Professional Documents

Culture Documents

Specification Data: 07 41 13 Standing Seam Sheet Metal Roof Panels

Specification Data: 07 41 13 Standing Seam Sheet Metal Roof Panels

Uploaded by

rfc8bxzzhcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification Data: 07 41 13 Standing Seam Sheet Metal Roof Panels

Specification Data: 07 41 13 Standing Seam Sheet Metal Roof Panels

Uploaded by

rfc8bxzzhcCopyright:

Available Formats

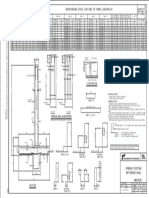

STANDING SEAM SHEET METAL ROOF PANELS 07 41 13

Factory Applied Sealant

with Striations 1-3/4"

SPECIFICATION DATA

18" Coverage

Factory Applied Sealant

with Striations 1-3/4"

12″16"

Vertical Seam

Coverage

Metal Sales

Manufacturing Corporation

Factory Applied Sealant

with Striations 1-3/4"

This specification data sheet is provided by Metal Factory Applied Sealant

Sales Manufacturing Corporation as a technical 12" Coverage

with Striations 1-3/4"

support tool incident to the sale of its Structural

Standing Seam Steel Roof Panel products. Contact 16″

18"Vertical

Coverage Seam

Metal Sales for more information on these and other

products. Factory Applied Sealant

Telephone: 800.406.7387 with Striations 1-3/4"

www.metalsales.us.com

16" Coverage

Section 07 41 13 - METAL ROOF PANELS Factory Applied Sealant

18″ Vertical Seam

with Striations 1-3/4"

1. PRODUCT NAME

Vertical Seam structural standing seam steel roof

Factory Applied Sealant

12" Coverage 1-3/4"

panels. with Striations

18" Coverage

2. MANUFACTURER

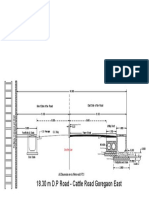

Keith Residence, Elizabethtown, KY

Metal Sales Manufacturing Corporation Factory Applied Sealant

545 South 3rd Street, Suite 200 with Striations 1-3/4"

Louisville, KY 40202 4. TECHNICAL DATA Penetration of Metal Roof Panel Systems by Static

Toll Free: 800.406.7387 Water Pressure Head.

Applicable Standards

16" Coverage

Phone: 502.855.4300 Sheet Metal and Air Conditioning Contractors’ Na-

Fax: 502.855.4200 ●ASTM A Factory

653 -Applied

Standard

Sealant Specification for Steel

tional Association (SMACNA): “Architectural Sheet

Web: www.metalsales.us.com Sheet, Zinc-Coated

with (Galvanized)

Striations or Zinc-Iron

1-3/4" Alloy-

Metal Manual.”

E-Mail: info@metalsales.us.com Coated (Galvannealed) by the Hot-Dip Process.

12" Coverage

●ASTM A 792 - Standard Specification for Steel Approvals

3. PRODUCT DESCRIPTION Sheet, 55% Aluminum-Zinc Alloy-Coated by the

Basic Use ●UL 263 - Fire Tests of Building Construction and

Hot-Dip Process. Materials.

For more than 50 years, Metal Sales has earned a

reputation as the premier provider of metal building ●ASTM A 1011 - Standard Specification for Steel, ●UL 580 - Tests For Uplift Resistance of Roof As-

components and accessories. Metal Sales main- Sheet and Strip, Hot-Rolled, Carbon, Structural, semblies.

tains the industry’s largest professional sales and High-Strength Low-Alloy, High-Strength Low-Alloy

with Improved Formability, and Ultra-High Strength. ●UL 790 - Standard Test Methods for Fire Tests of

service team, supported by 21 branches located

Roof Coverings.

throughout the United States, and offers a full line ●ASTM D 2244 - Standard Practice for Calculation

of high quality metal roof and wall panels for ag- of Color Tolerances and Color Differences from In- ●UL 2218 - Impact Resistance of Prepared Roof

ricultural, commercial, architectural, industrial, and strumentally Measured Color Coordinates. Covering Materials.

residential projects of every shape and size for both

●ASTM D 4214 - Standard Test Methods for Evalu- Miami-Dade County:

new construction and retrofit applications. Metal

ating the Degree of Chalking of Exterior Paint Films. Code Approvals, Notice of Acceptance (NOA).

Sales is dedicated to leading the metal building

component industry, by setting new standards for ●ASTM E 119 - Standard Test Methods for Fire ● Vertical Seam product: NOA 10-0114.04

operating efficiency, product design, active service Tests of Building Construction and Materials. State of Florida. Florida Building Code 2010:

management and lasting value. ●Vertical Seam product: 11560.9, 11560.10,

●ASTM E 1592 - Standard Test Method for Struc-

tural Performance of Sheet Metal Roof and Siding 14645.6

Manufacturer Memberships and Affiliations Systems by Uniform Static Air Pressure Difference.

CRRC - Cool Roof Rating Council Physical Properties:

MCA - Metal Construction Association ●ASTM E 1646 - Standard Test Method for Water

Test reports are available to design professionals

CSI - Construction Specifications Institute Penetration of Exterior Metal Roof Panel Systems

upon request.

MRA - Metal Roofing Alliance by Uniform Static Air Pressure Difference.

NRCA - National Roofing Contractors Association ●ASTM E 1680 - Standard Test Method for Rate Note: Industry designation for material thickness is

USGBC - United States Green Building Council of Air Leakage through Exterior Metal Roof Panel moving away from “gauge” to “nominal thickness” in

ENERGY STAR® Partner Systems inches. Manufacturer’s available panel thickness is

●ASTM E 2140 - Standard Test Method for Water 0.022 inch (formerly 26 ga.) or 0.028 inch (formerly

24 ga.) or 0.034 inch (formerly 22 ga.). Manufac-

Metal Sales Manufacturing Corporation www.metalsales.us.com 1

STANDING SEAM SHEET METAL ROOF PANELS 07 41 13

SPECIFICATION DATA

turer recommends use of a “minimum coated thick-

ness” requirement of 0.018 inch (0.46 mm) instead

of 26 ga., 0.023 inch (0.58 mm) instead of 24 ga.,

and 0.0296 inch (0.75 mm) instead of 22 ga.

Technical Properties for Vertical Seam:

►Panel Coverage: 12 inches (304.8 mm), 16 inch-

es (406.4 mm) or 18 inches (457.2 mm)

►Rib Height: 1-3/4 inches (44.5 mm)

►Material: Aluminum-zinc alloy-coated steel

sheet, ASTM A 792, Class AZ50 coating designa-

tion, Grade 50, structural quality, 0.022 inch (0.56

mm), 0.028 inch (0.71 mm) or 0.034 inch (0.86 mm)

nominal thickness

►Minimum Roof Slope Capability: 3:12 over Open

Framing

Lafayette Library and Learning Center, Lafayette, CA

►Minimum Roof Slope Capability: 1:12 over Solid

Substrate Fire Performance Thermal Insulation Installation

►Sealant: Factory-applied side lap sealant Flame-Spread Index: 25 or less (Class A), or 200 or Install polyethylene vapor retarder if required. In-

less (Class C). stall board insulation if required, in compliance with

►Attachment: Concealed clip designed for thermal Smoke-Developed Index: 450 or less. installation requirements in Division 07 Section

movement “Thermal Insulation.”

►Side Lap: Snap-together panel system 5. INSTALLATION Install blanket insulation if required, in compliance

Insulation Capacity: Accommodate blanket insu- with installation requirements in Division 07 Section

Handling and Storage

lation 1/2 inch (12.7 mm) to 4 inches (101.6 mm) “Thermal Insulation.”

Handle and store product according to Metal Sales

thickness recommendations. Deliver materials in original, un-

►Application: Applied over open framing or solid opened, undamaged containers with identification Metal Roof Panel Installation

substrate labels intact. Store materials above ground, under Verify that site conditions are acceptable for installa-

waterproof covering, protected from exposure to tion. Do not proceed with installation until unaccept-

►Surface Finish: PVDF (Kynar 500®), MS Color-

harmful weather conditions and at temperature and able conditions are corrected. Comply with panel

fast45 or Acrylic Coated Galvalume.

humidity conditions recommended by manufacturer. manufacturer’s installation instructions including

►Color: See list of available colors. Contact Metal Provide proper ventilation of metal panel system to but not limited to special techniques, interface with

Sales for more information. prevent condensation build-up between each panel other work, and integration of systems. Fasten met-

►Testing: Fire Resistance Rating: UL 790 Class A and trim or flashing component. Store metal panel al roof panels to supports with concealed clips at

Fire Resistance Rating and UL 263 products in manufacturer’s unopened packaging each standing-seam joint at location, spacing, and

Impact Resistance: UL 2218 Class 4 until ready for installation. Exercise caution in un- using proper fasteners as recommended by panel

Air Infiltration: Tested according to ASTM E 1680 loading and handling metal panel system to prevent manufacturer. Comply with installation tolerances

Water Infiltration: Tested according to ASTM E 1646 bending, warping, twisting and surface damage. as required.

Wind Uplift Resistance: Tested according to ASTM

E 1592 and in compliance with UL 580, Class 90 Preparation Accessory Installation

Wind Uplift, Construction #436, 446, and 448 Install substrate boards over roof deck and sheath- Install accessories using techniques recommended

Code and testing Agency Approvals: Miami-Dade ing over entire roof surface using recommended by manufacturer and which will assure positive

County Approved (NOA 10-0114.04), 2007 Florida fasteners. Install furring, eave angles, sub-purlins, anchorage to building and weather tight mount-

Building Code Approved: 2007 FBC Approved, and other miscellaneous roof panel support mem- ing. Provide for thermal movement. Coordinate

10916.6, 12449.1, 13794.1, 14799.2 bers and anchor according to metal roof panel installation with flashings and other components.

manufacturer’s recommendations. For Flashing and Trim, comply with performance

Environmental Considerations requirements, manufacturer’s written installation

Construction metals generally are readily recyclable Underlayment Installation instructions, and the SMACNA “Architectural Sheet

at the end of their service life. The raw materials Install self-adhering sheet underlayment and felt Metal Manual.” Provide concealed fasteners where

used in manufacture of standing seam panels also underlayment as required. Apply slip sheet over un- possible, and install units to true level. Install work

come from recycled sources. Post industrial and derlayment prior to installing metal roof panels. In- with laps, joints, and seams that will be permanently

post consumer recycled content varies. stall flashing in compliance with requirements in Di- watertight.

vision 07 Section “Sheet Metal Flashing and Trim.”

2 www.metalsales.us.com Metal Sales Manufacturing Corporation

STANDING SEAM SHEET METAL ROOF PANELS 07 41 13

SPECIFICATION DATA

Field Quality Control 7. WARRANTIES 8. MAINTENANCE

If requested by Owner, provide manufacturer’s field Weather Tightness Warranty No specific maintenance is required for properly in-

service consisting of product use recommendations Metal Sales’ Weather Tightness Warranty is avail- stalled Metal Sales standing seam panel products.

and periodic site visits for inspection of product able in several forms. Request sample warranty Periodic roof inspection to verify system integrity,

installation in accordance with manufacturer’s in- documents from manufacturer for review and edit- drainage functionality and repair of storm damage

structions. ing assistance. Warranty Period is optionally 5, 10, is advised.

or 20 years.

Precautions, Cleaning and Protection 9. TECHNICAL SERVICES

Touch-up paint is used to cover and protect unex- Type 1 Warranty: Technical assistance, including more detailed infor-

pected scratches on the paint finish that may occur Side-lap warranty only, with dollar limit. mation, product literature, test results, project lists,

during installation of panel. Touch-up paint will not assistance in preparing project specifications and

weather as well or at the same rate as the original Type 2 Warranty: arrangements for application supervision, is avail-

system. Test in an area that will not be noticeable. Trim and side-lap warranty, with dollar limit. able by contacting Metal Sales.

Metallic paint colors are available at an additional

charge. Minor differences in color and appearance Type 3 Warranty: 10. FILING SYSTEMS

are normal and to be expected. Side-lap warranty only, with no dollar limit. Additional product information is available from the

To minimize possible differences in appearance, manufacturer upon request.

an entire project should be painted at one time, Type 4 Warranty:

from one batch of paint, using the same applica- Trim and side-lap warranty, with no dollar limit. 1. McGraw-Hill Sweets

tion equipment. Additionally, fabricated panels, flat 2. BSD SpecLink

sheet, and flashings should be oriented in the same Premier Plus Warranty: 3. Arcom MasterSpec

direction. Single-source warranty, with no dollar limit.

After installation remove temporary coverings and

protection of adjacent work areas. Repair or replace Paint Finish Warranty

any installed products that have been damaged. Metal Sales’ standard PVDF (Kynar 500®) Fluoro-

Clean installed panels in accordance with manu- carbon System Warranty for film integrity, chalk rat-

facturer’s instructions prior to Owner’s acceptance. ing and fade rating in which manufacturer agrees to

Remove and lawfully dispose of construction debris repair or replace panels that show evidence of dete-

from Project site. Protect installed product and fin- rioration within specified warranty period. Deteriora-

ish surfaces from damage during construction. tion shall include but is not limited to color fading of

Building Codes more than 5 Hunter units when tested according to

Current data on building code requirements and ASTM D 2244, chalking in excess of a No. 8 rating

product compliance may be obtained from Metal when tested according to ASTM D 4214 or crack-

Sales technical support specialists. Installation ing, checking, peeling or failure of paint to adhere

must comply with the requirements of authority hav- to bare metal. Warranty Period for film integrity is

ing jurisdiction. 45 years and for chalk and fade rating is 35 years.

6. AVAILABILITY AND COST

Availability

Metal Sales products are nationally distributed and

supported from 21 convenient locations nationwide,

including Alaska. Metal Sales has the ability to ship

worldwide. Contact Metal Sales for information on

local availability.

Cost

Budget installed cost information may be obtained

from a local Metal Sales distributor or through the

manufacturer.

Tradewinds Model Home, FL

Metal Sales Manufacturing Corporation www.metalsales.us.com 3

You might also like

- AMS 2418 H Copper PlatingDocument8 pagesAMS 2418 H Copper PlatingJesse Krebs67% (3)

- Complete CofferdamDocument61 pagesComplete CofferdamJaideep Jai67% (3)

- DPWH Ext. BLDGDocument138 pagesDPWH Ext. BLDGAriel Peralta Adviento100% (1)

- AIChe Paper 73a Improve Bolted Joint Reliability PaperDocument10 pagesAIChe Paper 73a Improve Bolted Joint Reliability PaperCostynhaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Solve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Document8 pagesSolve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Arya AnujNo ratings yet

- Method Statement FOR Steel Reinforcement: ProjectDocument5 pagesMethod Statement FOR Steel Reinforcement: ProjectKelvin Lau67% (3)

- Galvanizing High Strength BoltsDocument9 pagesGalvanizing High Strength BoltsMikeNo ratings yet

- Weldlok Steel GratingDocument16 pagesWeldlok Steel GratingAKarkiNo ratings yet

- Promaseal ADocument4 pagesPromaseal AKamila JihaneNo ratings yet

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDocument30 pagesDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsNo ratings yet

- SDI - 127 Standard Steel Doors and FramesDocument14 pagesSDI - 127 Standard Steel Doors and FramesIsang BertingNo ratings yet

- Bulletin On Zinc Aluminum CoatingsDocument4 pagesBulletin On Zinc Aluminum CoatingsSithipong PongpraditNo ratings yet

- Weldlock GratingDocument16 pagesWeldlock Gratingsoni10483No ratings yet

- Metal Face Seals v3Document30 pagesMetal Face Seals v3ntchobanov0% (1)

- Centria SRS 3 NOA For Miami DadeDocument6 pagesCentria SRS 3 NOA For Miami DadeDNo ratings yet

- Steel StaircaseDocument1 pageSteel StaircaseawasarevinayakNo ratings yet

- GALV - Cut Edge ProtectionDocument5 pagesGALV - Cut Edge ProtectionHarry Aldous100% (1)

- VogtDocument5 pagesVogtjollyNo ratings yet

- 9 Rules For Successful Weld Repair of High Strength SteelDocument4 pages9 Rules For Successful Weld Repair of High Strength SteelRodolfoMarínNo ratings yet

- IC72 Panel Spec Data 1100367 PDFDocument3 pagesIC72 Panel Spec Data 1100367 PDFNiral PanchalNo ratings yet

- Tricosal Katalogas - en - P05 of 09Document4 pagesTricosal Katalogas - en - P05 of 09Adam Michael GreenNo ratings yet

- Corrosion Resistant Alloy Fasteners For Applications in Pulp and Paper PlantsDocument3 pagesCorrosion Resistant Alloy Fasteners For Applications in Pulp and Paper PlantsKhomasan JumpasriNo ratings yet

- Galvanized Steel Inspection GuideDocument20 pagesGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- Arcfix Arc StudDocument21 pagesArcfix Arc StudKiran Kumar KondapalliNo ratings yet

- A1 Fence Specs For WebsiteDocument22 pagesA1 Fence Specs For Websitetajland100% (1)

- Technical Lamination SDocument4 pagesTechnical Lamination SAlexander RichardsonNo ratings yet

- Regulator MaterialDocument2 pagesRegulator MaterialnicaiNo ratings yet

- Applications of ZN AlloyDocument2 pagesApplications of ZN AlloyuzairmetallurgistNo ratings yet

- STASTO Penstock Serie MR enDocument13 pagesSTASTO Penstock Serie MR envinston.s1949No ratings yet

- Why Cored Wire - 2. General Introduction To Elga and Elga Cored Wire Types 4. Productivity and Profitability 5. Heavy Vehicals 6.Document19 pagesWhy Cored Wire - 2. General Introduction To Elga and Elga Cored Wire Types 4. Productivity and Profitability 5. Heavy Vehicals 6.jojoNo ratings yet

- SPL Tapping InformationDocument9 pagesSPL Tapping InformationaldiNo ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualALONSO GOMEZNo ratings yet

- 3M™ Tapes For Solar Panel Fabrication PDFDocument8 pages3M™ Tapes For Solar Panel Fabrication PDFchipulinoNo ratings yet

- 1 - Volumen 1 - Fittings PDFDocument168 pages1 - Volumen 1 - Fittings PDFjuan_octoberNo ratings yet

- Tools GuideDocument2 pagesTools GuideMario RivasNo ratings yet

- How Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedDocument2 pagesHow Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedTay Hua SetNo ratings yet

- SS 409M WeldingDocument12 pagesSS 409M WeldingwentropremNo ratings yet

- Manual de Instalacion de Puertas de EmergenciaDocument28 pagesManual de Instalacion de Puertas de EmergenciaAlexander Rivero ReyesNo ratings yet

- 9096Document16 pages9096murdicksNo ratings yet

- Tolerances and Clearances For Commercial Hollow Metal Doors and FramesDocument16 pagesTolerances and Clearances For Commercial Hollow Metal Doors and FramessouravrobinNo ratings yet

- Section 5. Welding and BrazingDocument27 pagesSection 5. Welding and BrazingrobinyNo ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- TubingDataChartsDocument16 pagesTubingDataChartsoliver morellNo ratings yet

- Garlock Metallic Gasket Technical ManualDocument48 pagesGarlock Metallic Gasket Technical ManualMarcio NegraoNo ratings yet

- Catalog A9: Sealing Rings Retaining RingsDocument48 pagesCatalog A9: Sealing Rings Retaining Ringsshrikant mishraNo ratings yet

- Analysis of Process Parameters Effect On Friction Stir Welding of Aluminium 5083 and 6082Document9 pagesAnalysis of Process Parameters Effect On Friction Stir Welding of Aluminium 5083 and 6082Sreeharan Nagamani BNo ratings yet

- Aluminium GMAW WeldingDocument34 pagesAluminium GMAW Weldingcentaury2013No ratings yet

- Garlock Catalogo GasketDocument46 pagesGarlock Catalogo GasketServilab LudicasNo ratings yet

- Clamp Cover, Type 4x: Meets Type 3RX RequirementsDocument2 pagesClamp Cover, Type 4x: Meets Type 3RX RequirementsilhamNo ratings yet

- Sae Technical Paper Series: Todd M. LinkDocument10 pagesSae Technical Paper Series: Todd M. LinkhjnNo ratings yet

- Accesorios Roscados para PlásticosDocument32 pagesAccesorios Roscados para PlásticosjbertralNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- Earthing and Lightning Protection MetricDocument40 pagesEarthing and Lightning Protection MetricbalabhaviniNo ratings yet

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersDocument6 pagesTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasNo ratings yet

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Document2 pages55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Developments in Solid Oxide Fuel Cells and Lithium Ion Batteries: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandDevelopments in Solid Oxide Fuel Cells and Lithium Ion Batteries: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Arumugam ManthiramNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- CombinedDocument105 pagesCombinedjeevNo ratings yet

- Arc 105 AssignmentDocument20 pagesArc 105 Assignmentkayode oluwarotimiNo ratings yet

- Segmental Overview Soule 2022.02.23Document83 pagesSegmental Overview Soule 2022.02.23sridhara kumarNo ratings yet

- IEC StandardsDocument2 pagesIEC StandardsTeknik GresikNo ratings yet

- Dura MHC600 - : Manhole CoverDocument2 pagesDura MHC600 - : Manhole CovermaznahNo ratings yet

- The Ultimate Splicing SystemDocument4 pagesThe Ultimate Splicing SystemKevin ArNo ratings yet

- Cylinder 80-300 W INERGEN PDFDocument1 pageCylinder 80-300 W INERGEN PDFIskandar HasibuanNo ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- Diy Deckpatio08 PDFDocument2 pagesDiy Deckpatio08 PDFmladenericNo ratings yet

- Drawing Drain SectionDocument1 pageDrawing Drain SectionShahrookhKhanNo ratings yet

- PDFDocument88 pagesPDFHotnCrispy CrispyNo ratings yet

- Stas 175-87 RDocument6 pagesStas 175-87 RSzabolcs KovacsNo ratings yet

- Sandwich Type Bus DuctDocument2 pagesSandwich Type Bus DuctPankaj KumarNo ratings yet

- B02-Prepare Cost EstimateDocument128 pagesB02-Prepare Cost Estimateyo5208100% (1)

- L7 BQS652 Plants & Equipment MAY 2023Document65 pagesL7 BQS652 Plants & Equipment MAY 2023NURSASHA FAREESHA MARZUKINo ratings yet

- Slrsebp: Mason Industries, IncDocument2 pagesSlrsebp: Mason Industries, Incgenas7265No ratings yet

- RECYBETONDocument4 pagesRECYBETONlijiabinbinNo ratings yet

- Work Method Statement For: Concrete Coring WorksDocument14 pagesWork Method Statement For: Concrete Coring WorksAbdul AbbasNo ratings yet

- A Pkg-2 - Dhad-Sillod 23-12-17Document46 pagesA Pkg-2 - Dhad-Sillod 23-12-17Akshay PendurkarNo ratings yet

- Internationalism: International Style, Architectural Style That Developed in Europe and The UnitedDocument2 pagesInternationalism: International Style, Architectural Style That Developed in Europe and The UnitedVedant HedauNo ratings yet

- Famous Architect DictumDocument13 pagesFamous Architect DictumRusscel MarquesesNo ratings yet

- Retaining Wall Design - by Pillai & Menon PDFDocument23 pagesRetaining Wall Design - by Pillai & Menon PDFSaurabh SinghNo ratings yet

- A Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocument65 pagesA Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofMadhavpokale100% (1)

- Rekap StoringDocument2 pagesRekap Storingary fauzi rahmanNo ratings yet

- LSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDDocument8 pagesLSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDJuanPabloGonzalezFiblasNo ratings yet

- Quick Delivery - ProductCutSheet - SE1-12-432-A4X-QD - 20200929034630 PDFDocument2 pagesQuick Delivery - ProductCutSheet - SE1-12-432-A4X-QD - 20200929034630 PDFzumrottNo ratings yet