Professional Documents

Culture Documents

A Pricing Policy For A University - Based Smart Microgrid (Revised) : A Case Study of Federal University of Technology Owerri

A Pricing Policy For A University - Based Smart Microgrid (Revised) : A Case Study of Federal University of Technology Owerri

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Pricing Policy For A University - Based Smart Microgrid (Revised) : A Case Study of Federal University of Technology Owerri

A Pricing Policy For A University - Based Smart Microgrid (Revised) : A Case Study of Federal University of Technology Owerri

Copyright:

Available Formats

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

A Pricing Policy for a University- Based Smart

Microgrid (Revised): A Case Study Of Federal

University of Technology Owerri

Joe-Uzuegbu C. K.; Okafor E. N. C.; Onojo O. J.

Dept. of Electrical/Electronic Engineering,Federal University of Technology Owerri, Imo State Nigeria

Abstract:- Every Nigerian tertiary institution requires the need for alternative sources of electric energy, to

adequate power supply to operate effectively for its supplement what obtains from the utility grid, to satisfy the

administrative, academic and miscellaneous functions. most basic daily load requirements. The choice of

The challenge of insufficient power supply by utility alternative sources directly or indirectly impact the

generally remains a constant setback in these environment and economics of the tertiary institution under

institutions. This consequently leads to a high study.

dependence on alternative means of electricity

generation most of which are usually more expensive The case study institution for this research is the

than the supply from the public utility. The most Federal University of Technology Owerri,

common dependence is on diesel and petrol generators,

while a few others attempt to go on renewables. II. PROBLEM STATEMENT

Moreover, every institution also needs to break even on The Federal University of Technology (FUTO) campus

both productivity and finances after every academic is presently connected to the national grid, but because of

session. Thus there is the need to strike a balance the unavailability of power supply almost throughout the

between the cost of power generated for a set of year, there is a relatively high dependence on the backup

consumers, the cost of generation, and the profitability diesel generators. This leads to very high annual expenditure

of alternative power generation. This research is on fuel and generator maintenance costs, as basic load

concerned with using the load profile of the Federal demands have to be met for the smooth operation of

University of Technology Owerri to develop a pricing University activities.

policy for a microgrid network comprising two 500 kW

solar farms, a 100kW microhydro plant and the already Designing a workable smart micro-grid was necessary

existing diesel generators. The method of direct be the first step to curbing energy wastage and properly

cumulative computation was used with the data collected dispatching required energy to consumer loads based on a

both during the current market surveys for the load schedule algorithm. [1]

renewable components and the expected daily load usage

curves. This policy will enable a consumer to schedule III. RESEARCH OBJECTIVE

load usage and minimize energy wastage, determine

when the university can expect returns on investment on The main objective of the research is to develop a

alternative energy generation and enable the university pricing template for the smart micro-grid earlier developed

develop a tariff system of operation where necessary. for the Federal University of Technology. Other objectives

include:

Keywords:- Pricing Policy, Renewable, Return on Determining the optimal operational cost

Investment, Optimization, Tariff. Possible expectation on return on investment.

Developing a tariff system assuming each building is

I. INTRODUCTION financially responsible for their daily energy

Electric power is generally termed the life blood of consumption.

modern civilization. Similarly, every developed society IV. FEATURES OF THE PRE-DESIGNED SMART

cannot boast of civilization without good education, thus MICRO-GRID

the importance of good education cannot be over-

emphasized as relates community development. The average Two 500kW solar farms and one 100kW microhydro

Nigerian tertiary institution is saddled with the plant were proposed based on the daily load requirements of

responsibility of developing students academically, as well the university. The following are the features of the smart

as performing other tasks ranging from administration, microgrid designed and the relevant information curbed for

welfare (including staff andstudent accommodation, feeding, this work.

leisure), research, etc. Thus there is need for adequate power Plant-side Energy management algorithm, based on the

supply in order to execute these roles efficiently. following parameters,

State of charge (SOC) of battery bank

The Nigerian electricity utility system over the years Float voltage of battery bank

has proved insufficient to handle the daily energy

Power from the available plants

requirements of most tertiary institutions thereby prompting

Maximum and minimum chargingcurrents

IJISRT23NOV2085 www.ijisrt.com 2771

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Upper and lower limits for current and voltage during V. PLANT COMPONENTS

charging/discharging

Priority-based load demands The proposed plants were sized to accommodate a

functionally installed load of 1150kW in the day and

Consumer-side Energy management algorithm, which 3.5MW at night and comprises the following:

borders on

Time of day A. The 500kVA Solar Farm

Load priority The 500 kVA solar farms in the proposed design each

Plant availability consist of two wings of 1080 solar arrays. Each wing

consists of four streams of 270 x 250W monocrystalline

Load scheduling solar panels. Each stream of 270 panels is connected to give

Sizing of the renewable energy plant components an output voltage of 48-96 volts corresponding with that of

An architecture showing the interconnection of the plant the respective PV inverter rating and the battery bank

components arrangement. Depending on the cost, PV inverters can be

Sensitivity analysis to determine the optimal placement cascaded to feed the grid control inverter and the

of the various renewable plants. connected AC load. The specifications of each solar panel

are shown in the Table 1.

Other relevant information required for this work

include

The diesel generator distribution across theuniversity.

the cost of installing the individual renewable energy

plants.

The daily cost of public utility supply

Table 1: Solar Panel Specification [1]

DESCRIPTION RATING

Rated Maximum Power (PMax) 260 W

Open Circuit Voltage (VOC) 38.4 V

Rated Voltage (Vmpp) 31.4 V

Short Circuit Current (ISC) 8.94A

Rated Current (Impp) 8.37 A

Power Specification at STC 1000W/m2, 25°C

Application Class Class A

B. PV Inverter current of the PV array stream directly into grid compliant

It is a wall-mounted transformer-less inverter with two alternating current and feeds it into the grid and monitoring/

maximum power point (MPP) trackers which converts the control system.

Table 2: PV Inverter specification [1]

DESCRIPTION RATING

Rated Maximum Power (PAC) 500kW

Rated AC output voltage (VAC) 220V

AC voltage output range (VAC, Range ) 180V -280V

Current rating (IAC, @220V) 10.5 kA

Maximum rated current 12.5 kA

Maximum Input DC Voltage 750 V

Operating AC frequency (fAC) 50 Hz

cos Ф 0.84

Fuse Rating 250 A

C. Alternative AC Sources

These will include the diesel generators and the proposed

micro-hydro plant. The diesel generator distribution for the

university main campus and hourly fuel consumption charts

are shown in Table 3, Table 4 and Table 5 below.

IJISRT23NOV2085 www.ijisrt.com 2772

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 3: Diesel Generator Distribution in FUTO with marketvalue and installation cost

LOCATION CAPACITY LOAD SERVED Average Market + Installation

Price

Senate Building 500 kVA Alone N34.67 million

School of 500kVA SAAT, SAAT N34.67 million

Agriculture & Agric. annex, Biochemistry

Technology building, Center for

Nuclear research.

School of Health Technology 35kVA Alone N7.5 million

School of Science (SOSC) 500kVA SOSC building, Physics N34.67 million

building, Lab. Sciences

building.

CIS 500kVA Workshop 2, Workshop 3, N34.67 million

Mech. Engr. Workshop.

Estate & Works 135kVA Est & Works, N11.25 million

Student Affairs Unit.

GEJ Engineering 800kVA SEET, ICT N58.43 million

Complex (SEET) Building

Hostels 800kVA Hostel A-E N58.43 million

Library 275kVA Alone N23.86 million

Petroleum 500kVA Petr. & Chem. Eng. N34.67 million

Engineering Building (PET) building

NDDC Hostel 500kVA NDDC hostel, N34.67 million

Junior Staff quarters.

1000 Capacity Lecture 100kVA Alone N9.2 million

Theatre

FUTO Guest House 45kVA Alone N6.7 million

FUTO Consult 60kVA Futo Consult, N8.1 million

Health Center

University Computer 35kVA UCC, Afrihub N5.57 million

Center (UCC)

PTF Pumping Station 100kVA Alone N7.2 million

Table 4: Average Hourly consumption of diesel generators

LOCATION CAPACITY LOAD FULL-LOAD CONSUMPT

(PF=0.8) SUPPLIED ION PER HOUR (Liters);

Senate Building 500 kVA 400kW 135.125

School of Agriculture & Agric. Tech. 500kVA 400kW 135.125

School of Health Technology 35kVA 28kW 13.06

School of Science (SOSC) 500kVA 400kW 135.125

CIS 500kVA 400 kW 135.125

Estate & Works 135kVA 108 kW 37.073

GEJ Engineering Complex (SEET) 800kVA 640kW 215.37

Hostels 800kVA 640 kW 215.37

Library 275kVA 220kW 75.51

Petroleum Engineering Building (PET) 500kVA 400kW 135.125

NDDC Hostel 500kVA 400kW 135.125

1000 Capacity Lecture Theatre 100kVA 80kW 28.01

FUTO Guest House 45kVA 36kW 15.9

FUTO Consult 60kVA 48kW 18.17

University Computer Center (UCC) 35kVA 28kW 13.06

PTF Pumping Station 100kVA 80kW 28.01

D. The 100 kW micro hydro plant optimize this output for our proposed design. Fig 1 shows

This can be harnessed from the existing Otammiri stream the estimated cost of installing Hydro power plants per kW.

flowing through the university. Although previous studies The plant under consideration is a micro-hydro which falls

have shown that the flow rate of the stream can barely into the kW range of 10-100kW.

support 70kW, recent damming technologies can enable us

IJISRT23NOV2085 www.ijisrt.com 2773

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 1: Estimated cost of installing Hydro power plants per kW [3].

E. Monitoring And Control Components It can also be configured at the consumer end for

These comprise monitoring and control. This can then communicate

Battery inverters (islands): This inverter controls the wirelessly with the controller at the plant end via

electrical energy balance in an off-grid system, in a wireless routers and repeaters.

battery backup system, or in a system for increased self-

consumption. It is wall mounted and uses batteries for Remote Control/display:

the storage of energy. It is responsible for the seamless This component displays parameters like the state of

switching between the PV, alternative AC sources and charge of the battery, indicates how much power is coming

the Battery bank, while maintaining full control on the from the panels and whether the panels are charging the

charging of the battery bank. The AC output from the batteries while supplying the load, or whether the loads are

PV inverter feeds directly into the AC1 terminal of the just being fed from the battery bank. It also shows the power

island while alternative AC sources are fed into the AC2 offset between the batteries and the PV inverter.

slot. Some sensors and communication terminals with

This is also where the symmetry of the panels, the type

other islands also terminate here including an Ethernet

of batteries used for storage, the time of the day, whether the

link for online system monitoring.

monitoring will be done on or off grid, the properties of the

Cluster controller: It is the high performance alternative AC sources, etc can be specified. It also has a

communication hub for the micro grid which

push-button switch from which the island inverters can be

continuously collects all the data from the inverters on

turned on or off.

the system side, thereby keeping real-time information

on the system status. It is equipped with terminations for Sensors: These include Insolation Sensor, Battery

sensors and other devices for remote monitoring. temperature sensor, Ambient Temperature Sensor,

Motion sensor, etc.

It is a multi-functional energy efficient data logger

which offers numerous options for displaying, archiving LAN: This is the communication network with which

and processing data, even in networks with strict the grid communicates. The plant end and consumer end

security regulations. In the event of an ERROR message, each have their components connected via CAT 5E

it is configured to inform the operator immediately by twisted pair LAN cables. The plant and consumer ends

email or text message. It also has USB slots for communicate wirelessly via routers and repeaters. There

memory drives to store the logged data in the event is also room for remote monitoring in case internet

where there is no internet connection. Most of the access is available.

sensors (solar radiation sensor, ambient temperature

sensor, motion sensors, pressure sensors, key card Based on this information, the various capacities of the

sensors, etc) also feed into this device. proposed renewable power plants are shown in Table 5

below:

Table 5: Proposed Hybrid Plant Specifications

PROPOSED PLANT ESTIMATEDCAPACITY

Solar PV (PPV) 1000 kW (2x500)

Micro-Hydro (PHYDRO) 100 kW

Diesel Generator (PDiesel) 5 MW

Battery Bank PBattery 17.83 MWh

IJISRT23NOV2085 www.ijisrt.com 2774

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

VI. METHODOLOGY VII. OPTIMIZATION OF OPERATIONAL COST

As earlier mentioned, the aim for this research border From the cost functions derived from the two cases

on above, the operational cost was summarized into a linear

optimization problem where it was necessary to

A. Determining how much the university spends per kWh at determine the minimum operational cost for the proposed

each point in time for the following reasons: plants tofurnish a load of 4MW for at least 22 hours daily.

To adopt a tariff plan assuming each of the buildings

supplied would have to pay for their energy usage From our scenario, we have a combined renewable

To help the users cut down on their energy usage during plant (PV+ battery + Micro-Hydro) of capacity 1.1MW

peak periods and maximize usage when cost of which is expected to supply for at least 12 hours daily with a

generation is much lower. per kWh cost of N3.30 with availability factor of 0.4 based

on the average sun-hours of the location of our case study.

B. Determining a minimized operational cost for the Also a combined diesel capacity of 5MW is scheduled to

proposed system using the Revised Simplex method supply for at least 6 hours daily when the renewable plant is

The development of this pricing template will look at not available with a per kWh operational cost of N41 and

two (2) cases as derived from the load schedule from both availability factor of 0.7.

plant and consumer-side:

Case 1: Running purely on diesel generators for 24 hours Hence our optimization problem becomes Minimize C=

for the smooth running of university activities 3.3x + 41y

Case 2: Installing a 1MW solar plant and a 100 kW Subject to the constraints1.1x + 5y ≥ 4

micro-hydro plant and running solely on it. 12x + 6y ≥ 22

0.4x + 0.75y ≥ 1

Case 1 x≥0; y≥0

From the information on Tables 3, 4 and 5, assuming the

diesel generators supply the only power to the university, where x = renewable plant function;y=diesel function

the cost of supplying the installed load purely on diesel

Using the dual problem solution to revert the

will be N41.07/kWh

minimization problem into a maximization problem, our

Case 2: initial tableau becomes

When two 500kW solar farms and a 100kW

microhydro plant are used, The cost per kWh will be

N3.30/kWh

Table 6: Initial feasible solution of Cost minimization

Basic variable P s t u x y RHS

P 1 -4 -22 -1 0 0 0

a 0 1.1 12 0.4 1 0 3.3

b 0 5 6 0.75 0 1 41

P is our new objective function in the dual solution;

s, t, u are our new non-basic variables and a and b are our slack variables.

Table 7: Revised Simplex tableau after first iteration

Basic variable P s t u x y RHS

P 1 -1.98 0 -0.274 1.826 0 6.05

x 0 0.092 1 0.033 0.083 0 0.275

y 0 4.45 0 0.55 -0.5 1 39.35

Table 8: Revised Simplex tableau after the 2nd iteration,

Basic variable P s t u x y RHS

P 1 0 21.48 0.44 11.626 0 11.96

x 0 1 10.87 0.04 0.902 0 2.99

y 0 0 -48.37 0.39 -4.51 1 26.04

The dual method gives the same value for C and P. VIII. RETURN ON INVESTMENT

Hence our optimal cost of operation C will be N11.96/kWh

when the cost of renewable and diesel components are The return on investment can be calculated by

N2.99 and N26.04 respectively. accumulating the daily monetary savings per kW over a

period of time. Using the optimized operational cost,

IJISRT23NOV2085 www.ijisrt.com 2775

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Total daily savings is

N11.96/kWh/day x 4000kW x 24h = N1,148,160/day

The total investment on 2 x 500kW solar farm and a

100kWmicrohydro is N935,267,000

Dividing the daily savings per kW the investments

will give the number of days after which we will break even.

i.e N935267000/ (N1148160/day) = 814 days 14 hours

≈ 2 years, 2 months, 22 days and 14 hours after

commissioning

IX. CONCLUSION & RECOMMENDATION

Based on the above data and cases studied,

It is possible to know the optimal running costs and

savings

The possible return on investment while implementing

either of the renewable energy options was a little over 2

years

A benchmark for tariff structure development based on

the optimal operational cost for scenarios where

individual buildings may take financial responsibility for

their energy consumption such as to optimize profit.

The use of more accurate optimization methods should

be is recommended while considering more practicable

factors and for better results.

REFERENCES

[1]. Joe-Uzuegbu C.K - Design Of A Smart Micro-Grid

Using Hybrid Renewable Energy Resources; PhD

Thesis (2018)

[2]. K.M. Ravi Eswar - Smart Grid-Future for Electrical

Systems; International Journal of Electrical and

Electronics Research ISSN 2348-6988 (online) Vol. 3,

Issue 2, pp: (603- 612), Month: April - June 2015.

[3]. www.renewablesfirst.co.uk

IJISRT23NOV2085 www.ijisrt.com 2776

You might also like

- 1 s2.0 S2214785320368917 MainDocument7 pages1 s2.0 S2214785320368917 MainSheref ElbheryNo ratings yet

- Enhancement of Power of A Hybrid System Using Super CapacitorDocument10 pagesEnhancement of Power of A Hybrid System Using Super CapacitorIJRASETPublicationsNo ratings yet

- Development of A Smart Solar Energy ManaDocument5 pagesDevelopment of A Smart Solar Energy ManaCyber Gates Communication NetworkNo ratings yet

- A Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsDocument4 pagesA Power Electronic Smart Load Controller For Nanogrids and Autonomous Power SystemsjorgeNo ratings yet

- The Electricity Security in Nigeria: Design and Analysis of 750-kV Mega GridDocument12 pagesThe Electricity Security in Nigeria: Design and Analysis of 750-kV Mega GridjitendraNo ratings yet

- Verschueren 2011Document6 pagesVerschueren 2011Simo MilenkovićNo ratings yet

- Comparative Study of Electricity Production Cost of Renewable Energy Power Plants Case of Photovoltaic Plant and Biogas Generators Power Plant in Sahel AreaDocument10 pagesComparative Study of Electricity Production Cost of Renewable Energy Power Plants Case of Photovoltaic Plant and Biogas Generators Power Plant in Sahel AreaEditor IJTSRDNo ratings yet

- Reliability Investigation and Evaluation of Off-Grid Solar Photovoltaic (PV) Power SystemDocument16 pagesReliability Investigation and Evaluation of Off-Grid Solar Photovoltaic (PV) Power SystemAwoyinka Tunde DareNo ratings yet

- A Review On Simulation of Hybrid Microgrid System With Renewable Energy SourcesDocument10 pagesA Review On Simulation of Hybrid Microgrid System With Renewable Energy SourcesIJRASETPublicationsNo ratings yet

- LVDC Microgrid Perspective For A High E Ciency Distribution SystemDocument8 pagesLVDC Microgrid Perspective For A High E Ciency Distribution SystemJose CabusNo ratings yet

- Development and Evaluation of Fuel-Less Power GeneratorDocument5 pagesDevelopment and Evaluation of Fuel-Less Power GeneratorVoundai MahamatNo ratings yet

- Economic Feasibility Analysis of On-Grid PV System Without Battery Storage For A Commercial Building in Karachi, Pakistan PDFDocument4 pagesEconomic Feasibility Analysis of On-Grid PV System Without Battery Storage For A Commercial Building in Karachi, Pakistan PDFRuna Kabir PinkyNo ratings yet

- Grid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewDocument18 pagesGrid Integration of Small-Scale Photovoltaic Systems in Secondary Distribution Network-A ReviewroyNo ratings yet

- 36 PVplant Modeling GorganDocument7 pages36 PVplant Modeling Gorganvinsen letsoinNo ratings yet

- Industrial Power Assignment (2) (LO3+LO4) (2nd 2023-2024)Document34 pagesIndustrial Power Assignment (2) (LO3+LO4) (2nd 2023-2024)m2277moudNo ratings yet

- Power-Electronic Systems For The Grid Integration of Renewable Energy Sources A SurveyDocument15 pagesPower-Electronic Systems For The Grid Integration of Renewable Energy Sources A SurveyEsperance KAMPIRENo ratings yet

- Installation and Commissioning of A 100 KW Rooftop Solar PV Power PlantDocument5 pagesInstallation and Commissioning of A 100 KW Rooftop Solar PV Power PlantVasu GamiNo ratings yet

- A Power Saving Opportunity DC Power Distribution SystemDocument7 pagesA Power Saving Opportunity DC Power Distribution Systemsantiago nava perezNo ratings yet

- Cutting Campus Energy Costs With Hierarchical ControlDocument17 pagesCutting Campus Energy Costs With Hierarchical Controlomar hamidNo ratings yet

- Generation Capacity Design For A Microgrid For Measurable Power Quality IndexesDocument6 pagesGeneration Capacity Design For A Microgrid For Measurable Power Quality IndexesJitender KaushalNo ratings yet

- 1500 VDCPVpowerplantarchitectureDocument12 pages1500 VDCPVpowerplantarchitectureAmany HamdyNo ratings yet

- Control of Solar Powered Micro-Grids Using Electric VehiclesDocument7 pagesControl of Solar Powered Micro-Grids Using Electric Vehiclescarlos cervantesNo ratings yet

- Ijaerv13n24 38Document9 pagesIjaerv13n24 38tran duyNo ratings yet

- Ijisrt21oct009 PDFDocument32 pagesIjisrt21oct009 PDFwy9frghd7dNo ratings yet

- Impact of Electric Vehicles On Power Distribution NetworksDocument6 pagesImpact of Electric Vehicles On Power Distribution Networksscepo vujicNo ratings yet

- Design and Implementation of A 30KVA Hybrid Inverter Solar and Utility SupplyDocument6 pagesDesign and Implementation of A 30KVA Hybrid Inverter Solar and Utility SupplyEditor IJTSRDNo ratings yet

- Analysis of Output DC Current Injection in 100kW Grid Connected VACON 8000 Solar InverterDocument4 pagesAnalysis of Output DC Current Injection in 100kW Grid Connected VACON 8000 Solar InverteriaetsdiaetsdNo ratings yet

- Mohammed 2019Document6 pagesMohammed 2019RAMESH KHARADNo ratings yet

- Carrasco2006 PDFDocument15 pagesCarrasco2006 PDFAmiir AmirNo ratings yet

- Journal Idoniboyeobu Udoha 2018 MarchDocument17 pagesJournal Idoniboyeobu Udoha 2018 MarchSyakira WahidaNo ratings yet

- Power Electronicsfor Renewable Energy Systems Statusand TrendsDocument11 pagesPower Electronicsfor Renewable Energy Systems Statusand TrendsKHALIQ AHMEDNo ratings yet

- A Comprehensive Review On Distributed Power GenerationDocument5 pagesA Comprehensive Review On Distributed Power GenerationCésar Díaz LiberonaNo ratings yet

- Energy Management and Power Quality Improvement ofDocument15 pagesEnergy Management and Power Quality Improvement ofSamuel BhukyaNo ratings yet

- Analysis of The OV System Sizing and Economic FeasibilityDocument10 pagesAnalysis of The OV System Sizing and Economic FeasibilitysriNo ratings yet

- Main Project Phone ChargingDocument23 pagesMain Project Phone Chargingyoghisagar293No ratings yet

- Control of Distributed Generation Systems For Microgrid Applications A Technological ReviewDocument26 pagesControl of Distributed Generation Systems For Microgrid Applications A Technological ReviewRaghavendra LakshmanNo ratings yet

- Irjet V5i520Document5 pagesIrjet V5i520baby hNo ratings yet

- Hybrid Solar PV and WECS Power Quality Improvement by STATCOMDocument7 pagesHybrid Solar PV and WECS Power Quality Improvement by STATCOMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Construction of A 0.75KVA Inverter Power Supply For Nigerian Homes and OfficesDocument5 pagesDesign and Construction of A 0.75KVA Inverter Power Supply For Nigerian Homes and OfficesEditor IJTSRDNo ratings yet

- Efficient Charging of Battery and Production of PowerDocument7 pagesEfficient Charging of Battery and Production of Powermohan venkatNo ratings yet

- Hybrid Solar-Wind Charging Station For Electric Vehicles and Its SimulationDocument9 pagesHybrid Solar-Wind Charging Station For Electric Vehicles and Its SimulationIJRASETPublicationsNo ratings yet

- Jeas 0422 89Document10 pagesJeas 0422 89Shubham PrajapatiNo ratings yet

- A New Proposal To Solar and Grid-Connected Hybrid Electricity For Homes and Building in MalaysiaDocument4 pagesA New Proposal To Solar and Grid-Connected Hybrid Electricity For Homes and Building in MalaysiaSelamat Meliala, S.T.,MT Selamat Meliala, S.T.,MTNo ratings yet

- Effectual P and O Perturb and Observe Algorithm Based MPPT Control For Islanded Micro GridDocument11 pagesEffectual P and O Perturb and Observe Algorithm Based MPPT Control For Islanded Micro GridEditor IJTSRDNo ratings yet

- Designand Constructionof 5 KVASolar Power Inverter SystemDocument5 pagesDesignand Constructionof 5 KVASolar Power Inverter Systemsambostephen414No ratings yet

- HE 12883 MMolinaDocument6 pagesHE 12883 MMolinaMarcelo MolinaNo ratings yet

- Review On Power Quality of Hybrid Renewable Energy SystemDocument7 pagesReview On Power Quality of Hybrid Renewable Energy SystemIJRASETPublicationsNo ratings yet

- 08442403Document5 pages08442403Petrescu VasyNo ratings yet

- Piezoelectric Energy Harvesting For Self-Powered Wearable Upper Limb ApplicationsDocument21 pagesPiezoelectric Energy Harvesting For Self-Powered Wearable Upper Limb ApplicationsEdwinNo ratings yet

- Detailed Project Report (DPR) For 2.7 MW Power Plant Burjesia Area (Basra, Iraq)Document24 pagesDetailed Project Report (DPR) For 2.7 MW Power Plant Burjesia Area (Basra, Iraq)hardikNo ratings yet

- Design and Implementation of Three Phase Solar PV Integrated UPQC Based On Artificial Neural NetworksDocument7 pagesDesign and Implementation of Three Phase Solar PV Integrated UPQC Based On Artificial Neural NetworksIJRASETPublicationsNo ratings yet

- Ijesit201506 06Document12 pagesIjesit201506 06Jacob DavidNo ratings yet

- Grid and Solar Photovoltaic Sources Assisted Charging System For Electric VehiclesDocument12 pagesGrid and Solar Photovoltaic Sources Assisted Charging System For Electric VehiclesIJRASETPublicationsNo ratings yet

- Evaluation of Net Metering For Solar Rooftop SystemsDocument7 pagesEvaluation of Net Metering For Solar Rooftop SystemsIJRASETPublicationsNo ratings yet

- Feasibility Analysis of Stand-Alone Renewable Energy Supply For Telecommunication Tower Using HomerDocument6 pagesFeasibility Analysis of Stand-Alone Renewable Energy Supply For Telecommunication Tower Using Homerjuan ceronNo ratings yet

- Electronics 10 00088 v2Document17 pagesElectronics 10 00088 v2Pio_ChronicleNo ratings yet

- Microgrids Distributed Power GenerationDocument4 pagesMicrogrids Distributed Power GenerationBasilNo ratings yet

- 14 Load-Management - Energy-Economics - And-Environmental-Protection-Nex - 2023 - EneDocument16 pages14 Load-Management - Energy-Economics - And-Environmental-Protection-Nex - 2023 - EneMohammad Ashifur RahmanNo ratings yet

- Development of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersDocument5 pagesDevelopment of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersHariprasad RNo ratings yet

- AI Robots in Various SectorDocument3 pagesAI Robots in Various SectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyDocument6 pagesMSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Prevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyDocument4 pagesPrevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)Document7 pagesAn Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Geotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioDocument10 pagesGeotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Occupational Injuries among Health Care Workers in Selected Hospitals in Ogbomosho, Oyo StateDocument6 pagesOccupational Injuries among Health Care Workers in Selected Hospitals in Ogbomosho, Oyo StateInternational Journal of Innovative Science and Research Technology100% (1)

- Intrusion Detection and Prevention Systems for Ad-Hoc NetworksDocument8 pagesIntrusion Detection and Prevention Systems for Ad-Hoc NetworksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyDocument8 pagesNurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Innovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piDocument8 pagesInnovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemDocument6 pagesFuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Importance of Early Intervention of Traumatic Cataract in ChildrenDocument5 pagesImportance of Early Intervention of Traumatic Cataract in ChildrenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnDocument3 pagesDynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoDocument7 pagesIntegration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachDocument16 pagesThe Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparison of JavaScript Frontend Frameworks - Angular, React, and VueDocument8 pagesComparison of JavaScript Frontend Frameworks - Angular, React, and VueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportDocument4 pagesDiode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionDocument9 pagesAnalysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Breaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsDocument14 pagesBreaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Occupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonDocument11 pagesOccupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsDocument6 pagesA Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Total Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationDocument11 pagesTotal Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Organizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaDocument10 pagesOrganizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Influence of Artificial Intelligence On Employment Trends in The United States (US)Document5 pagesThe Influence of Artificial Intelligence On Employment Trends in The United States (US)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Pecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesDocument4 pagesPecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Classifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningDocument8 pagesClassifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Disseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsDocument15 pagesDisseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gender-Based Violence: Engaging Children in The SolutionDocument10 pagesGender-Based Violence: Engaging Children in The SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersDocument10 pagesMediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaDocument19 pagesThe Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingDocument8 pagesIntegrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Manual Operation LoadBankDocument23 pagesManual Operation LoadBankbuhari adnan100% (1)

- 75 kVA Specification SheetDocument2 pages75 kVA Specification SheetAlex MohanNo ratings yet

- PPLNTDocument3 pagesPPLNT2003217No ratings yet

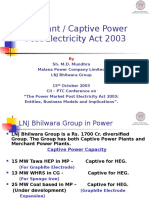

- M D Mundhra - Malana PowerDocument17 pagesM D Mundhra - Malana PowerrobinNo ratings yet

- Electrical Thumb Rules You MUST Follow (Part 1) - EEPDocument6 pagesElectrical Thumb Rules You MUST Follow (Part 1) - EEPGiri BabuNo ratings yet

- AGCDocument13 pagesAGCgauravpratapranaNo ratings yet

- 48V DC Power Systems: FeaturesDocument2 pages48V DC Power Systems: FeaturesAftab AliNo ratings yet

- Electricity Storage and RE For Island PowerDocument48 pagesElectricity Storage and RE For Island PowerFabiana ChusitNo ratings yet

- Day 17Document7 pagesDay 17Rapha MontereyNo ratings yet

- Design and Modelling of Multilevel Power Inverter: Presented byDocument27 pagesDesign and Modelling of Multilevel Power Inverter: Presented byPunit RatnaniNo ratings yet

- Fault Characteristics in Electrical EquipmentDocument6 pagesFault Characteristics in Electrical Equipmenthanner90No ratings yet

- Three-Phase Bridge Rectifiers (B6)Document15 pagesThree-Phase Bridge Rectifiers (B6)Nuke-Comm LeakageNo ratings yet

- Isochronous Vs Droop Control For GeneratorsDocument4 pagesIsochronous Vs Droop Control For GeneratorsVannex Mensidor100% (1)

- Ieee Power Electronics Project Titles 2013-2014Document5 pagesIeee Power Electronics Project Titles 2013-2014onepointerNo ratings yet

- Premier Magnetics IncDocument2 pagesPremier Magnetics IncMile ĐorđevićNo ratings yet

- Work Power EnergyDocument72 pagesWork Power EnergyBuela, Lance GabrielNo ratings yet

- EPAS 11 - Q1 - W5-W6 - Mod4Document29 pagesEPAS 11 - Q1 - W5-W6 - Mod4Alberto A. FugenNo ratings yet

- SPPG+How+to+Apply+for+Electricity+Connection Sep+2016Document138 pagesSPPG+How+to+Apply+for+Electricity+Connection Sep+2016Shaiful ShazwanNo ratings yet

- Circuit Diagram 4164 5022103Document115 pagesCircuit Diagram 4164 5022103p.rustika8905No ratings yet

- BC Hydro FoisDocument141 pagesBC Hydro FoisBob MackinNo ratings yet

- Social Infra-Power Distribution: 132/33KV Substation 132/33KV SubstationDocument1 pageSocial Infra-Power Distribution: 132/33KV Substation 132/33KV SubstationGanesh GhodakeNo ratings yet

- Project No. Electrical Maximum Demand Existing ConditionsDocument3 pagesProject No. Electrical Maximum Demand Existing ConditionsNicholas100% (1)

- Online Certification Program: Installation & Working of Solar Power PlantsDocument5 pagesOnline Certification Program: Installation & Working of Solar Power PlantsSarath Chandra VNo ratings yet

- Tansmission Standard IndexDocument8 pagesTansmission Standard IndexAhmed FathyNo ratings yet

- 1SCC303003C0201 Change-Over and Transfer SwitchesDocument92 pages1SCC303003C0201 Change-Over and Transfer SwitchesDwiyustiawan VeryNo ratings yet

- 3VM11404ED320AA0 Datasheet enDocument5 pages3VM11404ED320AA0 Datasheet enomarqasimNo ratings yet

- Grafana Profile ReviewedDocument27 pagesGrafana Profile ReviewedTosin GeorgeNo ratings yet

- Induced Sheath Voltages in 110 KV Power Cables - Case StudyDocument10 pagesInduced Sheath Voltages in 110 KV Power Cables - Case StudyrajimuruganNo ratings yet

- PP904PHEDocument7 pagesPP904PHEKopi143No ratings yet

- Otis Regenerative DrivesDocument2 pagesOtis Regenerative Drivestan0314No ratings yet