Professional Documents

Culture Documents

958 Hpr2 VTR

958 Hpr2 VTR

Uploaded by

v2nssysy6fOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

958 Hpr2 VTR

958 Hpr2 VTR

Uploaded by

v2nssysy6fCopyright:

Available Formats

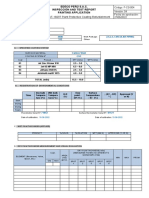

GRADWELL OILFIELD PRIVATE LIMITED

GR/PP/IMSF-29 REV.00

V3-VALIDATION TEST CERTIFICATE

effective date 10.01.2019

Customer Development Assembly Work Order No. GRAWO1819063 Test Certificate No. VTC-0092

Reference Standard API 11D1 Referred Procedure GR/QA/IMSW-36 Date 17/02/2019

HYDRAULIC SET HIGH ANGLE Binola Industrial Area

Product Description Testing Agency Gradwell Oilfield Pvt. Ltd. Location

PRODUCTION PACKER Gurugram (HR)

Model GR-HPR-2 Product No. GR-10501 Batch / ATF No. GRATF1819063-004

Product Size 9-5/8" Retrievable/ Permanent Retrievable Assembly Drawing No. GR-108280

4-1/2" 13.5 PPF API 8RD EU tubing pressure

Top End Connection 4-1/2" 13.5 PPF API 8RD EU BOX Bottom End Connection Setting Method

PIN hydraulic set

HNBR 90-70-90 DURO

Rated Differential Pressure (PSI) 5,000 Rated Working Temp 325° F O'ring/Packing Element: NITRILE 90DURO

(ORINGS)

Identification of

DPG-01 & DPG-02

Test Fixture Identification GR-152023-00; GR-152024-00 & GR-152025-00 gauges(Pressure/load/

TC-01 & TC-02

Temperature) :

TEST PARAMETERS

Validation Density of Testing

V3 Test Medium Hyd. Oil Shell S2 857 kg/m³

Grade of testing Medium

Test Casing Material/

Test Casing Size 9-5/8" Test Casing PPF 47 PPF AISI 4140, 110ksi MYS

Grade

Max Rated Test

Testing Casing Maximum ID 8.681'' +0.030/-0.000 Testing Casing Max. OD 9.8'' 5000

Differential Psi :

Retrieving

Temperature Cycle Range : 150° F - 325°F 54,000 LBS Setting Temp. : : 325 °F

Force / Pressure :

TEST RESULTS SUMMARY

Applied Setting Force / Product has been set successfully inside the casing by hydraulic actuation at

SettingForce / Pressure : 2500 PSI

Pressure : 2500psi.

1. Pressure Readings when Max Differential Pressure From Above TO Below:

Subjected Differential

Applied Pressure (Through Tubing /

: 500 psi ±1% Pressure from Tubing to 5000 psi Pressure Hold Time: : 15 min.

Below) :

Annulus :

Subjected Differential

Pressure Reduction /

Applied Annulus Pressure (Above) : 5500 psi ±1% Pressure across Packing 5000 psi : No Leakage detected

Leak Rate :

elements

2. Pressure Readings when Max Differential Pressure From Below TO Above:

Subjected Differential

Applied Pressure (Through Tubing /

5500 psi ±1% Pressure from Tubing to 5000 psi Pressure Hold Time: : 15 min.

Below) :

Annulus :

Subjected Differential

Pressure Reduction /

Applied Annulus Pressure (Above) : : 500 psi ±1% Pressure across Packing 5000 psi : No Leakage detected

Leak Rate :

elements

3. Other readings:

Applied Tension load :

Max. Applied Temp. : 325°F 43000 lbs

(if applicable)

Applied Compression load :

Applied Retrieving Force / Pressure : 54000 lbs 143000 lbs

(if applicable)

Witnessed By:

Tested By: Approved By:

(Head QA/QC, & HOD

(Assembly and Testing In-charge) (Director Operations)

Design)

Date: Date: Date:

GRADWELL OILFIELD PRIVATE LIMITED

GR/PP/IMSF-29 REV.00

V3-VALIDATION TEST CERTIFICATE

effective date 10.01.2019

PERFORM A MINIMUM OF TWO PRESSURE REVERSALS AT OR ABOVE THE MAXIMUM RATED PRESSURE FROM BELOW TO

ABOVE OR VICE VERSA.

A. Test Cycle for Max Rated Temperature + Pressure + Axial Loads:

Annulus pressure Pressure

Applied Load (lbs)

Intersection Point Tubing pressure (Psi) Variations

Temp (°F) Diff Psi Remarks

on RPE (psi) Compressi reading

Below Above Tension during hold

on

Test 1: Pressure hold at

325°, 5000 diff psi above the

1 500 325 500 5500 0 0 5,000 No leakage

packer.

Test2: (1st reversal) ,

Pressure hold at 325°, 5000

2 5500 325 5500 500 0 0 5,000 No leakage diff psi below the packer.

Test3: Pressure hold at 325°,

5000 diff psi below the

3 5500 325 5500 500 0 143,000 5,000 No leakage packer, 143000 lbs

compression.

Test4: Pressure hold at 325°,

no diff psi ascross the

4 500 325 500 500 0 143,000 0 No leakage packer, 143000 lbs

compression.

Test5: (2nd reversal) ,

Pressure hold at 325°, 5000

5 500 325 500 5500 0 135,000 5,000 No leakage diff psi above the packer,

135000 lbs compression.

Test6: Pressure hold at 325°,

no diff psi across the packer,

6 500 325 500 500 43,000 0 0 No leakage 43,000 lbs tension.

Hold Period 15 minutes after stabilization

Acceptance criterion: no more than 1 % reduction in the maximum rated differential pressure over the hold period after sufficient time has been allowed for stabilization. The

time period for stabilization is at the discretion of the Test Operator.

B. Test Cycle for Min Rated Temperature + Pressure (Cold Hold)

Annulus pressure

Applied Load (lbs)

(Psi) Pressure

Intersection Point Tubing pressure

Temp (°F) Diff Psi Variations Remarks

on RPE (psi)

Compressi reading

Below Above Tension

on

Test 7: 150˚F, 5000 diff psi

above Pressure Hold (Cold

7 500 150 500 5000 40,000 0 5,000 No leakage Hold)

Hold Period 15 minutes after stabilization

Acceptance criterion: no more than 1 % reduction in the maximum rated differential pressure over the hold period after sufficient time has been allowed

for stabilization. The time period for stabilization is at the discretion of the Test Operator.

Tested By: Witnessed By:

Approved By:

(Assembly and Testing In- (Head QA/QC, &

(Director Operations)

charge) HOD Design)

Date: Date: Date:

GRADWELL OILFIELD PRIVATE LIMITED

GR/PP/IMSF-29 REV.00

V3-VALIDATION TEST CERTIFICATE effective date 10.01.2019

PERFORM A MINIMUM OF TWO PRESSURE REVERSALS AT OR ABOVE THE MAXIMUM RATED PRESSURE FROM BELOW TO

ABOVE OR VICE VERSA.

C. Test Cycle for Max Rated Temperature + Pressure

Annulus pressure Pressure

Applied Load (lbs)

Intersection Point Tubing pressure (Psi) Variations

Temp (°F) Diff Psi Remarks

on RPE (psi) Compressi reading

Below Above Tension during hold

on

Test 5:(Temp Cycle -1

completed). 325˚F,

8 500 325 500 5500 0 0 5,000 No Leakage

5000 diff psi above

Pressure Hold

Hold Period 15 minutes after stabilization

Acceptance criterion: no more than 1 % reduction in the maximum rated differential pressure over the hold period after sufficient time has been allowed

for stabilization. The time period for stabilization is at the discretion of the Test Operator.

DETAILED DISCUSSION OF RESULT GRAPHS:

Test Graphs for all intersection points are attached as Appendix-1 to this test report.

Test 1: Pressure hold at 325°, 5000 diff psi above the packer.

Test 2: (1st reversal), Pressure hold at 325°, 5000 diff psi below the packer.

Test 3: Pressure hold at 325°,5000 diff psi below the packer, 143000 lbs compression.

Test 4: Pressure hold at 325°, no diff psi ascross the packer, 143000 lbs compression.

Test 5: (2nd reversal) , Pressure hold at 325°, 5000 diff psi above the packer, 135000 lbs compression.

Test 6: Pressure hold at 325°, no diff psi ascross the packer, 43,000 lbs tension.

Test 7: Pressure hold at 150˚F, 5000 diff psi above the packer, 43000lbs tension (Cold Hold).

Test 8:(Temp Cycle -1 completed). 325°, 5000 diff psi above Pressure Hold.

Test Summary / Conclusion:

Model BP-HPR-2 as defined above successfully tested as per V3 grade of validation according to API SPEC 11D1 requirements

REMARKS :

The size 9-5/8" # (47-53.5) PPF HYDRAULIC SET HIGH ANGLE PRODUCTION PACKER is successfully set inside test casing of 9-5/8'' #47

PPF in Maximum Casing ID 8.681" +0.030/ -0.000" at the rated minimum setting pressure and performed the V3 validation with minimum two

pressure reversals at max rated temp, and Loads plus cold hold at min rated temp on temp cycle range. packer withstands test differential

pressure rating of 5000 psi from below to above to below pressure sequence of the packer as per design Output document.

The Test for HYDRAULIC SET HIGH ANGLE PRODUCTION PACKER Passed the V3 validation qualification and conforms the requirements

as per API 11D1 Product specification

Tested By: Witnessed By:

Approved By:

(Assembly and Testing In- (Head QA/QC, &

(Director Operations)

charge) HOD Design)

Date: Date: Date:

You might also like

- TM 91425-688-10 - M98 Javelin Weapon SystemDocument332 pagesTM 91425-688-10 - M98 Javelin Weapon SystemDenis100% (4)

- ATPL Fragen 1Document18 pagesATPL Fragen 1martinNo ratings yet

- Screenshot 2019-12-04 at 17.37.04Document1 pageScreenshot 2019-12-04 at 17.37.04Arthur LottieNo ratings yet

- Stoichiometry Worksheet6-1Document6 pagesStoichiometry Worksheet6-1Von AmoresNo ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- PVT Report - 140319 - Zone - 8 - May'17 Separator SampleDocument28 pagesPVT Report - 140319 - Zone - 8 - May'17 Separator SampleIBIKUNLENo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ficha Técnica Castrol Synthetic CT 320Document2 pagesFicha Técnica Castrol Synthetic CT 320el pro jajaja GonzalezNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Castrol Alpha SP 150 Data SheetDocument2 pagesCastrol Alpha SP 150 Data SheetRonny Ali Ochoa YucraNo ratings yet

- Tabriz HIPS7240Document2 pagesTabriz HIPS7240alimotazedi57No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- 0500 Wireline Bridge PlugsDocument1 page0500 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Registry of Sleeve PlacementDocument10 pagesRegistry of Sleeve PlacementJorge Isaac Lara RamosNo ratings yet

- Ot ValidationDocument3 pagesOt ValidationRajdip ChaudhariNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Castrol Manual EP 80W-90: DescriptionDocument1 pageCastrol Manual EP 80W-90: Descriptionvicky kNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- Ficha Tecnica Castrol Optigear SyntheticDocument2 pagesFicha Tecnica Castrol Optigear SyntheticVictor Manuel Gonzalez PerezNo ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- Manual GL-4 80W-90: DescriptionDocument1 pageManual GL-4 80W-90: DescriptionSugianto DoankNo ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Customer Information Valve Identification: New Relief Valve Test Report Date October 05,2020Document1 pageCustomer Information Valve Identification: New Relief Valve Test Report Date October 05,2020Juan Manuel RodriguezNo ratings yet

- Tection Global 15W - 40Document2 pagesTection Global 15W - 40carmaNo ratings yet

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Cs1 Rundown Aplicacion - VacioDocument3 pagesCs1 Rundown Aplicacion - VacioJulio HuancaNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- DATASHEET - TécnicoDocument1 pageDATASHEET - TécnicoFernando RockerNo ratings yet

- Castrol Alphasyn EP 220Document2 pagesCastrol Alphasyn EP 220Vusal HasanovNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- 7451 (16-32) TENSILE-BOLT AFCO-newDocument17 pages7451 (16-32) TENSILE-BOLT AFCO-newMOHAMEDNo ratings yet

- Collar Cam Chain Guide Roller PdirDocument1 pageCollar Cam Chain Guide Roller PdirPreetam KumarNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Castrol Optigear Synthetic 1510.320Document2 pagesCastrol Optigear Synthetic 1510.320Hector JNo ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- 0412 Wireline Bridge PlugsDocument1 page0412 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- 183-19 Wpqc-W162-6''-Asme XiDocument1 page183-19 Wpqc-W162-6''-Asme Xibouchoucha jebaliNo ratings yet

- EPX RangeDocument2 pagesEPX RangecarmaNo ratings yet

- Arcelormittal Nippon Steel India Limited: Heat Analysis (%) of 24400486Document1 pageArcelormittal Nippon Steel India Limited: Heat Analysis (%) of 24400486pranav kariaNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Record of Welder Performance - Qualification Test: Welding ManualDocument43 pagesRecord of Welder Performance - Qualification Test: Welding Manualdreamboy87No ratings yet

- 1312dla 0704 - I14 ADocument2 pages1312dla 0704 - I14 AAnonymous W939WdINo ratings yet

- Extracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIADocument2 pagesExtracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIALoolooNo ratings yet

- HD384UADocument2 pagesHD384UAmohamad mostafaviNo ratings yet

- Castrol Axle EPX 80W-90Document1 pageCastrol Axle EPX 80W-90indeskeyNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- Gas Sampling Device Comem GSD: Data SheetDocument4 pagesGas Sampling Device Comem GSD: Data SheethecjavpaNo ratings yet

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- 3685 Mir 006 PDFDocument1 page3685 Mir 006 PDFashishpearlNo ratings yet

- 3685 Mir 006 PDFDocument1 page3685 Mir 006 PDFashishpearlNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- Kokum Kitchen MenuDocument2 pagesKokum Kitchen MenuAnkit MalhotraNo ratings yet

- Scope and Applicability: 1.1.1 StructureDocument9 pagesScope and Applicability: 1.1.1 StructureStevan SteticNo ratings yet

- Ha Vs NorthwesternDocument13 pagesHa Vs NorthwesternChad AlvarezNo ratings yet

- Push Installation From EPM ServerDocument4 pagesPush Installation From EPM ServermarahlhalatNo ratings yet

- MS P2 CompilationDocument451 pagesMS P2 CompilationJe KirsteneNo ratings yet

- 10 Cases From Layno vs. SandiganDocument15 pages10 Cases From Layno vs. SandiganKenette Diane CantubaNo ratings yet

- Comprehensive Healthcare Simulation. Grant and Cheng.Document417 pagesComprehensive Healthcare Simulation. Grant and Cheng.charlsandroid01No ratings yet

- La Cadena de Huáscar: Retórica de La Genealogía, La Infancia y La Niñez en Los Comentarios Reales de Garcilaso de La Vega, El IncaDocument29 pagesLa Cadena de Huáscar: Retórica de La Genealogía, La Infancia y La Niñez en Los Comentarios Reales de Garcilaso de La Vega, El IncaPaula Martínez SagredoNo ratings yet

- WIDGB2 Utest Language 6ADocument2 pagesWIDGB2 Utest Language 6AВика НизолаNo ratings yet

- Tle 7 - Q1.W1Document2 pagesTle 7 - Q1.W1Pia DelaCruz100% (2)

- Caledonian: BS 6346 PVC Insulated, Armored Power and Control CablesDocument28 pagesCaledonian: BS 6346 PVC Insulated, Armored Power and Control CablessurenediyaNo ratings yet

- Acute GastroenteritisDocument63 pagesAcute GastroenteritisSathya MoorthyNo ratings yet

- 04packaging MaterialsDocument11 pages04packaging MaterialsAyalew DesyeNo ratings yet

- Aes Secondary Emulsifier: Safety Data SheetDocument8 pagesAes Secondary Emulsifier: Safety Data Sheetgerardo sifuentesNo ratings yet

- Mujeeb Rahuman CVDocument3 pagesMujeeb Rahuman CVmakana qcNo ratings yet

- Ds About Magnesium OilDocument2 pagesDs About Magnesium OilMark Dingle100% (1)

- St. Lawrence Parish: 1520 East Delavan Avenue Buffalo, New York 14215Document2 pagesSt. Lawrence Parish: 1520 East Delavan Avenue Buffalo, New York 14215api-141905435No ratings yet

- Medical Glossary Midterms ExamDocument7 pagesMedical Glossary Midterms ExamFev BanataoNo ratings yet

- Gerund Vs Infinitive and Do Vs Make ExercisesDocument9 pagesGerund Vs Infinitive and Do Vs Make ExercisesVivita GuzmánNo ratings yet

- (Journal of NeurosurgeDocument10 pages(Journal of NeurosurgeMoustafa FouadNo ratings yet

- C+F-Spirometra İnfection in Cats and DogsDocument5 pagesC+F-Spirometra İnfection in Cats and Dogstaner_soysurenNo ratings yet

- Prof Ed 4Document2 pagesProf Ed 4Ivan BermundoNo ratings yet

- Lesson 1 Managing IT in A Digital WorldDocument5 pagesLesson 1 Managing IT in A Digital WorldliamdrlnNo ratings yet

- SMEA2402 - Manufacturing Processes LabDocument15 pagesSMEA2402 - Manufacturing Processes LabPurusothamanManiNo ratings yet

- Effect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientDocument6 pagesEffect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientChaguy VergaraNo ratings yet

- Arogya Sanjeevani - One PagerDocument1 pageArogya Sanjeevani - One Pagernaval730107No ratings yet