Professional Documents

Culture Documents

P10 - H12 - JSA - Electrical - Rev 00 - 20221204

P10 - H12 - JSA - Electrical - Rev 00 - 20221204

Uploaded by

imranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P10 - H12 - JSA - Electrical - Rev 00 - 20221204

P10 - H12 - JSA - Electrical - Rev 00 - 20221204

Uploaded by

imranCopyright:

Available Formats

Job Safety Analysis

TRS-HS-FRM-0001

Instructions for completing Job Safety Analysis (JSA) form

Section I -Enter general information about the site and job task.

Section II - Determine whether any of these operations apply to the job task to be performed. Make note of any special training, permit, certification, and risk

assessment requirements.

Section III - Identify any human/organizational factors that could impact the ability to perform the work safely.

1. Break the job down into steps - Be as specific as possible. Write each job step in a new row of column A (Activity/Step). It’s a good idea to leave an extra row

between steps in case you need them later. Add additional rows to the table as needed, or if completing the JSA on paper, print additional copies of the

sheet to accommodate all job steps.

2. Determine the hazards associated with each job step and write them in column B (Hazards). Use the examples of hazards provided below to trigger your

thinking about different types of hazards and energy sources.

3. List any control measures that will be taken to ensure that step is done safely in column C (Control Measures). Use the control measure examples and

hierarchy provided to trigger your thinking about different types of controls and their effectiveness at reducing risk. Controls toward the top of the table

tend to be more effective at minimizing the severity and/or likelihood of an event than the controls toward the bottom of the table. If this job involves a Life

Crucial Operation, continue to step 4. Otherwise, repeat steps 2-3 for each of the job steps identified, then proceed to step 8.

4. Considering the hazards involved and the control measures that will be in place, determine the worst credible severity of an incident that could result from

this job step. Use the severity table provided. Write the severity number in column D (Severity).

5. Considering the hazards involved and the control measures that will be in place, determine the likelihood that an incident will result from this job step. Use

the likelihood table provided. Write the likelihood number in column E (Likelihood).

6. Multiply the severity number by the likelihood number and enter the product in column F (Risk).

7. Consider the risk rating against the thresholds provided in the Overall Risk Ratings.

i. Very low and low risk ratings of 1-3. This level is generally considered acceptable provided that all control measures are applied.

ii. Medium risk ratings of 4-6. Medium risk requires a planned approach to control the hazard and applies additional controls if required. Action taken must

be documented on the risk assessment form.

iii. High and Very High-Risk ratings of 8-24. For all high and very high risk, Column G (Additional control measures) must be implemented to further reduce

the risk to a medium or low level. Such activities shall not be proceeded until applying additional control measures. The Construction Director/Manager or

facility Manager must personally review the activities with a High or Very High residual risk score and approve additional control measures by signing off

the JSA.

8. Repeat steps 2-7 for each of the job steps identified.

Section IV - Provide the name, company, and title of those who prepared and reviewed/approved this form in the signature box provided. The Construction

Director/Manager or facility Manager must review and approve the additional control measures that have a High or Very High-Risk rating before proceeding the task.

Additional space is also provided for crew members to sign the JSA if desired.

Reference Table in completing Section III – Job Safety Analysis (Column B – Hazard)

Biological & Electrical Chemical Gravity/Height Mechanical & Motion

Environmental Arc Flash Air Emissions Equipment Being Thrown Off/Under

Altitude Buried Utilities Chemical Products Tipping/Collapsing Equipment

Animal Bite/Sting Damage to Leads/Cables Carcinogenic Excavation/Trench Disintegration of Moving

Blood-Borne Pathogens Damage to Switches Combustible/Flammable Falling Objects Components

Contaminated Food/Water Energized Circuits/Conductors Explosive Floor Openings/Edges Driving/Vehicle Traffic

Insect-Borne Disease Inadvertent Energization Toxic Grating Removed Ejection of Workpiece/Debris

Pests Lack of Isolation/Grounding Corrosive Inadequate Support Entanglement

Poisonous Plants Missing/Damaged Insulation Reactive Lack of Access Ladders/Stairs Friction

Precipitation Overhead Lines Client/Process Chemicals Suspended Load Movement/Shifting

Temperature/Humidity Overload of Circuits Lack of Containment Unstable/Insecure Materials Moving Parts

Unsanitary Conditions Stored Energy Leakage/Spills Work Above/Below Others Pinch/Crush Points

Weather (Batteries/Capacitors) Material Incompatibility Work at Height/Fall Hazards Projectiles

Wind/Turbulence Water Near Electrical Produced/Disturbed by Work Walking/Working Surface Rotating Equipment

Pressure Conductors Asbestos Slippery Sharp Edges, Corners, or Points

Abrasive Blasting Work Environment Lead Uneven Shearing

Compressed Gases Cluttered Silica Obstructed Stored Energy

High Pressure Fluid Confined Space Welding Fumes Steep (Springs/Accumulators)

Pressure Testing Damaged Tools/Equipment Dust Moving/Swaying/Pitching Striking

Pressure Washing/Blasting Entrapment Water Discharges Insufficient/Unstable Trapped Between Equipment

Radiation Erosion Wastes Generated Ergonomic and Fixed Structures

Intense Light Hazardous Atmosphere Hazardous Awkward Unexpected/Uncontrolled

Lasers Oxygen Rich/Deficient Non-Hazardous Postures/Movement Movement

Microwaves Contaminants Sound Excessive Force/ Exertion

Naturally Occurring Ignition Sources Continuous Noise Heavy/Awkward Load

Radioactivity Radioactive Inadequate Ventilation Intermittent Noise Repetitive Motion

Material Poor Lighting/Glare Extreme Noise Same Position

X-Rays Restricted Access/Egress Impact Noise Vibration

Runoff

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 1 of 6

Job Safety Analysis

TRS-HS-FRM-0001

Reference Table in completing Section III – Job Safety Analysis (Column C – Control Measure)

Most Effective Controls Examples

Elimination Make connections at ground level before Remove a dangerous machine from service

(Remove the hazard altogether) erecting a structure to eliminate work at height Provide power outlets to avoid trailing cords

Substitution Use latex rather than oil-based paints

(Replace the material/process Reduce energy, such as speed, force, amperage, pressure, and temperature

with a less hazardous one) Use water-based detergents instead of organic solvents

Isolate hazardous energy

Engineering/Isolation Ventilation

sources Secondary containment

(Design effective control Machine guarding

Interlocks Barriers

measures to protect people and Enclosures

Platforms and guardrails Improve lighting

the environment) Circuit breakers

Exclusion zones

Warning Signs Horns Labels

High visibility paint

(Alert people to the hazards) Backup alarms Beepers Tags

Administrative Work rotation to minimize exposure

(Provide training, procedures, Inspect safety equipment Training and supervision

etc.) Good housekeeping practices

PPE

Safety glasses Fall harness and lanyards Respiratory protection

Least Effective (Personal protective

Hearing protection Gloves High visibility vests

equipment)

Reference Table in completing Section III – Job

Reference Table in completing Section III – Job Safety Analysis (Column D –Severity)

Safety Analysis (Column E – Likelihood)

Impact On Likelihood Chances of

Severity Level Probability

People Environment / Community Equipment / Property Level Occurrence

Long-term (multi-year) impacts to Extensive losses of high

air, surface/ground water, or soil; or value equipment/property

Single / Expected to occur

Critical / Widespread areas including offsite Loses exceeding $1,000,000; Very

6 Multiple 4 in most 1 in 100

Catastrophic area/community affected; or or Likely

fatalities circumstances

Some adverse publicity/media Major unplanned impact on

coverage project budget and schedule

Losses of

Lasting (up to one year) impacts to

equipment/property that

Injury or illness air, surface/ground water, or soil; or

cannot be readily replaced;

resulting in Offsite area/community affected; or Strong possibility

or

Major 4 permanent Events that are reportable to Likely 3 the event will 1 in 1,000

Losses exceeding $100,000;

total or partial regulatory authorities; or occur

or

disability Potential for adverse

Significant unplanned

publicity/media coverage

impact on project budget

Temporary (up to one month)

Injury or illness

impacts to air, surface/ground Loss of equipment that can

resulting in

water, or soil limited to the project be readily replaced; or

medical

site; or Losses exceeding $10,000; The event might

Moderate 2 treatment or Possible 2 1 in 10,000

Breach of regulatory requirement or or occur

temporary

limit; and Minor impact on project

disability/loss

No potential for adverse budget

of function

publicity/media coverage

No direct impact to air, No impact on equipment

Injury or illness surface/ground water, or soil; or functionality Highly unlikely but

requiring first- Effects restricted within buildings or Minor, cosmetic damage; or may occur in 1 in

Minor 1 Unlikely 1

aid treatment containment structures; and Repair costs easily covered exceptional 1,000,000

only No potential for adverse by normal project operating circumstances

publicity/media coverage budget

Reference Table in completing Section III – Job Safety Analysis (Column F – Risk)

Risk Matrix Overall Risk Ratings

Likelihood

Very Low Low Medium High Very High

Severity Unlikely Possible Likely Very Likely 1 2-3 4-6 8-18 24

1 2 3 4

Critical - 6 6 12 18 24

High and Very High-Risk ratings of 8-24.

Additional control measures must be implemented to further reduce the High

Major - 4 4 8 12 16 and very high risk to acceptable level.

Note: The Construction Director/Manager or Facility Manager must personally

review the activities with a High or Very High residual risk score and approve

Moderate - 2 2 4 6 8 suitable additional control measures by signing the JSA.

Minor - 1 1 2 3 4

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 2 of 6

Job Safety Analysis

TRS-HS-FRM-0001

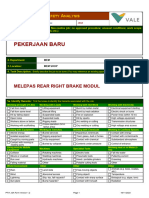

Section I – General Information

Emergency Procedures

Emergency Contact Name : TRSDC Emergency Operation Center (EOC) Emergency Contact Phone Number : Mr. Afridi / Mr. Liu

Primary Contact 011-212 7111 Primary Contact 059-600 1876

Secondary Contact +99 50 523 3422 Secondary Contact 055-347 0700

Details

Program Number. P 10-H 12 Company Name CHEAC

Project Name Pilling , foundation & Haul Road Date 11/24/2022

JSA /Risk Assessment Title Electrical Category ✘ New Revised

Specific Location Ummayhat 9-5- All Zones Building N/A

Plant Tools & Equipment Required Power Tools, Battery operated Tools & Hand Tools Area All Zone including Camp

Work Scope/Description Installation & Maintenance

Section II – Does this job require any of the following operations?

= Requires formal/special training = Requires certification or Competent/Qualified Person designations

= Requires a permit/form/report ∆ = Life Crucial Operations = Requires full Risk Assessment

Description Yes Description Yes

Aerial Lifts ∆ Cranes - Critical lift ∆

Confined Space ∆ Hot Work

Dismantling and Demolition Loading/Unloading Material ∆

Electrical Hazards ∆ ✘ Noise Exposure

Excavation/Trenching ∆ Powered Industrial Trucks ∆

First Line Breaks ∆ Radiation Area Work

Grating/Floor Plate/ Guardrail Removal ∆ ✘ Respiratory Hazards

Hazardous Energy Control ∆ Roof Work ∆

Hazardous Materials

Scaffolding ∆

Asbestos & Lead Work

Hazardous Materials

Site/Vehicle Traffic ∆

Crystalline Silica & Cadmium

Hazardous Waste Operations Steel Erection ∆

Heavy Equipment ∆ Work at Height (> 6 ft) ∆

Rigging, & Cranes ∆ Other

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 3 of 6

Job Safety Analysis

TRS-HS-FRM-0001

Section III – Job Safety Analysis Risk Assessment (Post Control Measures)

(A) (B) (C) (D) (E) (F) (G) (H) (I) (J)

Activity/Step Hazards Control Measures Severity Likelihood Risk Additional Control measures Severity Likelihood Risk

Follow permit to work system with

procedures

-All temporary power supply must be

installed by a competent electrician

-De-energized and lock out electrical

circuit/parts you will be working on.

-Personnel shall ensure that suitable

Personal Protective Equipment is worn

at all times when handling sharp or

otherwise potentially hazardous

materials

-Personnel shall ensure that a safe

system of work is implemented so as to

reduce the possibilities of

accidents/incidents caused by a lack of

Installation & Maintenance of

communication Shut of the power supply & Loto system

lighting devices, electrical Electrocution Physical

-All personnel involved must have shall be implemented.

appliance in camp, wiring & injuries Electric shock Trip, 3 2 6 2 1 3

electrical safety/LOTO training. Make sure store energy shall be

Cabling Slip, Fall, Cut

-All electrical cables for temporary completely released.

power supply must be of approved

materials and hung using lead stand to

prevent damage to electrical cords and

to prevent slip, trips, and fails

-Measure appropriate length of cable or

wire to be used. Used correct tools in

cutting handled and stored receipt in

accordance with procedure for material

control

-All tools should be insulated type

-Ensure that the work being carried out

is closely monitored and supervised by

a qualified, experienced, and trained

Engineer/supervisor.

-PPE

Generator maintenance Fire, Burn, Electrocution, Energized work-permit to work 3 3 9 Shut of the generator & Loto system 2 2 4

entanglement required. shall be implemented.

All Tools shall be insulated. Make sure store energy shall be

Electricians have proper training and completely released.

shall be certified by 3rd party.

Fire Watcher available.

All tools shall be inspected & colour

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 4 of 6

Job Safety Analysis

TRS-HS-FRM-0001

coded.

Electrician should wear shock proof

gloves & Shoes.

Rescue teams are available nearby.

Fire extinguisher shall be available.

Design shall be prior approved by

electrical engineer.

Required capacity shall be identified.

Energized after the inspected by an

Wrong circuit, installation by All ECLB and other material shall be ISO

Installation of DB Panels 2 2 4 electrical engineer. 2 1 2

incompetent person. certified & inspected.

All cables shall be fully load tested.

After the installation, DB panel shall be

detailed inspected and tagged by

electrical engineer

Energized work-permit to work

required.

All Tools shall be insulated.

Electricians have proper training and

Shut of the generator & Loto system

shall be certified by 3rd party.

shall be implemented.

Fire Watcher available.

Maintenance of DB Panels Fire, Burn, Electrocution, 3 2 6 Make sure store energy shall be 2 2 4

All tools shall be inspected & colour

completely released.

coded.

Electrician should wear shock proof

gloves & Shoes.

Rescue teams are available nearby.

Fire extinguisher shall be available.

Note: Insert additional rows or print additional sheets as necessary to accommodate all job steps.

Section IV – Approval and Signatures

Prepared by Company Position

Wang Peng CHEAC HSE Supervisor

Reviewed and Approved by Company Position

Liu CHEAC Supervisor/Engineer

Imran Wahab CHEAC HSE Representative

High and Very High residual risk rating (8-24)

Note: All High and Very High residual risk ratings (8-24) require review and approval by Construction Director/Manager or Facility Manager before starting work to ensure that the additional controls are adequate to execute the task safely.

Reviewed and Approved by Company Position

Mr. Dong CHEAC Construction Director/Manager or Facility Manager

Reviewed by Crew Company Position

Site Electrician

Safety Officer

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 5 of 6

Job Safety Analysis

TRS-HS-FRM-0001

Job Safety Analysis( TRS-HS-FRM-0001)

Revision 01, Rev. Date 29-July-2020 Page 6 of 6

You might also like

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Instructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisDocument7 pagesInstructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisMuhammad Umar Gondal100% (1)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Chapter 6 StressDocument9 pagesChapter 6 StressSiti Sarah Zalikha Binti Umar BakiNo ratings yet

- JSA For Elevator InstallationDocument11 pagesJSA For Elevator InstallationHamid RazaNo ratings yet

- Job Safety Analysis For Concrete Casting (R-01)Document13 pagesJob Safety Analysis For Concrete Casting (R-01)Suju RajanNo ratings yet

- JSA For Install Instrument Sample Point HousingDocument3 pagesJSA For Install Instrument Sample Point HousingNasrullah JanNo ratings yet

- Hazard Identification, Risk Assessment & Safe Working Procedure For Hazardous Area InspectionsDocument14 pagesHazard Identification, Risk Assessment & Safe Working Procedure For Hazardous Area InspectionsAnonymous KarIDvNo ratings yet

- JHA Template BlankDocument5 pagesJHA Template BlankChristopher Newby100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Cinderella by Roald DahlDocument5 pagesCinderella by Roald DahlRaquel Gonzalez33% (3)

- P10 - H12 - JSA - Lifting - Rev 00 - 20221204Document6 pagesP10 - H12 - JSA - Lifting - Rev 00 - 20221204imranNo ratings yet

- JSA Assessement geeneral updatedDocument11 pagesJSA Assessement geeneral updatedhabib42833No ratings yet

- Ro3 Co2co2 TBV Hse Ra 005.00Document19 pagesRo3 Co2co2 TBV Hse Ra 005.00like saddamNo ratings yet

- Logistic Management-Risk AssessmentDocument10 pagesLogistic Management-Risk Assessmentlike saddamNo ratings yet

- Ro3 Co2co2 TBV Hse Ra 006.00Document12 pagesRo3 Co2co2 TBV Hse Ra 006.00like saddamNo ratings yet

- Jsa For Termite Control Works - Rev. 00-Chec7Document9 pagesJsa For Termite Control Works - Rev. 00-Chec7jingzhongwei296No ratings yet

- Lifting JSADocument10 pagesLifting JSAiqbalmugal82No ratings yet

- 000.653.F0100 JSA - Hydrotesting of Fire Water LinesDocument8 pages000.653.F0100 JSA - Hydrotesting of Fire Water LinesMuhammad Umar GondalNo ratings yet

- Ro3 Co2co2 TBV Hse Ra 004.00Document12 pagesRo3 Co2co2 TBV Hse Ra 004.00like saddamNo ratings yet

- Generator RADocument16 pagesGenerator RABaher MohamedNo ratings yet

- CHW Pipe Installation, Insulation & Cladding - JSA - Risk AssessmentDocument13 pagesCHW Pipe Installation, Insulation & Cladding - JSA - Risk Assessmentlike saddamNo ratings yet

- Installation of PPR and PEX Pipes - JSA - Risk AssessmentDocument11 pagesInstallation of PPR and PEX Pipes - JSA - Risk Assessmentlike saddamNo ratings yet

- JSA-Risk Assessment - 01Document2 pagesJSA-Risk Assessment - 01like saddamNo ratings yet

- Installation of Air Curtain - JSA - Risk AssessmentDocument11 pagesInstallation of Air Curtain - JSA - Risk Assessmentlike saddamNo ratings yet

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Form 5.1.3.A JSA Specific Hazards Checklist EnglishDocument1 pageForm 5.1.3.A JSA Specific Hazards Checklist EnglishArchana SoorajNo ratings yet

- Risk Assessment MatrixDocument4 pagesRisk Assessment MatrixKunju MathewsNo ratings yet

- MS-AS-FRM-0063 Job Hazard Analysis Worksheet Form-1 (1)Document3 pagesMS-AS-FRM-0063 Job Hazard Analysis Worksheet Form-1 (1)reda ihsaneNo ratings yet

- MS-As-FRM-0063 Job Hazard Analysis Worksheet FormDocument3 pagesMS-As-FRM-0063 Job Hazard Analysis Worksheet Formأم رهامNo ratings yet

- The Form Should Be Used in Accordance With The Job Hazard Analysis Standard MS-AS-STD-0064Document3 pagesThe Form Should Be Used in Accordance With The Job Hazard Analysis Standard MS-AS-STD-0064Mounir HammoutiNo ratings yet

- Job Safety Analysis Blank FormatDocument2 pagesJob Safety Analysis Blank FormatKumar KushNo ratings yet

- Takina-Job-Safety-Analysis-and-Training-register_V2Document8 pagesTakina-Job-Safety-Analysis-and-Training-register_V2satishdawane2390No ratings yet

- SP02 JSA Form EnglishDocument5 pagesSP02 JSA Form Englishmartina19No ratings yet

- Utility Hazard AssessmentDocument2 pagesUtility Hazard AssessmentsafwanNo ratings yet

- Work Permit Sample For Contractro TresDocument6 pagesWork Permit Sample For Contractro TresretheepNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument6 pagesReview Safe Work Permit Hazard ChecklistSuud SenanNo ratings yet

- JSA 08 Laying of Conduit WiringDocument8 pagesJSA 08 Laying of Conduit Wiringsyed khaja misbhuddinNo ratings yet

- Risk Assessment Form1Document3 pagesRisk Assessment Form1Elites ChoraleNo ratings yet

- EHSMS09 Job Hazard Analysis (JHA) Formand Safe Work Method Statement (SWMS)Document4 pagesEHSMS09 Job Hazard Analysis (JHA) Formand Safe Work Method Statement (SWMS)yanaNo ratings yet

- Sewing Machine Risk AssessmentDocument2 pagesSewing Machine Risk Assessmenteunicemabena664No ratings yet

- Hazard EvaluationDocument3 pagesHazard EvaluationMobile SunNo ratings yet

- Job Hazard Analysis Worksheet Form HSEDocument2 pagesJob Hazard Analysis Worksheet Form HSEChaimaa EnnouhiNo ratings yet

- JSA For Limit Switch Checking & AdjustmentDocument3 pagesJSA For Limit Switch Checking & AdjustmentSwagata BeraNo ratings yet

- Job Safety & Environment Analysis (Jsa) : Activity or TaskDocument3 pagesJob Safety & Environment Analysis (Jsa) : Activity or TaskLusy Gusti EfendiNo ratings yet

- Job Safety Analysis KFS-IMSF-HRA-01-Job Safety AnalysisDocument2 pagesJob Safety Analysis KFS-IMSF-HRA-01-Job Safety AnalysisAmit ChahandeNo ratings yet

- iFUEL CON Risk AssessmentDocument3 pagesiFUEL CON Risk AssessmentHoang Quoc DungNo ratings yet

- Procter Risk Assessment CalculatorDocument241 pagesProcter Risk Assessment CalculatorFormosa SysNo ratings yet

- JSA - Unloading & Positioning of Pre Action EquipmentDocument7 pagesJSA - Unloading & Positioning of Pre Action EquipmentRAJKUMAR MUTHINENINo ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- TRA - Amine System Degreasing - October 14, 2018Document9 pagesTRA - Amine System Degreasing - October 14, 2018Ijaz HussainNo ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- 17 How To Identify Hazards Requiring Risk Management PDFDocument4 pages17 How To Identify Hazards Requiring Risk Management PDFSeet HmtNo ratings yet

- 13.2.10 RA SWP For Installation of Heat Tracing at DCLDocument15 pages13.2.10 RA SWP For Installation of Heat Tracing at DCLNebosh Diploma AssignmentNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- WirelessEstimatorJHA YESElevatedDocument5 pagesWirelessEstimatorJHA YESElevatedmohammed tofiqNo ratings yet

- SWP HousekeepingDocument2 pagesSWP HousekeepingSandra chiomaNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument5 pagesReview Safe Work Permit Hazard ChecklistHardtail HardcoreNo ratings yet

- Laser Surface Treatments for Tribological ApplicationsFrom EverandLaser Surface Treatments for Tribological ApplicationsNo ratings yet

- STA ElectricalDocument3 pagesSTA ElectricalimranNo ratings yet

- P10 - H12 - JSA - Lifting - Rev 00 - 20221204Document6 pagesP10 - H12 - JSA - Lifting - Rev 00 - 20221204imranNo ratings yet

- MS - Ground Improvement Trail TestDocument16 pagesMS - Ground Improvement Trail TestimranNo ratings yet

- MS - Rainy Season Drainage Construction-1115Document8 pagesMS - Rainy Season Drainage Construction-1115imranNo ratings yet

- Legal Reasoning For Seminal U S Texts Constitutional PrinciplesDocument13 pagesLegal Reasoning For Seminal U S Texts Constitutional PrinciplesOlga IgnatyukNo ratings yet

- Heirs of John Sycip vs. CA G.R. No. 76487 November 9 1990Document3 pagesHeirs of John Sycip vs. CA G.R. No. 76487 November 9 1990Mariel D. Portillo100% (1)

- 5 He-Man Vs Skeletor Their Final BattleDocument9 pages5 He-Man Vs Skeletor Their Final BattleRodrigo Sorokin100% (2)

- Chemsheets-Empirical - Molecular-FormulaDocument1 pageChemsheets-Empirical - Molecular-FormulaMouli MishraNo ratings yet

- The Law On Obligations and Contracts (Notes From Youtube) - PrelimDocument36 pagesThe Law On Obligations and Contracts (Notes From Youtube) - PrelimGwyneth ArabelaNo ratings yet

- Stacey Dunlap ResumeDocument3 pagesStacey Dunlap ResumestaceysdunlapNo ratings yet

- Data Sheet 68749835 Electronic Throttle BodyDocument3 pagesData Sheet 68749835 Electronic Throttle BodyDaniel AguirreNo ratings yet

- Language Test 6BDocument2 pagesLanguage Test 6BKelvin MyintNo ratings yet

- Not in His Image (15th Anniversary Edition) - Preface and IntroDocument17 pagesNot in His Image (15th Anniversary Edition) - Preface and IntroChelsea Green PublishingNo ratings yet

- Comprehension Toolkit 1Document3 pagesComprehension Toolkit 1api-510893209No ratings yet

- Grade 5 CommentsDocument17 pagesGrade 5 Commentsreza anggaNo ratings yet

- Bac 1624 - ObeDocument4 pagesBac 1624 - ObeAmiee Laa PulokNo ratings yet

- Realme Buds Q2s With AI ENC & Fast Charging Bluetooth HeadsetDocument2 pagesRealme Buds Q2s With AI ENC & Fast Charging Bluetooth HeadsetKhuni FreefireNo ratings yet

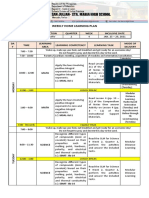

- Weekly Home Learning Plan: Grade Section Quarter Week Inclusive DateDocument3 pagesWeekly Home Learning Plan: Grade Section Quarter Week Inclusive DateMarvin Yebes ArceNo ratings yet

- What Love Is ThisDocument2 pagesWhat Love Is Thisapi-3700222No ratings yet

- Pengkarya Muda - Aliah BiDocument7 pagesPengkarya Muda - Aliah BiNORHASLIZA BINTI MOHAMAD MoeNo ratings yet

- PBL KaleidoscopeDocument3 pagesPBL KaleidoscopeWilson Tie Wei ShenNo ratings yet

- GIDC Rajju Shroff ROFEL Institute of Management Studies: Subject:-CRVDocument7 pagesGIDC Rajju Shroff ROFEL Institute of Management Studies: Subject:-CRVIranshah MakerNo ratings yet

- Frs Whatsapp Chat NotesDocument72 pagesFrs Whatsapp Chat NotesFarai NyaniNo ratings yet

- Teacher Newsletter TemplateDocument1 pageTeacher Newsletter TemplateHart LJNo ratings yet

- Dual-Band Wearable Rectenna For Low-Power RF Energy HarvestingDocument10 pagesDual-Band Wearable Rectenna For Low-Power RF Energy HarvestingbabuNo ratings yet

- Intrnship Report On WapdaDocument106 pagesIntrnship Report On WapdaNarain MenghwarNo ratings yet

- UNIT 3 Part 1-Propositional LogicDocument11 pagesUNIT 3 Part 1-Propositional LogicVanshika ChauhanNo ratings yet

- Study of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsDocument6 pagesStudy of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsOpenaccess Research paperNo ratings yet

- Ferdinando Carulli - Op 121, 24 Pieces - 4. Anglaise in A MajorDocument2 pagesFerdinando Carulli - Op 121, 24 Pieces - 4. Anglaise in A MajorOniscoidNo ratings yet

- Case Digest Extinguishment of ObligationsDocument25 pagesCase Digest Extinguishment of ObligationsLyneth GarciaNo ratings yet

- Study Session8Document1 pageStudy Session8MOSESNo ratings yet

- Referee Report TemplateDocument2 pagesReferee Report TemplateAna Jufriani100% (1)