Professional Documents

Culture Documents

AL6562

AL6562

Uploaded by

sergioviriliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AL6562

AL6562

Uploaded by

sergioviriliCopyright:

Available Formats

AL6562

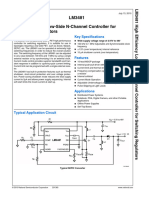

Transition Mode PFC LED Controller

Description Features

The AL6562 is a current mode Power Factor Correction Controller and Single Stage Fly-Back PFC Controller

is designed for operating in Transition Mode. With a superior linear Transition Mode Operation

performance multiplier, it ensures the device operates over a wide Low Start-Up, Operating and Quiescent Currents

input voltage range with superior THD (Total Harmonics Distortion). Internal Start-Up Timer

The output voltage is controlled by means of an error amplifier and a Enable/Disable Function on INV Input

precise (1% @ TJ = +25°C) internal voltage reference. Totem Pole, Push-Pull Output Drive

Adjustable Output Overvoltage Protection

The AL6562 is designed to meet stringent energy-saving standards

NEW PRODUCT

SO-8 : Available in “Green” Molding Compound (No Br, Sb)

with low start-up current, and can operate with low current

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

consumption when entering stand-by mode.

Halogen and Antimony Free. “Green” Device (Note 3)

OVP circuitry increases system robustness, allowing the device to

withstand transient caused at start-up and during load-disconnects.

Pin Assignments Applications

Electronic Single-Stage LED Driver

PFC Pre-Regulators to meet IEC61000-3-2

(Top View) High-End AC-DC Adaptor / Charger

INV 1 8 Vcc

COMP 2 AL656 2 7 GD

MULT 3 6 GND

CS 4 5 ZCD

SO-8

(SO-8/ M Package)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free,

"Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

Typical Applications Circuit

Figure 1 High Power Factor Non-Isolated Constant-Current LED Driver

AL6562 1 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Pin Descriptions

Pin Number Pin Name Brief Description

Inverting Input Pin of the Internal Error Amplifier

This pin is connected externally via a resistor divider from the regulated output voltage. It can provide

1 INV

input to inverting input of internal error amplifier. This pin can also be used as ENABLE/DISABLE

control input.

Output from Error Amplifier

A feedback compensation network consisting of resistor and capacitor connects between INV (Pin1)

2 COMP

and this pin to reduce the bandwidth and achieve stability of the voltage control loop and ensure high

power factor and low THD.

Input to the Internal Multiplier

3 MULT This pin connects to the rectified mains voltage through external resistor divider to provide a sinusoidal

NEW PRODUCT

voltage reference for the control current loop.

Current Sense Connecting to External Resistor for Current Feedback

The current flowing in the MOSFET is sensed through a resistor, the resulting voltage is applied to this

4 CS pin and compared with an internal sinusoidal-shaped reference generated by the multiplier to determine

MOSFET’s turn-off. This pin has an internal Leading-Edge-Blanking of about 200 nanoseconds to

improve noise immunity.

Zero Current Detection

5 ZCD This pin takes input from inductor’s demagnetization sensing to achieve zero current detection, required

for Transition Mode (TM) operation. A negative-going edge triggers turn-on of MOSFET.

System Ground

6 GND

Ground for circuit. Current return for both the signal circuitry and the gate drive stage.

Gate Driver Output

This pin is able to drive external MOSFET. The totem-pole output stage is able to drive MOSFET with a

7 GD peak current of 600mA/800mA for source and sink capability respectively. The high level voltage of this

pin is internally clamped at about 12V to avoid excessive gate voltage in case V CC pin is supplied by a

higher voltage.

System Power Input Pin

This pin is for supply voltage of both the signal part and gate driver of the IC. Upper limit is extended to

8 VCC

a maximum of 22V to provide more headroom for supply voltage changes. This pin has an internal 25V

Zener to protect the IC itself from overvoltage transients.

Functional Block Diagram

COMP MULT CS

2 3 4

1

INV

Multiplier 40K

INV_Disable

Overvoltage

1.7V 10 pF

Voltage Detection

0.47 V/0.3V Regulation

VCC

VCC 8

Internal R Q

R1 Supply 7.5V S

24V

UVLO

7

INV_Disable Driver GD

R2 Vref

Zero Current

Detector

2.1V Starter

1.6V

Upper &

ZCD_Disable Lower

Clamp

5 6

ZCD GND

AL6562 2 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Absolute Maximum Ratings (Note 4)

Symbol Description Value Unit

VCC IC Supply Voltage Self Limited V

Icc Operating Supply Current 30 mA

VINV,VCOMP,VMULT Input/Output of Error Amplifier, Input of Multiplier -0.3 to 7 V

Source: -50 mA

IZCD (Note 5) Zero Current Detector Max. Current

Sink: 10 mA

ESD(HBM) ESD (Human Body Model) 3000 V

NEW PRODUCT

ESD(MM) ESD (Machine Model) 200 V

TJ Junction Temperature Range -40 to +150 °C

TSTG Storage Temperature Range -65 to +150 °C

PTOT Power Dissipation 0.65 W

RθJA Thermal Resistance (Junction – Ambient) 150 °C/W

TLEAD Lead Temperature (Soldering, 10 sec) +260 °C

Notes: 4. Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be

affected by exposure to absolute maximum rating conditions for extended periods of time.

5. Currents flowing into device pins are considered as positive and out of device pins are considered as negative.

AL6562 3 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Electrical Characteristics

(Over recommended operating conditions unless otherwise specified VCC = 12.0V, TJ = -25°C to +125°C, CO = 1nF)

Symbol Parameter Conditions Min Typ. Max Units

SUPPLY VOLTAGE

VCC IC Supply Voltage After turn-on 10.3 22 V

VCC ON Turn-On Threshold 11.0 12.0 13.0 V

VCC OFF Turn-Off Threshold 8.7 9.5 10.3 V

VCC-HYS Hysteresis 2.2 2.5 2.8 V

VZ Zener Voltage ICC = 20 mA 22 24 V

NEW PRODUCT

SUPPLY CURRENT

Istart-up Start-Up Current Before turn-on, VCC=11V 40 70 µA

IQ Quiescent Current After turn-on 2.5 3.75 mA

@ 70kHz 3.5 5 mA

ICC Operating Supply Current

mA

In OVP condition, VINV = 2.7V 1.4 2.2

VZCD≤150mV, VCC>VCC-OFF 2.2 mA

IQ Quiescent Current

VZCD≤150mV, VCC<VCC-OFF 20 50 90 mA

ERROR AMPLIFIER

TJ = +25°C 2.465 2.5 2.535

VINV Voltage Feedback Input Threshold V

10.3V < VCC < 22V 2.44 2.56

VCC = 10.3V to 22V

Line Regulation 2 5 mV

(Note 6)

IINV Input Bias Current VINV = 0 to 3V -0.1 -1 µA

GV Voltage Gain OPEN LOOP 60 80 dB

GB Gain-Bandwidth 1 MHz

Source Current VCOMP = 4V, VINV = 2.4V -2 -4.0 -8 mA

ICOMP

Sink Current VCOMP = 4V, VINV = 2.6V 2.5 4.5 mA

Upper Clamp Voltage ISOURCE = 0.5 mA 5.8 V

VCOMP

Lower Clamp Voltage ISINK = 0.5 mA (Note 6) 2.1 2.25 2.4 V

VINVdis Disable Threshold 250 300 350 mV

VINVen Restart Threshold 400 470 540 mV

MULTIPLIER INPUT

VMULT Linear Operation Range 0-3 0 – 3.5 V

VCS VMULT = 0 to 0.5V,

Output Maximum Slope 1.65 1.9 V/V

VMULT VCOMP = upper clamp

K Gain (Note 7) VMULT = 1V,VCOMP = 4V 0.6 0.75 0.9 1/V

ZERO CURRENT DETECTOR

VZCDH Upper Clamp Voltage IZCD = 3mA 4.7 5.2 6.1 V

VZCDL Lower Clamp Voltage IZCD = -3mA 0.3 0.65 1.0 V

VZCDA Arming Voltage Positive-going edge 2.1 V

VZCDT Triggering Voltage Negative-going edge 1.6 V

IZCDb Input Bias Current VZCD =1 to 4.5V 2 µA

IZCDsrc Source Current Capability -2.5 -10 mA

IZCDsnk Sink Current Capability 3.0 mA

VZCDdis Disable Threshold 150 200 250 mV

VZCDen Restart Threshold 330 400 470 mV

IZCDres Restart Current after Disable VZCD<VDIS, VCC>VCC-OFF -80 -120 µA

STARTER

tSTART Start Timer Period 75 130 300 µs

Notes: 6. All parameters are in tracking.

7. The multiplier output is given by: current sense comparator O/P, .

AL6562 4 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Electrical Characteristics

Symbol Parameter Conditions Min Typ Max Units

OUTPUT OVER-VOLTAGE

IOVP Dynamic OVP Triggering Current 35 40 45 µA

VOVP_TH Static OVP Threshold 2.1 2.25 2.4 V

CURRENT SENSE COMPARATOR

ICS Input Bias Current VCS = 0 -1 µA

td(H-L) Delay to Output 200 350 ns

VCS-clamp Current Sense Clamp VCOMP = upper clamp 1.6 1.7 1.8 V

NEW PRODUCT

VMULT = 0 30 mV

VCS-offset Current Sense Offset

VMULT = 2.5V 5

GATE DRIVER

VOL Output Low Dropout Voltage IGDsink = 200 mA 0.9 1.9 V

IGDsource = 200 mA 2.5 3.0 V

VOH Output High Dropout Voltage 2.0 2.8 V

IGDsource = 20 mA

tf Voltage Fall Time 30 70 ns

tr Voltage Rise Time 60 110 ns

VOclamp Output Clamp Voltage ISOURCE = 5 mA, VCC =20 V 9 11 13 V

VCC =0 V to VCCon,

Vos UVLO Saturation 1.1 V

ISINK = 10 mA

AL6562 5 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Performance Characteristics

Supply Current vs. Supply Voltage Start-up & UVLO Vs. TJ

3.0

12.5

2.5 12.0

VCC-ON

Supply Current (mA)

2.0 11.5

NEW PRODUCT

Voltage (V)

11.0

1.5

CO=1nF

f=70kHz 10.5

1.0 o

TJ=25 C

10.0

0.5

9.5

VCC-OFF

0.0

0 5 10 15 20 25 9.0

-50 0 50 100 150

Supply Voltage (V)

o

Junction Temperature ( C)

Icc Consumption vs.TJ Vcc Zener Voltage Vs. TJ

28

8

4 Quiescent 27

2

26

1

ICC (mA)

VCC-CLAMP (V)

Disabled or during OVP

0.5 VCC=12V 25

CO=1nF

0.25 f=70kHz

24

0.125

0.0625 Before start-up 23

0.03125

22

-50 0 50 100 150 -50 0 50 100 150

o

o Junction Temperature ( C)

Junction Temperature ( C)

Feedback Reference Voltage vs. TJ OVP Current vs. TJ

2.60 43.0

42.5

VCC=12V

VCC=12V

2.55 42.0

41.5

VREF (V)

IOVP (A)

2.50

41.0

40.5

2.45

40.0

39.5

2.40

-50 0 50 100 150 39.0

-50 0 50 100 150

O

Junction Temperature ( C) o

Junction Temperature ( C)

AL6562 6 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Performance Characteristics (cont.)

Delay-to-output vs.TJ E/A Output Clamp Levels Vs. TJ

500 6.0

5.5

VCC=12V

400 Upper Clamp

5.0

VCC=12V

NEW PRODUCT

4.5

300

VCOMP (V)

td(H-L) (ns)

4.0

200

3.5

3.0

100 Lower Clamp

2.5

0 2.0

-50 0 50 100 150 -50 0 50 100 150

o o

Junction Temperature ( C) Junction Temperature ( C)

VCS-CLAMP vs.TJ Multiplied Gain Vs. TJ

2.0 1.0

1.8 0.8

VCC=12V

1.6

VCOMP=4V

Multiplier Gain

0.6

VCS-CLAMP (V)

VMULT=1V

1.4 0.4

VCC=12V

VCOMP=Upper Clamp

1.2 0.2

1.0 0.0

-50 0 50 100 150 -50 0 50 100 150

o o

Junction Temperature ( C) Junction Temperature ( C)

ZCD Source Capability vs.TJ ZCD Clamp Levels Vs. TJ

0

7

VCC=12V

6

VZCD=Lower Clamp Upper Clamp

-2

5

VCC=12V

IZCD= + 2.5mA

IZCD (mA)

4

VZCD (V)

-4

-6 2

1

Lower Clamp

-8

-50 0 50 100 150 0

-50 0 50 100 150

o

Junction Temperature ( C) Junction Temperature ( C)

o

AL6562 7 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Performance Characteristics (cont.)

Start-up Timer vs.TJ Multiplier Characteristics

200

1.8 VCOMP=MAX

VCOMP=5.0

190 VCC=12V VCOMP=4.5

1.6

VCOMP=4.0 VCOMP=3.5

180 1.4

NEW PRODUCT

170 1.2 VCOMP=3.2

tSTART (S)

VCS (V)

1.0

160

0.8 VCOMP=3.0

150

0.6

140

0.4 VCOMP=2.8

130

0.2

VCOMP=2.6

120 0.0

-50 0 50 100 150

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

o

Junction Temperature ( C) VMULT (V)

Gate-driver Output Low Saturation Gate-driver Output High Saturation

VGD (V)

6 VCC-2.0

5 o

VCC-2.5 TJ=25 C

o

TJ=25 C VCC=11V

4 VCC=11V SOURCE

SINK VCC-3.0

VGD (V)

VCC-3.5

2

VCC-4.0

1

0

0 200 400 600 800 1000 0 100 200 300 400 500 600 700

IGD (mA) IGD (mA)

Gate-driver Clamp vs. TJ UVLO Saturation vs. TJ

15 1.1

VCC=0V

1.0

14

VCC=20V

0.9

13

VGD_CLAMP (V)

VGD_OFF (V)

0.8

12

0.7

11

0.6

10 0.5

-50 0 50 100 150 -50 0 50 100 150

o

Junction Temperature ( C)

o Junction Temperature ( C)

AL6562 8 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Application Information

NEW PRODUCT

Figure 2 Boost Pre-Regulator PFC

POWER FACTOR CORRECTION

AL6562 functions as a transition mode PFC IC, meaning the MOSFET turns on when inductor current reaches zero, and turns off when the

current meets desired input current reference voltage, as shown in Figure 3. A typical current waveform is depicted with envelope as shown,

with the input current following that of the input voltage, achieving good power factor.

Figure 3 Typical Waveform of Inductor Current with Fixed ON Time

From a mathematical point of view, a PF value can be defined by:

θ

θ

∞

Where θ represents displacement factor with as the displacement angle between voltage and current fundamentals, and represents

distortion respectively.

AL6562 9 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Application Information (cont.)

, the distortion can further be defined by:

Where and are the RMS (Root Mean Square) value n-th fundamental component of the current respectively. If the current and

voltage are in phase, then θ= 0, which will lead to θ and the PF will be simplified as:

NEW PRODUCT

ZCD (Zero Current Detection)

The ZCD feature detects when the transformer primary current falls to zero, as the voltage across the inductor reverses, to initiate a new cycle

that switches on the power MOSFET. The signal for ZCD is obtained by an auxiliary winding on the boost inductor, as shown in Figure 2.

Multiplier

The internal multiplier takes two inputs, one from a portion of the instantaneous rectified line voltage (via pin 3, MULT) and the other from the

output of the E/A (via pin 2, COMP), to feed the PWM comparator to determine the exact instant when the MOSFET is to be switched off. The

output of multiplier is a rectified sinusoid, similar to the instantaneous rectified line voltage, multiplied by the scaling factor determined by

output of the Error Amplifier. The MULT output is then fed into the PWM comparator and is compared to the current sense voltage VCS, to

switch the Power MOSFET off. The formula governing all parameters is given by:

Multiplier Output:

Where: k is the multiplier gain. VMULT is set by external resistors R1 and R2.

OVP (Output Overvoltage Protection)

The output voltage can be kept constant by the operation of the PFC circuit close to its nominal value, as shown by Figure 2, which is set by

the ratio of the two external resistors R3 and R4. Neglecting ripple current, current flowing through R3, I R3, will equal the current through R4,

IR4. As the non-inverting input of the error amplifier is biased inside the AL6562 at 2.5V, the current through R4 is:

(1)

If any abrupt change of output voltage, ΔVO > 0 occurs due to a load drop, the voltage at pin INV will be kept at 2.5V by the local feedback of

the EA. The network connected between INV and COMP introduces a time constant to achieve high PF. The current through R4 will remain

equal to 2.5/R4, but IR3 will become:

(2)

The difference current will flow through the compensation network and enter the error amplifier output via pin

COMP. The AL6562 monitors the current flowing into the error amplifier output pin. When the detected current is higher than 40µA, the

dynamic OVP is triggered. The IC will be disabled and the driver signal will be stopped.

The output ΔVo that is able to trigger the Dynamic OVP function is then:

(3)

AL6562 10 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Application Information (cont.)

On the other hand, when the loading of PFC pre-regulator becomes low, the output voltage tends to stay steadily above the nominal value,

which is not the case when OVP is triggered by abrupt voltage increase. If this occurs, the E/A will saturate low, the external power transistor

is switched OFF, and the IC is put in idle state (static OVP). Normal operation is resumed as the error amplifier goes back into its linear region.

As a result, the device will work in burst-mode, with a repetition rate that can be very low. When either OVP is activated, the quiescent

consumption of the IC is reduced to minimum by the discharge of the capacitor and increases the hold-up capability of the IC supply.

NEW PRODUCT

THD (Total Harmonics Distortion)

The AL6562 reduces the THD by reducing conduction dead-angle occurring to the AC input current near the zero-crossings of the line voltage.

The important reason for this distortion to take place is the inability of the system to transfer energy effectively when the instantaneous line

voltage is very low, which is the case near line-voltage zero-crossing. This effect is magnified by the high-frequency filter capacitor placed after

the bridge rectifier, which retains some residual voltage that causes the diodes of the bridge rectifier to be reverse-biased and the input current

flow to temporarily stop.

To overcome this issue, the circuit section designed in the AL6562 forces the PFC regulator to process more energy near the line voltage

zero-crossings, as compared to that commanded by the control loop. This results in both minimizing the time interval when energy transfer is

lacking, and fully discharging the high-frequency filter capacitor after the bridge.

In essence, the circuit artificially increases the ON-Time of the Power Switch with a positive offset added to the output of the multiplier in the

proximity of the line voltage zero-crossings. This offset is reduced as the instantaneous line voltage increases, so that it becomes negligible as

the line voltage moves towards the peak of the sinusoidal waveform.

Therefore, to maximize the benefit from the THD improvement circuit, the high-frequency filter capacitor after the bridge rectifier should be

minimized and kept to satisfy the EMI filtering requirements.

Non-Latched IC Disable (Enable)

Pin 1, INV, inverting input to the error amplifier, can be adapted to disable the system when the voltage on this pin is below 0.2V. In order to

restart the system, a voltage exceeding 0.45V must be applied. The ON/OFF control signal can be driven by a PWM controller and using an

NPN transistor to pin 1 to shut it down.

AL6562 11 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Application Information (Cont.)

Single Stage LED Driver with PFC

One of the major applications of AL6562 is to provide a single stage power module with high PF for LED lighting. The following circuit, Figure 4,

shows a simplified fly-back AC-DC converter with both CC and CV feedback from output side, to prevent overload and also provide an over-

voltage protection facility.

CY1

NEW PRODUCT

Snuber Vo

C6 R7

R3 D1 C4

R8

Z1 C5 R6

R1 R4

AC C1 Opto-

input (5) (2) Coupler

ZCD COMP

(1)

R11

(8) Vcc R9

INV

AL6562

(3) MULT M1

GD (7) Secondary ILED

GND CS R12

C3 C2 (6) (4) side loop

R2 control

R5

CY2 R10

Figure 4 Single Stage PFC Isolated LED lighting

With its high performance, the AL6562 offers the following advantages that make this solution an appropriate method against the traditional

PWM controller, where a good PF value is required:

The input capacitance can be reduced to replace a bulky and expensive high-voltage electrolytic capacitor (as required by regular

offline SMPS) by a small-size, cheaper film capacitor.

Transition mode ensures low turn-on losses in MOSFET and higher efficiency can be achieved.

Lower parts count means lower material cost, as well as lower assembly cost for limited space.

AL6562 12 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Application Information (Cont.)

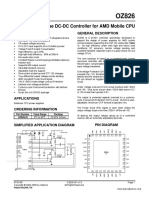

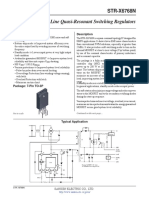

PFC Pre-Regulator

Another major application of AL6562 is to implement a wide-range mains input PFC pre-regulator, which acts as the input stage for the

cascaded DC-DC converter and can deliver above 350W in general.

There are two methods, in general, to design a pre-regulator stage:

1. With fixed frequency

NEW PRODUCT

or

2. With fixed ON time

The AL6562 can easily be implemented with fixed ON time due to its simplicity, while the fixed frequency technique is more complicated.

In fixed ON time mode, AL6562 is also working in transition mode where the inductor current will be turned on when zero crossing is detected.

By using boost-switching technique, the AL6562 shapes the input current by drawing a quasi-sinusoidal current in-phase with the line voltage.

A simplified circuit, shown in Figure 5, explains the operation as follows:

Figure 5 ZCD Pin Synchronization without Auxiliary Winding

The AC mains voltage is rectified by a diode bridge and delivered to the boost converter which boosts the rectified input voltage to a higher

regulated DC bus VO.

The error amplifier compares a portion of the output voltage with an internal reference and generates a signal error proportional to the

difference between them. The bandwidth of the internal error amplifier is set to be narrow within 20Hz; the output would be a DC value over a

given half-cycle. Output of E/A fed into multiplier, multiplied by a portion of the rectified mains voltage, will generate a scaled rectified sinusoid

whose peak amplitude depends on the rectified mains peak voltage as well as the value of error signal.

The output of the multiplier is fed into the non-inverting pin of the internal PWM comparator. As the output from the multiplier, a sinusoidal

reference for PWM, equals the voltage on the current sense pin CS(4), the MOSFET will be turned off. As a consequence, the peak inductor

current will follow the envelope of a rectified sinusoid. After the MOSFET is turned off, the boost inductor discharges its stored energy to the

load until zero current is detected and then the MOSFET will be turned on again.

In the case where there is no auxiliary winding on the boost inductor, a solution can be implemented by sconnecting the ZCD pin to the drain

of the power MOSFET through an R-C network: in this way the high-frequency edges experienced by the drain will be transferred to the ZCD

pin, hence arming and triggering the ZCD comparator.

The resistance value must be properly chosen to limit the current sourced/sunk by the ZCD pin. In typical applications with output voltages

around 400V, recommended values for these components are 22pF (or 33pF) for CZCD and 330K for RZCD. With these values proper

operation is ensured even with a few volts difference between the regulated output voltage and the peak input voltage.

AL6562 13 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Ordering Information

AL6562 XX–13

Package Packing

NEW PRODUCT

S : SO8 13 :13" Tape & Reel

13” Tape and Reel

Part Number Package Package code

Quantity Part Number Suffix

AL6562S-13 SO-8 S 2,500/Tape & Reel -13

Marking Information

(1) SO-8

AL6562 14 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

Package Outline Dimensions (All Dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for the latest version.

SO-8

Dim Min Max

A - 1.75

A1 0.10 0.20

NEW PRODUCT

0.254

A2 1.30 1.50

E1 E

Gauge Plane A3 0.15 0.25

A1 Seating Plane b 0.3 0.5

L

D 4.85 4.95

Detail ‘A’ E 5.90 6.10

E1 3.85 3.95

h 7°~9° e 1.27 Typ

45° h - 0.35

Detail ‘A’

L 0.62 0.82

A2 A A3

0 8

All Dimensions in mm

e b

D

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

Dimensions Value (in mm)

X 0.60

Y 1.55

C1 C1 5.4

C2 1.27

C2

AL6562 15 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

AL6562

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall

NEW PRODUCT

assume all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes

Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales

channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify

and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and

markings noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is

the final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the

express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause

the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems,

and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-

related information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated

and its representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices

or systems.

Copyright © 2015, Diodes Incorporated

www.diodes.com

AL6562 16 of 16 February 2015

Document Number: DS37542 Rev. 2 - 2 www.diodes.com © Diodes Incorporated

You might also like

- 400Khz 32V 2A Switching Current Boost Led Constant Current Driver Xl6001Document9 pages400Khz 32V 2A Switching Current Boost Led Constant Current Driver Xl6001Takaro YoshimotoNo ratings yet

- HW 5Document1 pageHW 5ottoporNo ratings yet

- Digital Logic Design ProjectsDocument23 pagesDigital Logic Design ProjectsMychon KanNo ratings yet

- 340Khz 23V 3A Synchronous DC/DC Buck Converter: (Top View)Document15 pages340Khz 23V 3A Synchronous DC/DC Buck Converter: (Top View)davi18No ratings yet

- Automatic Light Intensity Controller Using LDR and RelayDocument16 pagesAutomatic Light Intensity Controller Using LDR and RelayJaswitha KonaNo ratings yet

- WS3418 WinsemiDocument8 pagesWS3418 WinsemiPaul MejiaNo ratings yet

- (Top View) : 18V, 2A Synchronous DC-DC Buck ConverterDocument14 pages(Top View) : 18V, 2A Synchronous DC-DC Buck ConverterLuis EspinozaNo ratings yet

- DC/DC Converter Drives Lumileds White Leds From A Variety of Power SourcesDocument2 pagesDC/DC Converter Drives Lumileds White Leds From A Variety of Power SourceskurabyqldNo ratings yet

- Innoswitch3-Ce Family Datasheet PDFDocument30 pagesInnoswitch3-Ce Family Datasheet PDFfaridha bhanuNo ratings yet

- FAN7340 LED Backlight Driving Boost Switch: Features DescriptionDocument16 pagesFAN7340 LED Backlight Driving Boost Switch: Features DescriptionEnrile Labiano BaduaNo ratings yet

- Al8860 1019719Document18 pagesAl8860 1019719hansNo ratings yet

- AP3502Document11 pagesAP3502nassimNo ratings yet

- HDN-XX o YF3141-COTAG Sot-26 Sot23-6 DC-DCDocument11 pagesHDN-XX o YF3141-COTAG Sot-26 Sot23-6 DC-DCprreNo ratings yet

- Ap7361ea PDFDocument24 pagesAp7361ea PDFAlejandro DemitiNo ratings yet

- LM3481MM NOPB National SemiconductorDocument22 pagesLM3481MM NOPB National Semiconductorvs674584No ratings yet

- Data Sheet: ACPL-32JTDocument18 pagesData Sheet: ACPL-32JTkbrinaldiNo ratings yet

- AP22815 / AP22615: Single Channel Power Distribution Switch With Output OvpDocument17 pagesAP22815 / AP22615: Single Channel Power Distribution Switch With Output Ovpbong bernalbongNo ratings yet

- AP22815 / AP22615: Single Channel Power Distribution Switch With Output OvpDocument17 pagesAP22815 / AP22615: Single Channel Power Distribution Switch With Output Ovpbong bernalbongNo ratings yet

- MAQ3203YM Evaluation Board User GuideDocument23 pagesMAQ3203YM Evaluation Board User GuideJohnNo ratings yet

- 3A, 40V, 200Khz Step-Down Converter: Description FeaturesDocument10 pages3A, 40V, 200Khz Step-Down Converter: Description FeaturesEduardo Jose Fernandez PedrozaNo ratings yet

- Opamp Midterm 1Document60 pagesOpamp Midterm 1Mohit ShuklaNo ratings yet

- AL8862QDocument17 pagesAL8862QIvo MatosNo ratings yet

- SBB501S InternationalRectifierDocument12 pagesSBB501S InternationalRectifierruslan futkaradzeNo ratings yet

- Analog IC CourseDocument167 pagesAnalog IC CourseAmitNo ratings yet

- M8916Document9 pagesM8916ykcorNo ratings yet

- Technical InformationDocument31 pagesTechnical Informationsarang abadagireNo ratings yet

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- Project Jasi 2 Final PDFDocument30 pagesProject Jasi 2 Final PDFJaswitha KonaNo ratings yet

- G1138 GlobalSemiconductorDocument4 pagesG1138 GlobalSemiconductorNiltonNo ratings yet

- 12 100: Input ModuleDocument6 pages12 100: Input ModuleAndy Kong KingNo ratings yet

- AZ34063UDocument13 pagesAZ34063UjariarmaturesincNo ratings yet

- Dual-Phase DC-DC Controller For AMD Mobile CPU: Features General DescriptionDocument7 pagesDual-Phase DC-DC Controller For AMD Mobile CPU: Features General Descriptionlordycarlos8588No ratings yet

- IS31LT3360: 40V/1.2A Led Driver With Internal SwitchDocument15 pagesIS31LT3360: 40V/1.2A Led Driver With Internal SwitchFrancesco MenichelliNo ratings yet

- AP3041 Ic Driver Placa Simply Syled37i Que Se QuemaDocument14 pagesAP3041 Ic Driver Placa Simply Syled37i Que Se QuemaAndres Alegria0% (1)

- AP3041 Oscilador TV Haier 50yca PDFDocument14 pagesAP3041 Oscilador TV Haier 50yca PDFmaroNo ratings yet

- lc5222d Ds enDocument11 pageslc5222d Ds enRick HunterNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- LP 8545Document46 pagesLP 8545NalsonNo ratings yet

- Infrared Remote Switch ReportDocument3 pagesInfrared Remote Switch ReportsivamskrNo ratings yet

- Enpirion Power Datasheet: Description ApplicationDocument14 pagesEnpirion Power Datasheet: Description Applicationรัศมีเจริญชัย ธีรเมธNo ratings yet

- Ap 3502 em Regulador DCDC s1005Document11 pagesAp 3502 em Regulador DCDC s1005gerson evandro hanauerNo ratings yet

- SP1232FDocument11 pagesSP1232Fnazala fikri nugrahaNo ratings yet

- Boost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Document14 pagesBoost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Loengrin MontillaNo ratings yet

- Power Integrations SC1161D1 TL - C710264Document10 pagesPower Integrations SC1161D1 TL - C710264alfe20001120No ratings yet

- AL6562ADocument16 pagesAL6562ASibi DhayalanNo ratings yet

- Bit 3269Document6 pagesBit 3269zubiNo ratings yet

- PresentationDocument44 pagesPresentationRohit chachdaNo ratings yet

- Acpl 337J 500eDocument18 pagesAcpl 337J 500eAandk NovaNo ratings yet

- 31FL3731Document22 pages31FL3731László MondaNo ratings yet

- SC4541 Rev.2.1Document19 pagesSC4541 Rev.2.1Akhil GargNo ratings yet

- str-x6768n Ds en PDFDocument9 pagesstr-x6768n Ds en PDFCarlNo ratings yet

- Data Sheet: ACPL-331JDocument23 pagesData Sheet: ACPL-331JPiman MiriNo ratings yet

- Mains Failure Indicator AlarmDocument33 pagesMains Failure Indicator AlarmamolNo ratings yet

- XL6008 DatasheetDocument8 pagesXL6008 DatasheetAnonymous roFhLslwIFNo ratings yet

- High-Power Igbt Driver Data Sheet For 2Pd632Document11 pagesHigh-Power Igbt Driver Data Sheet For 2Pd632Narendra BholeNo ratings yet

- APX9131A: Features General DescriptionDocument12 pagesAPX9131A: Features General DescriptionChek OmarovNo ratings yet

- Mini Project On Dark Sensor Using IC555 TimerDocument16 pagesMini Project On Dark Sensor Using IC555 TimerPSNo ratings yet

- Unit 1Document82 pagesUnit 1Shaleva SinghNo ratings yet

- EUP3482 EutechMicroelectronics PDFDocument11 pagesEUP3482 EutechMicroelectronics PDFMarco MachadoNo ratings yet

- Primary Switch Mode Power SupplyDocument11 pagesPrimary Switch Mode Power Supplypratik jainNo ratings yet

- Datasheet PDFDocument23 pagesDatasheet PDFshamim ahmedNo ratings yet

- CR6224Document10 pagesCR6224sergioviriliNo ratings yet

- AVS08Document7 pagesAVS08sergioviriliNo ratings yet

- 28600D Psu-2Document2 pages28600D Psu-2sergioviriliNo ratings yet

- 28600D PsuDocument2 pages28600D PsusergioviriliNo ratings yet

- Low-Dropout, 3.3 V Regulator - High EfficiencyDocument8 pagesLow-Dropout, 3.3 V Regulator - High EfficiencysergioviriliNo ratings yet

- EPS12V Power Supply Design Guide, V2.91Document39 pagesEPS12V Power Supply Design Guide, V2.91sergioviriliNo ratings yet

- Exp3 Universal Gates 1Document23 pagesExp3 Universal Gates 1Joie Marie Yadao BulawanNo ratings yet

- LDST AssignentDocument2 pagesLDST AssignentRajesh RamwaniNo ratings yet

- Load and Line RegulationDocument4 pagesLoad and Line RegulationAbhayNo ratings yet

- FPGADocument14 pagesFPGASheikh Noor MohammadNo ratings yet

- 15ECL76 ManualDocument35 pages15ECL76 Manual1BO20EC026 TOLSTOY DAYCODS ANo ratings yet

- VHF - Str-6000a - SM SamyungDocument47 pagesVHF - Str-6000a - SM SamyungWilfredo DelgadoNo ratings yet

- Electronic Circuit AnalysisDocument7 pagesElectronic Circuit AnalysisIshansi AgrawalNo ratings yet

- EC303Document23 pagesEC303api-3853441No ratings yet

- Electronic Circuits Unit-2Document37 pagesElectronic Circuits Unit-2Siddhasen PatilNo ratings yet

- Experiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentDocument17 pagesExperiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentVictoria De GuzmanNo ratings yet

- EE103 Exp9 TOSHIT - 2101CB59Document5 pagesEE103 Exp9 TOSHIT - 2101CB59Rahul PalNo ratings yet

- Digital-to-Analog Analog-to-Digital Conversions: Microprocessor InterfaceDocument34 pagesDigital-to-Analog Analog-to-Digital Conversions: Microprocessor Interfaceeugen lupuNo ratings yet

- Op AmpDocument57 pagesOp AmpDivyanshu Yadav100% (1)

- Lec 102409005501 1Document15 pagesLec 102409005501 1Usman Arif100% (1)

- TTL Logic FamilyDocument25 pagesTTL Logic FamilyRohini RaghunathanNo ratings yet

- Wireless Design Seminar 2006Document237 pagesWireless Design Seminar 2006wagnalang1639No ratings yet

- Lab #1Document4 pagesLab #1Ashish KarkiNo ratings yet

- Emailing 300 TOP Operational Amplifiers Questions and Answers OP-AMP - PDF Version 1Document15 pagesEmailing 300 TOP Operational Amplifiers Questions and Answers OP-AMP - PDF Version 1Jesan tonikNo ratings yet

- Topik 1 - Linear DC Power SupplyDocument18 pagesTopik 1 - Linear DC Power Supplysaiman suiNo ratings yet

- Boolean Logic Class 11 CSDocument33 pagesBoolean Logic Class 11 CSsangeetamandal487No ratings yet

- Digital To Analog Converter DACDocument22 pagesDigital To Analog Converter DACmohammad zidanNo ratings yet

- OscillatorsDocument90 pagesOscillatorsYesNo ratings yet

- 2N3553 Silicon NPN Transistor RF Power Driver: Absolute Maximum RatingsDocument2 pages2N3553 Silicon NPN Transistor RF Power Driver: Absolute Maximum RatingsAhmad AftalNo ratings yet

- FinalProject-Circuits Lab 2Document15 pagesFinalProject-Circuits Lab 2Lynn CruzNo ratings yet

- 412n - Unit IV - Modeling of Sequential CircuitsDocument19 pages412n - Unit IV - Modeling of Sequential CircuitsMarc Neil ApasNo ratings yet

- Lec 9 Dynamic Logic CircuitsDocument51 pagesLec 9 Dynamic Logic CircuitsBhavesh AsodariyaNo ratings yet

- RRB Junior Engineer Electrical Model Paper 3 PDFDocument6 pagesRRB Junior Engineer Electrical Model Paper 3 PDFMallikarjunBhiradeNo ratings yet

- Assignment 4: Unit 6 - Week 4: Nodal AnalysisDocument6 pagesAssignment 4: Unit 6 - Week 4: Nodal AnalysissabilashNo ratings yet