Professional Documents

Culture Documents

92-01 Combination Pressure Reducing & Sustaining Valve CLAVAL

92-01 Combination Pressure Reducing & Sustaining Valve CLAVAL

Uploaded by

arixbonengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

92-01 Combination Pressure Reducing & Sustaining Valve CLAVAL

92-01 Combination Pressure Reducing & Sustaining Valve CLAVAL

Uploaded by

arixbonengCopyright:

Available Formats

MODEL 92-01

Combination Pressure Reducing

& Pressure Sustaining Valve

• Accurate Response to Slight Pressure Changes

• Check Feature Available

• Completely Automatic Operation

• Drip-Tight, Positive Seating Action

• Operation is Fully Hydraulic

The Cla-Val Model 92-01 Combination Pressure Reducing and

Pressure Sustaining Valve automatically performs two independent

functions. It maintains a constant downstream pressure, regardless

of fluctuating demand and sustains the upstream pressure to a pre-

determined minimum.

The pressure reducing control responds to slight variations in

downstream pressure and immediately repositions the main valve

to maintain the desired downstream pressure. The pressure

sustaining control is normally held open by the upstream pressure,

but modulates should the pressure drop to the control set point.

This, in turn, modulates the main valve to sustain the desired

upstream pressure.

If a check feature is added, and a pressure reversal occurs, the

downstream pressure is admitted into the main valve cover

chamber and the valve closes to prevent return flow.

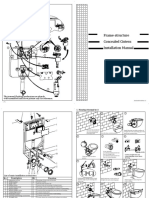

Schematic Diagram

Item Description

1 100-01 Hytrol Main Valve

2 X44A Strainer & Orifice

3 CRD Pressure Reducing Control

4 CRL-60 Pressure Relief Control

5 CV Flow Control (Opening)

Optional Features

Item Description

B CK2 Isolation Valve

C CV Flow Control (Closing)*

D Check Valves With Isolation Valve

F Remote Pilot Sensing

P X141 Pressure Gauge

V X101 Valve Position Indicator

* The (optional) closing speed control on this valve should

always be open at least three (3) turns off its seat.

in

Typical Applications

a

r eM

su

es

A Combination Pressure Reducing and Pressure Sustaining

r

hP Gauge

Valve is typically used to automatically reduce pressure for

Hig

the downstream distribution network and sustain a minimum

X43H Strainer

pressure in the high pressure main regardless of distribution

Isolation

demand.

Valve

CLA-VAL 92-01

Combination Pressure Reducing n

& Pressure Sustaining Valve u tio

ri b

D ist

Model 92-01 (Uses 100-01 Hytrol Main Valve) B (Diameter)

Pressure Ratings

J

100-01

(Recommended Maximum Pressure - psi) Threaded &

K

Pressure Class

Flanged X

Valve Body & Cover

H

Flanged Grooved Threaded

C

(MAX)

ANSI 150 300 300 End‡

Inlet Outlet

Grade Material

Standards* Class Class Class Details G E F

ASTM A536 Ductile Iron B16.42 250 400 400 400

GG FF

GGG

ASTM A216-WCB Cast Steel B16.5 285 400 400 400 Inlet D

DD

UNS 87850

A

Bronze B16.24 225 400 400 400 AA DDD

AAA

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Y

Materials

Z

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

1" - 36" 1" - 16" 1" - 16"

Available Sizes

B (Diameter)

25 - 900mm 25 - 400mm 25 - 400mm 100-01

J

Disc Retainer &

Diaphragm Washer Cast Iron Cast Steel Bronze

Grooved

K X

Trim: Disc Guide, Bronze is Standard H

Seat & Cover Bearing Stainless Steel is Optional

CC

(MAX)

Disc Buna-N Rubber

®

Diaphragm Nylon Reinforced Buna-N® Rubber

Inlet Outlet

Stem, Nut & Spring Stainless Steel EE

For material options not listed, consult factory. GGGG

Cla-Val manufactures valves in more than 50 different alloys.

Model 92-01 Dimensions (In Inches)

Inlet DDDD

AAAA

Valve Size (Inches) 1 1 1⁄ 4 1 1⁄ 2 2 2 1⁄ 2 3 4 6 8 10 12 14 16 18 20 24 30 36

A Threaded 7.25 7.25 7.25 9.38 11.00 12.50 — — — — — — — — — — — —

AA 150 ANSI — — 8.50 9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38 46.00 52.00 61.50 63.00 72.75

AAA 300 ANSI — — 9.00 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50 47.64 53.62 63.24 64.50 74.75

AAAA Grooved End — — 8.50 9.00 11.00 12.50 15.00 20.00 25.38 — — — — — — — — —

B Diameter 5.62 5.62 5.62 6.62 8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50 41.50 45.00 53.16 56.00 66.00

C Maximum 5.50 5.50 5.50 6.50 7.56 8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00 39.06 41.90 43.93 54.60 59.00

CC Maximum Grooved End — — 4.75 5.75 6.88 7.25 9.31 12.12 14.62 — — — — — — — — —

D Threaded 3.25 3.25 3.25 4.75 5.50 6.25 — — — — — — — — — — — —

DD 150 ANSI — — 4.00 4.75 5.50 6.00 7.50 10.00 12.69 14.88 17.00 19.50 20.81 — — 30.75 — —

DDD 300 ANSI — — 4.25 5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75 20.25 21.62 — — 31.62 — —

DDDD Grooved End — — — 4.75 — 6.00 7.50 — — — — — — — — — — —

E 1.12 1.12 1.12 1.50 1.69 2.06 3.19 4.31 5.31 9.25 10.75 12.62 15.50 12.95 15.00 17.75 21.31 24.56

EE Grooved End — — 2.00 2.50 2.88 3.12 4.25 6.00 7.56 — — — — — — — — —

F 150 ANSI — — 2.50 3.00 3.50 3.75 4.50 5.50 6.75 8.00 9.50 10.50 11.75 15.00 16.50 19.25 22.50 28.50

FF 300 ANSI — — 3.06 3.25 3.75 4.13 5.00 6.25 7.50 8.75 10.25 11.50 12.75 15.00 16.50 19.25 24.00 30.00

G Threaded 1.88 1.88 1.88 3.25 4.00 4.50 — — — — — — — — — — — —

GG 150 ANSI — — 4.00 3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69 — — 22.06 — —

GGG 300 ANSI — — 4.25 3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50 — — 22.90 — —

GGGG Grooved End — — — 3.25 — 4.25 5.00 — — — — — — — — — — —

H NPT Body Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

J NPT Cover Center Plug 0.25 0.25 0.25 0.50 0.50 0.50 0.75 0.75 1.00 1.00 1.25 1.50 2.00 1.00 1.00 1.00 2.00 2.00

K NPT Cover Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

Stem Travel 0.40 0.40 0.40 0.60 0.70 0.80 1.10 1.70 2.30 2.80 3.40 4.00 4.50 5.10 5.63 6.75 7.50 8.50

Approx. Ship Weight (lbs) 15 15 15 35 50 70 140 285 500 780 1165 1600 2265 2982 3900 6200 7703 11720

Approx. X Pilot System 11 11 11 13 14 15 17 29 31 33 36 40 40 43 47 68 79 85

Approx. Y Pilot System 9 9 9 9 10 11 12 20 22 24 26 29 30 32 34 39 40 45

Approx. Z Pilot System 9 9 9 9 10 11 12 20 22 24 26 29 30 32 34 39 42 47

Model 92-01 Metric Dimensions (Uses the 100-01 Hytrol Main Valve)

Valve Options

B (Diameter)

J

X141

100-01

Pressure

Threaded &

Gauge

Flanged K

X

H

C

(MAX)

Inlet Outlet

G E F

GG FF

GGG

D

X101AR Valve X101

Inlet

DD

Position Indicator Valve Position

A DDD

AA

AAA with Air Release Indicator

B (Diameter)

J

100-01

X144 e-FlowMeter

Grooved

K X

H CC

(MAX)

Inlet Outlet Y

EE

GGGG

Z

X43H Stainless

Strainer Steel Pilot

Inlet DDDD

AAAA

92-01 Dimensions (In mm)

Valve Size (mm) 25 32 40 50 65 80 100 150 200 250 300 350 400 450 500 600 750 900

A Threaded 184 184 184 238 279 318 — — — — — — — — — — — —

AA 150 ANSI — — 216 238 279 305 381 508 645 756 864 991 1051 1168 1321 1562 1600 1848

AAA 300 ANSI — — 229 254 295 337 397 533 670 790 902 1029 1105 1210 1326 1606 1638 1899

AAAA Grooved End — — 216 228 279 318 381 508 645 — — — — — — — — —

B Diameter 143 143 143 168 203 232 292 400 508 600 711 832 902 1054 1143 1350 1422 1676

C Maximum 140 140 140 165 192 208 270 340 406 435 530 614 635 992 1064 1116 1387 1499

CC Maximum Grooved End — — 120 146 175 184 236 308 371 — — — — — — — — —

D Threaded 83 83 83 121 140 159 — — — — — — — — — — — —

DD 150 ANSI — — 102 121 140 152 191 254 322 378 432 495 528 — — 781 — —

DDD 300 ANSI — — 108 127 149 162 200 267 337 395 451 514 549 — — 803 — —

DDDD Grooved End — — — 121 — 152 191 — — — — — — — — — — —

E 29 29 29 38 43 52 81 110 135 235 273 321 394 329 381 451 541 624

EE Grooved End — — 52 64 73 79 108 152 192 — — — — — — — — —

F 150 ANSI — — 64 76 89 95 114 140 171 203 241 267 298 381 419 489 572 724

FF 300 ANSI — — 78 83 95 105 127 159 191 222 260 292 324 381 419 489 610 762

G Threaded 48 48 48 83 102 114 — — — — — — — — — — — —

GG 150 ANSI — — 102 83 102 102 127 152 203 219 349 378 399 — — 560 — —

GGG 300 ANSI — — 102 89 110 111 135 165 216 236 368 397 419 — — 582 — —

GGGG Grooved End — — — 83 — 108 127 — — — — — — — — — — —

H NPT Body Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

J NPT Cover Center Plug 0.25 0.25 0.25 0.50 0.50 0.50 0.75 0.75 1.00 1.00 1.25 1.50 2.00 1.00 1.00 1.00 2.00 2.00

K NPT Cover Tapping 0.375 0.375 0.375 0.375 0.50 0.50 0.75 0.75 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

Stem Travel 10 10 10 15 18 20 28 43 58 71 86 102 114 130 143 171 190 216

Approx. Ship Weight (kgs) 7 7 7 16 23 32 64 129 227 354 528 726 1027 1353 1769 2812 3494 5316

Approx. X Pilot System 280 280 280 331 356 381 432 737 788 839 915 1016 1016 1093 1194 1728 2007 2159

Approx. Y Pilot System 229 229 229 229 254 280 305 508 559 610 661 737 762 813 864 991 1016 1143

Approx. Z Pilot System 229 229 229 229 254 280 305 508 559 610 661 737 762 813 864 991 1067 1194

100-01 Pattern: Globe (G), Angle (A), End Connections: Threaded (T), Grooved (GR), Flanged (F) Indicate Available Sizes

92-01

Inches 1 11⁄4 11⁄2 2 21⁄2 3 4 6 8 10 12 14 16 18 20 24 30 36

Valve

Selection

mm 25 32 40 50 65 80 100 150 200 250 300 350 400 450 500 600 750 900

Pattern G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G G G, A G G

Main Valve

100-01 T, F, T, F, T, F, T, F, F, F, F,

End Detail T T F F F F F F F F F

Gr* Gr Gr* Gr Gr Gr* Gr*

Maximum 55 93 125 210 300 460 800 1800 3100 4900 7000 8400 11000 14000 17000 25000 42000 50000

Suggested

Maximum

Flow Intermittent

68 120 160 260 370 580 990 2250 3900 6150 8720 10540 13700 17500 21700 31300 48000 62500

(gpm)

Minimum 1 1 1 1 2 2 4 10 15 35 50 70 95 120 150 275 450 650

Maximum 3.5 6 8 13 19 29 50 113 195 309 442 530 694 883 1073 1577 2650 3150

Suggested

Maximum

Flow Intermittent

4.3 7.6 10 16 23 37 62 142 246 387 549 664 863 1104 1369 1972 3028 3940

(Liters/Sec)

Minimum .03 .03 .03 .06 .09 0.13 0.25 0.63 0.95 2.2 3.2 4.4 6.0 7.6 9.5 17.4 28.4 41.0

100-01 Series is the full internal port Hytrol. For Lower Flows Consult Factory *Globe Grooved Only

Many factors should be considered in sizing pressure reducing valves including inlet pressure, outlet pressure and flow rates.

For sizing questions or cavitation analysis, consult Cla-Val with system details.

CRD Pressure Reducing Pilot Control CRL-60 Pressure Relief Pilot Control

The CRD Pilot is held open by the force The Model CRL-60 is normally held

of the compression spring above the closed by the force of the compression

diaphragm, and closes when the spring above the diaphragm. Control

downstream pressure acting on the pressure is applied under the

underside of the diaphragm exceeds the diaphragm. When the controlling

spring setting. The CRD senses pressure exceeds the spring setting, the

downstream pressure directly. disc is lifted off its seat, permitting flow

through the control. When control

Flow through the control responds to pressure drops below the spring setting,

changes in downstream pressure. the spring forces the control back to its

Turning the adjusting screw clockwise normally closed position. The controlling

increases the delivery pressure. Turning pressure is applied to the chamber

it counterclockwise decreases the beneath the diaphragm through a

pressure. A resilient disc assures tight sensing port on the CRL-60 body.

shut-off on dead-end service.

See the E-CRL-60 E-Sheet for more

See the E-CRD E-Sheet for more details. details.

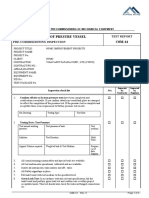

Pilot System Specifications

Adjustment Ranges Materials

Standard Pilot System Materials

CRD CRL-60

Pilot Control: Low Lead Bronze When Ordering,

2 to 30 psi 0 to 75 psi

Trim: Brass & Stainless Steel Type 303 Specify:

15 to 75 psi 20 to 105 psi*

20 to 105 psi 20 to 200 psi Rubber: Buna-N® Synthetic Rubber

1. Catalog No. 92-01

30 to 300 psi* 100 to 300 psi Optional Pilot System Materials 2. Valve Size

*Supplied unless otherwise specified Pilot Systems are available with optional 3. Pattern - Globe or Angle

Other ranges available, please consult factory. Stainless Steel or Monel materials. 4. Pressure Class

Note: Available with remote sensing control. 5. Threaded or Flanged

Temperature Range 6. Trim Material

Water: to 180°F 7. Adjustment Range

8. Desired Options

9. When Vertically Installed

CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Cla-Val 2019 • Printed in USA • Specifications subject to change without notice.

© Copyright

E-92-01 (R-04/2019)

You might also like

- Article 392. Cable Trays PDFDocument7 pagesArticle 392. Cable Trays PDFgilbertomjcNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelTiam Yee YongNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModelSaad KhNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: ModeltorqueuNo ratings yet

- Pressure Reducing Valve CatalogueDocument4 pagesPressure Reducing Valve CatalogueSteveNo ratings yet

- CLA-VAL Reguladora de Presion 90-01 BlueDocument4 pagesCLA-VAL Reguladora de Presion 90-01 BlueSergio HoyosNo ratings yet

- Válvula Reductora de Presión PDFDocument4 pagesVálvula Reductora de Presión PDFPaola LopezNo ratings yet

- E69001 PRV ClavalDocument4 pagesE69001 PRV ClavalPlanner CyberNo ratings yet

- AVK Control Valves BrochureDocument8 pagesAVK Control Valves BrochurePAul JoHn MeNdozaNo ratings yet

- Dorot Serie 300 PR - PsDocument2 pagesDorot Serie 300 PR - PsKelvin GutierrezNo ratings yet

- CLA-VAL Control ValveDocument4 pagesCLA-VAL Control ValvesuedasNo ratings yet

- Differential Pressure Valve E-250-01Document3 pagesDifferential Pressure Valve E-250-01Navin RamnauthNo ratings yet

- 90 01KO Data Sheet USDocument4 pages90 01KO Data Sheet USAngga ArdanaNo ratings yet

- Equilibar-Research Series-Back Pressure Regulators PDFDocument12 pagesEquilibar-Research Series-Back Pressure Regulators PDFdavidusc2010No ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsColinNo ratings yet

- Reducing and Reducing/Relieving Valves: ApplicationsDocument5 pagesReducing and Reducing/Relieving Valves: ApplicationsxxshNo ratings yet

- Equilibar-Research Series-Back Pressure RegulatorsDocument12 pagesEquilibar-Research Series-Back Pressure RegulatorsDr-Ganesh DombeNo ratings yet

- Pressure Reducing Valve: ModelDocument4 pagesPressure Reducing Valve: Modelguangyu LuNo ratings yet

- IHP Control ValvesDocument22 pagesIHP Control ValvesMayur Madhukar MankarNo ratings yet

- AVK Control ValvesDocument8 pagesAVK Control Valvesindra putraNo ratings yet

- Equilibar-GS GSD Series-General Service Back Pressure RegulatorsDocument12 pagesEquilibar-GS GSD Series-General Service Back Pressure RegulatorsDr-Ganesh DombeNo ratings yet

- Equilibar-BD Series-Industrial Back Pressure Regulators and ValvesDocument10 pagesEquilibar-BD Series-Industrial Back Pressure Regulators and ValvesadesemowoadedareNo ratings yet

- Valvula Contrabalance EbtDocument36 pagesValvula Contrabalance Ebtluisalbertocor5100% (1)

- Pressure Relief & Pressure Sustaining Valve: ModelDocument4 pagesPressure Relief & Pressure Sustaining Valve: ModelKevin E JodiNo ratings yet

- Typical Applications: Quick RelifeDocument4 pagesTypical Applications: Quick RelifeRaul HtaNo ratings yet

- Designed To Withstand Even The Toughest Environments... : Let'S Discuss!Document11 pagesDesigned To Withstand Even The Toughest Environments... : Let'S Discuss!john fritz montillenNo ratings yet

- Pressure Relief, Pressure Sustaining Valve: ModelDocument3 pagesPressure Relief, Pressure Sustaining Valve: ModelFILID MADNo ratings yet

- With Remotely Adjustable Pressure Control: HD Initial Position: VDocument1 pageWith Remotely Adjustable Pressure Control: HD Initial Position: VgnowasNo ratings yet

- Model 10 NEW 2007Document2 pagesModel 10 NEW 2007Hussein El BeqaiNo ratings yet

- Pressure Relief and Regulating Valves: ApplicationsDocument7 pagesPressure Relief and Regulating Valves: ApplicationsR.C.PerumalNo ratings yet

- 12 Series-30Document1 page12 Series-30RE musicNo ratings yet

- PRV 2 PDFDocument4 pagesPRV 2 PDFTiam Yee YongNo ratings yet

- 7.5. Cla-Val E-650-01Document4 pages7.5. Cla-Val E-650-01sigithvacNo ratings yet

- Rate of Flow Control ValveDocument4 pagesRate of Flow Control ValveRSalehNo ratings yet

- Introduction To RegulatorsDocument7 pagesIntroduction To Regulatorsoldboy1No ratings yet

- Pressure Relief and Regulating Valves: ApplicationsDocument7 pagesPressure Relief and Regulating Valves: ApplicationsxxshNo ratings yet

- Regulatori de PresiuneDocument3 pagesRegulatori de PresiuneAurelia AlexandraNo ratings yet

- Fluid Power Design Data SheetDocument2 pagesFluid Power Design Data SheetHamza ChenakerNo ratings yet

- Axial Flow Valves 9710 7 032713ADocument12 pagesAxial Flow Valves 9710 7 032713Adilor19No ratings yet

- Centrifugal Compressor OperationDocument5 pagesCentrifugal Compressor OperationAbdus Saboor Khalid100% (4)

- Fundamentals of Pressure Regulation: John M. Kruse Invensys Metering SystemsDocument4 pagesFundamentals of Pressure Regulation: John M. Kruse Invensys Metering SystemsrockieballNo ratings yet

- Data Sheet: Pressure RegulatorDocument4 pagesData Sheet: Pressure RegulatorFrank Jorge Hervas NinaNo ratings yet

- PRV Valve PDFDocument20 pagesPRV Valve PDFhindro kusumantoNo ratings yet

- 07 ValvesDocument12 pages07 ValvesRIAN NOFENDRINo ratings yet

- V S C Sec C Cte Ve Va: Pressure Control ValvesDocument13 pagesV S C Sec C Cte Ve Va: Pressure Control Valvesfrederick alayonNo ratings yet

- Catalogo Regulador Actaris CL 34Document12 pagesCatalogo Regulador Actaris CL 34Juan JuanNo ratings yet

- Safety Valve Flange 16KDocument2 pagesSafety Valve Flange 16KanisyariskiNo ratings yet

- Fluid Control ValvesDocument41 pagesFluid Control ValvesgaurangmarvaniaNo ratings yet

- Chapter 1: General InformationDocument26 pagesChapter 1: General InformationAnonymous 340A7vnwV1No ratings yet

- E211502 Eng Aug00Document6 pagesE211502 Eng Aug00Mohammed sabatinNo ratings yet

- Fundamentals of Pressure RegulatorsDocument5 pagesFundamentals of Pressure RegulatorsmahantoseeNo ratings yet

- Mechanical RegulatorDocument12 pagesMechanical Regulatorshashi chauguleNo ratings yet

- N1 Reducing ValveDocument8 pagesN1 Reducing ValveAlexander Mugabe100% (1)

- Surge Anticipation ValveDocument4 pagesSurge Anticipation ValveMathiTwadCNo ratings yet

- Hydac Proportional Leak-Free Pressure Control ValveDocument4 pagesHydac Proportional Leak-Free Pressure Control ValveMaxNo ratings yet

- Mankenberg dm662 enDocument2 pagesMankenberg dm662 enashwinmalooNo ratings yet

- Use of Pressure Control Valve: Presented byDocument12 pagesUse of Pressure Control Valve: Presented byPremangshu SahaNo ratings yet

- Frame-Structure Concealed Cistern Installation Manual: Internal Flushing Mechanism Assembly DrawingDocument4 pagesFrame-Structure Concealed Cistern Installation Manual: Internal Flushing Mechanism Assembly DrawingPaulo PangilinanNo ratings yet

- Klemsan Energy Management Solutions CatalogueDocument28 pagesKlemsan Energy Management Solutions CatalogueTapelea Cristian100% (1)

- Rugged & Compact CompactDocument2 pagesRugged & Compact CompactAnjum DuttaNo ratings yet

- Update DES Per Jam 15Document2 pagesUpdate DES Per Jam 15Tomi Ananda PradistyNo ratings yet

- TM9 616Document100 pagesTM9 616Chuck CharlesNo ratings yet

- TManual Chapter 01 PDFDocument22 pagesTManual Chapter 01 PDFJay Rameshbhai ParikhNo ratings yet

- Fuel Consumption Chart Diesel GeneratorsDocument1 pageFuel Consumption Chart Diesel GeneratorsYasir MehmoodNo ratings yet

- Flip-Flops and Its Applications: Module - 3Document41 pagesFlip-Flops and Its Applications: Module - 3Chethan RamachariNo ratings yet

- Home Requirement ListDocument12 pagesHome Requirement ListreemaaroraNo ratings yet

- Sop HMDSDocument13 pagesSop HMDSsumanta_2008dredifmaNo ratings yet

- Parts BookDocument118 pagesParts Bookepsa2200No ratings yet

- Installation Instructions Models HMS-S / HMS-D: Single/Dual Action Manual Pull StationDocument2 pagesInstallation Instructions Models HMS-S / HMS-D: Single/Dual Action Manual Pull StationGabriel BarrosNo ratings yet

- Experiment 8 - Ohms LawDocument3 pagesExperiment 8 - Ohms Lawarizhaiqal05No ratings yet

- PC - Print - 11-15-24 AmDocument4 pagesPC - Print - 11-15-24 AmTheo AnggaraNo ratings yet

- DAF NW Workbook 3615.1Document28 pagesDAF NW Workbook 3615.1BrunoPaulo100% (1)

- Lift Elevator Test QCDD FormDocument2 pagesLift Elevator Test QCDD FormSamir AminNo ratings yet

- Motor Yanmar 4tne94-AcgDocument30 pagesMotor Yanmar 4tne94-Acgjalcazar1810100% (1)

- Turns Ratio Meter XTRM 3A - 2Document2 pagesTurns Ratio Meter XTRM 3A - 2BCICSCNo ratings yet

- Автомобильная электроника PDFDocument21 pagesАвтомобильная электроника PDFmikeNo ratings yet

- M 5Document760 pagesM 5fahimNo ratings yet

- Huawei UPS Solutions: Huawei Energy Powering The FutureDocument6 pagesHuawei UPS Solutions: Huawei Energy Powering The FutureDomingo RuizNo ratings yet

- Ertical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingDocument13 pagesErtical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingAbd Al-Rahmman Al-qatananiNo ratings yet

- NSK Spherical Roller BearingDocument19 pagesNSK Spherical Roller BearingKaiser CarloNo ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- The Right ToolDocument100 pagesThe Right ToolElieazarNo ratings yet

- Boq Comparative ChartDocument13 pagesBoq Comparative ChartMulayam Yadav100% (1)

- Three Phase Changer ProjectDocument42 pagesThree Phase Changer ProjectDaniel Taiti Kimathi100% (1)

- How To Replace Timing Belt On Ford Focus 1.8 TDCi 2002-2005Document6 pagesHow To Replace Timing Belt On Ford Focus 1.8 TDCi 2002-2005Ivaylo GeorgievNo ratings yet

- Downloaded From Manuals Search EngineDocument26 pagesDownloaded From Manuals Search EngineGregory TsavdasNo ratings yet