Professional Documents

Culture Documents

Sign Barricades & Flagging Sop

Sign Barricades & Flagging Sop

Uploaded by

Dhaneswar SwainCopyright:

Available Formats

You might also like

- 2.1 - CR 10 (1) (A) Fall Protection PlannerDocument1 page2.1 - CR 10 (1) (A) Fall Protection PlannerSusan LouwNo ratings yet

- Cable Tray Inspection ListDocument1 pageCable Tray Inspection ListTreesa Archnana100% (3)

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- Yas Island Phase 2, Zone K - Garden Crescent - Part 1 - Technical Proposal - 2010.04.19Document92 pagesYas Island Phase 2, Zone K - Garden Crescent - Part 1 - Technical Proposal - 2010.04.19arunava sarkarNo ratings yet

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- Permit To DigDocument3 pagesPermit To DigMarco DonatiNo ratings yet

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- SWP-06 Lifting Operation DaimanDocument4 pagesSWP-06 Lifting Operation DaimanHassan AbdullahNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30100% (1)

- Concrete WorkDocument1 pageConcrete WorkChandru100% (1)

- Gopu.R:::: Patient Age / Sex 30 Y / Male BranchDocument1 pageGopu.R:::: Patient Age / Sex 30 Y / Male BranchGopu RNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- APC Questions Jan 05 - Sorted by CompetencyDocument8 pagesAPC Questions Jan 05 - Sorted by CompetencyHaneefa Ch100% (3)

- Night Work PermitDocument3 pagesNight Work PermitArmando AballeNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- Method Statement PDFDocument2 pagesMethod Statement PDFAl Manar PetroleumNo ratings yet

- Pre-Job Safety Assessment: Site InformationDocument2 pagesPre-Job Safety Assessment: Site Informationgueettaf faresNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift PlanMd Wãșéèm ÁkrãmNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Hira - Eot CraneDocument4 pagesHira - Eot CraneSantosh SinghNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- First Aid Report FormDocument1 pageFirst Aid Report FormSaikat ChakrabortyNo ratings yet

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocument21 pagesLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- Siemens LTD.: General Work Permit Serial No.Document3 pagesSiemens LTD.: General Work Permit Serial No.Dakshinamurthy PNo ratings yet

- MEWP Daily Inspection ChecklistDocument1 pageMEWP Daily Inspection ChecklistZukhrufal JannahNo ratings yet

- Risk Assessment For Confined SpaceDocument5 pagesRisk Assessment For Confined Spaceappu pocom3No ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- GC3 ObservationDocument16 pagesGC3 ObservationjithinNo ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- HR HR TEM007 GEN ALL Visitor Induction Rev1.0Document2 pagesHR HR TEM007 GEN ALL Visitor Induction Rev1.0Doni TriatmojoNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocument1 pageSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- De-Shuttering Risk Assisment SICAST ProjectDocument3 pagesDe-Shuttering Risk Assisment SICAST ProjectKashif RehmanNo ratings yet

- Fire Extinguisher ChecklistDocument1 pageFire Extinguisher ChecklistSafety Man ShopNo ratings yet

- Form-162-Scissor Lift Daily Inspection ChecklistDocument1 pageForm-162-Scissor Lift Daily Inspection Checklistshamroz khan100% (2)

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (2)

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- Working at Night Checklist (Particularly For Wine Grape Harvesting)Document1 pageWorking at Night Checklist (Particularly For Wine Grape Harvesting)Kostan AbdillahNo ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- Pre Mob Flatbed Truck Daily Inspection Checklist FormDocument3 pagesPre Mob Flatbed Truck Daily Inspection Checklist Formagusbudianto.dk168No ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Job Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron EtcDocument3 pagesJob Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron Etc123shripadNo ratings yet

- Msds Diesel PDFDocument11 pagesMsds Diesel PDFSooraj PoochaliNo ratings yet

- Tower Light Inspection ChecklistDocument1 pageTower Light Inspection ChecklistHabib ur rahmanNo ratings yet

- Hoarding For Construction SitesDocument2 pagesHoarding For Construction SitesSNo ratings yet

- Training Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDocument27 pagesTraining Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDhaneswar SwainNo ratings yet

- TrainingDocument16 pagesTrainingDhaneswar SwainNo ratings yet

- Child Labour Supplementary MaterialsDocument6 pagesChild Labour Supplementary MaterialsDhaneswar SwainNo ratings yet

- The Importance of EffectiveDocument6 pagesThe Importance of EffectiveDhaneswar SwainNo ratings yet

- PFD FileDocument31 pagesPFD FileDhaneswar SwainNo ratings yet

- Concrete Mixer Inspection ChecklistDocument1 pageConcrete Mixer Inspection ChecklistDhaneswar SwainNo ratings yet

- TF-Chimney & VFD-16.04.15Document9 pagesTF-Chimney & VFD-16.04.15Dhaneswar SwainNo ratings yet

- Construction Safety Inspection Checklist 1Document3 pagesConstruction Safety Inspection Checklist 1Dhaneswar SwainNo ratings yet

- Powerpoint Heat SafetyDocument11 pagesPowerpoint Heat SafetyDhaneswar SwainNo ratings yet

- Backsafe Australia Ladder Safety ChecklistDocument1 pageBacksafe Australia Ladder Safety ChecklistDhaneswar SwainNo ratings yet

- At TC3CN006 18 T1 Ja101Document3 pagesAt TC3CN006 18 T1 Ja101Dhaneswar SwainNo ratings yet

- Gas Cutting & WeldingDocument37 pagesGas Cutting & WeldingDhaneswar SwainNo ratings yet

- Ladder Inspection Checklist 10-2017Document2 pagesLadder Inspection Checklist 10-2017Dhaneswar SwainNo ratings yet

- Safety Quiz - Office Safety Answer KeyDocument2 pagesSafety Quiz - Office Safety Answer KeyDhaneswar SwainNo ratings yet

- Pole Inspection GuidelinesDocument36 pagesPole Inspection GuidelinesDhaneswar SwainNo ratings yet

- Sample EAIDocument7 pagesSample EAIDhaneswar SwainNo ratings yet

- Sample HIRADocument18 pagesSample HIRADhaneswar SwainNo ratings yet

- EMP PlanDocument8 pagesEMP PlanDhaneswar SwainNo ratings yet

- Confined Space PermitDocument3 pagesConfined Space PermitDhaneswar SwainNo ratings yet

- TF - Esp 1 & 2 22.01.15Document1 pageTF - Esp 1 & 2 22.01.15Dhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Answer KeyDocument2 pagesSafety Quiz - Electrical Answer KeyDhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Safety-1: DirectionsDocument2 pagesSafety Quiz - Electrical Safety-1: Directionsshreyas0% (1)

- Viviid Renewables PVT - LTDDocument37 pagesViviid Renewables PVT - LTDDhaneswar SwainNo ratings yet

- SHE Induction RegisterDocument2 pagesSHE Induction RegisterDhaneswar SwainNo ratings yet

- NTPC Solapur - Main Plant - 19.06.2014Document1 pageNTPC Solapur - Main Plant - 19.06.2014Dhaneswar SwainNo ratings yet

- Authorization Letter For New WorkersDocument2 pagesAuthorization Letter For New WorkersDhaneswar SwainNo ratings yet

- 02 - Accident ReportDocument6 pages02 - Accident ReportDhaneswar SwainNo ratings yet

- Work at Height Training SheetDocument1 pageWork at Height Training SheetDhaneswar SwainNo ratings yet

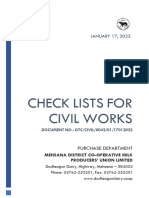

- Civil 0042 CHECKLIST FOR CIVIL WORKSDocument30 pagesCivil 0042 CHECKLIST FOR CIVIL WORKSDhaneswar SwainNo ratings yet

- TBT 17-Apr-2021 9.32 AmDocument1 pageTBT 17-Apr-2021 9.32 AmDhaneswar SwainNo ratings yet

- Glassage Part-A PDFDocument84 pagesGlassage Part-A PDFShyam AwalNo ratings yet

- Parts Book Vol 3Document207 pagesParts Book Vol 3jacques SUIRENo ratings yet

- Pump Room DrawingsDocument51 pagesPump Room Drawingstvshow zeeNo ratings yet

- CV - Thanasopoulos 3.7Document2 pagesCV - Thanasopoulos 3.7Dimitris ThanasopoulosNo ratings yet

- Introduction To Geo-TechnologyDocument45 pagesIntroduction To Geo-TechnologyEngr Muhammad WaseemNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- B 232 - B 232m - 01 - Qjizmi9cmjmytqDocument16 pagesB 232 - B 232m - 01 - Qjizmi9cmjmytqYayan RnsNo ratings yet

- Elements of Masonry DesignDocument83 pagesElements of Masonry DesigndyetNo ratings yet

- Michael Gabriel V. Mendoza: Civil EngineerDocument7 pagesMichael Gabriel V. Mendoza: Civil EngineerreiNo ratings yet

- Materials 12 02149 1 1Document12 pagesMaterials 12 02149 1 1Ilhame HarNo ratings yet

- Erco Guide 3 Indoor Lighting enDocument75 pagesErco Guide 3 Indoor Lighting enGilberto A. YlaganNo ratings yet

- Deck SlabDocument3 pagesDeck SlabPurnima SinghNo ratings yet

- Report and Design of Open Box Drain 10-10-2022Document107 pagesReport and Design of Open Box Drain 10-10-2022AKB CONSULTANTSNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Bus DuctDocument7 pagesBus DuctAlexander WijesooriyaNo ratings yet

- Responsibilities of A Construction Safety OfficerDocument2 pagesResponsibilities of A Construction Safety Officersteward reyes100% (1)

- Kitagawa DatasheetDocument20 pagesKitagawa Datasheetminhnt4321No ratings yet

- How To Construct A Soundproof Generator ShedDocument4 pagesHow To Construct A Soundproof Generator Shedgaylumberjack100% (2)

- Sieve Analysis: Construction MaterialsDocument10 pagesSieve Analysis: Construction MaterialsHeril JainNo ratings yet

- 0 4398 1Document98 pages0 4398 1Sindhe SwethaNo ratings yet

- Design of Two-Way SlabDocument48 pagesDesign of Two-Way SlabAboobackar SidheeqNo ratings yet

- Alw AE1F OoptiflowwDocument12 pagesAlw AE1F OoptiflowwCarlos LópezNo ratings yet

- Class 3 - Project Delivery MethodsDocument25 pagesClass 3 - Project Delivery MethodsAmanjot SinghNo ratings yet

- Roofers-Guide 2020 Version WebDocument66 pagesRoofers-Guide 2020 Version Webanderson oliveiraNo ratings yet

- MASA Image Brochure WebDocument8 pagesMASA Image Brochure WebCarlos cgNo ratings yet

- Technical Catalog Sandwich Panels Paneltech 2020.1Document88 pagesTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNo ratings yet

- Design Cal. 53.9 M Dia Clariflocculator (09!07!08) - r2Document225 pagesDesign Cal. 53.9 M Dia Clariflocculator (09!07!08) - r2ravi aroraNo ratings yet

Sign Barricades & Flagging Sop

Sign Barricades & Flagging Sop

Uploaded by

Dhaneswar SwainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sign Barricades & Flagging Sop

Sign Barricades & Flagging Sop

Uploaded by

Dhaneswar SwainCopyright:

Available Formats

S T A N D A R D OP E R A TI N G PR OC ED UR E

Signs, Barricades, Flagging

Workplaces where hazardous manual tasks take place have an

obligation to ensure the health and safety of their staff. Personnel are

not expected to perform excessive physical work as technology has

improved & workplaces recognise the need to control the risk of injury

1. PURPOSE AND SCOPE

This standard outlines the safety requirements for barriers and barricades to ensure that all personnel

and visitors are prevented or restricted from accessing areas where unfamiliar hazards may cause injury

or damage.

This standard applies to all works Projects.

2. DEFINITIONS

The terms barrier and barricade where used in this standard shall be interchangeable.

3. ROLES AND RESPONSIBILITIES

3.1 Authorised Person / Personnel

● A person who has the appropriate authority to proceed past or through and erected barrier (e.g. the

person who has signed the applicable HIRA and RA).

3.2 Barricade Tag

● A tag attached to every barrier or barricade identifying the date of erection, the reason for its erection,

the intended duration and the contact name of the person responsible for that barrier.

3.3 Safety Barrier

● A safety barrier shall be any temporary or semi-permanent structure or fence erected to protect, or to

expressly restrict access to, any authorised person who may be endangered by the presence of a hazard

which has the potential to affect the health or to cause injury to personnel or inflict damage to property.

● A barrier can be constructed from any of the following materials or combination thereof – Barrier mesh,

scaffolding tube or similar, free standing gates, or solid objects that have the capability to withstand 110

kg.

● The construction material used for a safety barrier shall be dependent on the intended purpose of the

barrier.

● No danger tape is to be permitted for this use.

3.4 Safety Barricade

● A safety barricade shall be any temporary or semi-permanent structure erected across an access way

to protect, or to expressly deny access to, any unauthorized person who may be endangered by the

presence of a hazard which has the potential to affect the health or to cause injury to personnel or inflict

damage to property.

● A barricade can be constructed from any of the following materials or combina-tion thereof –

chains, barrier mesh, scaffolding tube or similar, free standing gates, or solid objects.

Supplementary materials include flagging rope and plastic tape in an emergency.

4. PROCEDURE

4.1 Specific Requirements

● Barriers or barricades shall be erected in all cases where the presence of a hazard which has the

potential to affect the health or to cause injury to personnel or inflict damage to property has been

identified.

● All barriers shall have a barricade tag attached at all designated access points if applicable. Where

there are no designated access points, barrier tags shall be tied to the barrier at regular intervals to

clearly identify the reason why the barrier was erected. Barrier tags are to be supplemented by use of

warning/ advisory signs where applicable.

● All details on the tag shall be completed by the person responsible for erecting and maintaining the

barrier. (Contractor is responsible for the supply of the barriers tags).

● Only authorized personnel shall be entitled to proceed past, through, over or under a barrier.

Unauthorized personnel seeking access to restricted areas shall first get approval from the contractor or

person responsible for the erection of that barrier shall explain the hazards that have been identified or

exist and the appropriate PPE that needs to be worn within the restricted area.

● Barriers shall be inspected on a regular basis, minimum daily, to ensure the standard and suitability of

the barrier is adequately maintained for the life of the barrier. The date of each inspection shall be noted

on the barricade register.

● The extent of an area to be barricaded shall be kept to a minimum so as not to restrict access

unnecessarily. The extent and position of barriers shall be planned so that through access can be

maintained where available and that adjustment barriers do not unnecessarily block of through access.

As hazards are eliminated, the barriers shall be removed or relocated to open up access to others.

● Barriers shall not be left up for extended periods of time. Where it is not possible to eliminate the

hazard for an extended period of time e.g., void in floor waiting for equipment, the hazard shall be

isolated as close as possible to the hazard or controlled via other approved means.

● Only the responsible person nominated on the barricade tag shall be authorized to arrange for the

removal, dismantling or modification of any erected barrier. In the event that the responsible person so

nominated is not available, the site manager for the contractor involved may delegate that authority to

another person. In the event that a barrier is found to be interfering with construction activities and the

contractor concerned is unavailable and cannot be contacted, the Project Construction Manager shall be

authorized to take the appropriate action deemed necessary to correct the situation, provided it is safe to

do so and/or that other arrangements are made to isolate or control the hazard(s).

● There shall be three levels of barriers/barricades on this project. The level of barrier used shall

be dependent on its intended purpose. The levels shall range from Level 1, which shall be used to

mark boundaries of construction areas, up to Level 3, which shall be used to guard against high-

risk hazards. The different barriers shall be used as follows:

4.2 LEVEL 1 BARRIER: Delineation Barrier

4.2.1 Use

A barrier shall be erected to mark the boundary or limit of construction activity so as to prevent

unauthorized access by non-project inducted personnel and visitors and other project contractor

personnel who are not the main contractor working within that area.

4.2.2 Construction

Minimum construction of long-term delineation barriers shall be snow netting attached to pickets firmly

driven into the ground.

4.2.3 Signs

All barriers shall carry sufficient barricade tags and advisory signs at potential access points to clearly

identify the reason why the barrier was erected.

Advisory signs shall read ‘Restricted Access – Construction Personnel Only’ or similar. Signs shall

include company logo or identification of the contractor who has erected the barrier.

4.2.4 Authorised Personnel

● Any representative of the Project Management Team.

● Any personnel directly or indirectly (subcontract) employed by the contractor who has erected the

barricade as per authorization granted by the contractor.

● Any other person, other than above, who has received express approval, to enter into the area.

4.2.5 Purpose

● Barriers shall be erected by each individual contractor to define the extent of their current work areas

so as to restrict access to unauthorised persons. The purpose of a barrier shall be to restrict entry to

those personnel who are not aware of the general construction activities taking place within that area and

hazards associated with those construction activities.

● Barriers shall be used to safe guard personnel working within the area from external hazards adjacent

to the work area e.g., vehicular traffic.

4.3 LEVEL 2 BARRIER: Demarcation Barrier

4.3.1 Use

A demarcation barrier shall be erected within a construction area to prevent unauthorized access

temporarily into an area where a low risk event may exist or potentially exists. Examples of the

use of demarcation barrier include abrasive blasting activities, men working above, and

radioactive work.

4.3.2 Construction

Demarcation barriers shall be constructed, as a minimum, from snow netting (orange) attached to

permanent structure or portable structure where insufficient permanent structure exists to accurately

define the restricted area.

4.3.3 Signs

All demarcation barriers shall carry sufficient barricade tags and/or advisory signs at potential access

points to clearly identify the reason for the erection of the barrier.

4.3.4 Authorised Personnel

● A supervisor who is directly responsible for the coordination and supervision of the works being carried

out within the restricted area.

● An employee who is presently performing work in a restricted area as part of their normal duties under

the direction of the supervisor.

● Any other person, other than above, who has received express approval, to enter into the area.

4.3.5 Purpose

● The purpose of a demarcation barrier shall be to restrict entry into an area within the normal contract

construction area where specific low to medium risk hazards exist as a consequence of particular

construction activities taking place.

● Demarcation barriers shall be erected by each individual contractor to define the extent of each such

work area. These barriers shall be erected temporarily while those particular construction activities

causing the hazard(s) are taking place and they are to be positioned to restrict access to unauthorized

persons who may be endangered if they enter into that area.

● Only authorized persons equipped with the appropriate PPE to counter the specific hazard(s) identified

by the RA for the particular activity may enter the restricted area.

4.4 LEVEL 3 BARRIER: High Risk Hazard Barrier

4.4.1 Use

A Level 3 barrier shall be erected within a construction area to prevent unauthorized access into an area

where a high-risk hazard may exist or poten-tially exist. Examples of the use of Level 3 barriers include

incomplete flooring or handrail system, penetrations in access ways or floors, excavations or pits,

unguarded rotating fixed plant.

4.4.2 Construction

Barriers guarding against high risk hazards shall be constructed either from full barrier mesh,

free standing gates, or solid objects, scaffolding tube or similar. Where tubing are used, top and

mid rail sections shall be required as a minimum standard of construction. To further highlight

the barrier, snow netting may be used to supplement the above construction.

4.4.3 Signs

All barriers shall carry sufficient barricade tags and/or advisory signs at potential access points to clearly

identify the reason for the erection of the barrier.

4.4.4 Authorised Personnel

● A supervisor who is directly responsible for the coordination and supervision of the works being carried

out within the restricted area.

● An employee who is presently performing work in a restricted area as part of their normal duties under

the direction of the supervisor

● Any Management Representative of the Project who is performing inspection work associated with that

area.

● Any other person, other than above, who has received express approval from the erector of the

barricade, to enter into the area.

4.4.5 Purpose

● The purpose of a Level 3 barrier shall be to restrict entry into an area within the normal contract

construction area where high risk hazards exist as a consequence of particular construction activities

taking place.

● These barriers shall be erected temporarily while those particular con-struction activities causing the

hazard(s) are taking place and they are to be positioned to restrict access to unauthorized persons who

may be endangered if they enter into that area.

● Only authorized persons who have read and understood the RA prepared for that construction

activity, have been informed of all the relevant hazards, and are equipped with the appropriate

PPE to counter the specific hazard(s) identified by the HIRA and RA shall enter the restricted

area.

In case the lift has to be done over traffic areas, the road affected has been barricaded off and sufficient watchmen

have been placed to ensure that traffic stops at the barricades.

5. 5

Barricades Details/Requirements/Uses

Mesh barriers can be erected between existing structures or

framework.

Can be used with star pickets and/or barricade stands.

Mesh shall be installed with the top edge at a height between 900mm

-1200mm.

Must be used in conjunction with demarcation tape and information

Mesh Barriers tag.

Plastic double sided stands or safety cones are used to identify

ground related hazards where caution

is required, for example, where spills have occurred or cleaning is in

progress.

Cones and stands shall be placed in a prominent position.

Safety cone & Double

sided floor stand

The maximum distance between warning cones should be 1.5 meters.

Used to demarcate areas where work is taking place on roads and

ground, for example, cleaning up

spills, survey marking, around mobile plant.

Persons requiring access must familiarise themselves with the

hazards, risk assess the situation, and

Traffic cones only proceed into the area if it is safe to do so.

Scaffold tubing can be used to demarcate around an open sump, pit

or fall zone.

Scaffold must be erected by a licenced scaffolder.

Scaffold must be used in conjunction with demarcation tape and

information tag or signage.

Scaffold Tube

Trestles can be used to demarcate live areas within a stockyard in

conjunction with signage.

Trestles can be used as a form of protection for excavations where a

risk assessment deems the level of risk as acceptable (typically shallow

excavations).

Trestle

These styles of hard barricading are designed to prevent access and

protect people from hazardous processes, equipment and traffic areas.

Chains (plastic and metal) can be used to connect hard barricades

together to make a longer barricade.

Water/sand filled blocks can be connected together to demarcate long

term work areas.

Concrete blocks must have an approved lifting point or slots to fit forklift

Concrete Block tynes.

Barricade stands are used to demarcate areas where there is no

structure to fix demarcation tape or chains.

Can be used where the barricade needs to be moved to allow mobile

plant and equipment into the demarcated area.

Used in conjunction with demarcation tape and information tag.

Barricade stand

Temporary fencing is used to demarcate areas where there is no

structure to fix demarcation tape or chains.

Used in conjunction with demarcation tape and information tag.

Temporary Fence

Tape Purpose Conditions of entry Examples

Caution tape shall be used Persons requiring access Liquid spills

to demarcate areas that must make sure they work areas,

require personnel to be familiarise themselves with Temporary lay

warned of identified hazards the hazards, risk assess down area

prior to entry. the situation and providing

Demarcation it safe to do so may

Tape must be marked with proceed into the area.

Yellow tape caution “CAUTION”.

Danger tape shall be used to Personnel shall not enter or Unsupervised

demarcate areas and /or work within an area that is unprotected

equipment where there is an demarcated with Danger edges, drop zones,

immediate threat to people, tape contaminated

equipment and/or the sites

environment

Demarcation tape must be

marked with DANGER or

DANGER NO ENTRY

Document:- Last reviewed:

You might also like

- 2.1 - CR 10 (1) (A) Fall Protection PlannerDocument1 page2.1 - CR 10 (1) (A) Fall Protection PlannerSusan LouwNo ratings yet

- Cable Tray Inspection ListDocument1 pageCable Tray Inspection ListTreesa Archnana100% (3)

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- Yas Island Phase 2, Zone K - Garden Crescent - Part 1 - Technical Proposal - 2010.04.19Document92 pagesYas Island Phase 2, Zone K - Garden Crescent - Part 1 - Technical Proposal - 2010.04.19arunava sarkarNo ratings yet

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- Permit To DigDocument3 pagesPermit To DigMarco DonatiNo ratings yet

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- SWP-06 Lifting Operation DaimanDocument4 pagesSWP-06 Lifting Operation DaimanHassan AbdullahNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30100% (1)

- Concrete WorkDocument1 pageConcrete WorkChandru100% (1)

- Gopu.R:::: Patient Age / Sex 30 Y / Male BranchDocument1 pageGopu.R:::: Patient Age / Sex 30 Y / Male BranchGopu RNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- APC Questions Jan 05 - Sorted by CompetencyDocument8 pagesAPC Questions Jan 05 - Sorted by CompetencyHaneefa Ch100% (3)

- Night Work PermitDocument3 pagesNight Work PermitArmando AballeNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- Method Statement PDFDocument2 pagesMethod Statement PDFAl Manar PetroleumNo ratings yet

- Pre-Job Safety Assessment: Site InformationDocument2 pagesPre-Job Safety Assessment: Site Informationgueettaf faresNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift PlanMd Wãșéèm ÁkrãmNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Hira - Eot CraneDocument4 pagesHira - Eot CraneSantosh SinghNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- First Aid Report FormDocument1 pageFirst Aid Report FormSaikat ChakrabortyNo ratings yet

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocument21 pagesLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- Siemens LTD.: General Work Permit Serial No.Document3 pagesSiemens LTD.: General Work Permit Serial No.Dakshinamurthy PNo ratings yet

- MEWP Daily Inspection ChecklistDocument1 pageMEWP Daily Inspection ChecklistZukhrufal JannahNo ratings yet

- Risk Assessment For Confined SpaceDocument5 pagesRisk Assessment For Confined Spaceappu pocom3No ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- GC3 ObservationDocument16 pagesGC3 ObservationjithinNo ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- HR HR TEM007 GEN ALL Visitor Induction Rev1.0Document2 pagesHR HR TEM007 GEN ALL Visitor Induction Rev1.0Doni TriatmojoNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocument1 pageSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- De-Shuttering Risk Assisment SICAST ProjectDocument3 pagesDe-Shuttering Risk Assisment SICAST ProjectKashif RehmanNo ratings yet

- Fire Extinguisher ChecklistDocument1 pageFire Extinguisher ChecklistSafety Man ShopNo ratings yet

- Form-162-Scissor Lift Daily Inspection ChecklistDocument1 pageForm-162-Scissor Lift Daily Inspection Checklistshamroz khan100% (2)

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (2)

- SWMS Power FloatDocument10 pagesSWMS Power FloatSam LimNo ratings yet

- Working at Night Checklist (Particularly For Wine Grape Harvesting)Document1 pageWorking at Night Checklist (Particularly For Wine Grape Harvesting)Kostan AbdillahNo ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- Pre Mob Flatbed Truck Daily Inspection Checklist FormDocument3 pagesPre Mob Flatbed Truck Daily Inspection Checklist Formagusbudianto.dk168No ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Job Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron EtcDocument3 pagesJob Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron Etc123shripadNo ratings yet

- Msds Diesel PDFDocument11 pagesMsds Diesel PDFSooraj PoochaliNo ratings yet

- Tower Light Inspection ChecklistDocument1 pageTower Light Inspection ChecklistHabib ur rahmanNo ratings yet

- Hoarding For Construction SitesDocument2 pagesHoarding For Construction SitesSNo ratings yet

- Training Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDocument27 pagesTraining Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDhaneswar SwainNo ratings yet

- TrainingDocument16 pagesTrainingDhaneswar SwainNo ratings yet

- Child Labour Supplementary MaterialsDocument6 pagesChild Labour Supplementary MaterialsDhaneswar SwainNo ratings yet

- The Importance of EffectiveDocument6 pagesThe Importance of EffectiveDhaneswar SwainNo ratings yet

- PFD FileDocument31 pagesPFD FileDhaneswar SwainNo ratings yet

- Concrete Mixer Inspection ChecklistDocument1 pageConcrete Mixer Inspection ChecklistDhaneswar SwainNo ratings yet

- TF-Chimney & VFD-16.04.15Document9 pagesTF-Chimney & VFD-16.04.15Dhaneswar SwainNo ratings yet

- Construction Safety Inspection Checklist 1Document3 pagesConstruction Safety Inspection Checklist 1Dhaneswar SwainNo ratings yet

- Powerpoint Heat SafetyDocument11 pagesPowerpoint Heat SafetyDhaneswar SwainNo ratings yet

- Backsafe Australia Ladder Safety ChecklistDocument1 pageBacksafe Australia Ladder Safety ChecklistDhaneswar SwainNo ratings yet

- At TC3CN006 18 T1 Ja101Document3 pagesAt TC3CN006 18 T1 Ja101Dhaneswar SwainNo ratings yet

- Gas Cutting & WeldingDocument37 pagesGas Cutting & WeldingDhaneswar SwainNo ratings yet

- Ladder Inspection Checklist 10-2017Document2 pagesLadder Inspection Checklist 10-2017Dhaneswar SwainNo ratings yet

- Safety Quiz - Office Safety Answer KeyDocument2 pagesSafety Quiz - Office Safety Answer KeyDhaneswar SwainNo ratings yet

- Pole Inspection GuidelinesDocument36 pagesPole Inspection GuidelinesDhaneswar SwainNo ratings yet

- Sample EAIDocument7 pagesSample EAIDhaneswar SwainNo ratings yet

- Sample HIRADocument18 pagesSample HIRADhaneswar SwainNo ratings yet

- EMP PlanDocument8 pagesEMP PlanDhaneswar SwainNo ratings yet

- Confined Space PermitDocument3 pagesConfined Space PermitDhaneswar SwainNo ratings yet

- TF - Esp 1 & 2 22.01.15Document1 pageTF - Esp 1 & 2 22.01.15Dhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Answer KeyDocument2 pagesSafety Quiz - Electrical Answer KeyDhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Safety-1: DirectionsDocument2 pagesSafety Quiz - Electrical Safety-1: Directionsshreyas0% (1)

- Viviid Renewables PVT - LTDDocument37 pagesViviid Renewables PVT - LTDDhaneswar SwainNo ratings yet

- SHE Induction RegisterDocument2 pagesSHE Induction RegisterDhaneswar SwainNo ratings yet

- NTPC Solapur - Main Plant - 19.06.2014Document1 pageNTPC Solapur - Main Plant - 19.06.2014Dhaneswar SwainNo ratings yet

- Authorization Letter For New WorkersDocument2 pagesAuthorization Letter For New WorkersDhaneswar SwainNo ratings yet

- 02 - Accident ReportDocument6 pages02 - Accident ReportDhaneswar SwainNo ratings yet

- Work at Height Training SheetDocument1 pageWork at Height Training SheetDhaneswar SwainNo ratings yet

- Civil 0042 CHECKLIST FOR CIVIL WORKSDocument30 pagesCivil 0042 CHECKLIST FOR CIVIL WORKSDhaneswar SwainNo ratings yet

- TBT 17-Apr-2021 9.32 AmDocument1 pageTBT 17-Apr-2021 9.32 AmDhaneswar SwainNo ratings yet

- Glassage Part-A PDFDocument84 pagesGlassage Part-A PDFShyam AwalNo ratings yet

- Parts Book Vol 3Document207 pagesParts Book Vol 3jacques SUIRENo ratings yet

- Pump Room DrawingsDocument51 pagesPump Room Drawingstvshow zeeNo ratings yet

- CV - Thanasopoulos 3.7Document2 pagesCV - Thanasopoulos 3.7Dimitris ThanasopoulosNo ratings yet

- Introduction To Geo-TechnologyDocument45 pagesIntroduction To Geo-TechnologyEngr Muhammad WaseemNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- B 232 - B 232m - 01 - Qjizmi9cmjmytqDocument16 pagesB 232 - B 232m - 01 - Qjizmi9cmjmytqYayan RnsNo ratings yet

- Elements of Masonry DesignDocument83 pagesElements of Masonry DesigndyetNo ratings yet

- Michael Gabriel V. Mendoza: Civil EngineerDocument7 pagesMichael Gabriel V. Mendoza: Civil EngineerreiNo ratings yet

- Materials 12 02149 1 1Document12 pagesMaterials 12 02149 1 1Ilhame HarNo ratings yet

- Erco Guide 3 Indoor Lighting enDocument75 pagesErco Guide 3 Indoor Lighting enGilberto A. YlaganNo ratings yet

- Deck SlabDocument3 pagesDeck SlabPurnima SinghNo ratings yet

- Report and Design of Open Box Drain 10-10-2022Document107 pagesReport and Design of Open Box Drain 10-10-2022AKB CONSULTANTSNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Bus DuctDocument7 pagesBus DuctAlexander WijesooriyaNo ratings yet

- Responsibilities of A Construction Safety OfficerDocument2 pagesResponsibilities of A Construction Safety Officersteward reyes100% (1)

- Kitagawa DatasheetDocument20 pagesKitagawa Datasheetminhnt4321No ratings yet

- How To Construct A Soundproof Generator ShedDocument4 pagesHow To Construct A Soundproof Generator Shedgaylumberjack100% (2)

- Sieve Analysis: Construction MaterialsDocument10 pagesSieve Analysis: Construction MaterialsHeril JainNo ratings yet

- 0 4398 1Document98 pages0 4398 1Sindhe SwethaNo ratings yet

- Design of Two-Way SlabDocument48 pagesDesign of Two-Way SlabAboobackar SidheeqNo ratings yet

- Alw AE1F OoptiflowwDocument12 pagesAlw AE1F OoptiflowwCarlos LópezNo ratings yet

- Class 3 - Project Delivery MethodsDocument25 pagesClass 3 - Project Delivery MethodsAmanjot SinghNo ratings yet

- Roofers-Guide 2020 Version WebDocument66 pagesRoofers-Guide 2020 Version Webanderson oliveiraNo ratings yet

- MASA Image Brochure WebDocument8 pagesMASA Image Brochure WebCarlos cgNo ratings yet

- Technical Catalog Sandwich Panels Paneltech 2020.1Document88 pagesTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNo ratings yet

- Design Cal. 53.9 M Dia Clariflocculator (09!07!08) - r2Document225 pagesDesign Cal. 53.9 M Dia Clariflocculator (09!07!08) - r2ravi aroraNo ratings yet