Professional Documents

Culture Documents

ASTM E309 Eddy-Current Examination of Steel Tubular Products Using

ASTM E309 Eddy-Current Examination of Steel Tubular Products Using

Uploaded by

midmereOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E309 Eddy-Current Examination of Steel Tubular Products Using

ASTM E309 Eddy-Current Examination of Steel Tubular Products Using

Uploaded by

midmereCopyright:

Available Formats

Designation: E 309 – 95 (Reapproved 2006)

Standard Practice for

Eddy-Current Examination of Steel Tubular Products Using

Magnetic Saturation1

This standard is issued under the fixed designation E 309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

1. Scope SNT-TC-1A Recommended Practice for Personnel Qualifi-

1.1 This practice2 covers a procedure for applying the cation and Certification in Nondestructive Testing4

eddy-current method to detect discontinuities in ferromagnetic ANSI/ASNT CP-189 ASNT Standard for Qualification and

pipe and tubing (Note 1) where the article being examined is Certification of Nondestructive Testing Personnel4

rendered substantially non-magnetic by the application of a 2.3 Military Standard:

--```,``,,,``,`,`,``,``,`,`,``,-`-`,,`,,`,`,,`---

concentrated, strong magnetic field in the region adjacent to the MIL-STD-410E Nondestructive Testing Personnel Qualifi-

examining coil. cation and Certification5

NOTE 1—For convenience, the term tube or tubular product will 3. Terminology

hereafter be used to refer to both pipe and tubing.

3.1 General—Standard terminology relating to electromag-

1.2 The procedure is specifically applicable to eddy-current netic examination may be found in Terminology E 1316,

examination methods using an encircling-coil assembly. How- Section C, “Electromagnetic Testing.”

ever, eddy-current techniques that employ either fixed or

rotating probe-coil assemblies may be used to either enhance 4. Summary of Practice

discontinuity sensitivity on the large diameter tubular products 4.1 The examination is conducted using one of two general

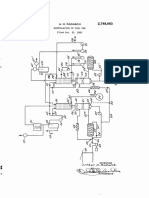

or to maximize the response received from a particular type of techniques shown in Fig. 1.

discontinuity. 4.1.1 One technique employs one or more exciter and sensor

1.3 This practice is intended for use on tubular products coils that encircle the tube and through which the tubular

having outside diameters from approximately 1⁄4 to 10 in. (6.35 product to be examined is passed. Some circuit configurations

to 254.0 mm). These techniques have been used for smaller and employ one or more coils that concurrently function as both

larger sizes however, and may be specified upon contractual exciters and sensors. Alternating current passes through the

agreement between the purchaser and the supplier. exciting coil which, by reason of its proximity, induces

corresponding currents (eddy currents) to flow in the tubular

2. Referenced Documents product. The sensor coil detects the resultant electromagnetic

2.1 ASTM Standards: 3 flux related to these currents. The presence of discontinuities in

E 543 Specification for Agencies Performing Nondestruc- the tubular product will alter the normal flow of currents and

tive Testing this change is detected by the sensor. The encircling-coil

E 1316 Terminology for Nondestructive Examinations technique is capable of examining the entire circumference of

2.2 Other Documents: a tubular product.

4.1.2 Another technique employs a probe coil with one or

1

more sensors that are in close proximity to the surface of the

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.07 on

tubular product to be examined. Since the probe is generally

Electromagnetic Method. small and does not encircle the article being examined, it

Current edition approved July 1, 2006. Published July 2006. Originally approved examines only a limited area in the vicinity of the probe. This

in 1966. Last previous edition approved in 2001 as E 309 - 95(2001).

2

For ASME Boiler and Pressure Vessel Code applications see related Recom-

mended Practice SE 309 in Section V of that Code.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society for Nondestructive Testing (ASNT), P.O. Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Delphi Steering Systems/5943248100

No reproduction or networking permitted without license from IHS Not for Resale, 02/10/2010 05:03:51 MST

E 309 – 95 (2006)

(a) Encircling Coil.

(b) Probe Coil—longitudinal scanning of weld seam only.

--```,``,,,``,`,`,``,``,`,`,``,-`-`,,`,,`,`,,`---

(c) Probe Coil—scanning along a spiral path.

FIG. 1 Encircling-Coil and Probe-Coil Techniques for Electromagnetic Testing of Tubular Products

technique is frequently used for examination of welded tubular devices, or both, a mechanical marker, or a signal-recording

products in which only the weld is examined by scanning along device, or a combination of these. Signals can be caused by

the weld zone. outer surface, inner surface, or subsurface discontinuities if the

4.1.3 The magnetic permeability of ferromagnetic materials eddy-current frequency provides sufficient depth of penetration

severely limits the depth of penetration of induced eddy (see 11.1). The eddy-current method is sensitive to metallur-

currents. Furthermore, the permeability variations inherent in gical variations that occur as a result of processing, thus all

ferromagnetic tubular products often cause anomalous test received indications are not necessarily indicative of defective

results. A useful solution to this problem involves the applica- tubing.

tion of a strong external magnetic field in the region of the

examining coil or probe. This technique, known as magnetic 5. Significance and Use

saturation, is applied to a magnetic material, such as a steel

tube, to suppress the magnetic characteristics of permeability, 5.1 The purpose of this practice is to outline a procedure for

hysteresis, etc., so that the material under examination is the detection and location of discontinuities such as pits, voids,

effectively rendered nonmagnetic. When achieved, this condi- inclusions, cracks, or abrupt dimensional variations in ferro-

tion allows an eddy-current system to measure and detect magnetic tubing using the electromagnetic (eddy-current)

electrical resistivity and geometrical variations (including de- method. Furthermore, the relative severity of a discontinuity

fects) independent of concurrent variations in magnetic prop- may be indicated, and a rejection level may be set with respect

erties. to the magnitude of the indication.

4.1.4 Changes in electromagnetic response caused by the 5.2 The response from natural discontinuities can be signifi-

presence of discontinuities are detected by the sensor, ampli- cantly different than that from artificial discontinuities such as

fied, and modified in order to actuate audio or visual indicating drilled holes or notches. For this reason, sufficient work should

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Delphi Steering Systems/5943248100

No reproduction or networking permitted without license from IHS Not for Resale, 02/10/2010 05:03:51 MST

E 309 – 95 (2006)

be done to establish the sensitivity level and set-up required to 7.5 Driving Mechanism—The movement of the tube

detect natural discontinuities of consequence to the end use of through the coil or past the probe shall be performed at uniform

the product. speed and with minimum vibration of the tube, coil, and probe.

5.3 Eddy-current examination systems are generally not 7.6 Reference Standard—The standard used to adjust the

sensitive to discontinuities adjacent to the ends of the tube. The sensitivity of the apparatus shall be free of interfering discon-

extent of the end effect region can be determined in accordance tinuities and shall be of the same nominal alloy, temper, and

with 8.6. dimensions as the tubes to be examined on a production basis.

It shall be of sufficient length to permit the spacing of artificial

6. Basis of Application discontinuities to provide good signal resolution and be me-

6.1 The following acceptance criteria may be specified in chanically stable while in the examining position in the

the purchase specification, contractual agreement, or else- apparatus. Artificial discontinuities placed in the tube shall be

where, and may require agreement between the purchaser and one or more of the following types. (See Fig. 2.)

the supplier: 7.6.1 Notches—Notches may be produced by Electric Dis-

6.1.1 Time of examination or point(s) in the manufacturing charge Machining (EDM), milling, or other means. Longitudi-

process at which the material will be examined, nal, transverse, or both may be used (Note 2). Orientation,

6.1.2 Maximum time interval between equipment calibra- dimensions (width, length, and depth), and configuration of the

tion checks, notches affect the response of the eddy-current system. Notch

6.1.3 Methods for determining the extent of end effect, depth is usually specified as a percentage of nominal wall

6.1.4 Size and type of product, thickness of the tubular product being examined. Notches may

6.1.5 Type, method of manufacture, dimensions, location, be placed on the outer, inner, or both surfaces of the reference

and number of artificial discontinuities to be placed on the standard. Outer surface notches provide an indication of

reference standard, system response to discontinuities originating on the outer tube

6.1.6 Methods of verifying dimensions and allowable toler- surface; whereas inner surface notches provide an indication of

ances of artificial discontinuities, system response to discontinuities originating on the inner tube

6.1.7 Extent of examination, and surface.

6.1.8 Disposition of material with indications.

NOTE 2—Longitudinal notch standards are normally used when testing

6.1.9 Operator Qualification and Certification—If required, with a rotating-probe system.

NDT personnel shall be qualified in accordance with a nation-

ally recognized NDT personnel qualification practice or stan- 7.6.2 Holes—Drilled holes may be used. They are usually

dard such as ANSI/ASNT-CP-189, SNT-TC-1A, MIL-STD- drilled completely through the wall. Care should be taken

410, or a similar document. The practice or standard used and during drilling to avoid distortion of the tube and hole.

its applicable revision shall be documented in the contractual 7.6.3 The configuration, orientation, and dimensions (diam-

agreement between the using parties. eter of holes and the width, length, and depth of notches) of the

6.1.10 Qualification of Nondestructive Agencies—If speci- artificial discontinuities to be used for establishing acceptance

fied in the contractual agreement, NDT agencies shall be limits should be subject to agreement between the purchaser

qualified and evaluated in accordance with Practice E 543. The and the supplier.

applicable edition of Practice E 543 shall be specified in the

--```,``,,,``,`,`,``,``,`,`,``,-`-`,,`,,`,`,,`---

8. Adjustment and Standardization of Apparatus

contractual agreement.

8.1 Select the apparatus, examining frequency, coil or probe

7. Apparatus configuration, magnetic saturation system, phase discrimina-

7.1 Electronic Apparatus—The electronic apparatus shall tion, and other circuitry, as well as speed of examination.

be capable of energizing the coils or probes with alternating

currents of a selected frequency and shall be capable of sensing

the changes in the electromagnetic response of the sensors.

Equipment may include appropriate signal processing circuits

such as a phase discriminator, filter circuits, etc., as required

for the particular application.

7.2 Encircling-Coil Assembly—The encircling-coil assem-

bly shall consist of one or more electrical coils that encircle the

article being examined.

7.3 Probe-Coil Assembly—The probe-coil assembly nor-

mally contains an exciting coil and a sensor, although in some

cases the exciter and sensor are one and the same.

7.4 Magnetic Saturation System—The magnetic saturation

system shall consist of a suitable method of applying a strong

magnetic field to the region of the tube adjacent to the coil or

(a) Longitudinal Notch (Milled or EDM) ID, OD, or both.

probe-coil assembly so as to render that region of the tube (b) Transverse Notch (Milled, Filed, or EDM) ID, OD, or both.

effectively nonmagnetic. Typical systems employ either per- (c) Drilled Hole (Radially Through One Wall).

manent magnets or electromagnets. FIG. 2 Various Types of Artificial Discontinuities

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Delphi Steering Systems/5943248100

No reproduction or networking permitted without license from IHS Not for Resale, 02/10/2010 05:03:51 MST

E 309 – 95 (2006)

8.2 Fabricate applicable reference standards in accordance 270°. This adjustment is typically accomplished by ensuring

with the agreement between the purchaser and the tubing uniform probe lift-off around the circumference of the tube.

supplier. 8.6 The extent of end effect (Note 4) is determined by using

8.3 Adjust the field strength of the magnetic saturation a special reference tube containing a series of similar notches

system to obtain an adequate level of magnetization in the tube or holes near one or both of the ends (Fig. 4). To evaluate the

in accordance with 8.3.1 and 8.3.2. This is the minimum degree end effect when notches or holes are placed near only one of

of magnetization required for the successful examination of the the ends, pass the tube through the system twice, once each

type and size tube represented by the reference standard. with the notches or holes at the leading and trailing ends. When

8.3.1 Adjust the eddy-current system sensitivity such that the notches or holes are located on the front end of the tube,

without the application of the external magnetization field the then the end effect region, or the region of inadequate exami-

examination of the reference standard results in excessive nation, extends from the front end of the tube to the point

“noise.” This condition is characterized by repeated alarms where the first of the holes or notches are detected with

from the instrument over the entire length of the tube. uniform response. When the holes or notches are on the last

8.3.2 On repeated examinations of the reference standard, end through the system, then the end effect region for that end

increase the magnetizing current or the magnetic field to the extends from the point at which the last hole or notch is

point where no further reduction in the tube “noise” is obtained detected with uniform response to the end of the tube.

from a further increase in magnetizing field strength.

NOTE 4—It is intended that the extent of the end effect region be

NOTE 3—It should be pointed out that there is sometimes a false determined only once for each specific diameter, gage, speed, coil

indication of saturation that can result in acceptance of a false saturation configuration, and test frequency, and need not be repeated for each run or

level (Fig. 3). during the periodic standardization checks.

8.4 Adjust the apparatus to obtain an optimum signal-to-

noise ratio by adjusting for the minimum sensitivity required to 9. Procedure

reliably detect the artificial discontinuities in the reference 9.1 Standardize the system at the start and end of each run

standard. This shall be performed under conditions (such as and at the beginning of each shift (or turn) using the reference

testing speed) identical to those to be used in the production standard.

examination of the tubular products if the system is influenced 9.2 Pass the tubes to be examined through the encircling

by these conditions. coil, or past the probe coil, with the apparatus adjusted in

8.5 While performing 8.4, or as a separate operation, rotate accordance with Section 8. Tubes that produce output signals

the reference standard in either 90 or 120° increments to not conforming to the limits in the purchase order or other

determine the location of the “electrical” center in the exam- agreed upon specifications may at the option of the manufac-

ining coil. Mechanically adjust the position of the tube within turer be set aside for re-examination. If upon re-examination

the coil to obtain nearly equal responses from the artificial the output signals are within acceptable limits, or are demon-

--```,``,,,``,`,`,``,``,`,`,``,-`-`,,`,,`,`,,`---

discontinuities regardless of their circumferential location. strated by other examination to be irrelevant, the tubes shall be

8.5.1 Determine the electrical center of a probe coil with accepted.

respect to the probe field-to-material normality and uniform 9.3 Tubes may be examined in the final drawn, annealed,

circumferential lift-off. Adjust the probe field-to-material nor- heat-treated, or as-welded condition, or at the point specified in

mality such that uniform signals are obtained from the stan- the purchase specification. The point in processing at which the

dardization notches or holes regardless of their position within examination is made should be agreed upon by the supplier and

the intended examination area under the probe. This adjust- the purchaser. The tubes shall be free of foreign substances that

ment is typically encountered when a probe is scanned along a could interfere with the effectiveness of the examination.

line such as a weld zone.

8.5.2 Establish electrical centering of a rotating probe by

adjusting the apparatus to obtain uniform signals from the

reference notches or holes when positioned at 0, 90, 180, and

FIG. 4 Location of Artificial Discontinuities (Drilled Holes) that

FIG. 3 Graph Depicting “False Saturation” Level Sometimes Can Be Used to Determine the Extent of End Effect (The typical

Encountered when Magnetically Saturating the Material under distance from the tube end and between each hole is 1⁄4 in. (6.35

Test mm).)

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Delphi Steering Systems/5943248100

No reproduction or networking permitted without license from IHS Not for Resale, 02/10/2010 05:03:51 MST

E 309 – 95 (2006)

10. Typical Sizes of Artificial Discontinuities 11. Precautionary Information

10.1 Longitudinal Notches—Longitudinal notch depth is 11.1 Since the density of eddy currents decreases nearly

usually specified as a percentage of nominal wall thickness and exponentially as the distance from the external surface in-

values of 10, 121⁄2 , or 20 % are typical. Longitudinal notch creases, the response to deep-seated discontinuities decreases.

width is a relevant variable for eddy-current examination and Correspondingly, discontinuity orientation also affects the

should be specified. Notch length is usually specified in the system response and should be taken into consideration when

form of a maximum dimension. Maximum notch lengths of 1⁄4 establishing the examination sensitivity.

, 1⁄2 and 1.0 in. are typical. 11.2 In preparing a reference standard for welded tubing,

10.2 Transverse Notches—Transverse notch depth is mea- artificial discontinuities should be placed in both the weld

sured at the deepest point and is usually specified as a metal and the parent metal when the responses are expected to

percentage of nominal wall thickness. Values of 10, 121⁄2 , and be different and if both are to be examined. The apparatus is

20 % are typical. Transverse notch width is a relevant variable then adjusted to obtain an optimum signal-to-noise ratio.

for eddy-current examination and is typically specified as 11.2.1 When examining only the weld area, the discontinui-

follows: “The width of the transverse notches shall be the ties shall be placed only in the weld area.

minimum practical but not more than 1⁄16 in.” 11.3 The examination frequency and the type of apparatus

10.3 Holes—When holes are used for standardization, they being used should be considered when choosing the examining

are usually drilled all the way through one wall of the tube. The speed. Certain types of equipment are effective only over a

diameter of these holes may be specified as a percentage of given speed range; therefore, the examining speed should fall

wall thickness, or arbitrary sizes may be chosen based on within this range.

factors involving intended service or other appropriate criteria. 11.4 Discontinuities such as scratches or seams that are

--```,``,,,``,`,`,``,``,`,`,``,-`-`,,`,,`,`,,`---

Typical hole diameters range from 20 to 50 % of the nominal continuous and uniform over the full length of the tube may not

tube wall thickness; although a 1⁄16-in. diameter hole is speci- always be detected with differential encircling coils or probes

fied for use with all sizes of tubing in one widely used scanned along the tube length.

industrial standard. It is considered good practice to include

holes with diameters greater and smaller than the reference size 12. Keywords

used to set the reject level since these provide a useful means 12.1 discontinuity; encircling coil; ferromagnetic pipe; fer-

of verifying that the dynamic response of the equipment is romagnetic tubing; magnetic saturation system; magnetizing

adequate. field strength; probe coil; tube; tubular product

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=Delphi Steering Systems/5943248100

No reproduction or networking permitted without license from IHS Not for Resale, 02/10/2010 05:03:51 MST

You might also like

- E 215 - 98 R04 - Rtixnq - PDFDocument7 pagesE 215 - 98 R04 - Rtixnq - PDFLeón SuárezNo ratings yet

- Astm e 1001Document9 pagesAstm e 1001KEN KNo ratings yet

- Taller de Autoaprendizaje No 3Document129 pagesTaller de Autoaprendizaje No 3WALTER ANDRES CORDOBA CACERENo ratings yet

- Astm E571 - 12Document5 pagesAstm E571 - 12maxpan max100% (2)

- Eddy-Current Examination of Steel Tubular Products Using Magnetic SaturationDocument5 pagesEddy-Current Examination of Steel Tubular Products Using Magnetic SaturationROHITNo ratings yet

- Astm e 309Document5 pagesAstm e 309김경은No ratings yet

- Astm E309-01Document5 pagesAstm E309-01Carlos Raul Caballero LeonNo ratings yet

- Astm E426-98 R03 E03 Et PDFDocument4 pagesAstm E426-98 R03 E03 Et PDFJORGE ARTURO TORIBIO HUERTA100% (1)

- E571-98 EC Nickel Alloy TubesDocument4 pagesE571-98 EC Nickel Alloy TubessanthakumarNo ratings yet

- Electromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular ProductsDocument5 pagesElectromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular Productshimaw20393No ratings yet

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysMaxNo ratings yet

- Astm E426Document4 pagesAstm E426Rafi YusohNo ratings yet

- Astm e 426Document4 pagesAstm e 426김경은No ratings yet

- Astm E1312Document3 pagesAstm E1312David Francisco Plata DuranNo ratings yet

- E 1312 - 99 RtezmtiDocument3 pagesE 1312 - 99 RtezmtiNorman ricardo RojoNo ratings yet

- E 213 - 04 - RtixmwDocument11 pagesE 213 - 04 - RtixmwGopi SelvarajNo ratings yet

- Astm E-570-09 RFL Steel TubeDocument7 pagesAstm E-570-09 RFL Steel TubempusNo ratings yet

- Eddy Current Examination of Steel Tubular Products Using Magnetic SaturationDocument2 pagesEddy Current Examination of Steel Tubular Products Using Magnetic SaturationChenjie ZhuNo ratings yet

- E 1001 - 04 - RtewmdeDocument9 pagesE 1001 - 04 - RtewmdeGopi SelvarajNo ratings yet

- E-570 Flujo DispersoDocument7 pagesE-570 Flujo DispersoAriel TerrensNo ratings yet

- Astm E243Document6 pagesAstm E243javierguillermo1983No ratings yet

- E703-14 Standard Practice For Electromagnetic (Eddy Current) Sorting of Nonferrous MetalsDocument5 pagesE703-14 Standard Practice For Electromagnetic (Eddy Current) Sorting of Nonferrous MetalsudomNo ratings yet

- Se 213Document6 pagesSe 213S.K.AGRAWALNo ratings yet

- Electromagnetic (Eddy Current) Sorting of Nonferrous Metals: Standard Practice ForDocument5 pagesElectromagnetic (Eddy Current) Sorting of Nonferrous Metals: Standard Practice Forgugu carterNo ratings yet

- Astm E570Document7 pagesAstm E570陳明書No ratings yet

- E243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesE243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesudomNo ratings yet

- ASME BPVC 2021 Section V ARticle 26 Eddy CurrentDocument6 pagesASME BPVC 2021 Section V ARticle 26 Eddy CurrentJuan CastilloNo ratings yet

- ASTM E 164 Standard Practice For Ultrasonic Contact Examination of WeldmentsDocument23 pagesASTM E 164 Standard Practice For Ultrasonic Contact Examination of WeldmentsILSEN N. DAETNo ratings yet

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysNathaniel LuraNo ratings yet

- Evaluacion de Tuberia Por UltrasonidoDocument11 pagesEvaluacion de Tuberia Por UltrasonidoJuan Pablo Torres AlvarezNo ratings yet

- Ultrasonic Examination of The Weld Zone of Welded Pipe and TubingDocument4 pagesUltrasonic Examination of The Weld Zone of Welded Pipe and TubingERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Electromagnetic (Eddy Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie TemperatureDocument3 pagesElectromagnetic (Eddy Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie Temperaturefredy lopezNo ratings yet

- ASTM E213 - Standard Practice For Ultrasonic Examination of Metal Pipe and TubingDocument11 pagesASTM E213 - Standard Practice For Ultrasonic Examination of Metal Pipe and Tubingvijaysharvesh01No ratings yet

- E566 - Eddy Current Sorting FerrousDocument5 pagesE566 - Eddy Current Sorting Ferrousshunmu_scribNo ratings yet

- E426-98 EC SS TubularDocument4 pagesE426-98 EC SS TubularsanthakumarNo ratings yet

- ASTM E273 US Tubos Solda LongitudinalDocument3 pagesASTM E273 US Tubos Solda LongitudinalJota JacquesNo ratings yet

- Astm e 213Document11 pagesAstm e 213Satwant singhNo ratings yet

- E273 Dgyx6217Document4 pagesE273 Dgyx6217benderman1No ratings yet

- A 388 - A 388M - 03 - Qtm4oc9bmzg4tqDocument8 pagesA 388 - A 388M - 03 - Qtm4oc9bmzg4tqRod RoperNo ratings yet

- Electromagnetic (Eddy-Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie TemperatureDocument3 pagesElectromagnetic (Eddy-Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie TemperaturesanthakumarNo ratings yet

- ASTM E 214 - 01 - Examen UT InmersionDocument3 pagesASTM E 214 - 01 - Examen UT InmersionMono-CCt100% (2)

- E 214 - 01 - Rtixna - PDFDocument3 pagesE 214 - 01 - Rtixna - PDFLeón SuárezNo ratings yet

- E 2775 - Guided WavesDocument11 pagesE 2775 - Guided WavesalexedamalaNo ratings yet

- E309 Yzar1817 (21301)Document6 pagesE309 Yzar1817 (21301)Mahmood KhanNo ratings yet

- E 273 - 15Document5 pagesE 273 - 15juan f100% (1)

- Ultrasonic Angle-Beam Contact Testing: Standard Practice ForDocument9 pagesUltrasonic Angle-Beam Contact Testing: Standard Practice ForgerardomediavillaepnNo ratings yet

- 243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Document7 pages243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Ali MohsinNo ratings yet

- ASTM E213-02 UT-Pipes & Tubing PDFDocument11 pagesASTM E213-02 UT-Pipes & Tubing PDFZeeshan HasanNo ratings yet

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDamian Vega GNo ratings yet

- Ultrasonic Contact Examination of Weldments: Standard Practice ForDocument23 pagesUltrasonic Contact Examination of Weldments: Standard Practice ForDiego GamarraNo ratings yet

- E243 13 PDFDocument6 pagesE243 13 PDFDaniel Mauricio Prieto ValderramaNo ratings yet

- Article 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesDocument7 pagesArticle 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesAnny CordeiroNo ratings yet

- Detection of Large Inclusions in Bearing Quality Steel by The Ultrasonic MethodDocument9 pagesDetection of Large Inclusions in Bearing Quality Steel by The Ultrasonic Methodmarcospaulo01No ratings yet

- ASTM E2096 Standard Practice For in Situ Examination of Ferromagnetic Heat-Exchanger Tubes Using Remote Field Testing PDFDocument9 pagesASTM E2096 Standard Practice For in Situ Examination of Ferromagnetic Heat-Exchanger Tubes Using Remote Field Testing PDFBF LuisNo ratings yet

- ASTM E2775 11 Guided Waves PDFDocument11 pagesASTM E2775 11 Guided Waves PDFjeswinNo ratings yet

- Astm E-2929Document11 pagesAstm E-2929DanielVegaNeiraNo ratings yet

- Standard Practice For Ultrasonic Examination of Austenitic Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Austenitic Steel ForgingssyyouNo ratings yet

- Ultrasonic Angle-Beam Contact Testing: Standard Practice ForDocument9 pagesUltrasonic Angle-Beam Contact Testing: Standard Practice ForNubia BarreraNo ratings yet

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Boq PCWDocument1 pageBoq PCWNARMADA ENGINEERINGNo ratings yet

- Materials 3 2 1 PDFDocument8 pagesMaterials 3 2 1 PDFAmaliNo ratings yet

- Chapter VIII Disinfection, Decontamination and SterilizatioDocument38 pagesChapter VIII Disinfection, Decontamination and Sterilizatioeyoel100% (1)

- 2102TN42Document1 page2102TN42mohamad mostafaviNo ratings yet

- BCM 2522 L1-MinDocument15 pagesBCM 2522 L1-MinLutendo Assurance MadzivhaaNo ratings yet

- Science10 Q4 M6Document12 pagesScience10 Q4 M6Kunyubunani BilatNo ratings yet

- Chemistry v1.00 For TI-89 Flash Application Senior Programmer: Matt AcostaDocument5 pagesChemistry v1.00 For TI-89 Flash Application Senior Programmer: Matt Acostahasta abajo garganta profundaNo ratings yet

- Contents:: Physics 121 Practice Problem Solutions 09 Magnetic FieldsDocument12 pagesContents:: Physics 121 Practice Problem Solutions 09 Magnetic FieldsEdem Koffi MissihounNo ratings yet

- Material Composition of Different MetalsDocument8 pagesMaterial Composition of Different MetalsAjesh KumarNo ratings yet

- Pseudo PressureDocument195 pagesPseudo PressureGonzalo Laura QuisbertNo ratings yet

- Patent US2748063Document6 pagesPatent US2748063Gökhan Kürşat demirNo ratings yet

- 9702 s16 QP 12 PDFDocument24 pages9702 s16 QP 12 PDFboulboutNo ratings yet

- A New Anode Material For Oxygen Evolution in Molten Oxide ElectrolysisDocument6 pagesA New Anode Material For Oxygen Evolution in Molten Oxide ElectrolysisjnNo ratings yet

- Continuum Damage Mechanics Model For Damage Assessment and Strength Prediction in Laminated Composite StructuresDocument15 pagesContinuum Damage Mechanics Model For Damage Assessment and Strength Prediction in Laminated Composite StructuresJad Antonios JelwanNo ratings yet

- Grade 7: Module 2, Quarter 3 Lesson 2.1Document29 pagesGrade 7: Module 2, Quarter 3 Lesson 2.1Judy Caroline CatacutanNo ratings yet

- Presented To: Dr. Islam Ullah Khan Presented By: Khadeeja Ikram Roll No: 0164-BH-CHEM-11Document45 pagesPresented To: Dr. Islam Ullah Khan Presented By: Khadeeja Ikram Roll No: 0164-BH-CHEM-11Abiyot NeguNo ratings yet

- Introduction To Magnetic Particle Testing: Basic ConceptsDocument3 pagesIntroduction To Magnetic Particle Testing: Basic ConceptsAshfaq KhanNo ratings yet

- Personal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)Document122 pagesPersonal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)playstationus465No ratings yet

- N3 Engineering Science April 2023 MemorandumDocument7 pagesN3 Engineering Science April 2023 MemorandumNkazimulo MbonaniNo ratings yet

- CH 11Document38 pagesCH 11Chala1989No ratings yet

- Preparation of Starch Nanoparticles in A New Ionic Liquid-in-Oil MicroemulsionDocument12 pagesPreparation of Starch Nanoparticles in A New Ionic Liquid-in-Oil MicroemulsionPaula NancyNo ratings yet

- Apparent Density by Physical Measurements of Manufactured Anode and Cathode Carbon Used by The Aluminum IndustryDocument3 pagesApparent Density by Physical Measurements of Manufactured Anode and Cathode Carbon Used by The Aluminum IndustryGuillermo ZapataNo ratings yet

- Price List Kmia. Oralarang Chemindo JogjaDocument6 pagesPrice List Kmia. Oralarang Chemindo JogjaAndi KurniawanNo ratings yet

- 02 Momentum, Impulse and CollisionDocument22 pages02 Momentum, Impulse and CollisionJoyce CulloNo ratings yet

- Wolfe - Cellular ThermodynamicsDocument13 pagesWolfe - Cellular Thermodynamicsandres_old_condeNo ratings yet

- Explanation of SPDF OrbitalsDocument2 pagesExplanation of SPDF OrbitalsDougNo ratings yet

- Air MassDocument13 pagesAir MassAnand raj Raja BabuNo ratings yet

- Draft IJRES Journal - Sulthan Zanky NaufalDocument9 pagesDraft IJRES Journal - Sulthan Zanky NaufalSULTHAN ZANKYNo ratings yet

- Module 3Document50 pagesModule 3Venkitaraj K PNo ratings yet