Professional Documents

Culture Documents

Maintenance Schedul PC 1250-8

Maintenance Schedul PC 1250-8

Uploaded by

krzn0101Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Schedul PC 1250-8

Maintenance Schedul PC 1250-8

Uploaded by

krzn0101Copyright:

Available Formats

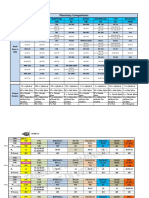

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE CHART

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)

CLEAN STRAINER OF PTO LUBRICATING OIL FILTER 4- 61

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

CHANGE OIL IN SWING MACHINERY CASE 4- 69

CHANGE OIL IN PTO CASE 4- 71

CHANGE OIL IN FINAL DRIVE CASE 4- 80

WHEN REQUIRED

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT 4- 18

CLEAN INSIDE OF COOLING SYSTEM 4- 21

CHECK AND TIGHTEN TRACK SHOE BOLTS 4- 25

CHECK AND ADJUST TRACK TENSION 4- 26

REPLACE BUCKET TEETH (XS) 4- 29

ADJUST BUCKET CREARANCE 4- 33

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID 4- 34

CHECK AND MAINTENANCE AIR CONDITIONER 4- 35

CLEAN LINE FILTER, REMOVE DIRT 4- 36

CHECK GAS SPRING 4- 37

BLEEDING AIR FROM HYDRAULIC SYSTEM 4- 38

BLEEDING AIR FROM FULE CIRCUIT 4- 42

CHECKS BEFORE STARTING

EVERY 10 HOURS MAINTENANCE

LUBRICATING 4- 46

EVERY 100 HOURS MAINTENANCE

LUBRICATING SWING CIRCLE 4- 48

EVERY 250 HOURS MAINTENANCE

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL 4- 49

CHECK LEVEL OF BATTERY ELECTROLYTE 4- 50

CHECK AND TIGHTEN TRACK FRAME AND AXLE CONNECTING BOLTS 4- 52

EVERY 500 HOURS MAINTENANCE

REPLACE FUEL PRE-FILTER CARTRIDGE 4- 53

REPLACE FULE MAIN FILTER CARTRIDGE 4- 55

CHECK SWING PINION GREASE LEVEL, ADD GREASE 4- 57

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS,FUEL COOLER FINS,

AFTERCOOLER FINS, CONDENSER FINS (machines equipped with air conditioner),

PTO OIL COOLER 4- 58

CLEAN INTERNAL AND EXTERNAL AIR FILTERS OF AIR CONDITIONER 4- 59

REPLACE PILOT FILTER ELEMENT 4- 60

CLEAN STRAINER OF PTO LUBRICATING OIL FILTER 4- 61

CHECK, REPLACE ALTERNATOR, AIR CONDITIONER COMPRESSOR DRIVE BELTS 4- 61

REPLACE DRAIN FILTER CARTRIDGE 4- 62

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE 4- 63

EVERY 1000 HOURS MAINTENANCE

REPLACE HYDRAULIC OIL FILTER ELEMENT 4- 65

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK 4- 66

CLEAN HYDRAULIC TANK RETURN STRAINER 4- 67

REPLACE FUEL TANK BREATHER ELEMENT 4- 68

CHANGE OIL IN SWING MACHINERY CASE 4- 69

CHANGE OIL IN PTO CASE 4- 71

GREASE, CHECK TENSION PULLEY ASSEMBLY OF ALTERNATOR, AIR CONDITIONER

COMPRESSOR DRIVE BELT 4- 72

CHECK WELDED STRUCTURE 4- 73

REPLACE SWING MOTOR COOLING FILTER ELEMENT 4- 76

EVERY 2000 HOURS MAINTENANCE

CHANGE OIL IN FINAL DRIVE CASE 4- 80

CHECK BOOST PIPING HOSE CLAMPS 4- 80

CHECK ALTERNATOR 4- 80

CHECK ENGINE VALVE CLEARANCE, ADJUST 4- 80

CLEAN HYDRAULIC TANK STRAINER 4- 81

CHECKING CHARGE PRESSURE OF NITROGEN GAS IN ACCUMULATOR (FOR CONTROL

CIRCUIT) 4- 82

EVERY 4000 HOURS MAINTENANCE

CHECK WATER PUMP 4- 86

CHECK STARTING MOTOR 4- 86

CHECK AIR COMPRESSOR, ADJUST 4- 86

REPLACE ACCUMULATOR (FOR CONTROL CIRCUIT) 4- 86

CHECK FOR LOOSENESS OF HIGH-PRESSURE PIPING CLAMP, HARDENING OF RUBBER 4-

87

CHECK FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER 4- 88

EVERY 5000 HOURS MAINTENANCE

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER 4- 89

EVERY 8000 HOURS MAINTENANCE

REPLACE HIGH-PRESSURE PIPING CLAMP 4- 91

REPLACE FUEL SPRAY PREVENTION CAP 4- 91

OVERHAUL STARTING MOTOR AND ALTERNATOR 4- 91

MAINTENANCE PROCEDURE

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100

HOURS)

Perform the following maintenance only after the first 100 hours.

Clean strainer of PTO lubricating oil filter

For details of the method of maintaining, see EVERY 500 HOURS MAINTENANCE.

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500

HOURS)

Carry out the following maintenance only after the first 500 hours of operation on new machines.

Change oil in swing machinery case

Change oil in PTO case

Change oil in final drive case

Special tools are needed for inspection and maintenance, so contact your Komatsu distributor.

For details of the method of replacing or maintaining, see EVERY 1000 HOURS and EVERY 2000

HOURS

SERVICE.

4

You might also like

- Isuzu c240 EngineDocument38 pagesIsuzu c240 Enginejads30117985% (33)

- Manual Sport Jet 90-120hp Oil Injection SystemDocument5 pagesManual Sport Jet 90-120hp Oil Injection SystemGerardo Espinola CardozoNo ratings yet

- Jt8 Engine 2Document100 pagesJt8 Engine 2ccoyure100% (9)

- Wildcat XX Service TrainingDocument50 pagesWildcat XX Service TrainingJennifer Schuler100% (2)

- 911 1972-1983 Workshop Manual Deel 1 Motor en KoppelingDocument146 pages911 1972-1983 Workshop Manual Deel 1 Motor en Koppelingdark_abyss2007255950% (2)

- Section K: Service Manual - Wheel Loading Shovel - 455ZXDocument4 pagesSection K: Service Manual - Wheel Loading Shovel - 455ZXJean Morales0% (2)

- Fuel Oil System by P.KDocument28 pagesFuel Oil System by P.Kkr_abhijeet72356587100% (1)

- 1300 Series PerkinsDocument1 page1300 Series Perkinstorjanice80% (5)

- Ford Racing CatalogDocument244 pagesFord Racing CatalogΖαχος ΤσελιοςNo ratings yet

- pc210 6kDocument12 pagespc210 6kАнатолийNo ratings yet

- Maintenance Check ListDocument3 pagesMaintenance Check ListYeny CatzinNo ratings yet

- Heui PDFDocument56 pagesHeui PDFGerman Ramos German Ramos100% (5)

- Induced Draught Fan CommissioningDocument9 pagesInduced Draught Fan CommissioningTamilarasanNo ratings yet

- Engine Overhaul - Bs-Iii Cummins EngineDocument28 pagesEngine Overhaul - Bs-Iii Cummins EngineAshesh BhattaraiNo ratings yet

- D6R Maintenance Interval ScheduleDocument12 pagesD6R Maintenance Interval Schedulepedro sanchezNo ratings yet

- GT650 Fuel System Manual PDFDocument9 pagesGT650 Fuel System Manual PDFsolidnateNo ratings yet

- Maintenance ScheduleDocument1 pageMaintenance ScheduleAbdul AzisNo ratings yet

- TT Oil Flooded Rotary Air CompressorDocument2 pagesTT Oil Flooded Rotary Air Compressorajo2402No ratings yet

- RH200 Engine & Pump Drive GearboxDocument26 pagesRH200 Engine & Pump Drive GearboxLuis jopi67% (3)

- D6TMaintenance Interval ScheduleDocument12 pagesD6TMaintenance Interval Schedulepedro sanchezNo ratings yet

- Preventive Maintenance Manual - DRFDocument115 pagesPreventive Maintenance Manual - DRFmliugong100% (8)

- Oxygen Plant MaintenanceDocument21 pagesOxygen Plant MaintenancesbhbiomedicalengineeringNo ratings yet

- PS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Document19 pagesPS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Fatra JuliandNo ratings yet

- 13 PowerplantDocument18 pages13 Powerplantfevary100% (4)

- 724K John Deere MantenimientoDocument2 pages724K John Deere MantenimientoErwin Castro100% (1)

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- Persiapan Preventive MaintenanceDocument20 pagesPersiapan Preventive MaintenanceTaufikNo ratings yet

- Wheel Loader 950H: Filter P.N./Oil TypeDocument5 pagesWheel Loader 950H: Filter P.N./Oil TypeKarim AbouhigaNo ratings yet

- M Shedule CutoutDocument48 pagesM Shedule CutoutHartono NoNo ratings yet

- Lub of Bolero SLXDocument21 pagesLub of Bolero SLXRohit PantNo ratings yet

- Maintenance and Electric ChartDocument9 pagesMaintenance and Electric Chartakamalapuri388100% (1)

- 912 Oil ChangeDocument4 pages912 Oil ChangeGaberNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- Fuel Emission Control SystemDocument11 pagesFuel Emission Control SystemHunny AggarwalNo ratings yet

- C5000SL инструкция по ремонту-01Document33 pagesC5000SL инструкция по ремонту-01Евгений ГубаревNo ratings yet

- Lubrication SystemDocument31 pagesLubrication SystemdwcdiscoNo ratings yet

- Cummins Om ManualDocument2 pagesCummins Om ManualVellai Pandi PNo ratings yet

- Recommended Maintenance ScheduleDocument50 pagesRecommended Maintenance ScheduleSpectrumRaijinNo ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredElvis PachecoNo ratings yet

- Water Cooling System 2. 3. Fuel Oil System 4. Lubricating Oil System Air SystemDocument23 pagesWater Cooling System 2. 3. Fuel Oil System 4. Lubricating Oil System Air SystemashNo ratings yet

- V40232 Clark C270 Torque ConverterDocument44 pagesV40232 Clark C270 Torque ConverterRemHenry100% (4)

- GA90-315 Power Point REV3Document27 pagesGA90-315 Power Point REV3amitans2003No ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- Manual de Sevicio S40Document581 pagesManual de Sevicio S40Franco MayangaNo ratings yet

- 9.4. Lubrication and MaintenanceDocument15 pages9.4. Lubrication and MaintenanceChristian Icaza SamaniegoNo ratings yet

- Preventive Maintanance Interval 10 Whell Loader SDLGDocument40 pagesPreventive Maintanance Interval 10 Whell Loader SDLGAdy Prasetyo100% (2)

- Torques PDFDocument1 pageTorques PDFluisNo ratings yet

- Perencanaan Preventive Maintenance Pada 416F Backhoe Loader CaterpillarDocument20 pagesPerencanaan Preventive Maintenance Pada 416F Backhoe Loader CaterpillarIqbal HamdiNo ratings yet

- Techdoc Print PageDocument47 pagesTechdoc Print PageBuku DigitalNo ratings yet

- GT PresentaionDocument98 pagesGT Presentaionmujeebtalib100% (6)

- 3G63 TurboDocument108 pages3G63 TurboLuis Felipe Dominguez del CastilloNo ratings yet

- Turbocharger - INGENIUM I4 2.0L PetrolDocument253 pagesTurbocharger - INGENIUM I4 2.0L Petrolkhaledserag23No ratings yet

- 6284 4 40 PDFDocument6 pages6284 4 40 PDFnpsNo ratings yet

- Power Train: - 170 - STMGXXX 4/97Document66 pagesPower Train: - 170 - STMGXXX 4/97Evan AT YoelNo ratings yet

- ER 58.11startup ProcedureDocument3 pagesER 58.11startup Proceduredongosuperstar100% (2)

- Hypress Compressor For VSP (Vertical Seismic Profile) JobDocument103 pagesHypress Compressor For VSP (Vertical Seismic Profile) JobIAN.SEMUTNo ratings yet

- RH200 Cooling SystemDocument14 pagesRH200 Cooling SystemLuis jopi100% (3)

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 pagesWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNo ratings yet

- Ashok LeylandDocument33 pagesAshok LeylandVasikar Vasi80% (5)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Esotec Esotar ManualDocument16 pagesEsotec Esotar ManualOnésio SantanaNo ratings yet

- Mercury2 8cyl GP Output Priority LayoutDocument2 pagesMercury2 8cyl GP Output Priority LayoutHonda Civic Wonder IndonesiaNo ratings yet

- Alemite Price List April 2019 PDFDocument52 pagesAlemite Price List April 2019 PDFZirai DasmalNo ratings yet

- High Pressure Hazard Safety AwarenessDocument57 pagesHigh Pressure Hazard Safety AwarenessPurnomo JarodNo ratings yet

- 02 PDFDocument17 pages02 PDFSerban LucianNo ratings yet

- Volvo AW50-55SN Saturn AF33-5: Back To MenuDocument12 pagesVolvo AW50-55SN Saturn AF33-5: Back To Menupmsgaspar100% (1)

- Pbe 91016 008bDocument4 pagesPbe 91016 008bRafael Dutil LucianaNo ratings yet

- Ps002 Pc45mr-3 General PsDocument2 pagesPs002 Pc45mr-3 General Pshendy_sikoraNo ratings yet

- 1010 Kva DG - RMC PlantDocument23 pages1010 Kva DG - RMC PlantShivam RaiNo ratings yet

- NUSSBAUM Truck Lifts Catalogue ENGLISHDocument24 pagesNUSSBAUM Truck Lifts Catalogue ENGLISHPavelNo ratings yet

- API 576 Study NotesDocument5 pagesAPI 576 Study NotesabdoNo ratings yet

- Swissauto SwissautoDocument16 pagesSwissauto SwissautoSimon CooperNo ratings yet

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocument38 pagesOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsJorge Perez DzulNo ratings yet

- Eaton Middle East ProfileDocument6 pagesEaton Middle East ProfileHaitham YounesNo ratings yet

- Tyre Modelling For Use in VehicleDocument20 pagesTyre Modelling For Use in VehicleBasil AzeemNo ratings yet

- Punch Press JH21-200Document133 pagesPunch Press JH21-200Mo NoNo ratings yet

- Subaru B9 Tribeca 06-: C. Certified Parts . ADD Products C Measure Year Parts Link Part No Item No. DescriptionDocument16 pagesSubaru B9 Tribeca 06-: C. Certified Parts . ADD Products C Measure Year Parts Link Part No Item No. DescriptionВалерий ГерасимовNo ratings yet

- Examination For DAY 1Document1 pageExamination For DAY 1Suryaman JsNo ratings yet

- 323 InstructionDocument13 pages323 InstructionHenry SilvaNo ratings yet

- Mu 5501Document1 pageMu 5501Prashant PatilNo ratings yet

- 113c2b Iveco Stock Clearance AstraDocument72 pages113c2b Iveco Stock Clearance AstrarrNo ratings yet

- Motor 3126B Ubicación de ComponentesDocument4 pagesMotor 3126B Ubicación de ComponentesAlexis MikeNo ratings yet

- Yanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts ManualDocument4 pagesYanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts Manualdenise100% (32)

- 3.NRG Planetary Gear InterchangeDocument10 pages3.NRG Planetary Gear InterchangeEpuAmerNo ratings yet

- UNI-K Spec Sheet 2024Document1 pageUNI-K Spec Sheet 2024pathan_riyazkhanNo ratings yet

- 1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 110 KDocument18 pages1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 110 KSteeven RodriguezNo ratings yet

- Sany Sy365cDocument8 pagesSany Sy365cWidiyanto Wibowo50% (2)

- Pneumatic Tire Roller Pneumatic Tire Rollers Series HP / Series H283Document2 pagesPneumatic Tire Roller Pneumatic Tire Rollers Series HP / Series H283Hamdi JemmaliNo ratings yet