Professional Documents

Culture Documents

04 Procedure For Inspection of Conduits Installation

04 Procedure For Inspection of Conduits Installation

Uploaded by

Islam IbrahimCopyright:

Available Formats

You might also like

- Mettler PM4600 Service Manual PDFDocument126 pagesMettler PM4600 Service Manual PDFArchaeoAnalytics MeetingNo ratings yet

- Method Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemDocument10 pagesMethod Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemRagu Rajan100% (1)

- m1028 LMTV PartsDocument1,272 pagesm1028 LMTV PartsAnthony Windover100% (1)

- Method Statement For Welding RepairDocument7 pagesMethod Statement For Welding RepairHarun AkkayaNo ratings yet

- W201 Cental Locking Wiring DiagramDocument3 pagesW201 Cental Locking Wiring DiagramMircea Daniel Ciupei100% (1)

- Checklist For Dismantling & Preservation of Existing MEP Works-FinalDocument2 pagesChecklist For Dismantling & Preservation of Existing MEP Works-FinalMohammed Javid100% (1)

- Field Quality Plan (FQP)Document2 pagesField Quality Plan (FQP)Ranjit Singh100% (4)

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiNo ratings yet

- 06 Procedure For Polarity and Continuity TestDocument5 pages06 Procedure For Polarity and Continuity TestIslam IbrahimNo ratings yet

- 03 Procedure For Inspection of Circuits, Feeders and Surge ProtectionDocument6 pages03 Procedure For Inspection of Circuits, Feeders and Surge ProtectionIslam IbrahimNo ratings yet

- 07 Procedure For Thermography Inspection of PanelboardsDocument6 pages07 Procedure For Thermography Inspection of PanelboardsIslam IbrahimNo ratings yet

- DRP001 Ouf Gal Spe B 000 001 S1Document25 pagesDRP001 Ouf Gal Spe B 000 001 S1Rafat KhanNo ratings yet

- Checklist For PCCDocument2 pagesChecklist For PCCShyam SutharNo ratings yet

- 2.1 QK-CL-08-00001-Installation of Plumbing Fixtures and TrimDocument3 pages2.1 QK-CL-08-00001-Installation of Plumbing Fixtures and TrimMoh'd SameerNo ratings yet

- 2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyDocument3 pages2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyMoh'd SameerNo ratings yet

- Construction Quality Checklist 1.1Document22 pagesConstruction Quality Checklist 1.1lowiyaun100% (1)

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- 2.14 QK-CL-09-00004-Installation of Vitrified Clay Pipes and Fittings For Underground External Drainage Piping SystemDocument1 page2.14 QK-CL-09-00004-Installation of Vitrified Clay Pipes and Fittings For Underground External Drainage Piping SystemMoh'd SameerNo ratings yet

- Services Rig Survey ReportDocument3 pagesServices Rig Survey ReportKuOneMohdAzrulNo ratings yet

- ECRL-S2-BR030-P1-PB-RFI-0001 Joint Inspection For Precast Prestressed T Beam of Bridge 30 P1 at Beam Yard CH70+000Document8 pagesECRL-S2-BR030-P1-PB-RFI-0001 Joint Inspection For Precast Prestressed T Beam of Bridge 30 P1 at Beam Yard CH70+000Nabilah MoktarNo ratings yet

- 2.3 QK-CL-08-00001-2-Connections, Adjusting and Cleaning of Plumbing FixturesDocument1 page2.3 QK-CL-08-00001-2-Connections, Adjusting and Cleaning of Plumbing FixturesMoh'd SameerNo ratings yet

- 2.12 QK-CL-09-00002-Installation and Water Tightness Test of HDPE Pipes and Fittings For Soil, Waste, Vent and Rainwater System For MusallaDocument1 page2.12 QK-CL-09-00002-Installation and Water Tightness Test of HDPE Pipes and Fittings For Soil, Waste, Vent and Rainwater System For MusallaMoh'd SameerNo ratings yet

- Sample Template Itp For Piping Fabrication and InstallationDocument16 pagesSample Template Itp For Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Reference REV Title: Distribution Part 7: Substations Date: September 2005 OF Revision DateDocument76 pagesReference REV Title: Distribution Part 7: Substations Date: September 2005 OF Revision DateGys SmedaNo ratings yet

- BMJV-QUA-F19 Method Statement Template R03 Storm WaterDocument11 pagesBMJV-QUA-F19 Method Statement Template R03 Storm WaterTaiwo OshinNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- KURD-SPC-PRJ-002 Flange Joint Integrity SpecificationDocument13 pagesKURD-SPC-PRJ-002 Flange Joint Integrity Specificationbmanojkumar16No ratings yet

- Weld Repair - PR - 0XXDocument10 pagesWeld Repair - PR - 0XXRAMAKRISHNANo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- Task 3 AnswersDocument10 pagesTask 3 AnswersShah ZeeshanNo ratings yet

- 2.11 QK-CL-09-00001-Installation and Water Tightness Test of Cast Iron Pipes and Fittings For Underground I AbovegroundDocument1 page2.11 QK-CL-09-00001-Installation and Water Tightness Test of Cast Iron Pipes and Fittings For Underground I AbovegroundMoh'd SameerNo ratings yet

- Eddy Current RFT ProcedureDocument12 pagesEddy Current RFT ProcedureJeganeswaran100% (1)

- Piping Fabrication and Welding - DNV OS F101Document18 pagesPiping Fabrication and Welding - DNV OS F101Yan FerizalNo ratings yet

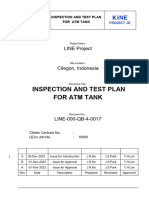

- 대아 ATM-LINE-000-QB-4-0017 - INSPECTION AND TEST PLAN FOR ATM TANK - Rev.0Document40 pages대아 ATM-LINE-000-QB-4-0017 - INSPECTION AND TEST PLAN FOR ATM TANK - Rev.0tomy.jipNo ratings yet

- Checklist-EDC TANKDocument14 pagesChecklist-EDC TANKPartheeban SkpNo ratings yet

- 2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingDocument1 page2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingMoh'd SameerNo ratings yet

- 关键设施设备自检自查整改跟踪表 CtuDocument21 pages关键设施设备自检自查整改跟踪表 Ctu池边树No ratings yet

- Welding Process Control - PR - 0XXDocument21 pagesWelding Process Control - PR - 0XXRAMAKRISHNA100% (2)

- Ofis 23059 Qa Pro NDT 00 01 RT ProcedureDocument97 pagesOfis 23059 Qa Pro NDT 00 01 RT ProcedureanandNo ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Qaqc MSM NCR FL3B CVL FR 01 PDFDocument1 pageQaqc MSM NCR FL3B CVL FR 01 PDFhafizd zullahNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- Weld Procedure Specification - PR - 0XXDocument7 pagesWeld Procedure Specification - PR - 0XXRAMAKRISHNANo ratings yet

- HDPE Pile Wheel SpacersDocument12 pagesHDPE Pile Wheel SpacersGhayas JawedNo ratings yet

- MSRA - ELE-01 Rev1 Installation of PVC ConduitDocument30 pagesMSRA - ELE-01 Rev1 Installation of PVC ConduitjavedNo ratings yet

- Dust Extractor IqoqpqDocument10 pagesDust Extractor Iqoqpqpinnacle qaNo ratings yet

- Construction Quality Checklist 0.1Document4 pagesConstruction Quality Checklist 0.1lowiyaunNo ratings yet

- Steel FabricationDocument2 pagesSteel FabricationShyam SutharNo ratings yet

- 758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ADocument12 pages758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ATran Van Nhut LinhNo ratings yet

- FPM 222 Checklist PlumbingDocument4 pagesFPM 222 Checklist PlumbingAarnav SinghNo ratings yet

- 2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationDocument1 page2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationMoh'd SameerNo ratings yet

- Ci̇vata Sikma TorklariDocument4 pagesCi̇vata Sikma Torklariakın ersözNo ratings yet

- 7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Document8 pages7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Lee JungNo ratings yet

- General Erection Procedure-R2Document28 pagesGeneral Erection Procedure-R2SukocoNo ratings yet

- Checklist SBG TretsleDocument2 pagesChecklist SBG TretsleIzzat IzzuddinNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Mteza A Abutment 12 - 033546Document2 pagesMteza A Abutment 12 - 033546Citymap Geospatial LtdNo ratings yet

- Mc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021Document2 pagesMc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021ehteshamNo ratings yet

- Procedure For Tightening of High Strength Bolted ConnectionsDocument13 pagesProcedure For Tightening of High Strength Bolted ConnectionsSyedAsrarNo ratings yet

- Concrete RemovalDocument129 pagesConcrete RemovalShuo ShiNo ratings yet

- 00 Procedure For Electrode Resistance Test and Earth Loop Resistance Test FinalDocument10 pages00 Procedure For Electrode Resistance Test and Earth Loop Resistance Test FinalIslam IbrahimNo ratings yet

- 02 Procedure For Inspection and Thermal Imaging of BuswaysDocument7 pages02 Procedure For Inspection and Thermal Imaging of BuswaysIslam IbrahimNo ratings yet

- 01 Procedure For Inspection - Verification of Cable TrayDocument6 pages01 Procedure For Inspection - Verification of Cable TrayIslam IbrahimNo ratings yet

- 06 Procedure For Polarity and Continuity TestDocument5 pages06 Procedure For Polarity and Continuity TestIslam IbrahimNo ratings yet

- HandoutsDocument5 pagesHandoutsJomar MontallanaNo ratings yet

- Power Circuit Breakers Insulated Case Circuit Breakers PDFDocument61 pagesPower Circuit Breakers Insulated Case Circuit Breakers PDFThar LayNo ratings yet

- T082 - Plumbing calculation-COVER PAGEDocument7 pagesT082 - Plumbing calculation-COVER PAGERanielNo ratings yet

- Hein Warner Hydraulic Excavator Spm9308128 Parts BookDocument5 pagesHein Warner Hydraulic Excavator Spm9308128 Parts Bookcarmen100% (59)

- AC Automotive System - Gauge ReadingsDocument22 pagesAC Automotive System - Gauge ReadingsPreslav VasilevNo ratings yet

- Air Conditioner Not CoolingDocument13 pagesAir Conditioner Not CoolingrayNo ratings yet

- XR351Document4 pagesXR351ecplpraveen100% (1)

- IPL, Husqvarna, R 152SV, 96141013408, 2012-03Document5 pagesIPL, Husqvarna, R 152SV, 96141013408, 2012-03branest2No ratings yet

- 36a79719q0013 014Document3 pages36a79719q0013 014farzinhafezNo ratings yet

- Ul01ao Iso Red TB SRCDocument3 pagesUl01ao Iso Red TB SRCIndustrial IT Solution Pvt. ltdNo ratings yet

- W 250: Compact Photoelectric Switch Series For A Broad Range of ApplicationsDocument18 pagesW 250: Compact Photoelectric Switch Series For A Broad Range of ApplicationsEdgardo FerulanoNo ratings yet

- Hmrsm04 003 LF SM enDocument19 pagesHmrsm04 003 LF SM enCristian BarraNo ratings yet

- Production Process Flow ChartDocument5 pagesProduction Process Flow ChartKenny RojasNo ratings yet

- C5101 ADocument2 pagesC5101 AKALILNo ratings yet

- Gearbox Rebuild: Thing We Are Fixing This MonthDocument2 pagesGearbox Rebuild: Thing We Are Fixing This Monthpingo pangoNo ratings yet

- RM 505 Speedy Rain Turbine Parts ListDocument3 pagesRM 505 Speedy Rain Turbine Parts ListacanutrNo ratings yet

- 2 Slice Sandwich/Grill Toaster SM3006/SM3006 (G) : Getting The Best From Your New Sandwich ToasterDocument4 pages2 Slice Sandwich/Grill Toaster SM3006/SM3006 (G) : Getting The Best From Your New Sandwich ToasterRonitNo ratings yet

- RunxinDocument149 pagesRunxinMAURONo ratings yet

- Vaishno Pricelist 10.07Document6 pagesVaishno Pricelist 10.07Mohit KhatriNo ratings yet

- Seiko SLH-2B Instructions ManualDocument4 pagesSeiko SLH-2B Instructions Manualsimpen84No ratings yet

- En tg200727 Uk0yr1215dDocument8 pagesEn tg200727 Uk0yr1215dTumenbayar LkhagvatserenNo ratings yet

- Categories of Hardware Tools and Its UsesDocument3 pagesCategories of Hardware Tools and Its UsesJessie James Bendicio VirtuosoNo ratings yet

- R2B-P3-206-02-M-ET-00001 - Rev.1 - Technical Specification For SCS-engDocument26 pagesR2B-P3-206-02-M-ET-00001 - Rev.1 - Technical Specification For SCS-engANDREANo ratings yet

- Ficha Tecnica MAC 3 y 5 (1) - 1Document3 pagesFicha Tecnica MAC 3 y 5 (1) - 1luis miguel escobar rondinelNo ratings yet

- Triangle Pump Product Catalog 5Document113 pagesTriangle Pump Product Catalog 5Joel CieltoNo ratings yet

- Ansi Neca Bicsi 568 2001 PDFDocument44 pagesAnsi Neca Bicsi 568 2001 PDFluisfch100% (2)

- DPT 2015Document4 pagesDPT 2015superpuma86No ratings yet

04 Procedure For Inspection of Conduits Installation

04 Procedure For Inspection of Conduits Installation

Uploaded by

Islam IbrahimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Procedure For Inspection of Conduits Installation

04 Procedure For Inspection of Conduits Installation

Uploaded by

Islam IbrahimCopyright:

Available Formats

Procedure for Inspection of conduits

installation and verification

Issue Date 24 Sep 2020 QI.P.6004

Amendment Page

Status: Add Modified Remove

1 DCR No: 45 Rev No.: 01 Rev Date: 02 Apr 2023

Name: Justin Jose Position: QHSE Officer Sign:

Status: Add Modified Remove

2 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

3 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

4 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

5 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

6 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

7 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

8 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

9 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

Status: Add Modified Remove

10 DCR No: Rev No.: Rev Date:

Name: Position: Sign:

DCR No: 45 Rev No:01 Rev. Date 02 Apr 2023 Page 2 of 6

Procedure for Inspection of conduits

installation and verification

Issue Date 24 Sep 2020 QI.P.6004

1. Scope

The purpose of this procedure is to streamline and standardize the process of inspection of conduits installation

and verification. The scope of this procedure is to check the compliance status of installation of conductors.

This procedure is applicable to employees, who are involved in the provision of inspection of conduits

installation and verification.

2. Reference Standards

- SBC 401 Chapter 61

3. Equipment & Tools Used

N/A

4. Procedure

TUV Austria ensures that a qualified and experienced Inspector is delivering this service with the help of a

Calibrated Infra-red Camera. Inspector shall perform the service taking steps including but not limited to;

• Review the Scope of Work to understand the work volume and Meeting with client focal point to

prepare a schedule.

• Indentifying items, which are to be inspected, with the help of client representative.

• Review the previous inspection reports if available.

• Taking all necessary Safety precautions prior to inspection.

• Ensuring removal of protection screens/covers by the client to gain access to the components.

• Carrying out inspection with the help of the Checklist as given below

• Verify the fill percentage of conduit.

• Verify that the conduit is properly supported.

• Verify PVC coating, threaded lubricant is applied. PVC patching compound must be on sleeves.

• Verify that the conduit connections are wrench tight. Use a strap wrench for PVC-coated conduit.

• Verify that the expansion joints are installed and bonded where needed

• Verify that locknuts are installed and installed correctly.

• Verify the installation of weatherproof hubs on outside installations.

• Verify that bushings are installed at boxes.

• Verify that there is no more than 360 degrees of bend between pull points.

• Verify that conduit is buried at the proper depth in underground installations.

DCR No: 45 Rev No:01 Rev. Date 02 Apr 2023 Page 3 of 6

Procedure for Inspection of conduits

installation and verification

Issue Date 24 Sep 2020 QI.P.6004

• Verify that conduit was reamed after cutting.

• Verify that conduit threads are properly cut

• Verify that conduits are fireproofed where needed.

• Verify that conduit bodies containing splices are completed in accordance with the SBC 401 Chapter

61 and NEC, Article 314-16(c)

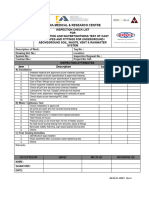

6. Checklist

Item Inspection Activity Comments

1. Support and spacing as per specification and drawings.

2. Support adjustment to terminal fittings

3. Conduit clean, Stub-ups protected. Open ends plugged not

damaged during construction period.

4. Field bend radius correct per specification and code. Bends free

of deformities

5. Installation neat and evenly spaced.

6. Spacing between instrument and power conduit as per

specification

7. Conduit permanently and effectively grounded

8. Proper fitting installed with threads fully engaged, proper

sealing compound used, no wrench cuts, conduit ends have

bushing and cover installed.

9. Seal and drains installed per drawings.

10. Aluminum, PVC or PVC coated conduits installed where

specified on drawings.

11. Flexible conduit with proper bending radius and whit standard

fittings

12. Metal junction boxes leveled and supported per drawings with

proper hubs, locknuts and bushing installed.

Seal poured.

DCR No: 45 Rev No:01 Rev. Date 02 Apr 2023 Page 4 of 6

Procedure for Inspection of conduits

installation and verification

Issue Date 24 Sep 2020 QI.P.6004

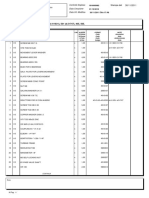

7.Report

DCR No: 45 Rev No:01 Rev. Date 02 Apr 2023 Page 5 of 6

Procedure for Inspection of conduits

installation and verification

Issue Date 24 Sep 2020 QI.P.6004

DCR No: 45 Rev No:01 Rev. Date 02 Apr 2023 Page 6 of 6

You might also like

- Mettler PM4600 Service Manual PDFDocument126 pagesMettler PM4600 Service Manual PDFArchaeoAnalytics MeetingNo ratings yet

- Method Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemDocument10 pagesMethod Statement of Flushing & Chemical Cleaning Procedure Chilled Water SystemRagu Rajan100% (1)

- m1028 LMTV PartsDocument1,272 pagesm1028 LMTV PartsAnthony Windover100% (1)

- Method Statement For Welding RepairDocument7 pagesMethod Statement For Welding RepairHarun AkkayaNo ratings yet

- W201 Cental Locking Wiring DiagramDocument3 pagesW201 Cental Locking Wiring DiagramMircea Daniel Ciupei100% (1)

- Checklist For Dismantling & Preservation of Existing MEP Works-FinalDocument2 pagesChecklist For Dismantling & Preservation of Existing MEP Works-FinalMohammed Javid100% (1)

- Field Quality Plan (FQP)Document2 pagesField Quality Plan (FQP)Ranjit Singh100% (4)

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiNo ratings yet

- 06 Procedure For Polarity and Continuity TestDocument5 pages06 Procedure For Polarity and Continuity TestIslam IbrahimNo ratings yet

- 03 Procedure For Inspection of Circuits, Feeders and Surge ProtectionDocument6 pages03 Procedure For Inspection of Circuits, Feeders and Surge ProtectionIslam IbrahimNo ratings yet

- 07 Procedure For Thermography Inspection of PanelboardsDocument6 pages07 Procedure For Thermography Inspection of PanelboardsIslam IbrahimNo ratings yet

- DRP001 Ouf Gal Spe B 000 001 S1Document25 pagesDRP001 Ouf Gal Spe B 000 001 S1Rafat KhanNo ratings yet

- Checklist For PCCDocument2 pagesChecklist For PCCShyam SutharNo ratings yet

- 2.1 QK-CL-08-00001-Installation of Plumbing Fixtures and TrimDocument3 pages2.1 QK-CL-08-00001-Installation of Plumbing Fixtures and TrimMoh'd SameerNo ratings yet

- 2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyDocument3 pages2.4 QK-CL-08-00002-1-Installation of Ductile Iron Pipes For Underground Water SupplyMoh'd SameerNo ratings yet

- Construction Quality Checklist 1.1Document22 pagesConstruction Quality Checklist 1.1lowiyaun100% (1)

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- 2.14 QK-CL-09-00004-Installation of Vitrified Clay Pipes and Fittings For Underground External Drainage Piping SystemDocument1 page2.14 QK-CL-09-00004-Installation of Vitrified Clay Pipes and Fittings For Underground External Drainage Piping SystemMoh'd SameerNo ratings yet

- Services Rig Survey ReportDocument3 pagesServices Rig Survey ReportKuOneMohdAzrulNo ratings yet

- ECRL-S2-BR030-P1-PB-RFI-0001 Joint Inspection For Precast Prestressed T Beam of Bridge 30 P1 at Beam Yard CH70+000Document8 pagesECRL-S2-BR030-P1-PB-RFI-0001 Joint Inspection For Precast Prestressed T Beam of Bridge 30 P1 at Beam Yard CH70+000Nabilah MoktarNo ratings yet

- 2.3 QK-CL-08-00001-2-Connections, Adjusting and Cleaning of Plumbing FixturesDocument1 page2.3 QK-CL-08-00001-2-Connections, Adjusting and Cleaning of Plumbing FixturesMoh'd SameerNo ratings yet

- 2.12 QK-CL-09-00002-Installation and Water Tightness Test of HDPE Pipes and Fittings For Soil, Waste, Vent and Rainwater System For MusallaDocument1 page2.12 QK-CL-09-00002-Installation and Water Tightness Test of HDPE Pipes and Fittings For Soil, Waste, Vent and Rainwater System For MusallaMoh'd SameerNo ratings yet

- Sample Template Itp For Piping Fabrication and InstallationDocument16 pagesSample Template Itp For Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Reference REV Title: Distribution Part 7: Substations Date: September 2005 OF Revision DateDocument76 pagesReference REV Title: Distribution Part 7: Substations Date: September 2005 OF Revision DateGys SmedaNo ratings yet

- BMJV-QUA-F19 Method Statement Template R03 Storm WaterDocument11 pagesBMJV-QUA-F19 Method Statement Template R03 Storm WaterTaiwo OshinNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- KURD-SPC-PRJ-002 Flange Joint Integrity SpecificationDocument13 pagesKURD-SPC-PRJ-002 Flange Joint Integrity Specificationbmanojkumar16No ratings yet

- Weld Repair - PR - 0XXDocument10 pagesWeld Repair - PR - 0XXRAMAKRISHNANo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- Task 3 AnswersDocument10 pagesTask 3 AnswersShah ZeeshanNo ratings yet

- 2.11 QK-CL-09-00001-Installation and Water Tightness Test of Cast Iron Pipes and Fittings For Underground I AbovegroundDocument1 page2.11 QK-CL-09-00001-Installation and Water Tightness Test of Cast Iron Pipes and Fittings For Underground I AbovegroundMoh'd SameerNo ratings yet

- Eddy Current RFT ProcedureDocument12 pagesEddy Current RFT ProcedureJeganeswaran100% (1)

- Piping Fabrication and Welding - DNV OS F101Document18 pagesPiping Fabrication and Welding - DNV OS F101Yan FerizalNo ratings yet

- 대아 ATM-LINE-000-QB-4-0017 - INSPECTION AND TEST PLAN FOR ATM TANK - Rev.0Document40 pages대아 ATM-LINE-000-QB-4-0017 - INSPECTION AND TEST PLAN FOR ATM TANK - Rev.0tomy.jipNo ratings yet

- Checklist-EDC TANKDocument14 pagesChecklist-EDC TANKPartheeban SkpNo ratings yet

- 2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingDocument1 page2.5 QK-CL-08-00002-2-Installation of Ductile Iron Pipes For Water Tank Main Pump Room PipingMoh'd SameerNo ratings yet

- 关键设施设备自检自查整改跟踪表 CtuDocument21 pages关键设施设备自检自查整改跟踪表 Ctu池边树No ratings yet

- Welding Process Control - PR - 0XXDocument21 pagesWelding Process Control - PR - 0XXRAMAKRISHNA100% (2)

- Ofis 23059 Qa Pro NDT 00 01 RT ProcedureDocument97 pagesOfis 23059 Qa Pro NDT 00 01 RT ProcedureanandNo ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Qaqc MSM NCR FL3B CVL FR 01 PDFDocument1 pageQaqc MSM NCR FL3B CVL FR 01 PDFhafizd zullahNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- Weld Procedure Specification - PR - 0XXDocument7 pagesWeld Procedure Specification - PR - 0XXRAMAKRISHNANo ratings yet

- HDPE Pile Wheel SpacersDocument12 pagesHDPE Pile Wheel SpacersGhayas JawedNo ratings yet

- MSRA - ELE-01 Rev1 Installation of PVC ConduitDocument30 pagesMSRA - ELE-01 Rev1 Installation of PVC ConduitjavedNo ratings yet

- Dust Extractor IqoqpqDocument10 pagesDust Extractor Iqoqpqpinnacle qaNo ratings yet

- Construction Quality Checklist 0.1Document4 pagesConstruction Quality Checklist 0.1lowiyaunNo ratings yet

- Steel FabricationDocument2 pagesSteel FabricationShyam SutharNo ratings yet

- 758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ADocument12 pages758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ATran Van Nhut LinhNo ratings yet

- FPM 222 Checklist PlumbingDocument4 pagesFPM 222 Checklist PlumbingAarnav SinghNo ratings yet

- 2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationDocument1 page2.13 QK-CL-09-00001-Site Readiness Check List For Vitrified Clay Pipes InstallationMoh'd SameerNo ratings yet

- Ci̇vata Sikma TorklariDocument4 pagesCi̇vata Sikma Torklariakın ersözNo ratings yet

- 7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Document8 pages7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Lee JungNo ratings yet

- General Erection Procedure-R2Document28 pagesGeneral Erection Procedure-R2SukocoNo ratings yet

- Checklist SBG TretsleDocument2 pagesChecklist SBG TretsleIzzat IzzuddinNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Mteza A Abutment 12 - 033546Document2 pagesMteza A Abutment 12 - 033546Citymap Geospatial LtdNo ratings yet

- Mc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021Document2 pagesMc-ph01-p04-06a03-Vme-sor-ele-000001 Site Observation Site Temporary Electrical Layout 24 Aug 2021ehteshamNo ratings yet

- Procedure For Tightening of High Strength Bolted ConnectionsDocument13 pagesProcedure For Tightening of High Strength Bolted ConnectionsSyedAsrarNo ratings yet

- Concrete RemovalDocument129 pagesConcrete RemovalShuo ShiNo ratings yet

- 00 Procedure For Electrode Resistance Test and Earth Loop Resistance Test FinalDocument10 pages00 Procedure For Electrode Resistance Test and Earth Loop Resistance Test FinalIslam IbrahimNo ratings yet

- 02 Procedure For Inspection and Thermal Imaging of BuswaysDocument7 pages02 Procedure For Inspection and Thermal Imaging of BuswaysIslam IbrahimNo ratings yet

- 01 Procedure For Inspection - Verification of Cable TrayDocument6 pages01 Procedure For Inspection - Verification of Cable TrayIslam IbrahimNo ratings yet

- 06 Procedure For Polarity and Continuity TestDocument5 pages06 Procedure For Polarity and Continuity TestIslam IbrahimNo ratings yet

- HandoutsDocument5 pagesHandoutsJomar MontallanaNo ratings yet

- Power Circuit Breakers Insulated Case Circuit Breakers PDFDocument61 pagesPower Circuit Breakers Insulated Case Circuit Breakers PDFThar LayNo ratings yet

- T082 - Plumbing calculation-COVER PAGEDocument7 pagesT082 - Plumbing calculation-COVER PAGERanielNo ratings yet

- Hein Warner Hydraulic Excavator Spm9308128 Parts BookDocument5 pagesHein Warner Hydraulic Excavator Spm9308128 Parts Bookcarmen100% (59)

- AC Automotive System - Gauge ReadingsDocument22 pagesAC Automotive System - Gauge ReadingsPreslav VasilevNo ratings yet

- Air Conditioner Not CoolingDocument13 pagesAir Conditioner Not CoolingrayNo ratings yet

- XR351Document4 pagesXR351ecplpraveen100% (1)

- IPL, Husqvarna, R 152SV, 96141013408, 2012-03Document5 pagesIPL, Husqvarna, R 152SV, 96141013408, 2012-03branest2No ratings yet

- 36a79719q0013 014Document3 pages36a79719q0013 014farzinhafezNo ratings yet

- Ul01ao Iso Red TB SRCDocument3 pagesUl01ao Iso Red TB SRCIndustrial IT Solution Pvt. ltdNo ratings yet

- W 250: Compact Photoelectric Switch Series For A Broad Range of ApplicationsDocument18 pagesW 250: Compact Photoelectric Switch Series For A Broad Range of ApplicationsEdgardo FerulanoNo ratings yet

- Hmrsm04 003 LF SM enDocument19 pagesHmrsm04 003 LF SM enCristian BarraNo ratings yet

- Production Process Flow ChartDocument5 pagesProduction Process Flow ChartKenny RojasNo ratings yet

- C5101 ADocument2 pagesC5101 AKALILNo ratings yet

- Gearbox Rebuild: Thing We Are Fixing This MonthDocument2 pagesGearbox Rebuild: Thing We Are Fixing This Monthpingo pangoNo ratings yet

- RM 505 Speedy Rain Turbine Parts ListDocument3 pagesRM 505 Speedy Rain Turbine Parts ListacanutrNo ratings yet

- 2 Slice Sandwich/Grill Toaster SM3006/SM3006 (G) : Getting The Best From Your New Sandwich ToasterDocument4 pages2 Slice Sandwich/Grill Toaster SM3006/SM3006 (G) : Getting The Best From Your New Sandwich ToasterRonitNo ratings yet

- RunxinDocument149 pagesRunxinMAURONo ratings yet

- Vaishno Pricelist 10.07Document6 pagesVaishno Pricelist 10.07Mohit KhatriNo ratings yet

- Seiko SLH-2B Instructions ManualDocument4 pagesSeiko SLH-2B Instructions Manualsimpen84No ratings yet

- En tg200727 Uk0yr1215dDocument8 pagesEn tg200727 Uk0yr1215dTumenbayar LkhagvatserenNo ratings yet

- Categories of Hardware Tools and Its UsesDocument3 pagesCategories of Hardware Tools and Its UsesJessie James Bendicio VirtuosoNo ratings yet

- R2B-P3-206-02-M-ET-00001 - Rev.1 - Technical Specification For SCS-engDocument26 pagesR2B-P3-206-02-M-ET-00001 - Rev.1 - Technical Specification For SCS-engANDREANo ratings yet

- Ficha Tecnica MAC 3 y 5 (1) - 1Document3 pagesFicha Tecnica MAC 3 y 5 (1) - 1luis miguel escobar rondinelNo ratings yet

- Triangle Pump Product Catalog 5Document113 pagesTriangle Pump Product Catalog 5Joel CieltoNo ratings yet

- Ansi Neca Bicsi 568 2001 PDFDocument44 pagesAnsi Neca Bicsi 568 2001 PDFluisfch100% (2)

- DPT 2015Document4 pagesDPT 2015superpuma86No ratings yet