Professional Documents

Culture Documents

CFM Doc Leap 1B Co Fda 3 V2

CFM Doc Leap 1B Co Fda 3 V2

Uploaded by

Paulo SanzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFM Doc Leap 1B Co Fda 3 V2

CFM Doc Leap 1B Co Fda 3 V2

Uploaded by

Paulo SanzCopyright:

Available Formats

COURSE OUTLINE

LEAP-1B

FDA

v2.0 JUL 2019

Level 3

THIS PAGE INTENTIONALLY LEFT BLANK

v2.0 JUL 2019

CTC- 623 – Level 3

Course Outline LEAP-1B

TABLE OF CONTENTS

CONVERSION TABLE ................................................ 4

GLOSSARY .................................................................5

For Training Purposes Only JUL 2019

CFM Proprietary Information Page 3

Course Outline LEAP-1B

CONVERSION TABLE

IMPERIAL / METRIC CONVERSIONS

1 mile = 1,609 km

1 ft = 30,48 cm

1 in. = 25,4 mm

1 mil. = 25,4 μ

1 sq.in. = 6,4516 cm²

1 USG = 3,785 l (dm³)

1 cu.in. = 16.39 cm³

1 lb. = 0.454 kg

1 psi. = 6.890 kPa

°F = 1.8 x °C + 32

METRIC / IMPERIAL CONVERSIONS

1 km = 0.621 mile

1m = 3.281 ft. or 39.37 in.

1 cm = 0.3937 in.

1 mm = 39.37 mils.

1 m² = 10.76 sq. ft.

1 cm² = 0.155 sq.in.

1 m³ = 35.31 cu. ft.

1 dm³ = 0.264 USA gallon

1 cm³ = 0.061 cu.in.

1 kg = 2.205 lbs

1 Pa = 1.45 10-4 psi.

1 kPa = 0.145 psi

1 bar = 14.5 psi

°C = ( °F - 32 ) /1.8

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 4

Course Outline LEAP-1B

GLOSSARY

ABBREVIATIONS MEANING DEFINITION

(E)EPROM (ELECTRICALLY) ERASABLE PROGRAMMABLE READ ONLY MEMORY

A/C AIRCRAFT

A/P AIRPLANE

A/T AUTOTHROTTLE

AC ALTERNATING CURRENT

ACARS AIRCRAFT COMMUNICATION ADRESSING REPORTING SYSTEM

ACAU AIR CONDITIONING ACCESSORY UNIT

ACMS AIRCRAFT CONDITION MONITORING SYSTEM

ACS AIRCRAFT CONTROL SYSTEM

AD AIRWORTHINESS DIRECTIVE

ADC AIR DATA COMPUTER

ADEPT AIRLINE DATA ENGINE PERFORMANCE TREND

ADIRS AIR DATA AND INERTIAL REFERENCE SYSTEM

ADIRU AIR DATA INERTIAL REFERENCE UNIT

ADV ADVISORY

AEMTC CFM CUSTOMER TRAINING CENTER (CHINA)

AFS AUTO FLIGHT SYSTEM

AGB ACCESSORY GEARBOX

AIDS AIRCRAFT INTEGRATED DATA SYSTEM

ALF AFT LOOKING FORWARD

ALT ALTITUDE

ALTN ALTERNATE

ALV ANTI LEAKING VALVE

AMB AMBIANT

AMM AIRCRAFT MAINTENANCE MANUAL

AOG AIRCRAFT ON GROUND

APR AUTOMATIC POWER RESERVE

APU AUXILIARY POWER UNIT

ARINC AERONAUTICAL RADIO INC. (SPECIFICATION)

ASM AUTOTHROTTLE SERVO MECHANISM

ATA AIR TRANSPORT ASSOCIATION

ATC AUTOTHROTTLE COMPUTER

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 5

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

ATHR AUTO THRUST

ATO ABORTED TAKE-OFF

ATS AIR TURBINE STARTER (VALVE)

AVM AIRCRAFT VIBRATION MONITORING

BAI BOOSTER ANTI-ICING

BITE BUILT-IN-TEST EQUIPMENT

BMC BLEED MANAGEMENT COMPUTER

BPRV BLEED PRESSURE REGULATING VALVE

BSI BORESCOPE INSPECTION

BSV BURNER STAGING VALVE (SAC)

BSV BURNER SELECTION VALVE (DAC)

BVCS BLEED VALVE CONTROL SOLENOID

C CELSIUS OR CENTIGRADE

CAS CALIBRATED AIR SPEED

CBP (HP) COMPRESSOR BLEED PRESSURE

CCDL CROSS CHANNEL DATA LINK

CCFG COMPACT CONSTANT FREQUENCY GENERATOR

CCT CORE COMPARTMENT TEMPERATURE

CCU COMPUTER CONTROL UNIT

CCW COUNTER CLOCKWISE

CDN COMBUSTOR DIFFUSER NOZZLE

CDP (HP) COMPRESSOR DISCHARGE PRESSURE

CDS COMMON DISPLAY SYSTEM

CDU CONTROL DISPLAY UNIT

CFDIU CENTRALIZED FAULT DISPLAY INTERFACE UNIT

CFDS CENTRALIZED FAULT DISPLAY SYSTEM

CFMAESSA CFM CUSTOMER TRAINING CENTER (INDIA)

CFMI JOINT GE/SNECMA COMPANY (CFM INTERNATIONAL)

CG CENTRE OF GRAVITY

Ch A CHANNEL A

Ch B CHANNEL B

CHATV CHANNEL ACTIVE

CIP(HP) COMPRESSOR INLET PRESSURE

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 6

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

CIT(HP) COMPRESSOR INLET TEMPERATURE

CLP COWL LOST PREVENTION

cm.g CENTIMETER x GRAMS

CMC CENTRALIZED MAINTENANCE COMPUTER

CMM COMPONENT MAINTENANCE MANUAL

CMS CENTRALIZED MAINTENANCE SYSTEM

CODEP HIGH TEMPERATURE COATING

CONT CONTINUOUS

CPU CENTRAL PROCESSING UNIT

CRT CATHODE RAY TUBE

CRTG CARTDRIGE

CSD CONSTANT SPEED DRIVE

CSI CYCLES SINCE INSTALLATION

CSN CYCLES SINCE NEW

CTAI COWL THERMAL ANTI-ICING

CTC CFM CUSTOMER TRAINING CENTER (FRANCE)

CTEC CFM CUSTOMER TECHNICAL EDUCATION CENTER (USA)

CTL CONTROL

Cu.Ni.In COPPER.NICKEL.INDIUM

CVT CENTER VENTILATION TUBE

CW CLOCKWISE

DC DELAY CANCELLATION

DAC DOUBLE ANNULAR COMBUSTOR

DAMV DOUBLE ANNULAR MODULATED VALVE

DAR DIGITAL ACMS RECORDER

DC DIRECT CURRENT

DCU DATA CON UNIT

DCV DIRECTIONAL CONTROL VALVE (BOEING)

DEU DISPLAY ELECTRONIC UNIT

DFCS DIGITAL FLIGHT CONTROL SYSTEM

DFDAU DIGITAL FLIGHT ACQUISITION UNIT

DFDRS DIGITAL FLIGHT DATA RECORDING SYSTEM

DISC DISCRETE

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 7

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

DIU DIGITAL INTERFACE UNIT

DMC DISPLAY MANAGEMENT COMPUTER

DMD DEMAND

DMS DEBRIS MONITORING SYSTEM

DMU DATA MANAGEMENT UNIT

DOD DOMESTIC OBJECT DAMAGE

DPM DEBRIS PARTICLE MONITORING

DPU DIGITAL PROCESSING MODULE

DRT DE-RATED TAKE-OFF

EAU ENGINE ACCESSORY UNIT

EBU ENGINE BUILDUP UNIT

ECA ELECTRICAL CHASSIS ASSEMBLY

ECAM ELECTRONIC CENTRALIZED AIRCRAFT MONITORING

ECS ENVIRONMENTAL CONTROL SYSTEM

ECU ELECTRONIC CONTROL UNIT (AIRBUS)

EDP ENGINE DRIVEN PUMP

EE ELECTRONIC EQUIPMENT

EEC ELECTRONIC ENGINE CONTROL (BOEING)

EFH ENGINE FLIGHT HOURS

EFIS ELECTRONIC FLIGHT INSTRUMENT SYSTEM

EGT EXHAUST GAS TEMPERATURE

EHSV ELECTRO HYDRAULIC SERVO VALVE

EICAS ENGINE INDICATING AND CREW ALERTING SYSTEM

EIS ENTRY INTO SERVICE

EIU ENGINE INTERFACE UNIT

EIVMU ENGINE INTERFACE AND VIBRATION MONITORING UNIT

EMF ELECTROMOTIVE FORCE

EMI ELECTRO MAGNETIC INTERFERENCE

EMU ENGINE MAINTENANCE UNIT

EPS ENGINE POWER SUPPLY

ESN ENGINE SERIAL NUMBER

ETL ELECTRICAL TERTIARY LOCK

ETOPS EXTENDED TWIN OPERATION SYSTEMS

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 8

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

EVMU ENGINE VIBRATION MONITORING UNIT

EWD/SD ENGINE WARNING DISPLAY / SYSTEM DISPLAY

F FARENHEIT

F/B FEEDBACK

FAA FEDERAL AVIATION ADMINISTRATION

FADEC FULL AUTHORITY DIGITAL ENGINE CONTROL

FAR FUEL/AIR RATIO

FAV FAN AIR VALVE

FCC FLIGHT CONTROL COMPUTER

FCD FAN COWL DOOR

FCU FLIGHT CONTROL UNIT

FCV FUEL CONTROL VALVE

FDA FAULT DETECTION ANNUNCIATION

FDAMS FLIGHT DATA ACQUISITION MANAGEMENT SYSTEM

FDIU FLIGHT DATA INTERFACE UNIT

FDRS FLIGHT DATA RECORDING SYSTEM

FDU FIRE DETECTION UNIT

FEIM FIELD ENGINEERING INVESTIGATION MEMO

FF FUEL FLOW

FFCCV FAN FRAME/COMPRESSOR CASE VERTICAL (VIBRATION SENSOR)

FHA FUNCTIONAL HAZARD ASSESSMENT

FI FLIGHT IDLE (F/I)

FIM FAULT ISOLATION MANUAL

FIN FUNCTIONAL ITEM NUMBER

FIT FAN INLET TEMPERATURE

FLA FORWARD LOOKING AFT

FLSCU FUEL LEVEL SENSING CONTROL UNIT

FLX TO FLEXIBLE TAKE-OFF

FMC FLIGHT MANAGEMENT COMPUTER

FMCS FLIGHT MANAGEMENT COMPUTER SYSTEM

FMGC FLIGHT MANAGEMENT AND GUIDANCE COMPUTER

FMGEC FLIGHT MANAGEMENT AND GUIDANCE ENVELOPE COMPUTER

FMS FLIGHT MANAGEMENT SYSTEM

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 9

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

FMU FUEL METERING UNIT

FMV FUEL METERING VALVE

FN FUEL NOZZLE

FOD FOREIGN OBJECT DAMAGE

FPA FRONT PANEL ASSEMBLY

FPI FLUORESCENT PENETRANT INSPECTION

FQIS FUEL QUANTITY INDICATING SYSTEM

FRV FUEL RETURN VALVE

FSDP FUEL STRAINER DELTA PRESSURE

FTA FAULT TREE ANALYSIS

FWC FAULT WARNING COMPUTER

FWD FORWARD

g.in GRAM(S) x INCH

GE GENERAL ELECTRIC

GEAE GENERAL ELECTRIC AIRCRAFT ENGINES

GEM GROUND-BASED ENGINE MONITORING

GI GROUND IDLE (G/I)

GMM GROUND MAINTENANCE MODE

GMT GREENWICH MEAN TIME

GND GROUND

GPH GALLONS PER HOUR

GPU GROUND POWER UNIT

GSE GROUND SUPPORT EQUIPMENT

HCF HIGH CYCLE FATIGUE

HCU HYDRAULIC CONTROL UNIT

HDS HORIZONTAL DRIVE SHAFT

HMU HYDROMECHANICAL UNIT

HOR HOLD-OPEN ROD

HP HIGH PRESSURE

HPC HIGH PRESSURE COMPRESSOR

HPCR HIGH PRESSURE COMPRESSOR ROTOR

HPRV HIGH PRESSURE REGULATING VALVE

HPSOV HIGH PRESSURE SHUT-OFF VALVE

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 10

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

HPT HIGH PRESSURE TURBINE

HPT(A)CC HIGH PRESSURE TURBINE (ACTIVE) CLEARANCE CONTROL

HPTC HIGH PRESSURE TURBINE CLEARANCE

HPTCCV HIGH PRESSURE TURBINE CLEARANCE CONTROL VALVE

HPTN HIGH PRESSURE TURBINE NOZZLE

HPTR HIGH PRESSURE TURBINE ROTOR

Hz HERTZ (CYCLES PER SECOND)

I/O INPUT/OUTPUT

IAS INDICATED AIR SPEED

ICU ISOLATION CONTROL UNIT

ID INSIDE DIAMETER

ID PLUG IDENTIFICATION PLUG

IDG INTEGRATED DRIVE GENERATOR

IFS INNER FIXED STRUCTURE

IFSD IN-FLIGHT SHUT DOWN

IFTB IN FLIGHT TURN BACK

IGB INLET GEARBOX

IGN IGNITION

IGV INLET GUIDE VANE

in. INCH(ES)

IOM INPUT OUTPUT MODULE

IPB ILLUSTRATED PARTS BREAKDOWN

IPC ILLUSTRATED PARTS CATALOG

IPCV INTERMEDIATE PRESSURE CHECK VALVE

IPS INCHES PER SECOND

IR INFRA RED

IV THRUST REVERSER ISOLATION VALVE

k x 1000

K KELVIN

kg/h KILOGRAMS PER HOUR

KIAS INDICATED AIR SPEED IN KNOTS

kV KILOVOLTS

L LEFT

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 11

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

L/H LEFT HAND

lbs. POUNDS, WEIGHT

LCD LIQUID CRYSTAL DISPLAY

LCF LOW CYCLE FATIGUE

LE (L/E) LEADING EDGE

LG LANDING GEAR

LGCIU LANDING GEAR CONTROL INTERFACE UNIT

LLP LIFE-LIMITED PARTS

Loil OIL LEVEL

LOTC LOSS OF THRUST CONTROL

LP LOW PRESSURE

LPC LOW PRESSURE COMPRESSOR

LPT LOW PRESSURE TURBINE

LPT(A)CC LOW PRESSURE TURBINE (ACTIVE) CLEARANCE CONTROL

LPTC LOW PRESSURE TURBINE CLEARANCE

LPTN LOW PRESSURE TURBINE NOZZLE

LPTR LOW PRESSURE TURBINE ROTOR

LRU LINE REPLACEABLE UNIT

LU LUBRICATION UNIT

LVDT LINEAR VARIABLE DIFFERENTIAL TRANSDUCER

mA MILLIAMPERES (CURRENT)

MCD MAGNETIC CHIP DETECTOR

MULTIPURPOSE CONTROL AND DISPLAY UNIT or MULTI-FUNCTION

MCDU

CONTROL AND DISPLAY UNIT

MCL MAXIMUM CLIMB

MCR MAXIMUM CRUISE

MCT MAXIMUM CONTINUOUS

MDDU MULTIPURPOSE DISK DRIVE UNIT

MEC MAIN ENGINE CONTROL

MFP MAIN FUEL PUMP

mils D.A. Mils DOUBLE AMPLITUDE

mm MILLIMETERS

Mm MINOR MODULE

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 12

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

MM MAJOR MODULE

MMEL MAIN MINIMUM EQUIPMENT LIST

MO AIRCRAFT SPEED MACH NUMBER

MPA MAXIMUM POWER ASSURANCE

MPH MILES PER HOUR

MTBF MEAN TIME BETWEEN FAILURES

MTBR MEAN TIME BETWEEN REMOVALS

MTC MODULATED TURBINE COOLING

mV MILLIVOLTS

mVDC MILLIVOLTS DIRECT CURRENT

N/C NORMALLY CLOSED

N/O NORMALLY OPENED

N1 (NL) LOW PRESSURE ROTOR ROTATIONAL SPEED

N1* DESIRED N1

N1ACT ACTUAL N1

N1CMD COMMANDED N1

N1DMD DEMANDED N1

N1K CORRECTED FAN SPEED

N1TARGET TARGETED FAN SPEED

N2 (NH) HIGH PRESSURE ROTOR ROTATIONNAL SPEED

N2* DESIRED N2

N2ACT ACTUAL N2

N2K CORRECTED CORE SPEED

NAC NACELLE

NAI NACELLE ANTI-ICE

NVM NON VOLATILE MEMORY

OAT OUTSIDE AIR TEMPERATURE

OD OUTLET DIAMETER

ODMS OIL DEBRIS MONITORING SYSTEM

OFDPS OIL FILTER DELTA PRESSURE SENSOR

OFS OIL FILTER SENSOR

OGV OUTLET GUIDE VANE

OLS OIL LEVEL SENSOR

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 13

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

OPTS OIL PRESSURE TEMPERATURE SENSOR

OPV OVERPRESSURE VALVE

OSG OVERSPEED GOVERNOR

OVBD OVERBOARD

OVHT OVERHEAT

P/B PUSH BUTTON

P/N PART NUMBER

P/T25 HP COMPRESSURE INLET TOTAL AIR PRESSURE/TEMPERATURE

P0 AMBIENT STATIC PRESSURE

P25 HP COMPRESSURE INLET TOTAL AIR PRESSURE

PAS PNEUMATIC AIR STARTER

Pb BYPASS PRESSURE

Pc REGULATED SERVO PRESSURE

Pcr CASE REGULATED PRESSURE

PCU PRESSURE CONVERTER UNIT

PDL PORTABLE DATA LOADER

Pf (CFM56-7B) HEATED SERVO PRESSURE

PLA POWER LEVER ANGLE

PMA PERMANENT MAGNETIC ALTERNATOR

PMC POWER MANAGEMENT CONTROL

PMUX PROPULSION MULTIPLEXER

Poil OIL PRESSURE

PPH POUNDS PER HOUR

PRSOV PRESSURE REGULATING SHUT-OFF VALVE

PRV PRESSURE RELIEF VALVE

Ps PUMP SUPPLY PRESSURE

PS12 FAN INLET STATIC AIR PRESSURE

PS13 FAN OUTLET STATIC AIR PRESSURE

PS3 COMPRESSOR DISCHARGE STATIC AIR PRESSURE (CDP)

Psf HEATED SERVO PRESSURE

PSI POUNDS PER SQUARE INCH

PSIA POUNDS PER SQUARE INCH ABSOLUTE

PSID POUNDS PER SQUARE INCH DIFFERENTIAL

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 14

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

PSIG POUNDS PER SQUARE INCH GAGE

PSM POWER SUPPLY MODULE

PSS PRESSURE SUB-SYSTEM

PSSA PRELIMINARY SYSTEM SAFETY ASSESSMENT

PSU POWER SUPPLY UNIT

PT TOTAL PRESSURE OR PRESSURE TRANSDUCER

PT2 FAN INLET TOTAL AIR PRESSURE (PRIMARY FLOW)

PT25 HPC TOTAL INLET PRESSURE

PTU POWER TRANSFER UNIT

QAD QUICK ATTACH DETACH

QAR QUICK ACCESS RECORDER

QEC QUICK ENGINE CHANGE

QTY QUANTITY

QWR QUICK WINDMILL RELIGHT

R/H RIGHT HAND

RAC/SB ROTOR ACTIVE CLEARANCE/START BLEED

RACC ROTOR ACTIVE CLEARANCE CONTROL

RAM RANDOM ACCESS MEMORY

RCC REMOTE CHARGE CONVERTER

RDS RADIAL DRIVE SHAFT

RH RIGHT HAND

RPM REVOLUTIONS PER MINUTE

RTD RESISTIVE THERMAL DEVICE

RTO REJECTED TAKE-OFF

RTV ROOM TEMPERATURE VULCANIZING (MATERIAL)

RVDT ROTARY VARIABLE DIFFERENTIAL TRANSDUCER

S/N SERIAL-NUMBER

S/R SERVICE REQUEST

S/TM SOLENOID/TORQUE MOTOR

S/V SHOP VISIT

SAC SINGLE ANNULAR COMBUSTOR

SACOC SURFACE AIR COOLING OIL COOLER

SAR SMART ACMS RECORDER

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 15

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

SAV STARTER AIR VALVE

SB SERVICE BULLETIN

SBV START BLEED VALVE

SCU SIGNAL CONDITIONING UNIT or SPLIT CONTROL UNIT(LEAP)

SCU/SVA SPLIT CONTROL UNIT/ SERVO VALVE ASSY

SDAC SYSTEM DATA ACQUISITION CONCENTRATOR

SDI SOURCE/DESTINATION IDENTIFIER (BITS)

SDU SOLENOID DRIVER UNIT

SER SERVICE EVALUATION REQUEST

SFC SPECIFIC FUEL CONSUMPTION

SFCC SLAT FLAP CONTROL COMPUTER

SFH SERVO FUEL HEATER

SFLA SYNCHRONIZED LOCKING FEEDBACK ACTUATOR

SG SPECIFIC GRAVITY

SLS SEA LEVEL STANDARD (CONDITIONS: 29.92 in.Hg / 59°F)

SLSD SEA LEVEL STANDARD DAY (CONDITIONS: 29.92 in.Hg / 59°F)

SMLA SYNCHRONIZED MANUAL LOCKING ACTUATOR

SMP SOFTWARE MANAGEMENT PLAN

SN SERIAL NUMBER

SOCIETE NATIONALE D'ETUDE ET DE CONSTRUCTION DE MOTEURS

SNECMA

D'AVIATION

SNLA SYNCHRONIZED NON-LOCKING ACTUATOR

SOL SOLENOID

SOV SHUT-OFF VALVE

STP STANDARD TEMPERATURE AND PRESSURE

STS STATUS

SVA SERVO VALVE ASSEMBLY

SVR SHOP VISIT RATE

SW SWITCH

SYS SYSTEM

T/C THERMOCOUPLE

T/E TRAILING EDGE

T/O TAKE-OFF

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 16

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

T/P TEMPERATURE / PRESSURE SENSOR

T/R THRUST REVERSER

T12 FAN INLET TOTAL AIR TEMPERATURE

T25 HP COMPRESSOR INLET TOTAL AIR TEMPERATURE

T3 HP COMPRESSOR DISCHARGE AIR TEMPERATURE

T48 EXHAUST GAS TEMPERATURE

T49.5 EXHAUST GAS TEMPERATURE

T5 LOW PRESSURE TURBINE DISCHARGE TOTAL AIR TEMPERATURE

TAI THERMAL ANTI-ICE

TAPS TWIN ANNULAR PREMIXING SWIRLER

TAT TOTAL AIR TEMPERATURE

TBC THERMAL BARRIER COATING

TBD TO BE DETERMINED

TBO TIME BETWEEN OVERHAULS

TBV TRANSIENT BLEED VALVE

TC (TCase) HP TURBINE CASE TEMPERATURE

TCC TURBINE CLEARANCE CONTROL

TCCV TURBINE CLEARANCE CONTROL VALVE

TCF TURBINE CENTER FRAME

TCJ TEMPERATURE COLD JUNCTION

TECU ELECTRONIC CONTROL UNIT INTERNAL TEMPERATURE

TEO ENGINE OIL TEMPERATURE

TGB TRANSFER GEARBOX

Ti TITANIUM

TLA THRUST LEVER ANGLE (BOEING)

TLA THROTTLE LEVER (AIRBUS)

TM TORQUE MOTOR

TMC TORQUE MOTOR CURRENT

TO/GA TAKE-OFF / GO AROUND

Toil OIL TEMPERATURE

TPU TRANSIENT PROTECTION UNIT

TR TRANSFORMER RECTIFIER

TRA THRUST RESOLVER ANGLE (BOEING)

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 17

Course Outline LEAP-1B

ABBREVIATIONS MEANING DEFINITION

TRA THROTTLE RESOLVER ANGLE (AIRBUS)

TRAS THRUST REVERSER ACTUATION SYSTEM

TRDV THRUST REVERSER DIRECTIONAL VALVE

TRF TURBINE REAR FRAME

TRPV THRUST REVERSER PRESSURIZING VALVE

TRSOV THRUST REVERSER SHUT-OFF VALVE

TSI TIME SINCE INSTALLATION (HOURS)

TSN TIME SINCE NEW (HOURS)

UER UNSCHEDULED ENGINE REMOVAL

UTC UNIVERSAL TIME CONSTANT

VAC VOLTAGE, ALTERNATING CURRENT

VBV VARIABLE BLEED VALVE

VDC VOLTAGE, DIRECT CURRENT

VDT VARIABLE DIFFERENTIAL TRANFORMER

VIB VIBRATION

VLV VALVE

VRT VARIABLE RESISTANCE TRANSDUCER

VSV VARIABLE STATOR VANE

WAI WING ANTI-ICE

WDM WATCHDOG MONITOR

Wf WEIGHT OF FUEL OR FUEL FLOW

WFM WEIGHT OF FUEL METERED

WOW WEIGHT ON WHEELS

WTAI WING THERMAL ANTI-ICING

For Training Purposes Only JUL 2019

CFM Proprietary Information

TOC Page 18

Course Outline LEAP-1B

Introduction

The FADEC is able to ensure functional operation in case of single component failure. In the

event of several failures, it will assume a failsafe strategy to preserve engine operational

capability.

FADEC Redundant Architecture 1 of 2

The FADEC system is designed with a dual redundant architecture. It consists of the EECs

with CCDL, dual * control sensors, dual * control harnesses, dual * coil, single hydro-

mechanical parts, ADC, DPC (2). (*) For critical data.

For Training Purposes Only

CFM Proprietary Information TOC Page 19

Course Outline LEAP-1B

FADEC Redundant Architecture 2 of 2

The FADEC system includes 2 redundant & independent EEC channels able to control the

engine. Each EEC channel determines its health status to compare it (via CCDL) to the other

one, in order to select the healthier as the active one.

EEC and Harnesses

Both EEC units have same electrical connectors and interfaces. The A/C electrical interfaces

are connected via J1, J2 and J4. The engine electrical interfaces are connected via J3, J5, J6

and J8. Ground support interface is connected via J9.

For Training Purposes Only

CFM Proprietary Information TOC Page 20

Course Outline LEAP-1B

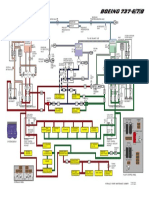

Engine Electrical Interface with Aircraft

Harnesses W4A & W2 (Channel A) and W4B & W2 (Channel B) interface EECs and A/C

electrical systems. W100, W200 & W300 ensure interfaces between A/C and Engine systems.

Engine Functions Linked to the EEC Units

Engine electrical interfaces with the EEC units are connectors J3, J5, J6, J7, and J8 via

harnesses HJ3A, HJ5A, HJ6A & HJ8A to channel A, and harnesses HJ3B, HJ5B, HJ6B &

HJ8B to channel B. Harness HJ7 is for the CCDL.

For Training Purposes Only

CFM Proprietary Information TOC Page 21

Course Outline LEAP-1B

EEC BITE and Ground Tests

The EEC units integrate BITE and ground test functions for the detection of internal unit

hardware failures: initialization and periodic tests. On ground with engine shutdown, ground

tests and special functions can be carried out.

EEC Parameter Selection

Inputs from systems are checked, selected & used in the control law. Channels A & B work in

same way. The processed data are then sent to engine or A/C systems via the output stage.

For Training Purposes Only

CFM Proprietary Information TOC Page 22

Course Outline LEAP-1B

Channel Selection Determination Principle 1 of 2

The FADEC system operates on an “active-stand-by” strategy, where only one of the two

EEC channels has complete control at any one time. The active channel has full authority

over all EEC outputs used for engine control.

Channel Selection Determination Principle 2 of 2

EEC Ch A & B are either in active or stand-by state, the healthier is the active one & has

priority. The STB Ch disconnects its torque motor & solenoid outpouts thanks to 3 disconnect

functions. Faults are sent via ARINC 429 bus.

For Training Purposes Only

CFM Proprietary Information TOC Page 23

Course Outline LEAP-1B

Flight Deck Display

The MDS uses engine parameters from the EEC to figure related values on MDS screens.

Displayed indication aspect depends on their values, limits...The 737 MAX features a center

display panel (with 4 MFD), a fwd & aft overhead panels.

Engine Display System

The MDS EI format is located on the left INBD DU. It displays engine data. There are two

configurations for display of Engine Indication: the Primary and the Secondary display.

For Training Purposes Only

CFM Proprietary Information TOC Page 24

Course Outline LEAP-1B

Overhead Panels

The overhead panel is divided into two main panel sections: forward P5 overhead panel and

aft P5 overhead panel. P5 overhead panel provides controls and indications for engine

systems.

Engine Alerts and Indications

Aft P5 overhead panel povides the following engine indications: ALTN, ENGINE CONTROL,

REVERSER AIR/GRD,REVERSER COMMAND,REVERSER LIMITED, ENG VALVE

CLOSED, FILTER BY PASS, ENG ANTI-ICE & MAINT.

For Training Purposes Only

CFM Proprietary Information TOC Page 25

Course Outline LEAP-1B

N1 Thrust Setting Parameter

The N1 figures the engine physical fan speed (in %N1), it is displayed by means of a pointer

on a round dial with a numerical readout enclosed within a box. The maximum N1 depends

on the current ambient conditions.

N1

N1 redline is the maximum certified engine operating limit (104.3%) for the engine fan speed,

it is displayed as a red radial tick mark on the outside of the dial. T/R in-transit and T/R

deployed are also displayed on the N1 dial.

For Training Purposes Only

CFM Proprietary Information TOC Page 26

Course Outline LEAP-1B

N2 Indication

N2 provides indication about the engine core speed (in %) and is displayed on the engine

indication display. N2 indication is set with limits and limit exceedances (redline: 117.5%).

Starting indication is MOTORING.

EGT Indication

Exhaust Gas Temperature (EGT) is displayed on the Engine Indication (EI) display (in °C).

This indication reflects the general health of both engines. EGT indication is set with limits

and limit exceedances (amber and redlines).

For Training Purposes Only

CFM Proprietary Information TOC Page 27

Course Outline LEAP-1B

EGT Limits at Start

Exhaust Gas Temperature (EGT) limits during the starting are: EGT start redline, EGT starting

limit exceedance and ENG FAIL alert. When EGT exceeds the ‘EEC start EGT limit' during a

ground start, the EEC performs specific actions.

Oil Pressure

The engine oil pressure is displayed on the engine indication display through a scaled column

and a numerical readout (in psid). Oil pressure indication is displayed with limits (amber &

redline) and exceedance (amber line & redline).

For Training Purposes Only

CFM Proprietary Information TOC Page 28

Course Outline LEAP-1B

Oil Temperature

The engine oil temperature is displayed, through a numerical readout (in °C) and a scaled

column, on the engine indication display. Oil temperature indication is displayed with limits

(amber & redline) and exceedance (amber line & redline).

Oil Quantity

The engine oil quantity is displayed (% of oil tank) on the engine indication display. If the oil

quantity falls below low limit, MDS informs the crew by inverting colors of digital readout and

outline box. Moreover, it displays a “LO” quantity alert.

For Training Purposes Only

CFM Proprietary Information TOC Page 29

Course Outline LEAP-1B

Fuel Flow

The FF indication is displayed on the engine indication display in lb/h or kg/h, as a numerical-

only illustration. FU value which comes from the DPC can be displayed on the engine

indication display instead of the FF value.

Vibrations

The engine vibration level, expressed in Cockpit Units (CU), is displayed on the engine

indication display. The Engine Vibration Monitoring (EVM) logic within the EEC processes

four independent vibration measurements of N1 & N2.

For Training Purposes Only

CFM Proprietary Information TOC Page 30

Course Outline LEAP-1B

Overhead Panel Fuel Control Module

Fuel control overhead panel displays engine alerts and indications concerning fuel via

dedicated lights: “ENG VALVE CLOSED” light and "FILTER BYPASS" light.

Crew Alerting Messages

The DPC provides engine crew alerting messages in black colored text within an amber

colored box on the engine indication display. It provides important alerts as FUEL FLOW,

THRUST, LOW OIL PRESSURE, OIL FILTER BYPASS & START VALVE OPEN.

For Training Purposes Only

CFM Proprietary Information TOC Page 31

Course Outline LEAP-1B

Anti-Ice Overhead Panel

A/I overhead panel displays engine alerts and indications concerning A/I system by using

dedicated lights. “ENG ANTI-ICE” light indicates when the EEC detects the blocking of engine

booster A/I valve in closed position while in flight.

Engine Maintenance System

The OMF collects fault reports from A/C LRUs & provides maintenance MSGs about A/C

systems. The OMF initiates & terminates menu mode operations for the EECs & queries them

for shop fault & engine configuration data.

For Training Purposes Only

CFM Proprietary Information TOC Page 32

Course Outline LEAP-1B

EEC with Aircraft Maintenance System

The A/C maintenance system provides usefull engine health information.The maintenance

system is designed with DPCs, EECs & ONS.The DPC allows communication between these

elements via ARINC 429.

ONS Component Location

The ONS system consists of a maintenance/BITE panel (on P61-4 area). It enables to

navigate through the OMF menu (on MFD), to perform ground tests and to upload A/C data

on a PMD via an RJ45 ethernet connection.

For Training Purposes Only

CFM Proprietary Information TOC Page 33

Course Outline LEAP-1B

Engine Maintenance System

Thanks to the monitoring of various sources & tests, the EEC system detects failures & over-

limits. The fault-reporting function is simultaneously performedby both EEC channels.

Powerplant - Functional Description OMF PMD or Max multifunction

displays

The OMF can be used either by means of the MFDs or PMD. Both ways feature identical

displays & some operations. The PMD has additional selection for "in- depth" maintenance on

the ONS. The PMD just needs the proper software.

For Training Purposes Only

CFM Proprietary Information TOC Page 34

Course Outline LEAP-1B

Maint Light/System Status

System status messages are set when a condition exists that does not require flight crew

action but require maintenance review. In case of system status fault indication, an amber

“MAINT” light is illuminated on aft overhead panel.

Status Message Page

The "STATUS MESSAGES" page can be reach from the "SYSTEM" page via the "MAINT"

key & "TOP LEVEL MAINTENANCE" menu. This page informs about airworthiness status of

the faults.The "MAINT" light is ON in case of status MSG.

For Training Purposes Only

CFM Proprietary Information TOC Page 35

Course Outline LEAP-1B

Maintenance Awareness System

The MAS provides airworthiness information about A/C systems. The "MAINT" light indicates

(except in flight) any fault impacting the airworthiness. The DPC collects airworthiness faults

from EEC & various A/C systems.

Maintenance Data Pages - General.

There are 10 systems which feature (1 or more) maintenance pages. These pages are

available on the ground & above 10 000 feet.The information are shown either in real time or

via snapshots in case of event.

For Training Purposes Only

CFM Proprietary Information TOC Page 36

Course Outline LEAP-1B

Maintenance Data Pages - Performance

Maintenance data pages are available in modes (identified by the title): real time, manual

event, auto event. Real time mode has a field for date and UTC time. A page shows: gross

weight, temperatures, speed, altitudes, eng vib, eng & oil data.

EPCS Maintenance Pages

EPCS provides maintenance data via 4 pages: # 1 & 2 for engine sensor data from EECs, # 3

for vibration related data, # 4 for digital discrete data from EECs. Snapshots of these pages

can be recorded either manually or automatically.

For Training Purposes Only

CFM Proprietary Information TOC Page 37

Course Outline LEAP-1B

Maintenance Data Pages-Exceedances

“ENGINE EXCEEDANCE” pages provide informations (date and time, concerned parameter

and profile data) when a limit exceedance occurs. The concerned parameters are N1, N2,

EGT and EGT start.

Maintenance Control Pages

The "MAINT CTRL PGS" tab allows to access: ACD, MSC, Latched message erase, & Maint

light pages. Through these pages, one can: manage various maintenance data & A/C

systems, set some systems into maintenance modes...

For Training Purposes Only

CFM Proprietary Information TOC Page 38

Course Outline LEAP-1B

Categories of Dispatch

Categories of dispatch are: No Dispatch (ND), Short-Time Dispatch (STD), Long-Time

Dispatch (LTD), economic dispatch and dedicated Flight Deck Effects (FDE).

Message Format

The message number identifies the fault and is used as reference to find the relevant

troubleshooting procedure in the Fault Isolation Manual (FIM).

For Training Purposes Only

CFM Proprietary Information TOC Page 39

Course Outline LEAP-1B

Reports

Reports are generated by the A/C OMF. A PMD can be connected to the A/C, it allows

access to the OMF menus and additional applications available for in-depth maintenance

actions.

EEC Maintenance Power Switch

EEC maintenance power switch allows to power EEC for maintenance operations. It is

controlled via a virtual switch on the “MAINT CTRL PGS” of the Multi-Function Display (MFD).

For Training Purposes Only

CFM Proprietary Information TOC Page 40

Course Outline LEAP-1B

Ground Test Enable Switch

The purpose of the "ground test enable switch" is to provide an additional layer of protection

and security for maintenance functions such as menu mode, data load, and engine trim

balance.

Ground Test Pages - General 1 of 3

Ground tests are provided to verify EEC-detected faults by performing functional checks of

various engine control system functions. Maintenance personnel uses the OMF to initiate and

run the tests.

For Training Purposes Only

CFM Proprietary Information TOC Page 41

Course Outline LEAP-1B

Ground Test Pages - General 2 of 3

The ground test page allows to select the test. The four parts for each ground test performed

are: Selection of ATA and required test, pre-condition page, test, and post condition page.

Ground Test Pages - General 3 of 3

The system test screen consists of: test initiation, test in progress, test pass and test fail. The

post conditions screen provides information to return the aircraft into service.

For Training Purposes Only

CFM Proprietary Information TOC Page 42

Course Outline LEAP-1B

Ground Test 1 of 2

Ground tests can be run with the Onboard Maintenance Function (OMF). Performed tests are:

actuator test, wet motor test, T/R interlock test, and harness test.

Ground Test 2 of 2

Ground tests can be run with the Onboard Maintenance Function (OMF). Performed tests are:

engine idle test, EEC test, ignition channel A test, ignition channel B test, and EEC blower

test.

For Training Purposes Only

CFM Proprietary Information TOC Page 43

Course Outline LEAP-1B

Special Functions Available

Special functions are used to configure the engine for other maintenance operations such as

water wash. They can also be used to access to Engine Serial Number entry or to reset the

Debris Monitoring System.

Multi Function Display - Special Functions

Special functions allow the selection of sub-systems (by ATA chapter) with their associated

system operations. They provide a means to verify inputs and control the subsystems into the

test system.

For Training Purposes Only

CFM Proprietary Information TOC Page 44

Course Outline LEAP-1B

Failure/Post Condition Special Function Screens

The special function condition failed screen displays all the faults recorded during the test.

The post condition screen provides information to return A/C into service.

Function Screen of Special Functions

The function screen offers the possibility to start, monitor or stop the current operation. A pop-

up window displays instructions on how to proceed for the current special functions operation.

For Training Purposes Only

CFM Proprietary Information TOC Page 45

Course Outline LEAP-1B

Special Functions 1 of 3: ESN Entry

The ESN entry function allows to change Engine Serial Number. This task must be done at

each EEC replacement since it stores this data. The ESN function communicates with EEC

channels A & B in order to have a dual record.

Special Functions 2 of 3

The special functions enable to perform either: fuel system preservation (igniters OFF), water

wash (igniters OFF), erase all faults (EEC Ch A & B), DMS reset (EEC CH B only).

For Training Purposes Only

CFM Proprietary Information TOC Page 46

Course Outline LEAP-1B

Special Functions 3 of 3

The following special functions are also available: thrust reverser cycle, fan accelerometer

selection, hydraulic offload, engine running simulation, lamp check.

Troubleshooting General

Unscheduled maintenance must be performed when flight faults, ground faults, service

problems or structural damage occurs. In order to perform this kind of maintenance, specific

and approved technical documentation must be used.

For Training Purposes Only

CFM Proprietary Information TOC Page 47

Course Outline LEAP-1B

OMF Menu Tree

Select “ONBD MAINT” in the system menu to access to the onboard maintenance function

(OMF) menus. There are three primary menus: line maintenance, extended maintenance, and

other functions.

Troubleshooting-IFIM Introduction

Interactive Fault Isolation Manual (IFIM) is a searchable database, which is used to isolate

and fix A/C faults. Status messages, observed faults, fault codes and maintenance messages

can be used to search the corresponding IFIM tasks.

For Training Purposes Only

CFM Proprietary Information TOC Page 48

Course Outline LEAP-1B

Troubleshooting-IFIM-Search Filter

On Interactive Fault Isolation Manual (IFIM), filter functions are integrated to perform

interactive search. It allows to select a filter by LRU/System, ATA chapter or cabin faults.

Troubleshooting-IFIM-Search Filter

On Interactive Fault Isolation Manual (IFIM), filter functions are integrated to perform

interactive search. It allows to select a filter by LRU/System, ATA chapter or cabin faults.

For Training Purposes Only

CFM Proprietary Information TOC Page 49

Course Outline LEAP-1B

THIS PAGE INTENTIONALLY LEFT BLANK

For Training Purposes Only

CFM Proprietary Information TOC Page 50

Course Outline LEAP-1B

For Training Purposes Only JUL 2019

CFM Proprietary Information Page 51

You might also like

- CFM Doc Leap 1b TM Bas 3 v2Document119 pagesCFM Doc Leap 1b TM Bas 3 v2Paulo SanzNo ratings yet

- CFM Doc Leap 1b TM Bas 3 v2Document119 pagesCFM Doc Leap 1b TM Bas 3 v2Paulo SanzNo ratings yet

- CFM 56-7B Basic EngineDocument183 pagesCFM 56-7B Basic EngineAnupam Vettukuzhiyil100% (1)

- Solution Manual For Exploring Microsoft Office Excel 2019 Comprehensive 1st Edition Mary Anne PoatsyDocument3 pagesSolution Manual For Exploring Microsoft Office Excel 2019 Comprehensive 1st Edition Mary Anne PoatsyKennethRamirezrcpem100% (85)

- CFM Doc Leap 1b Co Nac 3 v2.0Document19 pagesCFM Doc Leap 1b Co Nac 3 v2.0Paulo Sanz100% (1)

- CFM Doc Leap 1b Co Nac 3 v2.0Document19 pagesCFM Doc Leap 1b Co Nac 3 v2.0Paulo Sanz100% (1)

- 787 Hamilton AcronymmasterDocument13 pages787 Hamilton Acronymmasterlalo7772No ratings yet

- CFMOilDebris PDFDocument62 pagesCFMOilDebris PDFShreyas PingeNo ratings yet

- CTC-224 Engine SystemsDocument331 pagesCTC-224 Engine Systemsjivomir100% (2)

- 71-80 - GE90-115B Series Power PlantDocument13 pages71-80 - GE90-115B Series Power PlantAslam AwanNo ratings yet

- Engine MX Management Madrid May-12 2015Document31 pagesEngine MX Management Madrid May-12 2015Primadi Fajriansyah NawawiNo ratings yet

- CFM AMM ExtractsDocument126 pagesCFM AMM ExtractsIsrael De Sousa Oliveira (LATAM)No ratings yet

- 1100G-JM-LBM - 14 - Appendix B - Shop Maintenance Tasks PDFDocument4 pages1100G-JM-LBM - 14 - Appendix B - Shop Maintenance Tasks PDFVinay SinghNo ratings yet

- Trent 1000 TENDocument4 pagesTrent 1000 TENAnonymous R0s4q9X8100% (1)

- HPC Shroud & VSV System ImprovementsDocument15 pagesHPC Shroud & VSV System Improvementsali100% (2)

- 70 Power Plant CFM 56 PDFDocument392 pages70 Power Plant CFM 56 PDFAnonymous 298xlo3uU100% (2)

- Engine Change BootstrapDocument5 pagesEngine Change Bootstrapolegprikhodko2809No ratings yet

- 7B - MyCFMportal - CFM Symposium 2017Document14 pages7B - MyCFMportal - CFM Symposium 2017aliNo ratings yet

- Fan Lub CFM56-7 - HandbookDocument44 pagesFan Lub CFM56-7 - HandbookANDRANo ratings yet

- F16v3 Manual v1.02Document114 pagesF16v3 Manual v1.02Genocea Cfo100% (1)

- Under Control - Learning and Producing. EMCO Industrial Training SOFTWAREDocument8 pagesUnder Control - Learning and Producing. EMCO Industrial Training SOFTWARESalomé UnásNo ratings yet

- Seminar ReportDocument17 pagesSeminar ReportMURALINo ratings yet

- CFM Doc Leap 1B Co Intro 3 V2Document23 pagesCFM Doc Leap 1B Co Intro 3 V2Paulo SanzNo ratings yet

- CFM Doc Leap 1b Co Sys 3 v2Document83 pagesCFM Doc Leap 1b Co Sys 3 v2Paulo Sanz100% (1)

- CFM Doc Leap 1B Co Bas 3 V2Document39 pagesCFM Doc Leap 1B Co Bas 3 V2Paulo Sanz100% (1)

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- CTC 224 Engine SystemsDocument317 pagesCTC 224 Engine Systemsİsmail Uçar100% (1)

- Full Authority Digital Engine ControlDocument17 pagesFull Authority Digital Engine Controlberjarry5938100% (2)

- CFM Doc Leap 1B Cid Nac Eb 3 V1Document29 pagesCFM Doc Leap 1B Cid Nac Eb 3 V1Paulo SanzNo ratings yet

- Choice Global Support Capability: Flight HoursDocument9 pagesChoice Global Support Capability: Flight HoursGenaro Rodriguez100% (2)

- V2500 Line and Base Maintenance Engine OverviewDocument24 pagesV2500 Line and Base Maintenance Engine OverviewHENIGUEDRI100% (2)

- CFM Doc Leap 1B Cid Nac Ab 3 V1Document29 pagesCFM Doc Leap 1B Cid Nac Ab 3 V1Paulo SanzNo ratings yet

- CFM Doc Leap 1B Cid Eng Eb 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Eb 3 V1Paulo SanzNo ratings yet

- LEAP-1B Walkaround OverviewDocument22 pagesLEAP-1B Walkaround Overviewrakesh100% (1)

- LEAP-1B Oil Servicing - Best Practices v4Document5 pagesLEAP-1B Oil Servicing - Best Practices v4rakeshNo ratings yet

- 757 PW2 CH 80 2004 SingleDocument8 pages757 PW2 CH 80 2004 SingleDiego Ruddy Arcaine ZegarrundoNo ratings yet

- 544-09 - Heat MGMTDocument22 pages544-09 - Heat MGMTHENIGUEDRINo ratings yet

- B737NGWBT1T2L1Document9 pagesB737NGWBT1T2L1MedaNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument32 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức Huy100% (1)

- 1line Training BookletDocument50 pages1line Training BookletKshitiz Rastogi75% (4)

- 757 PW2 CH 72 2004 SingleDocument9 pages757 PW2 CH 72 2004 SingleDiego Ruddy Arcaine ZegarrundoNo ratings yet

- 757 PW2 CH 74 2004 SingleDocument6 pages757 PW2 CH 74 2004 SingleDiego Ruddy Arcaine ZegarrundoNo ratings yet

- b737 Mtips PDFDocument6 pagesb737 Mtips PDFابن كتاب ساميNo ratings yet

- V2500 Line and Base Maintenance Power PlantDocument42 pagesV2500 Line and Base Maintenance Power PlantHENIGUEDRI100% (1)

- 70 Power Plant CFM 56Document322 pages70 Power Plant CFM 56Agam Septiana100% (1)

- CFM LEAP 1A Walkround Overview PDFDocument15 pagesCFM LEAP 1A Walkround Overview PDFArpit Saraswat100% (2)

- ATA 76 PW1100 - Rev. 0 (16-12-19)Document38 pagesATA 76 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALNo ratings yet

- Trent XWB L & B Issue 3Document578 pagesTrent XWB L & B Issue 3hakoj29142100% (1)

- CFMPresentation PowerPointDocument159 pagesCFMPresentation PowerPointClaudio Alves100% (2)

- 1100G JM LBM 08 StartingDocument22 pages1100G JM LBM 08 StartingMAURO SOARES DA SILVA JUNIORNo ratings yet

- 7B - Ignition - System - CFM Symposium 2017 PDFDocument15 pages7B - Ignition - System - CFM Symposium 2017 PDFaliNo ratings yet

- 4 Power Generation and DistributionDocument51 pages4 Power Generation and DistributionFanhang ZhangNo ratings yet

- CFM Media Briefing India October11 2018Document26 pagesCFM Media Briefing India October11 2018cactus319No ratings yet

- Ecu Software - cfm56Document9 pagesEcu Software - cfm56aliNo ratings yet

- CFM56LINEMAINTENANCECOURSEDocument101 pagesCFM56LINEMAINTENANCECOURSEArnaldo Dias100% (1)

- Ata 00Document57 pagesAta 00JOSE SANDOVALNo ratings yet

- CFM Doc Leap 1B Cid Eng Ab 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Ab 3 V1Paulo Sanz100% (1)

- 19-Workscoping-WTT NashvilleDocument28 pages19-Workscoping-WTT NashvilleFaraz KhanNo ratings yet

- B737NG - 29 00 A3 01 PDFDocument1 pageB737NG - 29 00 A3 01 PDFMuhammed MudassirNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument42 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet

- PW1500G TRM Supplemental Material - Combustion Chamber Borescope Pictures - PWA115622 Rev CDocument2 pagesPW1500G TRM Supplemental Material - Combustion Chamber Borescope Pictures - PWA115622 Rev CaliNo ratings yet

- PowerplantDocument14 pagesPowerplantOSCARDELTA100% (2)

- Airbus A380 Inflight Uncontained Engine Failure PDFDocument305 pagesAirbus A380 Inflight Uncontained Engine Failure PDFMorgen GumpNo ratings yet

- Done By:: Indian Institute of Space Science and Technology ThiruvananthapuramDocument48 pagesDone By:: Indian Institute of Space Science and Technology Thiruvananthapuramsrijani pal100% (1)

- CTC-601 - Lexis - LEAP ENGINES - Sep 15 - (USB CD Lexis Version Only)Document9 pagesCTC-601 - Lexis - LEAP ENGINES - Sep 15 - (USB CD Lexis Version Only)estevamjr100% (4)

- A 3 1 8 /A 3 1 9 /A 3 2 0 /A 3 2 1 A 3 3 0 /A 3 4 0: AbbreviationsDocument22 pagesA 3 1 8 /A 3 1 9 /A 3 2 0 /A 3 2 1 A 3 3 0 /A 3 4 0: Abbreviationsjunebug172No ratings yet

- CFM Doc Leap 1b Co Sys 3 v2Document83 pagesCFM Doc Leap 1b Co Sys 3 v2Paulo Sanz100% (1)

- CFM Doc Leap 1B Co Bas 3 V2Document39 pagesCFM Doc Leap 1B Co Bas 3 V2Paulo Sanz100% (1)

- CFM Doc Leap 1B Cid Eng Ab 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Ab 3 V1Paulo Sanz100% (1)

- Career After Mechanical EngineeringDocument20 pagesCareer After Mechanical EngineeringNirav VaghasiaNo ratings yet

- A Comprehensive Survey of Deep Learning Techniques in Protein Function PredictionDocument11 pagesA Comprehensive Survey of Deep Learning Techniques in Protein Function PredictionEngr. Naveed MazharNo ratings yet

- 1Ghz Feederline Equalizer Ffe - 100 /RP-R: Benefits IncludeDocument3 pages1Ghz Feederline Equalizer Ffe - 100 /RP-R: Benefits IncludeosgarsotoNo ratings yet

- English Language Panel BrochureDocument2 pagesEnglish Language Panel BrochureChristus AugustNo ratings yet

- Design Rules For Additive ManufacturingDocument10 pagesDesign Rules For Additive ManufacturingKazalzs KramNo ratings yet

- Service Manual EPSONDocument115 pagesService Manual EPSONJoao Jose Santos NetoNo ratings yet

- A Water Pumping Control System With A Programmable Logic Controller (PLC) PDFDocument8 pagesA Water Pumping Control System With A Programmable Logic Controller (PLC) PDFsunnyday32No ratings yet

- List of Study Centres of Guru Jambheshwar UniversityDocument10 pagesList of Study Centres of Guru Jambheshwar UniversityPatrick AdamsNo ratings yet

- Remote Controlled Relay PNI CA500 For Controlling 1 or 2 Garage Doors, Gates, BariersDocument3 pagesRemote Controlled Relay PNI CA500 For Controlling 1 or 2 Garage Doors, Gates, BariersSo DurstNo ratings yet

- CV - Irfan - Data EntryDocument2 pagesCV - Irfan - Data EntryIrfan AzmiNo ratings yet

- Test and Inspection For Low Voltage Cubicle SwitchboardDocument3 pagesTest and Inspection For Low Voltage Cubicle Switchboardnidnitrkl051296No ratings yet

- HP Opencall Ss7 Platform Operations Guide: For Release 3.2 On Hp-Ux Pa-RiscDocument430 pagesHP Opencall Ss7 Platform Operations Guide: For Release 3.2 On Hp-Ux Pa-Riscopenid_AgrpmDdZNo ratings yet

- CV DrKasimDocument6 pagesCV DrKasimhieuhuech1No ratings yet

- Application Form For Mobile Banking: Branch: Sol Id: DateDocument2 pagesApplication Form For Mobile Banking: Branch: Sol Id: DateKaran chetryNo ratings yet

- MT - M03 - C01 - SLM - Testing Landscape For Mobile Application Chapter PDFDocument32 pagesMT - M03 - C01 - SLM - Testing Landscape For Mobile Application Chapter PDFHari PsNo ratings yet

- GSM&PSTN Dual-Network Burglar Alarm System User GuideDocument38 pagesGSM&PSTN Dual-Network Burglar Alarm System User Guidesalamanc59No ratings yet

- TDJ 609015 172717DEI 65FT2v03Document1 pageTDJ 609015 172717DEI 65FT2v03Дарья КамынинаNo ratings yet

- Vice President Distribution Supply Chain Logistics in Houston TX Resume Herbert JahnDocument3 pagesVice President Distribution Supply Chain Logistics in Houston TX Resume Herbert JahnHerbertJahnNo ratings yet

- Cyber Security Analysis of Internet Banking in Emerging Countries: User and Bank PerspectivesDocument12 pagesCyber Security Analysis of Internet Banking in Emerging Countries: User and Bank PerspectivesRebecca BolledduNo ratings yet

- IC-S19RH 說明書中英版Document25 pagesIC-S19RH 說明書中英版La perrritaaaNo ratings yet

- Introduction To Control SystemDocument33 pagesIntroduction To Control Systemmarina890416No ratings yet

- Diagraru¡S: Vehicle Unit (VECU)Document4 pagesDiagraru¡S: Vehicle Unit (VECU)WalterNo ratings yet

- Manual Dm5eDocument104 pagesManual Dm5etoluviejoNo ratings yet

- Operation Database Workshop Kudu LabDocument24 pagesOperation Database Workshop Kudu LabRhi PenNo ratings yet

- NC Studio V10 Glass Cutting V8Document99 pagesNC Studio V10 Glass Cutting V8Mesa Macotec1No ratings yet

- 200/300 BAR INERT GAS Fire Suppression SystemsDocument30 pages200/300 BAR INERT GAS Fire Suppression SystemsKamen GrozdanovNo ratings yet