Professional Documents

Culture Documents

Ysc Ms 769 DW 0001sht1of2rev B

Ysc Ms 769 DW 0001sht1of2rev B

Uploaded by

balamuralinakshatraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ysc Ms 769 DW 0001sht1of2rev B

Ysc Ms 769 DW 0001sht1of2rev B

Uploaded by

balamuralinakshatraCopyright:

Available Formats

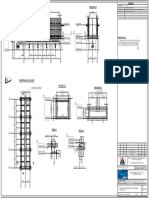

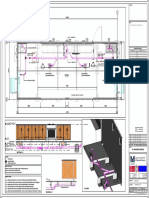

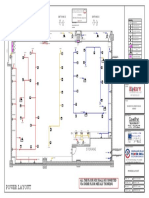

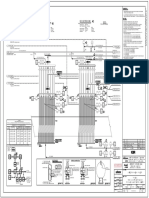

S1 DESIGN DATA NOTES :

GOOSE NECK WITH N9 1. ALL DIMENSIONS ARE IN `mm' AND ELEVATIONS ARE IN `m' UNLESS OTHERWISE SPECIFIED.

WITH DIP PIPE RAFTER IS CONTINUOUSLY TANK NAME FIRE WATER / UTILITY WATER TANKS

BIRD SCREEN WELDED TO THE ROOF PLATE

(REFER NOTE-29) B TAG No. 769-D-3053 A/B 2. ALL ELEVATIONS ARE REFERRED TO BASE LINE INDICATED IN THE DRAWING,

WITH DIP PIPE N13 ROOF PLATE WITH DIP PIPE 75 8 THK (REFER NOTE:34)

REFER NOTE:36

1825[5'-11.85'']

MW1 RAFTER 12 [7/16"] THK. N17A TANK INSIDE DIAMETER 52'-9" (16078mm) (TOP OF ANNULAR PLATE EL.(±) 0.000 m)

SS 316 (DO NOT PAINT)

7[1/4'']THK.

BY LTEH

TANK DETAILS

B BY LTEH N12 B 25 B

N11 MW4 HINGE N17 N17B THICKENED ROOF TANK HEIGHT 54.7' (16670mm) 3. SIZE OF WELD SHALL BE THE LESSER THICKNESS OF THE JOINED MEMBER

ROOF CIRCUMFERENTIAL RADIUS CORNERS

150

150

B 14 THK. [0.551"] ROOF PLATE QUANTITY 2 Nos. (UNLESS OTHERWISE SPECIFIED).

150

HANDRAIL 1:4 1:4 THICKENED ROOF

12 [7/16"] THK. Ø12 HOLE ROOF TYPE SELF SUPPORTED CONE ROOF 4. NOZZLE < 50NB SHALL BE STIFFENED BY 2 Nos. 50x6 THK. FLAT AT 90° APART

SHELL WALKWAY 14 THK. [0.551"]

(ALL AROUND) SHELL PLATE 5. BOLT HOLES IN NOZZLE FLANGES & MANHOLES SHALL STRADDLE VERTICAL

EL.+16670 BOTTOM SLOPE & TYPE SLOPE 1:120 & CONE UP TOWARDS TANK CENTER

B TANK INSIDE CENTER LINES ON SHELL & RADIAL CENTERLINES ON ROOF.

==

63

WITH DIP PIPE B N6 (TOP OF TANK SHELL)

HHLL=52'-4" HLL=52'-1" EL.+16218 [53'-2 1/2"] FIELD ERECTED/SHOP FABRICATED FIELD ERECTED 6. WELD CROWNS OF THE BOTTOM ANNULAR PLATE JOINTS SHALL BE GROUND FLUSH

EL.+16218 [53'-2 1/2"] (15951.6 mm) LLL=51'-5" LLLL=51'-1" N8 B

N5 N1 (15875 mm) ANNULAR STORAGE FLUID FIRE & UTILITY WATER AT THE CONTACT AREAS WITH THE FIRST SHELL COURSE.

300

(15671.75 mm)

31.5

(15570.19 mm) EL.+15443 [50'-8"] 6

DESIGN

N4 TOP OF FW LEVEL=50'-5" PLATE 7. ALL SHELL/ROOF REINFORCEMENT PAD & NOZZLES SHALL BE AS PER API-650

CODE

N2 B 6

100% DAILY USE

API 650 THIRTEENTH EDITION, MARCH 2020. ANNEX : E,

50% DAILY USE

WITH DIP PIPE EL( ± )0.00m DESIGN CODE 8. ALL NOZZLE FLANGES DIMENSIONS SHALL BE AS PER ASME B-16.5 UPTO &

1100 [3'-7 5/16"]

F,P & L

1835[6'-0.245'']

1.5

TOP OF ANNULAR PLATE INCLUDING 600NB (RAISED FACE/WELD NECK) & ABOVE DN600 AS PER

7[1/4'']THK.

EL.+16218 [53'-2 1/2"]

N7 CAGE LADDER OPERATING TEMPERATURE 140 F (60°C)

ANSI B-16.47 SERIES 'A' AND MANHOLE AS PER API 650. B

CIRCUMFERENTIAL B DETAIL OF EARTHING LUGS OPERATING PRESSURE ATM + LIQUID COLUMN

9. NOZZLE NECK AND MANHOLE NECK 10"(250 NB) AND ABOVE WHICH IS

OPERATING DATA

SPIRAL WAY TO ROOF B (4 NOS. EQUALLY SPACED) LOW LIQUID LEVEL (LLL) 51'-5" (15671.75 mm)

B FABRICATED FROM PLATE SHALL BE 100% RADIOGRAPHED.

150

TYP

FROM GRADE

LOW LOW LIQUID LEVEL (LLLL) 51'-1" (15570.19 mm)

DIP PIPE CL OF SUMP B 10. VERTICAL SHELL JOINTS SHOULD PREFERABLY BE OFFSET BY 1000mm.

1.5

2000[6'-6.74'']

SUPPORT HIGH LIQUID LEVEL (HLL) 52'-1" (15875 mm)

7[1/4'']THK.

11. ANNULAR PLATE RADIAL JOINTS SHALL STAGGER VERTICAL SHELL JOINTS AT

2600(8'-6/4') HIGH HIGH LIQUID LEVEL (HHLL) 52'-4" (15951.6 mm) LEAST BY 300 mm

(FROM SHELL OUTSIDE) SPECIFIC GRAVITY 0.99 @ 100°F

B B 12. STIFFENING RING JOINTS SHALL OFFSET THE SHELL HORIZONTAL

VENT HOLE ON THE STILL WELL NORMAL / GROSS CAPACITY 114370.6 ft³ (3238.6m³) B

B N10 JOINTS BY 150 mm.

(TYP.)

BOTTOM PLATE WORKING CAPACITY (STORAGE CAPACITY) 100165.3 ft³ (2836.4m³) 13. FOR SHELL NOZZLES, PROJECTION ARE REFERRED FROM CENTER LINE OF

1.5

2000[6'-6.74'']

7[1/4'']THK.

B DESIGN INTERNAL TEMPERATURE 185 °F (85°C) SHELL TO FLANGE CONTACT FACE & FOR NOZZLE ON ROOF PROJECTION ARE

6000

TYP

15.87 lbf/ft² (g) (0.759 Kpa) + FULL OF LIQUID REFERRED FROM TOP OF TANK SHELL TO FLANGE CONTACT FACE.

12

SLOPE 12 7 DESIGN INTERNAL PRESSURE

16670 [54'-8 5/16"]

6000

TYP

7 12 DESIGN EXTERNAL PRESSURE (VACUUM) -5.22 lbf/ft² (g) (0.25 Kpa) 14. WELDS SHALL BE VISUALLY INSPECTED FOR ANY DEFECTS PRIOR TO PERFORMING

(TANK HEIGHT)

B HYDRO STATIC TEST PRESSURE 15.87 lbf/ft² (g) (0.759 Kpa) + FULL OF WATER NONDESTRUCTIVE EXAMINATION (RADIOGRAPHY, MAGNETIC PARTICLE, LIQUID

DESIGN LIQUID LEVEL 52.33 ft (15950.2 mm)

1.5

PENETRANT, ULTRASONIC). VISUAL INSPECTION SHALL NOT REPLACE ANY

2000[6'-6.74'']

12

7[1/4'']THK.

150

900

DESIGN SPECIFIC GRAVITY B 0.99 @ 100°F REQUIRED NONDESTRUCTIVE EXAMINATION. B

CL OF TANK TESTING AND INSPECTION AS PER API 650, PROJECT & COMPANY SPECIFICATION 15. REINFORCEMENT PADS FOR NOZZLES & MANWAYS SHALL BE PNEUMATICALLY

12

12

12 MINIMUM DESIGN METAL TEMPERATURE 41 °F (5°C) TESTED AT 1.02 kg/sq.cm WITH SOAP SOLUTION, THIS TEST SHALL BE CARRIED

B

STORAGE TANK LIQUID FLOW RATE - BEFORE FILLING THE TANK FOR HYDROSTATIC TESTING

1.5

8[0.315'']THK.

2000[6'-6.74'']

i) FILLING (PUMP-IN RATE) 4010 FT³/HR (113.55 m³/hr)

DESIGN DATA

Ø1520 16. THE TANK BOTTOM PLATE TO LAP ``ROOF TILE" STYLE TOWARDS CENTER (CONE UP).

16078 [52'-9"] I.D DETAIL D2 ii) EMPTYING (PUMP-OUT RATE) 2000 USGPM (460 m³/hr) 17. THE TANK MATERIALS, DESIGN, FABRICATION, INSPECTION, TESTING

16078 [52'-9"]

DETAIL OF DRAIN SUMP SHELL PLATE :0 TOLERANCE AND ERECTION ARE IN COMPLIANCE WITH ARAMCO STANDARD

TANK INSIDE DIAMETER

B BOTTOM PLATE / ANNULAR PLATE :0 32-SAMSS-005 & API 650 13th EDITION 2020. B

CORROSION ALLOWANCE

ANCHOR BOLT : 3.2 mm 18. VACUUM BOX TESTING AS PER 32-SAMSS-005 & API 650. SHALL BE PERFORMED

2500[8'-2.425'']

1.5

9[0.354'']THK.

(FPW) FIXED ROOF (CONE) :0 FOR BOTTOM PLATES.

30° 30° FPW (FPW) 3 BASIC WIND SPEED (3-sec

ts

ts

4 96 mph (43 m/sec) 19. ALL GRATINGS SHALL BE MADE BY ELECTRO FORGING PROCESS.

ts

ts

2600 [8'-6 1/4"] WIND DATA GUST) B

20. GRATINGS SHALL BE HOT DIP GALVANIZED.

ts

ts

FROM SHELL OD B IMPORTANCE FACTOR 1.15 21. FOR CS INTERNAL PIPE SHALL HAVE COATING FOR BOTH INTERNAL & EXTERNAL SURFACE

HINGE

4 Ss 0.16 g AS PER PAINTING SPECIFICATION.

3

EL.+1219 [4']

10[0.394'']THK.

2500[8'-2.425'']

1.5

EL.+902 [2'-11 1/2"] LLL3=6'-3" VORTEX NOZZLE N3 N14 TANK

MW2 MW3 NECK S1 0.046 g 22. ALL ERECTION LUGS AND CLEATS TO BE REMOVED PRIOR TO HYDRO TESTING.

BREAKER INSIDE 8 < ts < 9 ts = 7

ts = 10 0.03 g 23. RADIOGRAPHY SHALL BE AS PER 32-SAMSS-005 & API 650.

WITH BLIND EL.+406 [1'-4"] SEISMIC DATA So

EL.+406 [1'-4"] EL.+762 [2'-6"] N10

FLG. N15 BOTTOM PLATE SITE CLASS D 24. IMPRESS CURRENT CATHODIC PROTECTION SHALL BE SUPPLIED INSIDE THE

EL.+500 [1'-7 3/4"] NAME PLATE TYP. WELDING DETAIL OF VERTICAL SHELL JOINTS

N16 7 [1/4"] thk. TANKS AS WELL AS UNDER THE BOTTOM AND ANNULAR PLATES. TANK VENDOR TO

D1 SEISMIC USE GROUP (SUG) III

DESIGN AND SUPPLY INTERNAL CP SYSTEM AND PROVIDE CONNECTIONS FOR

SUMP AS PER LOCATION JAFURAH, SAUDI ARABIA

50

ANNULAR PLATE

B EXTERNAL CP. THE QUALIFICATIONS OF THE DESIGN VENDOOR'S. WHO IS

EL.±0.00 B 1:120 1:120 API 650 PWHT / PRE - HEATING REQUIREMENT NA

(TOP OF ANNULAR PLATE) 8 [5/16"] thk. RESPONSIBLE FOR DESIGNING CP SYSTEMS SHALL BE VALIDATED BY SAUDI ARAMCO CSD.

4 NOS. GROUNDING LUGS 1520 [4'-11 3/4"] O.D ts

INTERNAL PIPE SHELL PLATE : SPOT 25. TANK SETTLEMENT MEASUREMENT SHALL BE PERFORMED ACCORDINGLY TO

@90° APART) DO NOT PAINT ELEVATION

BOTTOM ANNULAR PLATE : SPOT PARAGRAPH 32-SAMSS-005 & API 650.

20 NOS - M24 ANCHOR BOLTS

D2 SECTION S1-S1 SHELL INSIDE

AT 16246 BCD

FIRE WATER / UTILITY WATER TANKS (769-D-3053 A/B) FLUSH-STACKED RADIOGRAPHY BOTTOM PLATE : NIL 26. ALL NDT SHALL BE IN ACCORDANCE WITH APPROVED ITP FOR THE

S1 Fz ON THE INSIDE PROJECT, API 650 13th EDITION 2020 @ 32-SAMSS-005.

B

(Ø16.078m x 16.67m H) ROOF PLATE : NIL

1.5

(FPW) 27. EXTERNAL STRUCTURAL STEEL SHALL BE HOT DIPPED GALVANIZED AND

OTHER DATA

150 NOZZLE : REFER NOTE 9 COATED IN ACCORDANCE WITH SAES-H-001.

SHELL WASHER Ø60 Mz

FPW SHELL :1 28. ALL EXTERNAL BOLTING MATERIAL SHALL BE FLUOROPOLYMER COATED IN

20 THK ANNULAR PLATE SHELL PLATE JOINT EFFICIENCY

PLATE B

BOTTOM 60° BOTTOM PLATE 8 THK 10 THK ROOF : 0.35 ACCORDANCE WITH 09-SAMSS-107.

ANNULAR PLATE

16

PLATE ANNULAR PLATE 7 THK SHELL : NIL

35 8 3 SEAL WELD ts 29. AS PER SAES-D-109 SECTION 9.2.4, VENT SHALL BE PROTECTED BY

TYP 6 TYP SLOPE 1:120 8 TYP INSULATION

7 TYP ROOF : NIL CORROSION RESISTANT COARSE MESH BIRD SCREEN OF 13MM NOMINAL OPENING.

DRIP RING

8

(TY °

7 < ts < 10

7

TANK HEATING COIL (YES / NO) NO

45

P)

6 3 THK 30. STILLWELL FOR LEVEL TRANSMITTER SHALL HAVE INTERNAL FLANGED

7

1.5

5 THK. (min.) STIFF. PLATE CATHODIC PROTECTION (YES / NO) YES CONNECTION (CARBON STEEL ON TOP SIDE AND SDSS ON BOTTOM SIDE).

TYP. WELDING DETAIL OF

300

45°

BACKING STRIP 50 16 THK 65 600 60 75

BOTTOM 50 (100) 50 5 OPERATING WEIGHT (NON-CORRODED) 3322.8 MT 31. REINFORCING PADS AND ALL OTHER EXTERNAL ATTACHMENT PADS SHALL

PLATE (TYP) MIN. HORIZONTAL SHELL JOINTS

TYP Mx TEST WEIGHT (NON-CORRODED) 3413.3 MT HAVE ROUNDED CORNERS OF MINIMUM 50 MM (2 IN.) RADIUS. PADS THAT

EMPTY WEIGHT (NON-CORRODED) 122.1 MT B COVER SHELL SEAMS SHALL BE PROVIDED WITH A 6 MM TELLTALE HOLE.

TYP. WELDING DETAIL TYP. JOINT IN ANNULAR PLATES 5 THK. (MIN.) FOUNDATION

My Fy 32. FOR HYDROTEST, TEST WATER LEVEL CONSIDERED UP TO DESIGN LIQUID

OF BOTTOM PLATE (REFER NOTE-6) ANNULAR

BACKING STRIP Fx MATERIAL SPECIFICATION LEVEL i.e, 52'-4" AS PER CL. NO. 5.6.3.2 OF API 650.

PLATE 100 TYP. WELDING DETAIL OF SHELL PLATE A 283 Gr.C 33. THE MANUFACTURER SHALL SUPPLY THE FOLLOWING:

SECTION S2-S2 SHELL PLATE TO ANNULAR PLATE, BOTTOM PLATE ANNULAR PLATE A 283 Gr.C a) MINIMUM TWO SETS OF SPARE GASKETS WITH A BLIND FLANGE FOR EACH

0° (TYPICAL DETAIL OF ANCHOR CHAIR) B MANWAY AND BLINDED NOZZLE IN THE TANK.

BOTTOM PLATE A 283 Gr.C

N b) MINIMUM ONE SET OF SERVICE GASKET SET AND TWO SETS OF SPARE

ROOF PLATE A 283 Gr.C

9°

GASKETS FOR EACH NOZZLE WITH COMPANION FLANGES IN THE TANK.

TYP18°

S2 ALLOWABLE NOZZLE LOAD MANWAY NECKS / SUMP A 283 Gr.C C) ALL BOLTING WITH MINIMUM 10% SPARE BOLTING (3 MINIMUM FOR

MANWAY FLANGES / COVER PLATE A 283 Gr.C EACH SIZE) PER TANK.

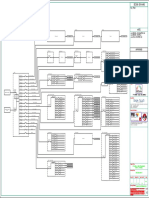

NOZZLE SIZE DIRECT LOADS (KN) MOMENT LOADS (KNm)

34. ALL GROUNDING LUGS ARE OF SS316 MATERIAL & SHALL BE UNPAINTED.

200 NOZZLE NECKS (PIPES) ≤ 250 NB A 106 Gr.B (NOTE:21) B

DESCRIPTION

74 TAG 35. ALL STRUCTURAL ATTACHMENT WELDS TO THE TANK SHELL, BOTTOM, ROOF

20 NOS. 200 (INCH) (NB) Fx Fy Fz Mx My Mz NOZZLE NECKS (FAB) > 250 NB B A 283 Gr.C (NOTE:21) B AND APPERTUNANCES SHALL BE CONTINUOUSLY SEAL WELDED.

ANCHOR BOLT

M24 ANCHOR BOLTS Ø27 TYP

N1 RAW WATER INLET 6" 150 3.40 3.40 4.80 2.40 2.40 3.40 NOZZLE FLANGES / BLIND FLANGE A 283 Gr.C / A 105/ ASTM A182 F53 UNS S32750 (INTERNAL) 36. SHELL COURSE WIDTH IS ROUNDED OFF TO NEAREST INTEGER.

16

B.C.D @16246

SPIRAL WOUND 316 SS WINDINGS, FLEXIBLE GRAPHITE

S2a S2a Ø40 HOLE N2 UTILITY WATER OUTLET 4" 100 2.30 2.30 3.20 1.10 1.10 1.50 GASKETS FOR NOZZLES B

FILLED WITH CARBON STEEL OUTER RING AS PER ASME 16.2 HOLD LIST :

CL OF

FIRE WATER OUTLET W / VORTEX

N3 16" 400 11.10 11.10 15.70 16.70 16.70 23.60 GASKETS FOR MANHOLES CNAF

100

Ø40 1. PIPE SUPPORT CLEAT INFORMATION.

150

BREAKER

EXTERNAL BOLTS / NUTS - NOZZLES / MANHOLES A 193 Gr.B7 / A 194 Gr.2H (NOTE:28) B 2. PIPE SUPPORT LOADING INFORMATION ON TANK PLATFORM.

SHELL PLATE N4 UTILITY WATER SPILL BACK 2" 50 0.90 0.90 1.20 0.20 0.20 0.30 B

300

R20 INTERNAL BOLTS / NUTS - NOZZLES ASTM A193 B8M / ASTM A194 B8M 3. FLOAT AND TAPE TYPE LEVEL GAUGE.

TANK INSIDE TOP PLATE N5 FIRE WATER SPILL BACK 10" 250 6.20 6.20 8.70 6.40 6.40 9.10

S2b S2b 16 THK PIPE FITTINGS SA 234 WPB

CL OF TANK TYP N6 FW PUMP TEST LINE 8" 200 4.70 4.70 6.60 4.20 4.20 5.90

Ø16246 REINFORCEMENT PAD A 283 Gr.C

N7 DIESEL FIRE WATER PUMP RELIEF 8" 200 4.70 4.70 6.60 4.20 4.20 5.90

M24 ANCHOR B.C.D GROUNDING CLIP SS 316

N8 OVERFLOW 12" 300 7.70 7.70 10.90 9.40 9.40 13.30

60 BOLT SECTION S2a-S2a SECTION S2b-S2b NAME PLATE SS 304

N10 DRAIN W/DRAW-OFF SUMP 6" 150 3.40 3.40 4.80 2.40 2.40 3.40

CL OF TANK

GRATING (GALVANIZED) A 36

N15 TANKER CONNECTION (With Blind Flange) 6" 150 3.40 3.40 4.80 2.40 2.40 3.40

ANCHOR BOLTS / NUTS / WASHER F 1554 Gr.36 / 105 / & A 563 Gr.A / DH

S2

90° STRUCTURAL BOLTS / NUTS A 307 Gr.B / A 563 Gr.A B

DETAIL-D1 SHELL NOZZLES ACCESS PLATFORM AND HANDRAIL A 36

100 NOZZLE CIRCUMFERENTIAL STAIRS A 36

SIZE RF PAD

SHELL PROJECTION SCH./ RATING TYPE FACING THK RF PAD DRIP RING A 36

ORIENTATION OF ANCHOR CHAIR MARK No. SERVICE

(REFER THK. (NOTE:15) OD

PLATE WETTED/NON-WETTED STRUCTURALS A 283 Gr.C

EL(+)0.500m NOTE:13) (INCH) (NB)

B ISOLATION GASKET PHENOLIC

8299 30" 750 10 1545 B

LEGENDS L50x50x6

MW2 1 AS PER API 650 SHELL MANWAY WITH HINGE STILLWELL FOR N12, N13 INTERNAL

ASTM A790 UNS S32750 (NOTE-30)

8299 MW3 30" 750 1 AS PER API 650 10 1545 SHELL MANWAY WITH HINGE B PIPE(SEAMLESS), FLANGE WITH HARDWARE

1 NB NOMINAL BORE 6

8247 N1 6" 150 1 80 150 # WN RF 8 400 RAW WATER INLET (WITH DIP PIPE)

2 LLL LOW LIQUID LEVEL

DETAIL OF SETTLEMENT MARKER

B ROOF NOZZLES

B 8221 N2 4" 100 1 80 150 # WN RF 7 305 UTILITY WATER OUTLET W / VORTEX BREAKER B

3 LLLL LOW LOW LIQUID LEVEL NOZZLE

(8 NOS. EQUALLY SPACED) 8375 N3 16" 400 14thk 150 # WN RF 850 FIRE WATER OUTLET W / VORTEX BREAKER SIZE RF PAD

4 HLL HIGH LIQUID LEVEL 1 14 PROJECTION SCH./ RATING TYPE FACING THK RF PAD

(REFER MARK No. SERVICE

5 HHLL

HIGH HIGH LIQUID 8199 N4 2" 50 1 80 B 150 # WN RF - - UTILITY WATER SPILL BACK

(INCH) (NB)

THK. (NOTE:15) OD

LEVEL NOTE:13)

FULL PENETRATION PAINTING SPECIFICATION 8274 N5 10" 250 1 60 150 # WN RF 8 585 FIRE WATER SPILL BACK (WITH DIP PIPE)

1300 MW1 30" 750 1 AS PER API 650 12 B 1545 ROOF MANWAY WITH HINGE

6 FPW 8249 N6 8" 200 1 80 150 # WN RF 8 485 FW PUMP TEST LINE (WITH DIP PIPE)

WELD

INTERNAL 1300 MW4 30" 750 1 B AS PER API 650 12 1545 ROOF MANWAY WITH HINGE

7 C/C CENTER TO CENTER SAES-H-001 & 101 V (APCS-2A) 8249 N7 8" 200 1 80 150 # WN RF 8 485 DIESEL FIRE WATER PUMP RELIEF (WITH DIP PIPE)

COATINGS : B 2600 N9 16" 400 1 14thk 150 # WN RF 12 850 VENT W/GOOSE NECK & SP BIRD SCREEN

8 ℄ CENTER LINE 8272 N8 12" 300 1 14thk 150 # WN RF 8 685 OVERFLOW

EXTERNAL 1300 N11 6" B 150 1 40 150 # WN RF 12 375 GAUGE HATCH (WITH DIP PIPE)

9 TYP TYPICAL SAES-H-001 & 101 V (APCS-1D) 8249 N10 6" 150 1 80 150 # WN RF 10 400 DRAIN W/DRAW-OFF SUMP

COATINGS : B 1300 N12 4" 150 1 40 150 # WN RF 12 375 LEVEL INSTRUMENT W/ STILLING WELL

10 THK THICKNESS B 8199 N14 2" 50 1 80 150 # WN RF - B - SAMPLING POINT (WITH BLIND FLANGE)

1300 N13 4" 150 1 40 150 # WN RF 12 375 LEVEL INSTRUMENT W/ STILLING WELL

BOLT CIRCLE 6" 150 # WN TANKER CONNECTION (WITH BLIND FLANGE)

11 BCD

DIAMETER

UNDERSIDE OF SAES-H-001 & 101 V (APCS-3) 8249 N15 150 1 80 RF 10 400

1300 N17 4" 100 1 40 150 # WN RF 12 275 FLOAT TYPE LEVEL GAUGE

BOTTOM PLATE : 8199 N16 2" 50 1 80 150 # WN RF - - TEMPERATURE GAUGE

12 NA NOT APPLICABLE 1300 N17A 2" 50 1 40 150 # WN RF 12 175 TAPE TYPE LEVEL GAUGE

B

1300 N17B 2" 50 1 40 150 # WN RF 12 175 TAPE TYPE LEVEL GAUGE

DRAWING/DOCUMENT.NO. REFERENCE DRAWINGS DRAWING/DOCUMENT. NO. REFERENCE DRAWINGS DRAWING/DOCUMENT. NO. REFERENCE DRAWINGS DRAWING/DOCUMENT. NO. REFERENCE DRAWINGS DRAWING/DOCUMENT. NO. REFERENCE DRAWINGS DRAWING/DOCUMENT. NO. REFERENCE DRAWINGS

TD-827666 B TANK DATA SHEET YSC-MS-769-CA-0001 MECHANICAL DESIGN CALCULATION YSC-MS-769-DW-0003 SHT 01 TO 02 BOTTOM PLATE LAYOUT AND DETAILS YSC-MS-769-DW-0008 SHT 01 TO 04 SHELL NOZZLE DETAILS YSC-MS-769-DW-0012 SHT 01 TO 07 SPIRAL STAIR DETAILS YSC-MS-769-DW-0018 ROOF PLATFORM DETAILS

32-SAMSS-005 MANUFACTURE OF ATMOSPHERIC TANKS YSC-MS-769-CA-0002 NOZZLE LOAD CALCULATION YSC-MS-769-DW-0004 SHT 01 TO 02 DETAIL OF SHELL PLATE YSC-MS-769-DW-0009 ROOF MANHOLE DETAILS YSC-MS-769-DW-0013 SHELL PLATFORM DETAILS YSC-MS-769-DW-0019 DETAIL OF CAGE LADDER

SAES-D-100 DESIGN CRITERIA OF ATMOSPHERIC AND LOW-PRESSURE STORAGE TANK YSC-MS-769-DS-0001 API 650 STORAGE TANK DATA SHEET YSC-MS-769-DW-0005 SHT 01 TO 03 ROOF PLATE LAYOUT AND DETAILS YSC-MS-769-DW-0010 SHT 01 TO 02 ROOF NOZZLE DETAILS YSC-MS-769-DW-0014 PERIPHERAL HANDRAIL DETAILS

YSC-MS-769-DW-0002 NOZZLE ORIENTATION DETAILS YSC-MS-769-DW-0007 SHELL MANHOLE DETAILS YSC-MS-769-DW-0011 NAME PLATE DETAILS YSC-MS-769-DW-0015 PIPE SUPPORT DETAILS

You might also like

- Lokotrack ST4.8 GA Drawing 2022 R013Document3 pagesLokotrack ST4.8 GA Drawing 2022 R013Guilherme AssisNo ratings yet

- Steel ConstructionDocument70 pagesSteel ConstructionTony PedaNo ratings yet

- Calculation of Foundation Design Excel SheetDocument11 pagesCalculation of Foundation Design Excel SheetRODRIGO, RHYZA100% (1)

- Blow Up Plan Elevation 'A' Elevation 'B' Elevation 'C' Elevation 'D'Document1 pageBlow Up Plan Elevation 'A' Elevation 'B' Elevation 'C' Elevation 'D'Angelyka Ablog AsadaNo ratings yet

- Dfu UpcDocument1 pageDfu UpcAllan AyesNo ratings yet

- Mulimbayan Residence - PL (For Construction)Document7 pagesMulimbayan Residence - PL (For Construction)Jhanchris CortezNo ratings yet

- Arvin: Vintage 50Document14 pagesArvin: Vintage 50rodrigoNo ratings yet

- REPL-CGD-GAD-CSP-E008 - Rev A - OVERALL EARTHING LAYOUT FOR DT STATIONDocument1 pageREPL-CGD-GAD-CSP-E008 - Rev A - OVERALL EARTHING LAYOUT FOR DT STATIONsubudhipriyanjali23No ratings yet

- Door No. Location Description Quantity Opening D - 7 14Th Floor (Sauna) Frameless Glass Door (With Smoke Glass)Document1 pageDoor No. Location Description Quantity Opening D - 7 14Th Floor (Sauna) Frameless Glass Door (With Smoke Glass)Al Noel 歡呼 ThordzNo ratings yet

- Additional PowerDocument1 pageAdditional Powerwaleedhegazy24No ratings yet

- Door No. Location Description Quantity Opening D - 1 Basement 3 To Roofdeck (Typical Service Stair) Fire Rated DoorDocument1 pageDoor No. Location Description Quantity Opening D - 1 Basement 3 To Roofdeck (Typical Service Stair) Fire Rated DoorAl Noel 歡呼 ThordzNo ratings yet

- 2020 DA Plans - Isola - .EmailDocument29 pages2020 DA Plans - Isola - .EmailSơn NguyễnNo ratings yet

- S19091 HQR BSSJV PK2 Afc FD M MDR 02 RF 00 0202 02 BDocument1 pageS19091 HQR BSSJV PK2 Afc FD M MDR 02 RF 00 0202 02 BAnonymous NR3qZ30No ratings yet

- ag N-Ze 1507 (En)Document1 pageag N-Ze 1507 (En)TOM YEENo ratings yet

- LOTO Drawing PPB FIlterDocument1 pageLOTO Drawing PPB FIlterWibisono SternNo ratings yet

- Detail A End Block Elevation Insert Assembly: CaliforniaDocument1 pageDetail A End Block Elevation Insert Assembly: CaliforniaProfessor PuppiesNo ratings yet

- REPL-CGD-GAD-CSP-E004 - Rev A - OVERALL CABLING LAYOUT FOR DT STATIONDocument1 pageREPL-CGD-GAD-CSP-E004 - Rev A - OVERALL CABLING LAYOUT FOR DT STATIONsubudhipriyanjali23No ratings yet

- Bcda Cia D Mpi C 40 0 431Document1 pageBcda Cia D Mpi C 40 0 431Civil Design EngineerNo ratings yet

- Pages From 4355-AI-DX-00000017 - DSDocument2 pagesPages From 4355-AI-DX-00000017 - DSamitNo ratings yet

- S0501 (4) - 21026-Column Details - Sheet 2Document1 pageS0501 (4) - 21026-Column Details - Sheet 2李喆No ratings yet

- Ma1cap1200 Conectores M23 12PDocument1 pageMa1cap1200 Conectores M23 12PMary LuNo ratings yet

- Notes: Equipment List Item No DescriptionDocument6 pagesNotes: Equipment List Item No DescriptionKonge ThethtunaungNo ratings yet

- AOS WHITEFIELD-07.03.2022 - Electrical-PLANDocument1 pageAOS WHITEFIELD-07.03.2022 - Electrical-PLANMr. AliNo ratings yet

- Lighting and Small Power Cable Routing Layout Drawing-Ss02Document1 pageLighting and Small Power Cable Routing Layout Drawing-Ss02RaeesNo ratings yet

- CSP DrawingsDocument1 pageCSP Drawingsmuhammad saqib IlyasNo ratings yet

- DAILY REJECTION DATA (Jan 2024)Document8 pagesDAILY REJECTION DATA (Jan 2024)rahulkumarqa01No ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24634 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24634 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- F005 76-10526-Detail DesignDocument1 pageF005 76-10526-Detail DesignMazen IsmailNo ratings yet

- Beam Section Details: Typical Gravity Reinforced Concrete Beam DetailDocument1 pageBeam Section Details: Typical Gravity Reinforced Concrete Beam DetailMARKCHRISTMASNo ratings yet

- C.Boldrini: Geographic North 22.377° Prevaling Summer Wind S/WDocument1 pageC.Boldrini: Geographic North 22.377° Prevaling Summer Wind S/Wtitir bagchiNo ratings yet

- Notes: Epc Contract For Tyra Redevelopment Project - WHRPDocument1 pageNotes: Epc Contract For Tyra Redevelopment Project - WHRPaung aungNo ratings yet

- Schedule of Plinth BeamDocument1 pageSchedule of Plinth BeamAnonymous cclKewWGVNo ratings yet

- 0 35 511 27069 1 0 PDFDocument1 page0 35 511 27069 1 0 PDFbrjsekarNo ratings yet

- General Notes: Light Switches DetailDocument1 pageGeneral Notes: Light Switches DetailMary FelicianoNo ratings yet

- Restrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideDocument1 pageRestrainer Retrofit On An Existing Structure: Hinge Seat Side Supported SideProfessor PuppiesNo ratings yet

- t76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsDocument1 paget76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsTayyab AchakzaiNo ratings yet

- Road Ouside Plant To Ipc Port Road Ouside Plant To Ipc PortDocument1 pageRoad Ouside Plant To Ipc Port Road Ouside Plant To Ipc PortAllif ArrozynNo ratings yet

- Ign Rfa M SD 41Document1 pageIgn Rfa M SD 41Faqih FadhilaNo ratings yet

- S101A - FOUNDATION PLAN -SECTOR ADocument1 pageS101A - FOUNDATION PLAN -SECTOR Abatopotcholo03No ratings yet

- 6-111-8 Orifice PlatesDocument1 page6-111-8 Orifice PlatesJavier JimenezNo ratings yet

- Instrumentation Drawings: Submitted byDocument6 pagesInstrumentation Drawings: Submitted bysmithNo ratings yet

- Notes:: Piping Standards CommitteeDocument1 pageNotes:: Piping Standards CommitteeMustapha SedikNo ratings yet

- Koc Approvals Contractor RevisionDocument2 pagesKoc Approvals Contractor RevisionEr Md AamirNo ratings yet

- Kitchen Unit - Drainage Layout2Document1 pageKitchen Unit - Drainage Layout2SHAHJAHAN KHANNo ratings yet

- Keterangan Alat Keterangan Alat Keterangan Simbol Keterangan SimbolDocument2 pagesKeterangan Alat Keterangan Alat Keterangan Simbol Keterangan SimbolPratiwi Putri LimNo ratings yet

- CKD Giv DWG Asb PR b1 PL 006 Layout Meshtray Lantai 1Document1 pageCKD Giv DWG Asb PR b1 PL 006 Layout Meshtray Lantai 1Parid SuwantoNo ratings yet

- TECB RIY3 EQ SI 104 Layout1Document1 pageTECB RIY3 EQ SI 104 Layout1Ahmed AdelNo ratings yet

- Truong Tin Construction and Housing Trading Company LimitedDocument1 pageTruong Tin Construction and Housing Trading Company LimitedTai Ng DucNo ratings yet

- Engr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZDocument1 pageEngr. Ramon A. Orbita Engineering Utilities 2 Tan, Maria Francheska ZBalte, Richard F.No ratings yet

- Attachment#2 Dedicated Cooling WaterDocument19 pagesAttachment#2 Dedicated Cooling WaterYusufNo ratings yet

- DMS No.52 - Walkway ShopdrawingsDocument11 pagesDMS No.52 - Walkway ShopdrawingsMohammad Abu mtawehNo ratings yet

- Ma1eap1700 Conectores M23 M40 P17Document1 pageMa1eap1700 Conectores M23 M40 P17Mary LuNo ratings yet

- J414212001PADocument1 pageJ414212001PASehna SerajNo ratings yet

- 13 - Single Line DiagramDocument6 pages13 - Single Line DiagramKoplak MakmurNo ratings yet

- Porte Cochere Repair SetDocument10 pagesPorte Cochere Repair SetjavierjimenezcholletNo ratings yet

- Detail of Floor Drain Detail of Water Meter: General Notes Septic Tank ComputationDocument1 pageDetail of Floor Drain Detail of Water Meter: General Notes Septic Tank ComputationCamille ArielNo ratings yet

- 10 603159 4200000030 Sac SRV Wir 000109 - 01Document7 pages10 603159 4200000030 Sac SRV Wir 000109 - 01Domie Neil Bucag SalasNo ratings yet

- Power LayoutDocument1 pagePower LayoutEng-Al Raie SaadNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80541Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraNo ratings yet

- Acciona Beata Building 1 Structural 1 SignedDocument8 pagesAcciona Beata Building 1 Structural 1 Signedodelcarmen.supcNo ratings yet

- 1179 B CP DW 0011 A Oziengbe Gas Compression Pipeline Pig Launcher ModelDocument1 page1179 B CP DW 0011 A Oziengbe Gas Compression Pipeline Pig Launcher ModelAtty AttyNo ratings yet

- 20100PE-DW02-0003 Rev0 11-SD-2121-2Document1 page20100PE-DW02-0003 Rev0 11-SD-2121-2Jovit BeaNo ratings yet

- Ysc-ms-769-Dw-0005 SHT 3 of 3 Rev-CDocument1 pageYsc-ms-769-Dw-0005 SHT 3 of 3 Rev-CbalamuralinakshatraNo ratings yet

- Ysc Ms 769 DW 0001sht2of2 Rev BDocument1 pageYsc Ms 769 DW 0001sht2of2 Rev BbalamuralinakshatraNo ratings yet

- API 578 Sample QuestionsDocument8 pagesAPI 578 Sample QuestionsbalamuralinakshatraNo ratings yet

- LineDocument1 pageLinebalamuralinakshatraNo ratings yet

- LineDocument1 pageLinebalamuralinakshatraNo ratings yet

- Routine Test ACSR AS 450Document6 pagesRoutine Test ACSR AS 450bagja wigunaNo ratings yet

- Design of Structural MemberDocument18 pagesDesign of Structural Memberfrancis sebastian lagamayoNo ratings yet

- Ppa412n - Designers and Builders of The PastDocument17 pagesPpa412n - Designers and Builders of The PastpaulineNo ratings yet

- Ceiling Works PaintingDocument8 pagesCeiling Works PaintingJancis TugadeNo ratings yet

- Extracted Pages From How To Assemble A SwitchboardDocument1 pageExtracted Pages From How To Assemble A SwitchboardChhenglong HengNo ratings yet

- High Performance Cost-Effective Buildings: With Kayson's Cast-in-Situ Monolithic Reinforced Concrete Construction SystemDocument16 pagesHigh Performance Cost-Effective Buildings: With Kayson's Cast-in-Situ Monolithic Reinforced Concrete Construction Systemsohail2006No ratings yet

- Precast Connections Using Grout Sleeve Coupler Systems - Concrete Article February 2018Document2 pagesPrecast Connections Using Grout Sleeve Coupler Systems - Concrete Article February 2018Nuno MiguelNo ratings yet

- HT SupplyDocument9 pagesHT SupplyShiv Kumar VermaNo ratings yet

- Lopez - DFI 45th Conference - 2020Document10 pagesLopez - DFI 45th Conference - 2020Thomas GlasbyNo ratings yet

- Sparepart SimDocument34 pagesSparepart Simbintang fajarNo ratings yet

- BS IiiDocument75 pagesBS IiiRagavVijayadevNo ratings yet

- BPU Newsletter Issue 11Document3 pagesBPU Newsletter Issue 11lucasNo ratings yet

- Sta. Elena Construction and Development CorporationDocument3 pagesSta. Elena Construction and Development CorporationNikaNo ratings yet

- Trabajos Asignados 1Document623 pagesTrabajos Asignados 1Eli JimNo ratings yet

- 6035 L2u205 PPT Outcome5Document21 pages6035 L2u205 PPT Outcome5shahin.noktehdan4102No ratings yet

- CH 3Document31 pagesCH 3Zahim HarkiNo ratings yet

- Car Car ChurchDocument17 pagesCar Car ChurchBelamy E. BalaneNo ratings yet

- Material Transfer To Anjur Site 1 StripDocument8 pagesMaterial Transfer To Anjur Site 1 Stripsubhash.walkarNo ratings yet

- ASME Section VIII UHA-51 Impact Test Changes Cryogenic VesselsDocument3 pagesASME Section VIII UHA-51 Impact Test Changes Cryogenic Vesselsmechanical_engineer11No ratings yet

- Johnson Cook StrengthDocument2 pagesJohnson Cook StrengthClaudio Martín GimenezNo ratings yet

- Standard Penetration TestDocument32 pagesStandard Penetration TestIndranil Banerjee100% (1)

- FP914Document153 pagesFP914esutjiadiNo ratings yet

- Geomatic Survey - Ramboll UK LimitedDocument7 pagesGeomatic Survey - Ramboll UK LimitedEndashaw DebruNo ratings yet

- Industrial Plant Design: Instructor: Engr. Louie CantaDocument44 pagesIndustrial Plant Design: Instructor: Engr. Louie CantaJohn AlvarezNo ratings yet

- Ground Floor Plan RevisedDocument1 pageGround Floor Plan Revisedsaeed abbasiNo ratings yet

- MH PDFDocument7 pagesMH PDFSaubatul IslamiyahNo ratings yet

- Reinforced Cement Concrete Work Rate Analysis Sheet 124Document4 pagesReinforced Cement Concrete Work Rate Analysis Sheet 124Kutty MaranNo ratings yet