Professional Documents

Culture Documents

WWT - Activated Sludge Process Design

WWT - Activated Sludge Process Design

Uploaded by

Venkatesh Kumar Ramanujam0 ratings0% found this document useful (0 votes)

13 views1 pageThe document discusses the design of activated sludge systems. It outlines the main elements that must be considered in design, including the aeration tank, aeration system, sedimentation tank, return sludge system, and excess sludge removal. Key design criteria include detention time, mixed liquor suspended solids levels, air supply levels, return sludge ratios, tank dimensions, and sludge volume index measurements. The sludge volume index test measures sludge settleability and is defined as the volume in milliliters occupied by one gram of sludge after 30 minutes of settling.

Original Description:

Original Title

WWT_Activated Sludge Process Design

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the design of activated sludge systems. It outlines the main elements that must be considered in design, including the aeration tank, aeration system, sedimentation tank, return sludge system, and excess sludge removal. Key design criteria include detention time, mixed liquor suspended solids levels, air supply levels, return sludge ratios, tank dimensions, and sludge volume index measurements. The sludge volume index test measures sludge settleability and is defined as the volume in milliliters occupied by one gram of sludge after 30 minutes of settling.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views1 pageWWT - Activated Sludge Process Design

WWT - Activated Sludge Process Design

Uploaded by

Venkatesh Kumar RamanujamThe document discusses the design of activated sludge systems. It outlines the main elements that must be considered in design, including the aeration tank, aeration system, sedimentation tank, return sludge system, and excess sludge removal. Key design criteria include detention time, mixed liquor suspended solids levels, air supply levels, return sludge ratios, tank dimensions, and sludge volume index measurements. The sludge volume index test measures sludge settleability and is defined as the volume in milliliters occupied by one gram of sludge after 30 minutes of settling.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

Activated Sludge Process Design

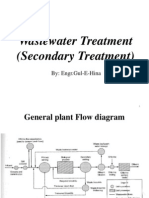

Design of Activated Sludge Systems:

Design of activated-sludge process involves details of sizing and operation of the

following main elements.

1. Aeration tank (reactor)-capacity and dimensions.

2. Aeration system-oxygen requirements and oxygen transfer system.

3. Final sedimentation tank – (deifier)

4. Return activated sludge system.SV1

5. Excess activated sludge withdrawal system and subsequent treatment and

disposal of waste sludge. Since the whole process takes place in al liquid

medium the hydraulic regime essentially in the aeration tank and final

sedimentation tank.

6. MLSS – a mixture of settled sewage + activated sludge dissolved oxygen < 2mg/l

Design Criteria

1. F/M ratio = 0.2 – 0.5 day -1 or 0.2 – 0.5 kg BOD's / kg MLSS – d

2. Detention time (aeration time) of sewage = 6 to 6 hours

3. MLVSS or MLSS = 1500 -3000 mg/l

4. Air supply = 10m3/m3 sewage treated

5. return sludge = 0.25 -10 of Q (influent sewage flow) Qr / Q = 0.20-0.30 =

Vs/100Vs (Volume of sludge)

6. Depth = 3-5m

7. L=W ratio =5:1

8. SVI 50-150 ml/gm

Sludge Volume Index (SVI-TEST)

It is the measure of the settle ability and compatibility of sludge and is made from a

laboratory column setting test.

DEF: the sludge volume index is defined as ‘the volume in mm occupied by 1 gm of

sludge after it has settled for a specified period of time’ generally ranging from 20 min to

1 or 2hr in a 1 – or 2-l cylinder. One-half hour is most common setting time allow the

mixed liquor o settle for 30 min. ( larger cylinder is desirable to minimize bridging of

sludge floe and war effects). Take the reading let Vs is the settled volume of sludge

(ml/l) in 30 min. SV1=

Imp (comment) If SVI is 50-150 ml/mg, the sludge settle ability if Good.

You might also like

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaNo ratings yet

- Waste Water EngineeringDocument65 pagesWaste Water EngineeringAjit DyahadrayNo ratings yet

- Assignment 6Document4 pagesAssignment 6Neeraj Gupta100% (1)

- A Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Document21 pagesA Portion of The Activated Sludge, From The Secondary Clarifier Is Returned To Mix With The Effluents of Primary Clarifier.Náģå Rájú ÇhïmąţäNo ratings yet

- Activated Sludge Process, Design Criteria, Advantages & DisadvantagesDocument3 pagesActivated Sludge Process, Design Criteria, Advantages & DisadvantagesThrishnaa BalasupurManiamNo ratings yet

- Activated Sludge ProcessDocument28 pagesActivated Sludge Processusmansherdin100% (2)

- Design Consideration: F/M) Which Depends On The Expected Winter Temperature of MixedDocument12 pagesDesign Consideration: F/M) Which Depends On The Expected Winter Temperature of MixedVipin RoseNo ratings yet

- Activated SludgeDocument14 pagesActivated Sludgemosaad khadrNo ratings yet

- Waste Water Treatment: Process Design Consideration On Activated Sludge ProcessDocument31 pagesWaste Water Treatment: Process Design Consideration On Activated Sludge ProcesslukmanindranugrahaNo ratings yet

- Unit Operations Tutorial 2015-2016Document13 pagesUnit Operations Tutorial 2015-2016hazimraad0% (1)

- ASP - PPT - EE-TTDocument31 pagesASP - PPT - EE-TTRitesh KumarNo ratings yet

- Lecture 8 + Biological-Activated SludgeDocument7 pagesLecture 8 + Biological-Activated Sludgehhjjrr22331No ratings yet

- Activated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikDocument34 pagesActivated Sludge Design (Complete Mix Reactor) : Setyo S. MoersidikTiti SariNo ratings yet

- Ijaret: ©iaemeDocument11 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- Midterm - Exam CHEM4012 2011 2012Document5 pagesMidterm - Exam CHEM4012 2011 2012sahartalebiNo ratings yet

- Lecture 3Document8 pagesLecture 3Raj BakhtaniNo ratings yet

- PWTLecture8 (SedimentationII)Document55 pagesPWTLecture8 (SedimentationII)JojoNo ratings yet

- Very Poor Poor Good Very Good Excellen TDocument11 pagesVery Poor Poor Good Very Good Excellen TNanthan DevNo ratings yet

- The F To M RatioDocument6 pagesThe F To M Ratiojokish100% (2)

- Activated Sludge ProcessDocument10 pagesActivated Sludge ProcessSai Raghava Rajeev100% (1)

- Wastewater Treatment Plant Options and Design CriteriaDocument14 pagesWastewater Treatment Plant Options and Design Criteriaahmed elbazNo ratings yet

- Experiment-3-Reynold-and-osborne Final VersionDocument15 pagesExperiment-3-Reynold-and-osborne Final VersionHon Siong LinNo ratings yet

- Module - 9 Secondary Treatment AS, EAAS, SBRDocument39 pagesModule - 9 Secondary Treatment AS, EAAS, SBRFaran Masood100% (1)

- Activated Sسمعيلثludge Calculation SheetDocument14 pagesActivated Sسمعيلثludge Calculation SheetYasser Fathy Aly100% (1)

- Tutorial 1-CH2402 - 2019Document4 pagesTutorial 1-CH2402 - 2019Naduni RanasingheNo ratings yet

- Advanced SanitaryHwk 2Document2 pagesAdvanced SanitaryHwk 2ashraf refaatNo ratings yet

- UPO-1: Unit Processes and Operations (Physico-Chemical) - Question PapersDocument20 pagesUPO-1: Unit Processes and Operations (Physico-Chemical) - Question PapersDr. Akepati Sivarami Reddy100% (2)

- Analyzing A Malfunctioning Clarifier With COMSOLDocument5 pagesAnalyzing A Malfunctioning Clarifier With COMSOLLinnaZuluagaNo ratings yet

- Chapter 4 StudentDocument48 pagesChapter 4 StudentMaster-s Hero-sNo ratings yet

- Unit 3Document155 pagesUnit 3rangaNo ratings yet

- Al Aweer WWTP-jihadDocument17 pagesAl Aweer WWTP-jihadYousef ZamNo ratings yet

- CH 4 Sewage TreatmentDocument134 pagesCH 4 Sewage TreatmentGetu BogaleNo ratings yet

- Sludge Volume IndexDocument3 pagesSludge Volume IndexNicole Feliciano100% (1)

- CE570 Final Exam Fall 2023Document4 pagesCE570 Final Exam Fall 2023farajelmabroukNo ratings yet

- 5 Heuristics 2020 PDFDocument17 pages5 Heuristics 2020 PDFTanmay PatelNo ratings yet

- Chapter 4.6 - Secondary Treatment Part - 2 (WW)Document25 pagesChapter 4.6 - Secondary Treatment Part - 2 (WW)Kak NinaNo ratings yet

- CSTR in SeriesDocument16 pagesCSTR in SeriesAhmadAzriMohamad50% (2)

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (3)

- Venturi ScrubberDocument22 pagesVenturi ScrubberTanzeela RiazNo ratings yet

- Mineral Processing 2 L3Document27 pagesMineral Processing 2 L3ahmed kishkNo ratings yet

- Water: Comparison of Three Systems For Biological Greywater TreatmentDocument15 pagesWater: Comparison of Three Systems For Biological Greywater TreatmentRocio HaroNo ratings yet

- Example For Chapter 2Document8 pagesExample For Chapter 2Giang Nguyễn TrườngNo ratings yet

- CE 428 - DesignActivated Sludge SystemDocument3 pagesCE 428 - DesignActivated Sludge System8925138229100% (1)

- 1Document4 pages1Jerelyn CalicdanNo ratings yet

- Aerobic Secondary Treatment of Wastewater PDFDocument7 pagesAerobic Secondary Treatment of Wastewater PDFdanndiamond100% (3)

- PIAS-Sistem Lumpur AktifDocument32 pagesPIAS-Sistem Lumpur AktifTeknik Pdam Kota KupangNo ratings yet

- Activated Sludge DesignDocument21 pagesActivated Sludge DesignChokri ChakiirNo ratings yet

- SBR Plant Design PDFDocument8 pagesSBR Plant Design PDFvishuNo ratings yet

- Engr. Abaid UllahDocument37 pagesEngr. Abaid UllahminahilNo ratings yet

- Chapter 8 - Activated Sludge PDFDocument12 pagesChapter 8 - Activated Sludge PDFRieskaYuniarNo ratings yet

- Design Calculation For Softener Unit: Client: - TechproDocument10 pagesDesign Calculation For Softener Unit: Client: - TechproHazairin As-Shiddiq RahmanNo ratings yet

- 06-Biological Treatment (Seuspended Growth)Document28 pages06-Biological Treatment (Seuspended Growth)Mahmud RamadanNo ratings yet

- Design Details of Sewage Treatment Plan With SBR PDFDocument8 pagesDesign Details of Sewage Treatment Plan With SBR PDFali ahmadiNo ratings yet

- MI 429 Lecture 7Document15 pagesMI 429 Lecture 7Innocent RevocatusNo ratings yet

- Principle of Working of Grit ChamberDocument11 pagesPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- Lecture 7 + Biological-Activated Sludge PDFDocument13 pagesLecture 7 + Biological-Activated Sludge PDFAli AlibrahimiNo ratings yet

- Design Calculation Sewage PitDocument12 pagesDesign Calculation Sewage PitM N Hoda67% (3)

- In This Project We Will Design A Treatment Station, So We: - Pond ClassificationDocument16 pagesIn This Project We Will Design A Treatment Station, So We: - Pond ClassificationSayed Abo ElkhairNo ratings yet

- Characteristics of SludgeDocument8 pagesCharacteristics of SludgeSudharsananPRSNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Key Process Considerations For Caustic Treatment in CDUDocument4 pagesKey Process Considerations For Caustic Treatment in CDUVenkatesh Kumar RamanujamNo ratings yet

- Real-Time Crude and Desalter MonitoringDocument4 pagesReal-Time Crude and Desalter MonitoringVenkatesh Kumar RamanujamNo ratings yet

- Evaluating Hydrogen Rich Fuel Gas FiringDocument4 pagesEvaluating Hydrogen Rich Fuel Gas FiringVenkatesh Kumar RamanujamNo ratings yet

- Rate/Unit 1 100 0 0 101 200 3.5 350 201 500 4.6 1380 501 2807.5 6.6 18529.5 20259.5 50Document1 pageRate/Unit 1 100 0 0 101 200 3.5 350 201 500 4.6 1380 501 2807.5 6.6 18529.5 20259.5 50Venkatesh Kumar RamanujamNo ratings yet

- Energy Efficiency 4 PillarsDocument5 pagesEnergy Efficiency 4 PillarsVenkatesh Kumar RamanujamNo ratings yet

- The Mughal World Life in India'sDocument411 pagesThe Mughal World Life in India'sVenkatesh Kumar RamanujamNo ratings yet

- Consider The Role of Safety Layers in The Bhopal DisasterDocument6 pagesConsider The Role of Safety Layers in The Bhopal DisasterVenkatesh Kumar RamanujamNo ratings yet

- Salt Fouling FCCDocument6 pagesSalt Fouling FCCVenkatesh Kumar RamanujamNo ratings yet

- Crude Oil CharacterizationDocument51 pagesCrude Oil CharacterizationVenkatesh Kumar Ramanujam67% (3)

- Drinking Water DesignDocument1 pageDrinking Water DesignVenkatesh Kumar RamanujamNo ratings yet

- Twenty Rules For TroubleshootingDocument3 pagesTwenty Rules For TroubleshootingVenkatesh Kumar RamanujamNo ratings yet

- Coagulation FlocculationDocument12 pagesCoagulation FlocculationVenkatesh Kumar RamanujamNo ratings yet

- Design Aspects of Drinking Water PlantDocument32 pagesDesign Aspects of Drinking Water PlantVenkatesh Kumar RamanujamNo ratings yet