Professional Documents

Culture Documents

Operation Instructions DCM-Modul 2.x

Operation Instructions DCM-Modul 2.x

Uploaded by

jose camilo torres dominguezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Instructions DCM-Modul 2.x

Operation Instructions DCM-Modul 2.x

Uploaded by

jose camilo torres dominguezCopyright:

Available Formats

Operating Instructions DCM Module

Table of Contents

Preliminary Remark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Path--dependent control of SCHOTTEL systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Path--dependent speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Further applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Structure and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LED indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating mode switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Software configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hardware configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Analog output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Alarm relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DCM Module: View of front side and boards, left-- and right--hand side . . . . . . . . . . 9

2 Configuration, Mounting and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Overview on jumper configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pulling out the contact connector strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inserting the contact connector strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pulling the DCM Module out of the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inserting the DCM Module into the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Functional check of path--dependent control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Functional check of path--dependent speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parameterisation of CAN sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Path--dependent control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Path--dependent speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Measuring points and nominal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Alarm relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CAN bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 1 / 31

5 Pin Configuration and Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Preliminary Remark

These instructions shall be of information and help for Important instructions relevant to technical and

every person engaged in initial start--up, operation and operational safety are pointed out by the following

maintenance of SCHOTTEL systems. This requires to symbols:

read, understand and observe these documents.

These instructions are to be made available to ! CAUTION

everybody carrying out works on the system.

We do not accept any liability for damages and troubles Indicates working and operating methods that are to be

in operation resulting from disregard of these strictly observed to exclude any risk for persons.

instructions.

It is taken for granted that every user is familiar with the

systems and informed on all possible dangers.

! ATTENTION

Refers to working and operating methods that are to be

Only professional electricians are allowed to carry out strictly observed to avoid damages to or destruction of

any work on the system. the material.

References to illustrations in the text are written in

brackets, e.g. (1/3). The first number indicates the NOTE

illustration number in the manual, the second number

is the position number in the illustration. Indicates exceptional features in the working process

that are to be observed.

All illustrations are diagrammatic projections without

any claim for completeness.

i INFORMATION

Any technical modification to SCHOTTEL systems not

carried out by personnel appointed by SCHOTTEL Application references and information.

does require written consent.

This excludes modifications or control settings detailed During any work carried out on SCHOTTEL systems it

in our instructions. is required to observe the ”Safety and Environmental

Protection Regulations SV 1” as well as the relevant

laws in force in each country of utilisation.

Given that SCHOTTEL systems are subject to further

development we reserve the right of technical

modifications.

These instructions were elaborated with utmost care.

In case of further information required, please contact:

SCHOTTEL GmbH

Mainzer Straße 99

D--56322 Spay

Phone +49 (0) 2628 / 61--0

Fax +49 (0) 2628 / 61--300

E--Mail info@schottel.de

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 3 / 31

4 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

1 Technical Description

Application

The DCM Module (1/2) is an electronic module, which

reads, processes outputs control signals . Generally it

is applied for the following system applications:

D Path--dependent control of SCHOTTEL systems

D Speed setting of driving motors

Path--dependent control of SCHOTTEL systems

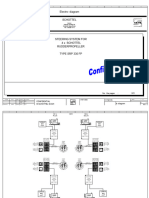

Figure 1 shows a diagrammatic view of the application

of the DCM Module for the control of SCHOTTEL

systems (1/4). 1

D In case of the path--dependent control, the DCM

Module compares the current setting on the

steering stand (1/1) with the current feed--back

(1/5). The differential value from setting and

feed--back is calculated by the DCM Module and

transmitted to the amplifier unit (1/3) (e.g. DPV

Module). 2

D Depending on the differential value transmitted

from the DCM Module, the amplifier unit controls

the SCHOTTEL system until the feed--back value

matches the value of the setting (differential value

= 0).

5

3

Path--dependent speed setting

Also with the path--depending speed setting, a set

value from the steering stand is read--in into the DCM

Module. According to the read--in set value, the DCM

Module provides an output signal.

Further applications

The path--dependent control of SCHOTTEL systems 4

and the path--dependent speed setting are appli--

cations, which are taken into consideration in this

document.

Further applications of the DCM Module are described

in the according construction information.

Figure 1

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 5 / 31

Structure and Function

The DCM Module essentially consists of:

1

D 2 boards with electronic main components, The

DIL switches and jumpers for hardware configu--

ration of the module, see Figure 5, page 9.

D 8 digital inputs (2/2)

D 4 digital outputs (2/1)

D 4 analog inputs (2/3) 10 V / 0 ... 20 mA, 2

(depending on configuration of jumper J7 and J8)

According to the jumper configuration, 2 analog

inputs are positioned on the potentiometers AI3

(3/1) and AI4 (3/2) or externally onto the terminal

connections 23 (3/3) and 24 (3/4) 3

D 2 analog outputs (2/4) (0 ... 10 V / 0 ... 20 mA) 2

D LED’s for indicating status and operating condi--

tions, see section ”LED indications”.

Figure 2

3

4

Figure 3

6 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

LED indications

18 LED’s indicate the following operating conditions:

1

LED Operating condition CAN DPV 1

F 100 shines with an error in CAN bus

shines with an error of

F 101 DCM DPV 2

power supply

F 102 shines with an error Setpoint

F 103 shines with an error of feed--back

F 104 shines with a programmed error

2

F 105 shines with a programmed error

flashes/shines during parameterisa-

SF 1

tion

SF 2 Special function

shines with operating voltage pres-

PWR

ent on the module

shines with functional readiness

RUN

and goes out with a failure

IN 0 shines with active digital input 0.0

IN 1 shines with active digital input 0.1

IN 2 shines with active digital input 0.2

IN 3 shines with active digital input 0.3

OUT 0 shines with active digital input 0

OUT 1 shines with active digital input 1

OUT 2 shines with active digital input 2

OUT 3 shines with active digital input 3

With a failure, one of the LED’s F100 ... F 105 shines.

In trouble free condition, the LED’s PWR and RUN

shine, and depending on the operational situation the

LED’s IN 0 ... IN 3, OUT 0 ... OUT 3, or SF 1 or SF 2.

Operating mode switch

The operating switch (4/3) is used to set the operating

mode ON and LD. With operating mode LD the DCM

Module is fitted with up--dated software.

During utilization of the ship, the switch must always be

in position ON.

3

System diagnosis

Via the interfaces (4/1) and (4/2), a SCHOTTEL Service Figure 4

engineer is always able to do a quick hardware

diagnosis.

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 7 / 31

Software configuration Analog input signals

According to the use, the DCM Module is programmed The DCM Module can be approached with analog input

ex works with a system software. The system software signals (0 ... 10 V or 0 ... 20 mA) – depending on the

is decisive for the application (path--dependent control, jumper configuration.

path--dependent speed setting, etc.). For transmitting

the system software onto the DPV Module, the Both inputs are optionally adjustable with the

operating mode switch (5/4) must be in position LD. potentiometers AI3 and AI4.

During operation, the operating mode switch must

always be in position ON. Analog output signals

By standard, in case of SCHOTTEL systems, the

Hardware configuration analog output signal 0 ... 10 V is put onto a buffer

amplifier (5/3). Over the buffer amplifier, the according

With a defect of one DCM Module, an according spare component is approached with an output signal from 4

module can be replaced in the SCHOTTEL electric mA up to 20 mA.

systems without much efforts by professional

personnel. Because of the various application Optionally, the DCM Module as analog output signal

possibilities, it is required to observe the Ident No. of the can also transmit an electric signal from 4 to 20 mA,

DCM Module. The hardware of the DCM Module first is depending on the configuration of the jumpers.

to be specifically configured for the according

application, and thereafter to be mounted and

application--specific installed. Alarm relay

For configuration, the DCM Module has to be taken out The DCM-- Module is fitted with an alarm relay, of which

of the housing beforehand. Then, on the boards on the the potential--free make--contact is available at the

left--hand side (5/12) are adjusted the DIL switches contact connector strips, and normally is used for

(5/13) and the CAN load resistance (5/3). On both changing from path--dependent to time--dependent

boards the jumpers have to be inserted according to operation, if the DCM Module is no longer ready for

application. operation. Furthermore, a message is transmitted via

the make--contact to the ship’s warning system.

The left--side board (5/12) has 8 jumper consoles, the

right--side board (5/11) has 14 jumper consoles. In case

of the jumper consoles with 2 sockets (5/1) one jumper Battery

might be inserted or not. In case of the jumper consoles

with 3 sockets (5/2), the jumper on the bridges 1, 2, or The DCM Module is fitted with a battery (5/10) for

on the bridges 2, 3 might be inserted or not. The socket saving date and hour. The battery is of no influence on

identification 1, 2, 3 (5/9) is printed on the boards. the system software. The battery cannot be replaced.

The overview of the jumper configurations J1 to J12

can be found on page 10.

With the DIL switches (5/13) are activated those

functions, which are required for adaptation to the

SCHOTTEL system.

During installation, the housing of the DCM Module is

mounted onto the mounting rail. During the electric

installation, the contact connector strips (5/6) can be

pulled out of a defective module and then can be

pushed into an exchange module.

8 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

6

7

5

2 2

3 9 10

1 1 1

2 2

6

1

1

OFF 123

ON

3

3 1

1

321

321

12 11 1

13 2 9 2 2 2

9

Figure 5 DCM Module: View of front side and boards, left-- and right--hand side

1 Jumper console with 2 sockets 10 Battery CR2032

2 Jumper console with 3 sockets 11 DCM Module, board right--hand side

3 CAN Bus load resistance 12 DCM Module, board left--hand side

4 Operating mode switch 13 DIL switch

top: block S4

5 LED indications for operating states,

bottom: block S3

see page 7

(marked on the board)

6 Contact connector strips

7 LED indications of the digital and analog outputs,

see page 7

8 Potentiometer AI 3 and AI 4

9 Socket identification 1, 2, 3

with jumper console with 3 sockets

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 9 / 31

2 Configuration, Mounting and Setting

! ATTENTION

Overview on jumper configurations

According to its use, the DCM Module is to be first Name Function

configured, then mounted and set for the

application. Terminal connection 31

Analog output AO 0

Pin 1--2: AO 0 voltage output

! ATTENTION J1 Pin 2--3: AO 0 current output

All the following instructions are to be carefully Pin 1--2: AO 0 voltage output

observed for being able to insert the total system J2 Pin 2--3: AO 0 current output

operationally reliable subsequent to the replacement of

a DCM Module. Pin 1--2: AO 0 voltage output

J3 Pin 2--3: AO 0 current output

Terminal connection 32

Configuration Analog output AO 1

Pin 1--2: AO 1 voltage output

1. Switch the electric system off and secure against J4 Pin 2--3: AO 1 current output

unintended switch--on.

2. For pulling out the contact connector strips from Pin 1--2: AO 1 voltage output

the defective DCM Module, see page 12. J5 Pin 2--3: AO 1 current output

Do not loosen any electric installations on the

contact connector strips. Pin 1--2: AO 1 voltage output

J6 Pin 2--3: AO 1 current output

3. Pull the defective and the new DCM Module out of

the housing, see Figure 8, page 12. Terminal connection 24

Wiring AI4

4. Transfer the positions of all DIL switches (6/3) from

the defective module to the new DCM Module. J7 Pin 1--2: 0 -- 10 V / 0 -- 20 mA

Pin 2--3: potentiometer AI 4

5. Transfer the positions of all jumper positions (6/1)

from the defective module to the new DCM Module Terminal connection 23

Overview on the jumper configurations, see Wiring AI3

right--hand column. Jumpers J13 and J14 must Pin 1--2: 0 -- 10 V / 0 -- 20 mA

always be put onto pin 2 and 3. J8

Pin 2--3: potentiometer AI 3

6. Transfer the position of the load resistance (6/2)

from the defective module to the new DCM Input wiring

Module. Open: AI 2: voltage input

J9 Plugged: AI 2: current input

! ATTENTION

J 10

Open: AI 1: voltage input

Plugged: AI 1: current input

The load resistance (7/1) as last CAN bus element

must be always in pos. ON, see the diagrammatic Open: AI 3: voltage input

section in Figure 7 and in the wiring diagram. J 11 Plugged: AI 3: current input

7. Push the new DCM Module into to the housing Open: AI 4: voltage input

inside the switch cabinet and insert the contact

J 12 Plugged: AI 4: current input

connector strips in the module.

10 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

1 1 2 1 1

1

J13 1

J14

ON OFF

J9

J10 1

J8

J11 J7 1

J1

J12 J2

J3

1

J4

J5

J6

Figure 6

CAN

1

OFF OFF ON

Figure 7

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 11 / 31

Installation

Pulling out the contact connector strips

D Pull the contact connector strips (8/1) out of a

defective DCM Module (8/4) using a screwdriver. 1

2

Inserting the contact connector strips

D Insert the contact connector strips (8/1) after the 3

configuration on the new DCM Module.

4

! ATTENTION

When inserting the contact connector strips (8/1) all 1

contact connector numbers (8/3) have to tie in. Wrong

insertion may cause the destruction of the DCM

Module.

All contact connector strips must be tightly seated in the

DCM Module.

Pulling the DCM Module out of the housing 1

D Push the catches (8/2) down with a screwdriver,

Figure 8

and pull the DDCM Module (8/4) out. For

configuration of the DCM Module it is required to

pull the DCM Module out of the housing.

1 2 1 2

Inserting the DCM Module into the housing

D Push the DCM Module in until it engages in the

housing.

3 3

General check

After configuration and installation, the following

checks are to be carried out:

D Check position of all operating mode switches

(9/3). Prior to connecting the electric system, on all

modules these have to be in position ON.

1 2

D Connect the electric system. The LED PWR (9/1)

and RUN (9/2) of all modules have to shine. If on

one module one of the mentioned LED’s does not 3

shine, the electric system or the DCM Module is

not ready for operation, for this, see chapter

”Trouble Shooting”, page 20.

Figure 9

12 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

NOTE

For further information on the functional check of the

path--dependent control, see page 14.

For further information on the functional check of the

path--dependent speed setting, see page 15.

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 13 /31

Functional check of path--dependent control

(10/2). The propulsion units (10/4) for setting the

i INFORMATION path--dependent control are approached by the

amplifier unit until the set value and feed--back value

When using the DCM Module (10/5) for the are identical.

path--dependent control, no other settings are required

after configuration and installation are carried out. After If setting and feed--back devices (10/1) are fitted with

switch--on of the entire system, the DCM Module CAN sensors as shown in Figure 10, in case of need,

approaches the amplifier unit (10/3) after changing the these can be parameterized via the DCM Module, see

path--dependent thrust direction on the default unit page 16.

3 4

1 2

M

24 V GND

Figure 10

14 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Functional check of path--dependent speed setting

i INFORMATION

When using the DCM Module for the path--dependent According to the configuration, the output signal can be

speed setting, the following settings are required after checked with an universal measuring device (11/2)

configuration and installation are carried out. After (measuring range from 0 ... 20 V or 0 ... 25 mA).

switch--on of the entire system, the DCM Module

approaches the amplifier unit (11/3) after changing the Figure 11 shows the application with analog output

path--dependent speed on the default unit (11/1). signal 0 .. 10 V.

Figure 11 shows the application of the DCM Module for If the default unit is fitted with a CAN sensor (no

the path--dependent speed setting (11/1) with analog illustration), in case of need this sensor can be

output AO1 and AGND. After the configuration and parameterized via the DCM Module, see page 18.

installation, the following settings are required,

depending on the configuration of jumper J7 and J8:

D Starting point from which the speed of the motor

(11/5) shall be increased – to be set at

potentiometer AI3 (11/3)

(Position of the setting lever (11/6)

D Maximum motor speed – to be set at potentiometer

AI4 (11/4)

2

6

1

000.0

min 0 GND

.

max.

V DC

3 U

I

4

5

24 V GND

AO1

AGND

Figure 11

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 15 /31

Parameterisation of CAN sensors

Path--dependent control

6. Connect the DCM Module for path--dependent

i INFORMATION control. LED PWR and RUN are shining,

After the replacement of a CAN sensor (12/1) in the LED SF 1 (13/7) is flashing.

default unit of the path--dependent control (12/4) or in

the feed--back unit (12/2), parameterisation can be

carried out via the DCM Module (12/3). 7. Within 10 seconds after switch--on of the DCM

Module, give two short 24 V--pulses at connection

17 of the contact connector strip (13/4). LED SF 1

NOTE is shining.

Installation of the new CAN sensors must be

completely terminated.

DCM Module for path--dependent control must be

ready for operation. NOTE

The settings driving direction ahead (0o) must not be

1. For parameterisation (zero position setting) of the changed during the parameterisation.

path--dependent control, the SCHOTTEL

propulsion (13/3) is to be manually set into driving After the 10 seconds have elapsed, the DCM Module

direction ahead (0o). Switch off the electric blocks the release of zero position setting. LED SF 1 is

approach on the propulsion units (13/2) for flashing in a slow rhythm.

path--dependent control.

If the zero position setting is to be repeated, beforehand

it is required to switch off the DCM Module for the

2. Turn the default unit for path--dependent control path--dependent control. Thereafter, the positions 6.

(13/1) into driving direction ahead (0o). and 7. are to be repeated.

3. Switch off the DCM Module for path--dependent 8. After successful parameterisation, switch the

control (13/5) . LED PWR (13/8) and RUN (13/6) DCM Module for path--dependent control off.

do not shine. LED PWR and RUN are not shining.

4. Pull the contact connector strips (13/4) out from 9. Pull the contact connector strips out from the DCM

the DCM Module and open the module, see page Module and open the module, see page 12.

12.

5. Put the DIL switch S 3.8 (13/10) on the switch 10. Put DIL switch S3.8 on the switch block S 3 in

block S3 (13/9) to pos. ON. Push the DCM Module OFF--position. Push the DCM Module into the

into the housing and insert the contact connector housing and insert the contact connector strips in

strips in the DCM Module, see page 12. the DCM Module, see page 12.

16 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

1 1

4 3

Figure 12

1 2 2

0o

0o

M

3

8 6

4

S4

S3

5 24 V GND

10

Figure 13

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 17 /31

Path--dependent speed setting

5. Connect the DCM Module for path--dependent

i INFORMATION speed regulation. LED PWR and RUN are shining.

LED SF 1 (15/2) is flashing.

After the replacement of a CAN sensor (14/1) in the

default unit of the path--dependent speed regulation 6. Within 10 seconds after switch--on of the DCM

(14/2), parameterisation can be carried out via the Module , give two short 24 V--pulses at connection

DCM Module (14/3). 17 of the contact connector strip (15/5). LED SF

1 is shining.

NOTE

NOTE

Installation of the new CAN sensors must be

completely terminated. Setting of the zero position for the speed setting must

DCM Module for path--dependent speed regulation not be changed during the parameterisation.

must be ready for operation. After the 10 seconds have elapsed, the DCM Module

blocks the release of parameterisation. LED SF 1 is

1. Put the default unit for path--dependent speed flashing in a slow rhythm.

regulation (15/1) to zero position.

If the parameterisation is to be repeated, it is required

to switch off the DCM Module for the path--dependent

2. Switch off the DCM Module for path--dependent speed regulation beforehand. Thereafter, the positions

speed regulation (15/6) . LED PWR (15/3) and 5. and 6. are to be repeated.

RUN (15/4) do not shine.

7. After successful parameterisation, switch the

DCM Module for path--dependent speed

3. Pull the contact connector strips out from the DCM regulation off. LED PWR and RUN are not shining.

Module and open the module, see page 12.

8. Pull the contact connector strips out from the DCM

4. Put the DIL switch S 3.8 (15/7) on the switch block Module and open the module, see page 12.

S3 (15/3) to pos. ON. Push the DCM Module into

the housing and insert the contact connector strips 9. Put DIL switch S 3.8 to pos. OFF. Push the DCM

in the DCM Module, see page 12. Module into the housing and insert the contact

connector strips in the DCM Module, see page 12.

18 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

1 2 3

Figure 14

3 4

S4

S3

6 24 V GND

7

Figure 15

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 19 /31

3 Trouble Shooting

NOTE 1

The following table does only include possible defects,

which may generate because of wrong configuration,

installation or settings of the DCM Module.

Errors of the ship’s electrical system (e.g. defective

supply voltages, cable breakages and similar) are not 13 14 15 16 17 18 19 20

4A1

touched.

If it is not possible to remove the fault with these

measures it is required to inform the SCHOTTEL

Service.

The SCHOTTEL Service needs the following

information: 1410XXXX 115XXXX

=

+B

Bl.

D SCHOTTEL password, order number (16/2) and

wiring diagram Ident--no. (16/3) 2

D Denomination (16/1) of the DCM Module in the

wiring diagram 3

D Description of the error and how it affects the

function of the system.

Figure 16

i INFORMATION

For the perfect function of the DCM Module the

following basic prerequisites must be met:

1. The operating mode switch (17/1) must be in pos.

ON.

1

2. For the specific application, all jumpers must be

put onto the according pins, see pos. 1 in Figure 6,

page 11.

3. All DIL switches must be set for the specific

application, see pos. 3 in Figure 6, page 11. 2

4. The load resistance must be in pos. ON if the

module is the last device in the CAN loop. Within

the CAN loop, the load resistance of all modules

must be on OFF, see pos. 2 in Figure 6, page 11

and Figure 12 page 17.

With absence of one of the basic prerequisites, the

DCM Module is not ready for operation. Figure 17

20 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Malfunction/Error Possible cause Check / Removal

SCHOTTEL propulsion is perma- Setting and/or feed--back: Parameterisation of CAN sensor,

nently turning around CAN--Sensor not parameterized see page 16

(continuous run of the path--de-

pendent control)

Interchanged signal on the poten- Check connections and correct, if

tiometer of the default or feed-- required.

back unit.

Phase--sequence information to- Check phase--sequence informa-

wards the amplifier interchanged tion and correct, if required.

With hydraulics: change valves.

With frequency converter:

change phase--sequence in-

formation,

e.g. cw (=clockwise) with ccw

(=counterclockwise).

SCHOTTEL propulsion turns op- DIL switch 1 of switch block S3 in Correct DIL switch 1 of switch

posite to setting wrong position block S3 and parameterise CAN

(Wrong turning direction of the sensors of default and feed--

path--dependent control) back, see page 16

Check signals of feed--back AI3

Interchanged signal on the poten- and AI4 and change, if required.

tiometer of the default or feed-- Correct the position of the poten-

back unit. tiometer on the feed--back unit.

Check phase--sequence informa-

Phase--sequence information to- tion and correct, if required.

wards the amplifier interchanged With hydraulics: change valves.

With frequency converter:

change phase--sequence in-

formation,

e.g. cw (=clockwise) with ccw

(=counterclockwise).

Although the electric system is There is no voltage supply at the For checking the voltage supply

connected, LED PWR does not module. at the DCM Module, see page

shine. 24.

Ensure voltage supply at the

DCM Module, e.g. check function

of safety cut--out, check correct

function of the connections, etc.

DCM Module defective Replace the DCM Module

Although the electric system is Module not ready for operation. Check if one of the LED’s F100,

connected, LED RUN does not F101, F102, F103, F104 or F105

shine. is shining, see follow--up table.

(alarm message error)

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 21 /31

Malfunction/Error Possible cause Check / Removal

LED F100 shines. Error in the CAN bus system Check entire wiring of the CAN

bus system for correct connec-

tions, and wiring for damage.

Replace damaged lines, if re-

quired.

Pay attention to correct connec-

tions.

Check position of load resis-

tance, see point 6., page 10 and

20

Measure resistance between

CAN High and CAN Low: 60 Ω

LED F101 shines. Error in the voltage supply For checking the voltage supply

at the DCM Module, see page

24.

Checking the voltage supply.

Pay attention to the specifications

in the wiring diagram.

LED F102 shines. ”Setpoint” error

(error in the setting):

With setting via CAN sensor Check if LED F 100 shines

Check supply of the CAN sensor,

check CAN address (see wiring

diagram), replace CAN sensor, if

required

(also see failure / error,

LED F100 shines)

With setting via potentiometer Check wiring of the potentiometer

for damage.

Replace damaged lines, if re-

quired.

Pay attention to correct connec-

tions.

Check supply of the potentio-

meter, check signals, replace the

potentiometer, if required.

22 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Malfunction/Error Possible cause Check / Removal

LED F103 shines. ”Feedback” error

(error in feedback):

With setting via CAN sensor Check if LED F 100 shines

Check supply of the CAN sensor,

check CAN address (see wiring

diagram) replace CAN sensor, if

required.

(also see failure / error,

LED F100 shines)

With setting via potentiometer Check wiring of the potentiometer

for damage.

Replace damaged lines, if re-

quired.

Pay attention to correct connec-

tions.

Check supply of the potentio-

meter, check signals, replace the

potentiometer, if required.

LED F104 shines. Presently not used Consult SCHOTTEL.

LED F105 shines. Presently not used Consult SCHOTTEL.

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 23 /31

4 Measuring points and nominal data

Supply

D Contact connection 25 (18/1): GND

D Contact connection 26 (18/2): 24 V DC

D Contact connection 27 (18/1): GND

D Contact connection 28 (18/2): 24 V DC

24 V

1

2

Figure 18

9 10

Alarm relay

D Contact connection 9 (19/9): Potential--free

D Contact connection 10 (19/10): Potential--free

Figure 19

24 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

CAN bus

D Contact connection 1 (20/1): 5 V CAN--VCC

5V

D Contact connection 4 (20/4): CAN--GND

D Contact connection 2 (20/2): CAN--H 1

2

D Contact connection 3 (20/3): CAN--L

3

4

Figure 20

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 25 /31

Inputs

Analog inputs

D Contact connection 21 (21/21): AI 1

0 ... 10 V DC 0 ... 10 V

21

D Contact connection 22 (21/22): AI 2 22

0 ... 10 V DC 23

D Contact connection 23 (21/23): AI 3

0 ... 10 V DC / 0 ... 20 mA

depending on configuration of the jumpers J8

D Contact connection 24 (21/24): AI 4

0 ... 10 V DC / 0 ... 20 mA

depending on configuration of the jumpers J7

D Contact connection 29 (21/29): AGND

AGND for analog inputs AI 1, AI 2, AI 3 and AI 4

24

29

i INFORMATION

Optionally it is possible to use all analog inputs as Figure 21

current input. Each input processes a current signal

from 0 ... 20 mA. With a jumper, each analog input can

be configured accordingly.

26 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Digital inputs

D Contact connection 25 (22/25): GND

13

D Contact connection 13 (22/13): DI 0.0 High: 24 V 14

High: 24 V / Low: 0 V Low: 0 V

15

D Contact connection 14 (22/14): DI 0.1

High: 24 V / Low: 0 V 16

D Contact connection 15 (22/15): DI 0.2

High: 24 V / Low: 0 V

D Contact connection 16 (22/16): DI 0.3

High: 24 V / Low: 0 V

25

Figure 22

17

D Contact connection 25 (23/25): GND

High: 24 V

D Contact connection 17 (23/17): DI 1.0

High: 24 V / Low: 0 V Low: 0 V

D Contact connection 18 (23/18): DI 1.1

High: 24 V / Low: 0 V

D Contact connection 19 (23/19): DI 1.2 18

High: 24 V / Low: 0 V

19

D Contact connection 20 (23/20): DI 1.3

High: 24 V / Low: 0 V

20

25

Figure 23

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 27 /31

Outputs

Analog outputs

D Contact connection 29 (24/29): AGND

GND for analog outputs 30, 31 and 32

D Contact connection 30 (24/30): 10 V DC

Reference voltage

D Contact connection 31 (24/31): 0 ... 10 V DC

D Contact connection 32 (24/32): 0 ... 10 V DC

0 ... 10 V DC

32

i INFORMATION

31

Optionally it is possible to use all analog outputs as 10 V DC

30

current output. Each output emits a current signal from 29

0 ... 20 mA. With a jumper, each analog output can be

configured accordingly.

Figure 24

Digital outputs

5

D Contact connection 5 (25/5): DO 0 High: 6

High: 24 V / Low: 0 V

24 V 7

D Contact connection 6 (25/6): DO 1 8

High: 24 V / Low: 0 V Low:

0V

D Contact connection 7 (25/7): DO 2

High: 24 V / Low: 0 V

D Contact connection 8 (25/8): DO 3

High: 24 V / Low: 0 V

D Contact connection 28 (25/28): GND

28

Figure 25

28 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

5 Pin configuration and Technical Data

Pin configuration

Pin configuration

Contact Designation

Voltage output CAN

1

(+ 5 V DC VCC)

2 CAN--Bus CAN--H

3 CAN--Bus CAN--L

Reference potential CAN

4

(CAN--GND)

5 Digital output 0 DO 0

6 Digital output 1 DO 1

7 Digital output 2 DO 2

8 Digital output 3 DO 0

9 Alarm relay

10 Alarm relay

11 RS 232 TXD

12 RS 232 RXD

13 Digital input 0 DI 0.0

14 Digital input 1 DI 0.1

15 Digital input 2 DI 0.2

16 Digital input 3 DI 0.3

Figure 26

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 29 /31

Pin configuration

Contact Designation

17 Digital input 0 DI 1.0

18 Digital input 1 DI 1.1

19 Digital input 2 DI 1.2

20 Digital input 3 DI 1.3

21 Analog input AI 1

22 Analog input AI 2

23 Analog input AI 3

24 Analog input AI 4

25 Voltage supply GND

26 Voltage supply 24V

27 Voltage supply GND

28 Voltage supply 24V

29 Analog reference potential AGND

Reference voltage output 10 V

30

10 V REF

31 Analog output AO 0

32 Analog output AO 1

Figure 27

30 / 31 STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 en

Technical Data

General

Prototype assay GL

Operating data

Power supply 24 V DC / 100 mA

Admissible voltage variation incl. residual ripple -- 25 % . . . +50 %

Current consumption in no--load operation < 200 mA

Admissible ambient temperature 0 . . . 70°C

Electric separation ----

Digital inputs

Digital inputs DI0.0 ... DI 0.3 24 V DC

Low: 0 ... 5 V, High: 15 ... 36 V

Digital inputs DI1.0 ... DI 1.3 24 V DC

Low: 0 ... 5 V, High: 15 ... 36 V

Digital outputs

Digital outputs DI0.0 ... DI 0.3 500 mA @ 24 V DC

Analog inputs

Analog input AI1 ... AI4 0 ... 10 V DC or 0 ... 20 mA

depending on jumper position

with 10--bit resolution

Reference voltage output 10 V DC ( IRef < 10 mA)

Analog outputs

Analog output AO0 ... AO1 0 ... 10 V DC or

0 ... 20 mA

with 12--bit resolution

Alarm relay switching contact

Switching contact 1000 mA @ 30 V DC

en STD--Ka Operating Instructions DCM Module 2.x 07/1384 1162900 31 /31

You might also like

- Fundamentals of Database System Note Unit 1-4 PDFDocument50 pagesFundamentals of Database System Note Unit 1-4 PDFAge100% (8)

- Charles 5000 Manual) 40-50-60ampDocument14 pagesCharles 5000 Manual) 40-50-60amporlandoNo ratings yet

- Fast Vessels WVS-WLS 234-1 - 430-1Document8 pagesFast Vessels WVS-WLS 234-1 - 430-1Mohammed SaberNo ratings yet

- BNWAS Flyer ROCKSON-GuardianV11Document6 pagesBNWAS Flyer ROCKSON-GuardianV11djoko susantoNo ratings yet

- Miller Spectrum 1250 Plasma CutterDocument48 pagesMiller Spectrum 1250 Plasma CutterDeyber DerasNo ratings yet

- Manual S-125 PDFDocument400 pagesManual S-125 PDFChristian Andy H. ChavezNo ratings yet

- Siemens cp581 Manual PDFDocument464 pagesSiemens cp581 Manual PDFjesusNo ratings yet

- Intecont Satus ManualDocument108 pagesIntecont Satus ManualMiladinm1100% (1)

- Selenium Webdriver & BDD With SpecflowDocument45 pagesSelenium Webdriver & BDD With SpecflowTatyana Asenova100% (1)

- Diagr Elet SRP330Document372 pagesDiagr Elet SRP330David YepezNo ratings yet

- File 11 060f737db116526.88891431Document35 pagesFile 11 060f737db116526.88891431Patrick ByronNo ratings yet

- Repeater Compass - Type 133-560Document46 pagesRepeater Compass - Type 133-560RANDSON NEVESNo ratings yet

- Nodriza ViDocument453 pagesNodriza Vimichael pachecoNo ratings yet

- Proportional Valve Group: Service and Parts ManualDocument142 pagesProportional Valve Group: Service and Parts ManualMilos BubanjaNo ratings yet

- Bonny 13 EspañolDocument284 pagesBonny 13 EspañolOscar CorderoNo ratings yet

- Volvo Penta Inboard Diesel: 570 KW (775 HP) Crankshaft Power Acc. To ISO 8665Document2 pagesVolvo Penta Inboard Diesel: 570 KW (775 HP) Crankshaft Power Acc. To ISO 8665deepakgkdNo ratings yet

- Um0244 01 GBDocument84 pagesUm0244 01 GBnetharafernando1No ratings yet

- ECU 100, GCU 100, Parameter List 4189340796 UKDocument85 pagesECU 100, GCU 100, Parameter List 4189340796 UKTeknisi Abal AbalNo ratings yet

- Service Manual: Nera CDocument228 pagesService Manual: Nera CAfanNo ratings yet

- Generator Protection Module GPM500: Projection ManualDocument122 pagesGenerator Protection Module GPM500: Projection Manualдмитрий100% (1)

- Pelco Spectra IV Series Dome Drive ManualDocument100 pagesPelco Spectra IV Series Dome Drive ManualCesar RodriguezNo ratings yet

- 94-0137-4-B Mini-RadaScan Installers GuideDocument70 pages94-0137-4-B Mini-RadaScan Installers GuideAshly JosephNo ratings yet

- Xmt425vsauto Line (Lh250371a)Document68 pagesXmt425vsauto Line (Lh250371a)Jose Arcesio Betancourt TrujilloNo ratings yet

- Pelco API SDK 2.1.2 Programming GuideDocument125 pagesPelco API SDK 2.1.2 Programming GuideGerson MayerNo ratings yet

- Owners Manual 2018Document49 pagesOwners Manual 2018Marv-Vic SantosNo ratings yet

- CS3000 Service v6 E5 09 1 EDocument83 pagesCS3000 Service v6 E5 09 1 EHarman SandhuNo ratings yet

- Master Instrb El 004 GB 1Document113 pagesMaster Instrb El 004 GB 1Александр АлександровNo ratings yet

- Manual SerDia2010 EN PDFDocument217 pagesManual SerDia2010 EN PDFAttila EngiNo ratings yet

- CM p4766 69 SJTP Issue ADocument53 pagesCM p4766 69 SJTP Issue Azzz zzzNo ratings yet

- Operating Instructions: Marine Transmission ZF 9000 SeriesDocument162 pagesOperating Instructions: Marine Transmission ZF 9000 SeriesbogdanmichaelNo ratings yet

- Manual 700Document58 pagesManual 700Romanhnap100% (1)

- Kongsberg K-Pos DP-21: SMS Serenity KM Project No. 6736278Document8 pagesKongsberg K-Pos DP-21: SMS Serenity KM Project No. 6736278edi2805No ratings yet

- Autopilot ARMONDocument1 pageAutopilot ARMONAlejandro Huracán Viveros MetztliNo ratings yet

- Field Service Manual 5300MK2Document318 pagesField Service Manual 5300MK2Teyfik koyuncuNo ratings yet

- vr7000 Installation Manual PDFDocument152 pagesvr7000 Installation Manual PDFhomecncrouterNo ratings yet

- DOSE Lighting For Ships PDFDocument103 pagesDOSE Lighting For Ships PDFNE wIN100% (1)

- GS-4069 RT - Service - Manual - Diesel - CEDocument75 pagesGS-4069 RT - Service - Manual - Diesel - CEBAKINEC AZERSKIYNo ratings yet

- 94-0393-4 RadaScan Operators GuideDocument57 pages94-0393-4 RadaScan Operators GuideAlexGrigorjev100% (1)

- CB-142 English Manual Mb-070102-1e-Cb&drwgDocument31 pagesCB-142 English Manual Mb-070102-1e-Cb&drwgTaufiq Omar HasanNo ratings yet

- Inv 2nd FLR CabinetDocument2 pagesInv 2nd FLR CabinetJack HarrisonNo ratings yet

- Hydraulic Spring Return Actuator (Type HSTP - F)Document2 pagesHydraulic Spring Return Actuator (Type HSTP - F)advantage025No ratings yet

- EMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFDocument183 pagesEMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFpevareNo ratings yet

- Old Steering CalibrateDocument1 pageOld Steering Calibratejrj82No ratings yet

- WISKA clientCMS MANUAL EN v3Document54 pagesWISKA clientCMS MANUAL EN v3akhilNo ratings yet

- FI-FI Control SystemDocument19 pagesFI-FI Control SystemMohamedNo ratings yet

- SteyrDocument2 pagesSteyrinforlexNo ratings yet

- MU231 Operator's ManualDocument78 pagesMU231 Operator's Manualdjoko susantoNo ratings yet

- LD5 Installation ManualDocument66 pagesLD5 Installation Manualarlindojl100% (1)

- VHF FM8500 Operator's Manual K2 9-12-05 PDFDocument99 pagesVHF FM8500 Operator's Manual K2 9-12-05 PDFsrinu1984100% (1)

- Stober 03Document140 pagesStober 03Luis Alberto Rocca SurcoNo ratings yet

- Rolls-Royce AzT US 255 CP - 3800 Electrical Service Manual Serial No. 66823 & 66824 For YN 512530Document336 pagesRolls-Royce AzT US 255 CP - 3800 Electrical Service Manual Serial No. 66823 & 66824 For YN 512530abnezam52No ratings yet

- Procedure For Uploading A New Mipeg X System Software - Rev ADocument3 pagesProcedure For Uploading A New Mipeg X System Software - Rev AEpuAmer100% (2)

- Yamaha RX-V2067, HTR-9063, RX-A2000 PDFDocument190 pagesYamaha RX-V2067, HTR-9063, RX-A2000 PDFboroda24100% (1)

- Owners Manual Dtorque 111 en FinalDocument206 pagesOwners Manual Dtorque 111 en FinalAlberto100% (1)

- NR 18 - Self-Propelled Scissor PlatformDocument67 pagesNR 18 - Self-Propelled Scissor PlatformCPSSTNo ratings yet

- Unidrive SPM User GuideDocument304 pagesUnidrive SPM User GuidenorbertNo ratings yet

- Per EmcDocument802 pagesPer Emcapi-3709675No ratings yet

- Bosch - Rexroth - Marine Technic - 2002Document291 pagesBosch - Rexroth - Marine Technic - 2002nguyenvanhai19031981No ratings yet

- Pritarder ChecklistDocument43 pagesPritarder ChecklistFlorinRusuNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Operation Instructions DPV-ModulDocument30 pagesOperation Instructions DPV-Moduljose camilo torres dominguezNo ratings yet

- PIM-530 Series Interface Module With Modbus Over RS-485: Installation and Operation GuideDocument37 pagesPIM-530 Series Interface Module With Modbus Over RS-485: Installation and Operation GuideJorge EspinozaNo ratings yet

- Network Design Assignment Help - Computer Network Assignment HelpDocument4 pagesNetwork Design Assignment Help - Computer Network Assignment HelpComputer Network Assignment HelpNo ratings yet

- Del TronDocument13 pagesDel TronJevaNo ratings yet

- Honeywell Fusion4-SSC-A Manual PDFDocument232 pagesHoneywell Fusion4-SSC-A Manual PDFRodrigo CiezaNo ratings yet

- Plantilla Doble División SinteticaDocument4 pagesPlantilla Doble División SinteticaAngelBoyNo ratings yet

- Thomson TSC800 BrocureDocument2 pagesThomson TSC800 BrocureANDRE LUIZ RAMOS DE FREITASNo ratings yet

- Material Requirements Planning (MRP) and ERP: Chap14Document44 pagesMaterial Requirements Planning (MRP) and ERP: Chap14syafiraaviolaNo ratings yet

- MacroDocument73 pagesMacroAbhijeet ThamakeNo ratings yet

- Practical: 10 Write A Program For Thread Synchronization. AlgorithmDocument5 pagesPractical: 10 Write A Program For Thread Synchronization. AlgorithmhimanshuNo ratings yet

- Adobe CCT - DatasheetDocument2 pagesAdobe CCT - DatasheetLilik NurfiantoNo ratings yet

- Experian 2021 DataBreachIndustryForcast D3Document10 pagesExperian 2021 DataBreachIndustryForcast D3scottrdavisNo ratings yet

- ADL Huawei Digital Transformation Main ReportDocument45 pagesADL Huawei Digital Transformation Main ReportLETSOGILENo ratings yet

- What Is A BrowserDocument9 pagesWhat Is A BrowserDdyash DayaNo ratings yet

- Laravel 2023Document6 pagesLaravel 2023Mohamed BakryNo ratings yet

- CCIE Practice Lab: OSPF: Ritten byDocument16 pagesCCIE Practice Lab: OSPF: Ritten byYogesh KhollamNo ratings yet

- Website: Vce To PDF Converter: Facebook: Twitter:: Fc0-U61.Vceplus - Premium.Exam.75QDocument22 pagesWebsite: Vce To PDF Converter: Facebook: Twitter:: Fc0-U61.Vceplus - Premium.Exam.75QDaniel De Los Santos LugoNo ratings yet

- Intecont Plus BW: I. Table of Contents Belt Weigher Basic VersionDocument17 pagesIntecont Plus BW: I. Table of Contents Belt Weigher Basic VersionArturMirandaNo ratings yet

- QBlade Guidelines v06Document77 pagesQBlade Guidelines v06huy2910 dangdangNo ratings yet

- Brkiot 2517Document92 pagesBrkiot 2517Senta ClausNo ratings yet

- Numerical Approximations, Scientific, Notation and IndicesDocument6 pagesNumerical Approximations, Scientific, Notation and IndicesDeadly ChillerNo ratings yet

- Types in PythonDocument14 pagesTypes in PythonArya BhattNo ratings yet

- Skse ReadmeDocument3 pagesSkse ReadmeJayseDVSNo ratings yet

- Tweak - PDF - Mobile Computers - ComputingDocument1 pageTweak - PDF - Mobile Computers - ComputingRohan100% (1)

- Schneider Electric PowerLogic-T300 EMS59000Document4 pagesSchneider Electric PowerLogic-T300 EMS59000Harshal PulekarNo ratings yet

- Core Java - Preparation Topics1Document7 pagesCore Java - Preparation Topics1Sanjeev SharmaNo ratings yet

- Casino NFT Game - MobiloitteDocument2 pagesCasino NFT Game - MobiloitteMobiloitte TechnologiesNo ratings yet

- En V3.1 Legrand Data Center Technical Specification 2020-02-01Document62 pagesEn V3.1 Legrand Data Center Technical Specification 2020-02-01Luis OchoaNo ratings yet

- Pxe-R500 OmDocument13 pagesPxe-R500 OmNattachai BoonchooNo ratings yet

- PowerCalc Catalyst 9400 08-03-2023Document5 pagesPowerCalc Catalyst 9400 08-03-2023Ngoc The NguyenNo ratings yet