Professional Documents

Culture Documents

Saflok 700

Saflok 700

Uploaded by

Gireesh Krishna KadimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saflok 700

Saflok 700

Uploaded by

Gireesh Krishna KadimiCopyright:

Available Formats

Purlin Spacings

GAUGE 0.4mm 0.5mm 0.6mm Curving

Natural springing occurs at 36m radius in the convex and 60m radius in the concave. It is important to reduce purlin spacings by

20% when spring curving a roof.

Material ALUMINIUM-ZINC ALUMINIUM-ZINC ALUMINIUM

ROOFS mm mm mm Rolling Straight Onto A Roof

Single Span 1400 1700 1400 It is possible to roll form straight onto a roof using a scaffold ramp. The limitations are the building height and space needed to

End Span 1600 1900 1500 roll. A departure angle would damage the sheet when leaving the mill and again when bending to settle onto the roof. The sheet-

Internal/Double Span 1800 2100 2000 ing cannot be roll formed onto a building higher than 10m.

Cantilever (Unstiffened) 150 150 180

Cantilever (stiffened) 350 300 380 Sealed Joints

SIDE CLADDING For sealed joints use fasteners or rivets and neutral – cure silicone sealant branded as suitable for use with AZ steel.

Single Span 2 100 2 300 1600

End Span 2 400 2 600 2200 Disclaimer:

. Care has been taken to ensure that the information provided is accurate. MRM does not assume responsibility for inaccuracies or misinter-

Internal Span 2 600 2 700 2400

pretations of this data.

Cantilever 300 400 300

. MRM is continuously engaged in product development, please ensure that you have the most recent issue of information from MRM.

Approximate Mass/m² 5.2kg 6.2kg 2.9kg

. Photographs and illustrations are typical examples of roofing and cladding products and cladding products and applications.

Installation

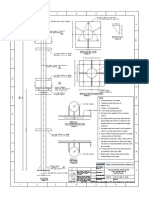

Step1. Starting with the female rib first, align first sheet and hold down

Step2. Place saddle washers over the first 3 ribs above the purlins [starting from the female rib side]. Align, and fasten the

saddle washers through the rib using an appropriate Fixtite® or Safintra approved fastener.

Step3. Position the next sheet, engaging the female rib firmly over the male rib of the previous sheet. Repeat step 2

NOTE: The bonded washer can only be fixed from the top.

Note: This clip is positively fixed. Care should be taken when

detailing industrial length sheeting and flashing due to thermal

F10 Clip expansion. MRM recommends the use of a Flashing Slider Clip

for very long sheets. Please consult our Technical Department for

assistance.

Purlin

Barge Flushing

Specialised Fixing Accessories

Polysider Clip

For use with Saflok polycarbonate sheeting. Must be installed with saddle washer. Polycarbonate sheets must be positively fixed –

consult our technical department for advice.

*Version 2019

Fasteners

Trusted and reliable Roofing Product

Where insulation is to be installed, you may need to increase the length of the fasteners given below, depending on the density NAIROBI THIKA NYERI

and thickness of the insulation. When the fastener is properly tightened: Old Mombasa Road Kiboko Road Nyeri-Nyahururu Road,

Into metal: there should be at least three threads protruding past the purling you are fixing to, but the shankguard must not Cell: +254 788 202020/ 735511180 Cell: +254 780 909030 Cell: +254 733887790

from Mabati Rolling Mills Limited

Email: marketing.mrmroofing@safalgroup.com Email: thika.mrmroofing@safalgroup.com Email:nyeri.mrmroofing@safalgroup.com

reach that purlin.

Into timber: the fastener must penetrate the timber by the same amount that the recommended fastener would do if there were MARIAKANI KISUMU NAKURU

no insulation. Mariakani Sabuni Road, Industrial Area Nairobi-Nakuru Highway,

Cell: +254 722 205396 / 722 205397 Cell: +254 733 600 150 Cell: +254 738865980

Email: mrmcoils@safalgroup.com Email: kisumu.mrmroofing@safalgroup.com Email: nyeri.mrmroofing@safalgroup.com

Cranking MOMBASA ELDORET KITENGELA

SAFLOK 700 sheets may be cranked and bullnosed but not reverse bullnosed. Minimum radius is 450mm. On – site cranking is Mombasa-Malindi Highway, Kapsoya, Uganda Road Kitengela MRM Showroom

available on request. Cell: +254 733 474 766 Cell: +254 780909040 Nairobi- Namanga Road

Email: mombasa.mrmroofing@safalgroup.com Email: eldoret.mrmroofing@safalgroup.com Cell: +254 708593691

Email: mrmroofing.kitengela@safalgroup.com

KISII

Industrial Area Road, Daraja Mbili,

Cell: +254 718215659

Email: kisii.mrmroofing@safalgroup.com Toll Free Number: 0800 722 711

Product Description & Features

Concealed-fix roofing, also referred to as secret fix, is designed for very low pitched roofs. Because clips under the sheet hold it Saflok 700 clips are calculated at 330g per clip – require approximately 1.5 clips per m²

down, the sheet is not punctured with fasteners, and remains completely watertight even at a very low slope. The securing clips

are pre-fixed into the purlins and the sheet is mechanically snapped onto the clip Span tables are for SAFLOK 700 with light foot traffic only. Span tables are based on 1.5Kn downward point load, and1.6kPa

upward pressure. The span tables are maximum recommended spans are based on buildings up to 10m high for a basic design

A concealed fix sheet can also expand and contract over the clips as the temperature changes, this system is ideal for long spans wind speed of 28m/s, Terrain Category

on industrial, commercial and retail buildings.

Note: It is important to reduce purlin spacings by 20% when spring curving a roof.

The Saflok 700® concealed fix roofing system is an interlocking trapezoidal rib profile that can be rolled on site in lengths of up to

120metres Lengths & Roof Pitch

SAFLOK 700 can be ordered in any practical length as per customer requirements. On site rolling is recommended for length in

Saflok 700® may be rolled in coating of an 55% aluminium-zinc protective alloy on a carbon steel base, (bare or colour coated) or excess of 13metres. The minimum roof pitch when using SAFLOK is 2º on steel and 3º on wood.

Aluminium (Mill Finish or G4 Colortech). On high slope roofs, the aesthetics of Saflok may be affected by occasional oil canning

in the pans. This becomes visually apparent on slopes greater than 5 degrees, as the roof material becomes increasingly visible. It

does not affect the structural integrity of the sheet in any way, and MRM will not entertain claims made for all canning.

Drainage Table

DRAINAGE TABLE ROOF SLOPE

Saflok 700® can be curved or bullnosed to a minimum internal radius of 450mm-500mm. Reverse cranking is not possible.

RAINFALL INTENSITY

MM/HOUR 2º 3º 5º 8º 10º

Further information available on request.

250 75 90

300 65 75 95

400 50 55 70 80 90

500 40 45 55 65 70

Maximum roof run for footsteps and rainfall intensities shown HIGH WIND LOAD INSTALLATION DETAILING (HIGH WIND ZONES AND COASTAL

WID BELTS)

The installation process for using the High Wind Load System (HWLS) is a pierced fix method. The High Wind Load System is

recommended for terrain categories A & B, (For reference on terrain categories, please refer to the Safal Group Design and

installation Manual). Note that the HWLS is not a concealed fix system, and is therefore recommended only for the perimeter and/

or overhang areas of the building. Buildings taller than 10m would also require special design attention and the use of the HWLS.

233.3 191.7

41

700mm Effective c over width

725mm Overall width

Saflok 700 Sheet

Saflok 700 Clip

SL 700 Clip

The fully interlocking SAFLOK 700 clip incorporates two anchors to clasp the two inner ribs and a dual action component to

positively hold down the male-female joint. Stiffener ribs on 1mm baseplate and formidable strength, specifically over the goose- Purlin

neck. The clip’s male hooks allow for full width engagement on the profile’s female goose-neck grooves.

The clips have 4 fastening points along their length for stability, particularly over the blanket insulation. Column

The geometry of the anchor unit is engineer- designed for optimal performance under high wind load and foot traffic. The entire

clip is manufactured from 1mm high-tensile GI or AZ coated steel for strength and compatibility with sheeting.

Sample Specification

MRM 0.50mm thick SAFLOK 700 Colorplus ® AZ150 interlocking roof sheeting fixed to steel internal purlins at 2000mm, and

ridge/eaves purlins at 1700mm centres using SAFLOK 700 clips which must be screw fixed to steel purlins with Fixtite ® or

Safintra approved wafer head self-tapping screws. The sheeting will be a double interlocking concealed fix SAFLOK 700 profile

as manufactured by MRM, roll formed in continuous lengths from certified G550 steel or aluminium 3004 H14. The profile shall

be roll formed with 4ribs and centres not exceeding 233mm and a cover width not exceeding 700mm. The male rib is to include

spurs to ensure a double interlocking action with adjacent sheets. The minimum sheet depth will be 41mm. Two stiffening ribs

are incorporated in each pan. We do not recommend using Saflok on a pitch exceeding 5 degrees due to possibility of oil canning.

You might also like

- 1 Euro Houses PDFDocument24 pages1 Euro Houses PDFChia Ning Ku100% (3)

- Rauch Rammed Earth - CutDocument69 pagesRauch Rammed Earth - Cutkkd108100% (3)

- Wheel Stop Installation ProcedureDocument1 pageWheel Stop Installation ProcedureabdouNo ratings yet

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Case Study - PERTDocument2 pagesCase Study - PERTNishan ShettyNo ratings yet

- Salient Features: Imperflex (S)Document2 pagesSalient Features: Imperflex (S)Engr KamalNo ratings yet

- Topdek PIR Installation Guide A5 Sept 2020Document12 pagesTopdek PIR Installation Guide A5 Sept 2020fahim007No ratings yet

- CG3334 IBR Brochure - 1Document2 pagesCG3334 IBR Brochure - 1jitendra.jangidNo ratings yet

- Ancon Two-Part Wall Tie: Installation GuideDocument2 pagesAncon Two-Part Wall Tie: Installation GuideHASEEBNo ratings yet

- Ancon SPB Frame CrampDocument1 pageAncon SPB Frame CrampBA19ARC009 Deepali BhatiaNo ratings yet

- Ancon SPB Frame CrampDocument1 pageAncon SPB Frame CrampBA19ARC009 Deepali BhatiaNo ratings yet

- Rex DWC Catalogue IS-14930..Document2 pagesRex DWC Catalogue IS-14930..ajeetNo ratings yet

- GLOBAL IBR 686 Brochure 2022 - R0Document4 pagesGLOBAL IBR 686 Brochure 2022 - R0chintan mistryNo ratings yet

- Scaffolding Components PostersDocument3 pagesScaffolding Components PostersRavi Shankar Turlapati100% (1)

- 7 Details Passive House PDFDocument1 page7 Details Passive House PDFEvin LawlorNo ratings yet

- Onduline Fixing GuideDocument7 pagesOnduline Fixing GuideksshashidharNo ratings yet

- DSI-Products and Systems of MiningDocument12 pagesDSI-Products and Systems of MiningJustin CorbettNo ratings yet

- Global Corrugated 2017 09 PDFDocument4 pagesGlobal Corrugated 2017 09 PDFAntonio MarrufoNo ratings yet

- INSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVDocument7 pagesINSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNo ratings yet

- C Ceil ScreenDocument13 pagesC Ceil ScreenBukirwa MariamNo ratings yet

- 0138 IBR Brochure 2019 LRDocument4 pages0138 IBR Brochure 2019 LRPieter SteenkampNo ratings yet

- Cedar Shingles GuideDocument20 pagesCedar Shingles GuideSimonNo ratings yet

- 44Document4 pages44Bhanuka SamarakoonNo ratings yet

- Annexure - XIII - Drawing - Mounting StructurelDocument1 pageAnnexure - XIII - Drawing - Mounting Structurelisan.structural TjsvgalavanNo ratings yet

- PALRUF 100 Technical Guide (En)Document6 pagesPALRUF 100 Technical Guide (En)mohammed nafethNo ratings yet

- Stratagreen Strata Green Straightcurve BrochureDocument24 pagesStratagreen Strata Green Straightcurve Brochureohshitmybad13No ratings yet

- Hambleside Danelaw Rooflights Cladding Installation Fixings File000516Document12 pagesHambleside Danelaw Rooflights Cladding Installation Fixings File000516andi wirawanNo ratings yet

- Shock CordsDocument4 pagesShock CordsNavdeep Singh SidhuNo ratings yet

- Grs Ibr 2017 08 PDFDocument4 pagesGrs Ibr 2017 08 PDFMike MatshonaNo ratings yet

- Cracking in BrickworkDocument2 pagesCracking in BrickworkruwanthaNo ratings yet

- Clipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONDocument2 pagesClipsal 4CC AND 4FCC INSTALLATION ISTRUCTIONducvuong99.vtNo ratings yet

- Samicapor Acc 366.55-10-374.15Document4 pagesSamicapor Acc 366.55-10-374.15jalilemadiNo ratings yet

- Samicapor Acc 366.55-10-374.15 PDFDocument4 pagesSamicapor Acc 366.55-10-374.15 PDFjalilemadiNo ratings yet

- Daya Dukung Pondasi Tiang Pada Tanah PasirDocument4 pagesDaya Dukung Pondasi Tiang Pada Tanah PasirRafaArdiSyahrezaNo ratings yet

- DRY1903 Guidelines For Sectioning Repairs On Headers and Sills R0Document10 pagesDRY1903 Guidelines For Sectioning Repairs On Headers and Sills R0Trinh ThanhNo ratings yet

- Comax 1000Document2 pagesComax 1000hitendra_gkNo ratings yet

- Arc Resistant Charging BarsDocument2 pagesArc Resistant Charging BarszimdoNo ratings yet

- 0138 Corrugated Brochure 2019 LRDocument4 pages0138 Corrugated Brochure 2019 LRPieter SteenkampNo ratings yet

- SP Concare Pvt. LTD.: Repair & RetrofittingDocument15 pagesSP Concare Pvt. LTD.: Repair & RetrofittingAnkita Baban GavadeNo ratings yet

- Kingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENDocument12 pagesKingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENlames1No ratings yet

- Specguide Gypwall 74s55z dlfl15Document2 pagesSpecguide Gypwall 74s55z dlfl15parathasiNo ratings yet

- meyJOIST Install RefwebDocument2 pagesmeyJOIST Install RefwebTony MontanaNo ratings yet

- Grateshield Gratemesh: Rate HieldDocument4 pagesGrateshield Gratemesh: Rate HieldSarwar KhanNo ratings yet

- Corrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsDocument4 pagesCorrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsTaufiqTaufiqNo ratings yet

- Patio With Lysaght Flatdek: A New Standard in Structural BeamsDocument4 pagesPatio With Lysaght Flatdek: A New Standard in Structural BeamsAlfian Syaiful HaqNo ratings yet

- WL-01 Op2Document2 pagesWL-01 Op2Alfonso valenzuelaNo ratings yet

- Masonry Reinforcement WindpostsDocument16 pagesMasonry Reinforcement Windpostsrexsan8aloysiousNo ratings yet

- Chainwire Brochure LRDocument3 pagesChainwire Brochure LRBen GregsonNo ratings yet

- Care & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation InstructionsDocument1 pageCare & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation Instructionskevin_au18No ratings yet

- FL100Document3 pagesFL100Arlan GutierrezNo ratings yet

- Lysaght Select Seam SeriesDocument12 pagesLysaght Select Seam SeriesFar AwayNo ratings yet

- 2M Series: Smaller, Lighter-Weight Alternative For D38999 PerformanceDocument55 pages2M Series: Smaller, Lighter-Weight Alternative For D38999 PerformanceAlejandro JimenezNo ratings yet

- Fusealloy Fabrication Guidelines 2016Document25 pagesFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyNo ratings yet

- Kingspan - EU100 KS1000 RW Insulated Roof Panel Revised Hip Detail - Technical Update - UKDocument6 pagesKingspan - EU100 KS1000 RW Insulated Roof Panel Revised Hip Detail - Technical Update - UKtam vanyNo ratings yet

- EazyOne 1.5kN Brochure - B+M ArchitecturalDocument4 pagesEazyOne 1.5kN Brochure - B+M Architecturalilovemesomegames22No ratings yet

- First Floor Si No Description of Work Unit Qty Vitrified Tile Flooring Unit PriceDocument26 pagesFirst Floor Si No Description of Work Unit Qty Vitrified Tile Flooring Unit PriceHasan JamalNo ratings yet

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDocument20 pagesGypwall 3.2: General Purpose Metal Stud Partition SystemA CNo ratings yet

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDocument20 pagesGypwall 3.2: General Purpose Metal Stud Partition SystemA CNo ratings yet

- Fero Strata Product Profiles Combined - Zezt - Com.auDocument19 pagesFero Strata Product Profiles Combined - Zezt - Com.auSplitset TürkiyeNo ratings yet

- Lysaght Panelrib 18 Sept 2008Document4 pagesLysaght Panelrib 18 Sept 2008Daniel McCallumNo ratings yet

- Richpac® Spiral Wound Gask ETDocument13 pagesRichpac® Spiral Wound Gask ETIgor NircaNo ratings yet

- G-RV6 EnglishDocument3 pagesG-RV6 EnglishAnthony AngNo ratings yet

- Gutter and Rainwater GoodsDocument12 pagesGutter and Rainwater Goodsprathaban723No ratings yet

- Colorbond XRW Datasheet New V8Document2 pagesColorbond XRW Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- Colorbond Ultra Datasheet New V8Document2 pagesColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNo ratings yet

- ColorBond 4pager XRW NewDocument2 pagesColorBond 4pager XRW NewGireesh Krishna KadimiNo ratings yet

- Colorbond 2019 Build Your ImaginationDocument2 pagesColorbond 2019 Build Your ImaginationGireesh Krishna KadimiNo ratings yet

- Architectural Solutions in SteelDocument68 pagesArchitectural Solutions in SteelGireesh Krishna KadimiNo ratings yet

- About LYSAGHT®Document2 pagesAbout LYSAGHT®Gireesh Krishna KadimiNo ratings yet

- Department of Electrical Engineering: Energy Conservation and Audit (2180910)Document13 pagesDepartment of Electrical Engineering: Energy Conservation and Audit (2180910)VIPULNo ratings yet

- PDCB - GC RFQ PDFDocument272 pagesPDCB - GC RFQ PDFAlexandru Simion CosmaNo ratings yet

- Analyser Sample SystemsDocument19 pagesAnalyser Sample Systemsaslam.amb100% (1)

- BI 2015 IBC Amendments 01-25-2017Document208 pagesBI 2015 IBC Amendments 01-25-2017Carl CrowNo ratings yet

- Overview of Solar DesalinationDocument17 pagesOverview of Solar Desalinationalagar krishna kumarNo ratings yet

- Pri-Cor-Pjm-Bld-001-E-R01 (Buildings Lumpsum)Document61 pagesPri-Cor-Pjm-Bld-001-E-R01 (Buildings Lumpsum)projects sureshNo ratings yet

- IELTS Writing Task 1 SimonDocument28 pagesIELTS Writing Task 1 SimonblablahieuNo ratings yet

- 4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiDocument7 pages4990 - Habibullah Associates For HVAC Works at Dolmen Mall, KarachiZain KhanNo ratings yet

- Jabfloor JabliteDocument10 pagesJabfloor JabliteAshik ShahNo ratings yet

- Renovation Building Cold ClimateDocument46 pagesRenovation Building Cold ClimateAmeni MokniNo ratings yet

- Guidence On LNG Sloshing in Memberane TanksDocument25 pagesGuidence On LNG Sloshing in Memberane Tanksneeraj singhNo ratings yet

- Book 6 - Floor & Ceilings Jan 09Document66 pagesBook 6 - Floor & Ceilings Jan 09Mely PadIlla MaTaNo ratings yet

- Qbiss Air Brochure SIDocument40 pagesQbiss Air Brochure SIMauricio Senior RamírezNo ratings yet

- Froilabo Oven 2013 A4Document6 pagesFroilabo Oven 2013 A4Widya Okta UtamiNo ratings yet

- Is 9901-1 PDFDocument12 pagesIs 9901-1 PDFJGD123No ratings yet

- Amusement ParkDocument5 pagesAmusement Parksandip_exl100% (1)

- Paint Plating Automotive Testing InstrumentsDocument23 pagesPaint Plating Automotive Testing InstrumentsSatyendra PandeyNo ratings yet

- 6247 17714 1 PB PDFDocument11 pages6247 17714 1 PB PDFkenneth mayaoNo ratings yet

- Avantis 70 HV - Aluminium Windows With Hidden Vent - Sapa Building SystemDocument12 pagesAvantis 70 HV - Aluminium Windows With Hidden Vent - Sapa Building SystemSapa Building SystemNo ratings yet

- BMB Brochure 2015 PDFDocument38 pagesBMB Brochure 2015 PDFlai nguyenNo ratings yet

- CSS01 08 PDFDocument2 pagesCSS01 08 PDFEarl Angelo D. AcuñaNo ratings yet

- A Detailed Guide To Insulating Your HomeDocument28 pagesA Detailed Guide To Insulating Your Homebeerbaron1111No ratings yet

- Silo Data Sheet PDFDocument4 pagesSilo Data Sheet PDFAhmed Ben HmidaNo ratings yet

- Peikko - Diagonal TiesDocument32 pagesPeikko - Diagonal TiesbedogyulaNo ratings yet

- Building Envelopes Large BuildingsDocument39 pagesBuilding Envelopes Large BuildingsbatteekhNo ratings yet

- Ayrshire Steel FramingDocument41 pagesAyrshire Steel FramingingdanbeloiuNo ratings yet