 40-09 Park Neutral Position Switch Assy (Atm) AdjustmentDocument6 pages40-09 Park Neutral Position Switch Assy (Atm) AdjustmentCelso BidinotiNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- MSA5T0205A11493Document6 pagesMSA5T0205A11493anibalbelltNo ratings yet

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- 5 - Manual Trans Removal PDFDocument3 pages5 - Manual Trans Removal PDFEduardo SantosNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever RHDocument43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever RHBắc HoàngNo ratings yet

- ST 11Document4 pagesST 11Mega VentasNo ratings yet

- Front Wiper and Washer: 2. Headlight RelayDocument4 pagesFront Wiper and Washer: 2. Headlight RelaymiguelNo ratings yet

- Transmission Valve Body Assy (A246E) : ReplacementDocument4 pagesTransmission Valve Body Assy (A246E) : ReplacementJesusNo ratings yet

- Transmission Valve BodyDocument4 pagesTransmission Valve Bodyjeremih alhegnNo ratings yet

- 1GR FE StartingDocument27 pages1GR FE StartingJorge Miguel Couto CabralNo ratings yet

- LC Winch ManualDocument20 pagesLC Winch ManualDNo ratings yet

- Disassembly: Screw ExtractorDocument3 pagesDisassembly: Screw ExtractorMoh DeBrNo ratings yet

- Generator 3Document1 pageGenerator 3Racing GarageNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Telescopic HandlersDocument4 pagesTelescopic HandlersIslam AttiaNo ratings yet

- XCMG 25Document14 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG XC6-3006K - XC6Document11 pagesXCMG XC6-3006K - XC6Islam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- SpecificationsDocument5 pagesSpecificationsIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Technical SpecificationsDocument4 pagesTechnical SpecificationsIslam AttiaNo ratings yet

- XCMG XC6Document4 pagesXCMG XC6Islam AttiaNo ratings yet

- XCMG QUY55 Crawler Crane Operator's ManualDocument88 pagesXCMG QUY55 Crawler Crane Operator's ManualIslam AttiaNo ratings yet

- Bomag BT 60 - 4 Operating Instructions ManualDocument58 pagesBomag BT 60 - 4 Operating Instructions ManualIslam AttiaNo ratings yet

- XCMG XCB-D - DT30-35-40 Diesel Forklifts Technical SpecificationsDocument2 pagesXCMG XCB-D - DT30-35-40 Diesel Forklifts Technical SpecificationsIslam AttiaNo ratings yet

- XCMG RT70E Load ChartDocument24 pagesXCMG RT70E Load ChartIslam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- 3006KDocument4 pages3006KIslam AttiaNo ratings yet

- XCMG SQ10SK3Q Operation and Maintenance ManualDocument36 pagesXCMG SQ10SK3Q Operation and Maintenance ManualIslam Attia0% (1)

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- A-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Document5 pagesA-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- XCMG QUY150 Load ChartDocument8 pagesXCMG QUY150 Load ChartIslam AttiaNo ratings yet

- XCMG QY-12 Electrical Wiringing SchematicDocument6 pagesXCMG QY-12 Electrical Wiringing SchematicIslam AttiaNo ratings yet

- Bomag BMP 8500 Operating and Maintenance ManualDocument128 pagesBomag BMP 8500 Operating and Maintenance ManualIslam AttiaNo ratings yet

- XCMG ZL50GN G-Series Wheel Loader - Outline DimensionDocument6 pagesXCMG ZL50GN G-Series Wheel Loader - Outline DimensionIslam AttiaNo ratings yet

- GR05-CD-F479 P.S.C.C.H.Co Comm.15.13Document11 pagesGR05-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- Bomag BW 900-2 Operators and Maintenance ManualDocument72 pagesBomag BW 900-2 Operators and Maintenance ManualIslam Attia100% (1)

- GR01-CD-F479 P.S.C.C.H.Co Comm.15.13Document33 pagesGR01-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- APC200 ECM-ECI Error Codes Ver1.8 Feb 2008Document13 pagesAPC200 ECM-ECI Error Codes Ver1.8 Feb 2008Islam AttiaNo ratings yet

- DT Service PartsDocument4 pagesDT Service PartsCentral HydraulicsNo ratings yet

- SPC Platina 100ES KS REV02 UG JUNE 16Document69 pagesSPC Platina 100ES KS REV02 UG JUNE 16Sahadev PatraNo ratings yet

- Shantui Motor Grader BrochureDocument6 pagesShantui Motor Grader BrochureMamankz TheaNo ratings yet

- Allis Chalmers 710c 714c 715c Loader Backhoe Parts CatalogDocument20 pagesAllis Chalmers 710c 714c 715c Loader Backhoe Parts CatalogRichard100% (54)

- Block Del MotorDocument11 pagesBlock Del MotorLuwīsi Karikamo RomaniNo ratings yet

- Lista de Partes Cover de Entrada AD5 232540799 - en PDFDocument3 pagesLista de Partes Cover de Entrada AD5 232540799 - en PDFAndres Sanchez100% (1)

- Listado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020Document6 pagesListado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020edwin cuellarNo ratings yet

- Our Remanufacturing ProcessDocument3 pagesOur Remanufacturing Processapi-519135325No ratings yet

- Joywell TRANSMISSION BDocument59 pagesJoywell TRANSMISSION BЕкатерина КалашниковаNo ratings yet

- Kymco People S - Parts List ManualDocument118 pagesKymco People S - Parts List ManualAmoema MasterBcnNo ratings yet

- Screw JackDocument14 pagesScrew JackSadeesh ManujaNo ratings yet

- Lecture 17 Shaft Loading PDFDocument26 pagesLecture 17 Shaft Loading PDFAndrew Tan100% (1)

- 3-3.5T R Parts ListDocument590 pages3-3.5T R Parts Listcastillodelvalle240No ratings yet

- Spare Parts CatalogueDocument563 pagesSpare Parts CatalogueRoberto Juniior Mendoza DiazNo ratings yet

- Difference Between Two Stroke and Four Stroke EngineDocument6 pagesDifference Between Two Stroke and Four Stroke Enginesharma5544No ratings yet

- 75up PDFDocument64 pages75up PDFHenryMonteagudoParedesNo ratings yet

- 1 Epicyclic Gear Train ExperimentDocument6 pages1 Epicyclic Gear Train Experimentshuyun88100% (6)

- Track-Type Tractor - d11r (Tractor Oruga)Document24 pagesTrack-Type Tractor - d11r (Tractor Oruga)Christian Kari100% (2)

- Advantages of 4 Stroke Engine:-: DifferencesDocument3 pagesAdvantages of 4 Stroke Engine:-: DifferencescidracNo ratings yet

- DongfengDocument82 pagesDongfengtahutempebullatNo ratings yet

- Design of Machine Elements 2Document8 pagesDesign of Machine Elements 2Sameer WaliaNo ratings yet

- Manual de Partes - Pulsar 135 LSDocument74 pagesManual de Partes - Pulsar 135 LSJhony Jheferson Lopez PizarroNo ratings yet

- Fabia Gearbox 0A8Document118 pagesFabia Gearbox 0A8adrianionescu4u100% (1)

- 35382Document59 pages35382esharp016257No ratings yet

- VXN150 Vixion Crankshaft & Piston PDFDocument2 pagesVXN150 Vixion Crankshaft & Piston PDFHarris Jum'anianda100% (1)

- VS1400Document2 pagesVS1400timingtoolNo ratings yet

- Flat Rate - Kukje Engine T474 - T494 - T574Document68 pagesFlat Rate - Kukje Engine T474 - T494 - T574pbatista94No ratings yet

- Nautac Open 11 ChassisDocument14 pagesNautac Open 11 ChassisStephane DococheNo ratings yet

- Final Part List CGR1213Document12 pagesFinal Part List CGR1213kkmechNo ratings yet

- Cylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesDocument12 pagesCylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesdiansulaemanNo ratings yet

Overhaul: 1. Remove Starter Yoke Assy

Overhaul: 1. Remove Starter Yoke Assy

Uploaded by

Islam AttiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overhaul: 1. Remove Starter Yoke Assy

Overhaul: 1. Remove Starter Yoke Assy

Uploaded by

Islam AttiaCopyright:

Available Formats

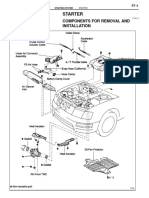

19−9

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

190L5−01

OVERHAUL

1. REMOVE STARTER YOKE ASSY

(a) Remove the nut, and disconnect the lead wire from the C

terminal.

(b) Remove the 2 through bolts.

(c) Pull out the starter yoke with the armature.

(d) Remove the O−ring from the starter yoke.

A74096

2. REMOVE MAGNET STARTER SWITCH ASSY

(a) Remove the 2 screws and magnet starter switch.

A74097

(b) Remove these parts from the starter drive housing.

(1) Starter magnet switch return spring

(2) Starter idle gear pinion

(3) Starter idle gear clutch roller

(4) (2)

(3) (4) Starter idle gear retainer

(1) (5) Starter clutch

(5) A62427

(c) Using a magnetic finger, remove the steel ball from the

Magnetic Finger clutch shaft hole.

3. REMOVE STARTER BRUSH HOLDER ASSY

ST0948

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−10

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

(a) Remove the 2 screws and end cover from the starter

yoke.

(b) Remove the O−ring from the starter yoke.

A62428

(c) Using a screwdriver, hold the spring back and disconnect

the 4 brushes from the brush holder.

(d) Remove the brush holder from the armature.

A62429

4. REMOVE STARTER ARMATURE ASSY

5. INSPECT STARTER ARMATURE ASSY

Continuity

(a) Check the commutator for open circuit.

(1) Using an ohmmeter, check that there is continuity

between the segments of the commutator.

If there is no continuity between any segment, replace the ar-

mature.

P10584

(b) Check the commutator for ground.

(1) Using an ohmmeter, check that there is no continu-

No Continuity

ity between the commutator and armature coil core.

If there is continuity, replace the armature.

(c) Check the commutator for dirty and burn on surface.

If the surface is dirty or burnt, correct it with sandpaper (No.400)

or a lathe.

P10585

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−11

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

(d) Check for the commutator circle runout.

(1) Place the commutator on V−blocks.

(2) Using a dial gauge, measure the circle runout.

Maximum circle runout: 0.05 mm(0.0020 in.)

If the circle runout is greater than maximum, correct it on a lathe.

P10586

(e) Using vernier calipers, measure the commutator diame-

ter.

Standard diameter: 35.0 mm (1.378 in.)

Minimum diameter: 34.0 mm (1.339 in.)

If the diameter is less than minimum, replace the armature.

P10587

(f) Check that the undercut depth is clean and free of foreign

materials. Smooth out the edge.

Standard undercut depth: 0.7 mm (0.028 in.)

Minimum undercut depth: 0.2 mm (0.008 in.)

If the undercut depth is less than minimum, correct it with a

hacksaw blade.

ST0040

6. INSPECT STARTER YOKE ASSY

Continuity (a) Check the starter yoke for open circuit.

(1) Using an ohmmeter, check that there is continuity

between the lead wire and brushes.

If there is no continuity, replace the starter yoke.

P10588

(b) Check the shunt coil for open circuit.

(1) Using an ohmmeter, measure the resistance be-

tween shunt coil terminals (A) and (B).

(A)

(B) Resistance: 1.5 − 1.9 W at 20_C (68_F)

If the resistance is not as specified, replace the starter yoke.

A76125

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−12

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

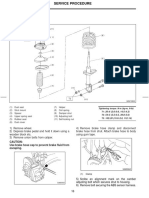

Brush Holder Side 7. INSPECT BRUSH

(a) Check the brushes length

(1) Using vernier calipers, measure the brush length.

Standard length: 15.0 mm (0.591 in.)

Minimum length: 9.0 mm (0.354 in.)

If the length is less than minimum, replace the brush holder and

starter yoke.

Length

Starter Yoke Side

Length

A62430

8. INSPECT STARTER BRUSH HOLDER ASSY

(a) Check the blush holder insulation

(1) Using an ohmmeter, check that there is no continu-

ity between the positive (+) and negative (−) brush

holders.

If there is continuity, repair or replace the brush holder.

No continuity

A66735

(b) Check the brush spring load.

(1) Take the pull scale reading the instant the brush

spring separates from the brush.

Standard spring load:

21.5 − 27.5 N (2.2 − 2.8 kgf, 4.8 − 6.2 lbf)

Minimum spring load: 12.7 N (1.3 kgf, 2.9 lbf)

If the spring load is less than the minimum, replace the brush

holder.

ST0019

9. INSPECT STARTER CLUTCH SUB−ASSY

Free (a) Check the clutch pinion gear.

(1) Hold the starter clutch and rotate the pinion gear

clockwise, and check that it turns freely.

Lock

(2) Try to rotate the pinion gear counterclockwise and

check that it locks.

If necessary, replace the starter clutch.

P10821

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−13

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

10. INSPECT MAGNET STARTER SWITCH ASSY

(a) Check the pull−in coil for open circuit.

Terminal C (1) Using an ohmmeter, check that there is continuity

between terminals 50 and C.

Terminal 50 If there is no continuity, replace the magnet starter switch.

A76119

(b) Check the holding coil for open circuit.

(1) Using an ohmmeter, check that there is continuity

between terminal 50 and the switch body.

If there is no continuity, replace the magnet starter switch.

Terminal 50

A76120

11. INSTALL STARTER ARMATURE ASSY

(a) Apply grease to the bearings, and install it to the starter yoke.

12. INSTALL STARTER BRUSH HOLDER ASSY

(a) Place the brush holder on the armature.

(b) Using a screwdriver, install the 4 brushes.

(c) Install a new O−ring to the groove of the field frame.

A62429

(d) Install the end frame with the 2 screws.

Torque: 3.8 N×m (39 kgf×cm, 34 in.×lbf)

13. INSTALL MAGNET STARTER SWITCH ASSY

(a) Apply grease to the steel ball, and install it to the clutch

shaft hole.

A62428

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

19−14

STARTING & CHARGING − STARTER ASSY(2.0KW) (1GR−FE)

(b) Apply grease to the these parts (2) − (5), and its to the

starter drive housing.

(1) Starter magnet switch return spring

(2) Starter idle gear pinion

(4) (2)

(3) (3) Starter idle gear clutch roller

(1) (4) Starter idle gear retainer

(5) Starter clutch

(5) A62427

(c) Install the magnet starter switch with the 2 screws.

Torque: 9.3 N×m (95 kgf×cm, 82 in.×lbf)

14. INSTALL STARTER YOKE ASSY

(a) Install a new O−ring to the groove of the starter yoke.

A74097

(b) Align the protrusion of the starter yoke with the groove of

the magnet starter switch.

A76121

(c) Install the starter yoke and armature with the 2 through

bolts.

Torque: 9.3 N×m (95 kgf×cm, 82 in.×lbf)

(d) Connect the lead wire to the C terminal with the nut.

Torque: 5.9 N×m (60 kgf×cm, 52 in.×lbf)

A74096

1GR−FE ENGINE REPAIR MANUAL (RM1005E)

You might also like

- Sienna Timing Belt ReplacementDocument8 pagesSienna Timing Belt ReplacementGlenn Martin100% (1)

- Eaton Orbital Motors SteeringDocument20 pagesEaton Orbital Motors SteeringIslam Attia0% (1)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulDocument26 pagesPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Overhaul: Manual Transmission/TransaxleDocument9 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezNo ratings yet

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Starter Assy (1.2Kw) (1Az-Fe) : OverhaulDocument8 pagesStarter Assy (1.2Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocument6 pagesStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitIslam AttiaNo ratings yet

- Generator Assy (1Az-Fe) : OverhaulDocument5 pagesGenerator Assy (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Overhaul: 1. Remove Magnetic Switch AssyDocument6 pagesOverhaul: 1. Remove Magnetic Switch AssyichamoNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitKolela DjibrilNo ratings yet

- StarterDocument16 pagesStarterswap2gzNo ratings yet

- Overhaul: 1. Remove Generator Rear End CoverDocument5 pagesOverhaul: 1. Remove Generator Rear End CoverHenry SilvaNo ratings yet

- ដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យDocument9 pagesដេម៉ារ័រប្រភេទពីញ៉ុងប្លាណេទៃ 1MZ FE ដោះបំបែកនិងត្រួតពិនិត្យSopharith YimNo ratings yet

- Generator: Removal of Generator (4A-Fe)Document20 pagesGenerator: Removal of Generator (4A-Fe)henysNo ratings yet

- 13 - Starting TOYOTA PDFDocument19 pages13 - Starting TOYOTA PDFAngello Esquerre RojasNo ratings yet

- Overhaul: Manual Transmission/TransaxleDocument10 pagesOverhaul: Manual Transmission/TransaxleMax K.No ratings yet

- ST 6Document2 pagesST 6Mega VentasNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- InspectionDocument2 pagesInspectionRacing GarageNo ratings yet

- Automatic Transaxle2 PDFDocument11 pagesAutomatic Transaxle2 PDFluisNo ratings yet

- 19 - Starting Hal 1-12Document12 pages19 - Starting Hal 1-12Fahmi NurinNo ratings yet

- Removal: Torx Screw Screw CaseDocument2 pagesRemoval: Torx Screw Screw CasejuanNo ratings yet

- 19 - Starting and Charging PDFDocument22 pages19 - Starting and Charging PDFJen-Yung ChangNo ratings yet

- Automatic Transmission & TransDocument50 pagesAutomatic Transmission & TransminaryNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Removal: Automatic Transmission (A750F)Document5 pagesRemoval: Automatic Transmission (A750F)joe nathanNo ratings yet

- Automatic Transaxle's DisassemblyDocument32 pagesAutomatic Transaxle's Disassemblymohamed A.abdeltwabNo ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Valve Clearance: InspectionDocument5 pagesValve Clearance: InspectionПежов СитроенNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotors100% (1)

- Main Shaft AssemblyDocument6 pagesMain Shaft AssemblyFrancis MartinezNo ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- Cylinder Block (1Az-Fe) : OverhaulDocument17 pagesCylinder Block (1Az-Fe) : OverhaulHenry SilvaNo ratings yet

- Front Strut: A: RemovalDocument4 pagesFront Strut: A: RemovalmiguelNo ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- TestDocument2 pagesTestsalusfrankNo ratings yet

- 40-09 Park Neutral Position Switch Assy (Atm) AdjustmentDocument6 pages40-09 Park Neutral Position Switch Assy (Atm) AdjustmentCelso BidinotiNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument17 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceHenry SilvaNo ratings yet

- MSA5T0205A11493Document6 pagesMSA5T0205A11493anibalbelltNo ratings yet

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument17 pagesOverhaul: 1. Remove Valve LifterIslam AttiaNo ratings yet

- 5 - Manual Trans Removal PDFDocument3 pages5 - Manual Trans Removal PDFEduardo SantosNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever RHDocument43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever RHBắc HoàngNo ratings yet

- ST 11Document4 pagesST 11Mega VentasNo ratings yet

- Front Wiper and Washer: 2. Headlight RelayDocument4 pagesFront Wiper and Washer: 2. Headlight RelaymiguelNo ratings yet

- Transmission Valve Body Assy (A246E) : ReplacementDocument4 pagesTransmission Valve Body Assy (A246E) : ReplacementJesusNo ratings yet

- Transmission Valve BodyDocument4 pagesTransmission Valve Bodyjeremih alhegnNo ratings yet

- 1GR FE StartingDocument27 pages1GR FE StartingJorge Miguel Couto CabralNo ratings yet

- LC Winch ManualDocument20 pagesLC Winch ManualDNo ratings yet

- Disassembly: Screw ExtractorDocument3 pagesDisassembly: Screw ExtractorMoh DeBrNo ratings yet

- Generator 3Document1 pageGenerator 3Racing GarageNo ratings yet

- Platz 02Document7 pagesPlatz 02dawitmesfin9No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- XCMG Iflex5 Operators ManualDocument44 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Telescopic HandlersDocument4 pagesTelescopic HandlersIslam AttiaNo ratings yet

- XCMG 25Document14 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- XCMG XC6-3006K - XC6Document11 pagesXCMG XC6-3006K - XC6Islam AttiaNo ratings yet

- XCMG 25Document7 pagesXCMG 25Islam AttiaNo ratings yet

- SpecificationsDocument5 pagesSpecificationsIslam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Technical SpecificationsDocument4 pagesTechnical SpecificationsIslam AttiaNo ratings yet

- XCMG XC6Document4 pagesXCMG XC6Islam AttiaNo ratings yet

- XCMG QUY55 Crawler Crane Operator's ManualDocument88 pagesXCMG QUY55 Crawler Crane Operator's ManualIslam AttiaNo ratings yet

- Bomag BT 60 - 4 Operating Instructions ManualDocument58 pagesBomag BT 60 - 4 Operating Instructions ManualIslam AttiaNo ratings yet

- XCMG XCB-D - DT30-35-40 Diesel Forklifts Technical SpecificationsDocument2 pagesXCMG XCB-D - DT30-35-40 Diesel Forklifts Technical SpecificationsIslam AttiaNo ratings yet

- XCMG RT70E Load ChartDocument24 pagesXCMG RT70E Load ChartIslam AttiaNo ratings yet

- XCMG Forklifts Technical ManualsDocument16 pagesXCMG Forklifts Technical ManualsIslam AttiaNo ratings yet

- 3006KDocument4 pages3006KIslam AttiaNo ratings yet

- XCMG SQ10SK3Q Operation and Maintenance ManualDocument36 pagesXCMG SQ10SK3Q Operation and Maintenance ManualIslam Attia0% (1)

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- XCMG Iflex5 Operators ManualDocument42 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- A-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Document5 pagesA-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- XCMG QUY150 Load ChartDocument8 pagesXCMG QUY150 Load ChartIslam AttiaNo ratings yet

- XCMG QY-12 Electrical Wiringing SchematicDocument6 pagesXCMG QY-12 Electrical Wiringing SchematicIslam AttiaNo ratings yet

- Bomag BMP 8500 Operating and Maintenance ManualDocument128 pagesBomag BMP 8500 Operating and Maintenance ManualIslam AttiaNo ratings yet

- XCMG ZL50GN G-Series Wheel Loader - Outline DimensionDocument6 pagesXCMG ZL50GN G-Series Wheel Loader - Outline DimensionIslam AttiaNo ratings yet

- GR05-CD-F479 P.S.C.C.H.Co Comm.15.13Document11 pagesGR05-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- Bomag BW 900-2 Operators and Maintenance ManualDocument72 pagesBomag BW 900-2 Operators and Maintenance ManualIslam Attia100% (1)

- GR01-CD-F479 P.S.C.C.H.Co Comm.15.13Document33 pagesGR01-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- APC200 ECM-ECI Error Codes Ver1.8 Feb 2008Document13 pagesAPC200 ECM-ECI Error Codes Ver1.8 Feb 2008Islam AttiaNo ratings yet

- DT Service PartsDocument4 pagesDT Service PartsCentral HydraulicsNo ratings yet

- SPC Platina 100ES KS REV02 UG JUNE 16Document69 pagesSPC Platina 100ES KS REV02 UG JUNE 16Sahadev PatraNo ratings yet

- Shantui Motor Grader BrochureDocument6 pagesShantui Motor Grader BrochureMamankz TheaNo ratings yet

- Allis Chalmers 710c 714c 715c Loader Backhoe Parts CatalogDocument20 pagesAllis Chalmers 710c 714c 715c Loader Backhoe Parts CatalogRichard100% (54)

- Block Del MotorDocument11 pagesBlock Del MotorLuwīsi Karikamo RomaniNo ratings yet

- Lista de Partes Cover de Entrada AD5 232540799 - en PDFDocument3 pagesLista de Partes Cover de Entrada AD5 232540799 - en PDFAndres Sanchez100% (1)

- Listado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020Document6 pagesListado de Materiales Disciplina Electrica Cybe 4 Nuevos Pozos 03-11-2020edwin cuellarNo ratings yet

- Our Remanufacturing ProcessDocument3 pagesOur Remanufacturing Processapi-519135325No ratings yet

- Joywell TRANSMISSION BDocument59 pagesJoywell TRANSMISSION BЕкатерина КалашниковаNo ratings yet

- Kymco People S - Parts List ManualDocument118 pagesKymco People S - Parts List ManualAmoema MasterBcnNo ratings yet

- Screw JackDocument14 pagesScrew JackSadeesh ManujaNo ratings yet

- Lecture 17 Shaft Loading PDFDocument26 pagesLecture 17 Shaft Loading PDFAndrew Tan100% (1)

- 3-3.5T R Parts ListDocument590 pages3-3.5T R Parts Listcastillodelvalle240No ratings yet

- Spare Parts CatalogueDocument563 pagesSpare Parts CatalogueRoberto Juniior Mendoza DiazNo ratings yet

- Difference Between Two Stroke and Four Stroke EngineDocument6 pagesDifference Between Two Stroke and Four Stroke Enginesharma5544No ratings yet

- 75up PDFDocument64 pages75up PDFHenryMonteagudoParedesNo ratings yet

- 1 Epicyclic Gear Train ExperimentDocument6 pages1 Epicyclic Gear Train Experimentshuyun88100% (6)

- Track-Type Tractor - d11r (Tractor Oruga)Document24 pagesTrack-Type Tractor - d11r (Tractor Oruga)Christian Kari100% (2)

- Advantages of 4 Stroke Engine:-: DifferencesDocument3 pagesAdvantages of 4 Stroke Engine:-: DifferencescidracNo ratings yet

- DongfengDocument82 pagesDongfengtahutempebullatNo ratings yet

- Design of Machine Elements 2Document8 pagesDesign of Machine Elements 2Sameer WaliaNo ratings yet

- Manual de Partes - Pulsar 135 LSDocument74 pagesManual de Partes - Pulsar 135 LSJhony Jheferson Lopez PizarroNo ratings yet

- Fabia Gearbox 0A8Document118 pagesFabia Gearbox 0A8adrianionescu4u100% (1)

- 35382Document59 pages35382esharp016257No ratings yet

- VXN150 Vixion Crankshaft & Piston PDFDocument2 pagesVXN150 Vixion Crankshaft & Piston PDFHarris Jum'anianda100% (1)

- VS1400Document2 pagesVS1400timingtoolNo ratings yet

- Flat Rate - Kukje Engine T474 - T494 - T574Document68 pagesFlat Rate - Kukje Engine T474 - T494 - T574pbatista94No ratings yet

- Nautac Open 11 ChassisDocument14 pagesNautac Open 11 ChassisStephane DococheNo ratings yet

- Final Part List CGR1213Document12 pagesFinal Part List CGR1213kkmechNo ratings yet

- Cylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesDocument12 pagesCylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesdiansulaemanNo ratings yet