Professional Documents

Culture Documents

N2 Generator Atlas Copco - NGM+7-70 - EN For SBK1

N2 Generator Atlas Copco - NGM+7-70 - EN For SBK1

Uploaded by

Taufan JustvandsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

N2 Generator Atlas Copco - NGM+7-70 - EN For SBK1

N2 Generator Atlas Copco - NGM+7-70 - EN For SBK1

Uploaded by

Taufan JustvandsCopyright:

Available Formats

Nitrogen generators

Membrane technology

NGM+ 7-70

mo

20%

re e

ffic

ien

t

Reliable on-site nitrogen generation

with best-in-class performance

Membrane technology has traditionally offered

high-quality, reliable on-site nitrogen generation. Membrane inside

Atlas Copco’s new NGM+ now raises the bar with

exceptionally low air and energy consumption,

giving you the lowest cost of ownership on the

market today. Maximizing the robustness and

simplicity of membrane technology, the NGM+ is a

compact, quiet and dependable presence on your

production floor.

Cost savings Absolute reliability Ease of use

• Minimal energy consumption per • Continuous supply of nitrogen with • Easy purity adjustment on

unit of N2. a stable purity. controller.

• 20% less feed air required than a • Advanced control and monitoring • Fast, straightforward start-up

traditional generator. features optimize the uncluttered and commissioning.

• Lowest total cost of ownership in its build and stable performance of

class. membrane technology.

• No wasteful feed air heater required. • Can be combined with a cylinder or

bulk gas supply system.

• Best-in-class membrane technology.

The superior membrane generator

• Complete set-up: Precision O2 sensor, feed air monitoring,

and gas purity regulation valve are included as standard.

• Premium membrane:

- Dry, high-quality N2 at the lowest air consumption.

- Pre-aged membranes eliminate performance loss after

commissioning.

- Soft start protects membrane and extends lifetime.

• Elektronikon® Touch controller:

- Allows for plug-and-play installation.

- Easy purity setting, alerts and connectivity options.

- Feed air monitoring and optional interception.

• Compact design:

- Built-in premium filtration with low pressure drop.

- No external tanks required for operation with

2935 0956 41 © 2021, Atlas Copco Airpower NV, Belgium. All rights reserved. Designs and specifications are subject to change without notice or obligation. Read all safety instructions in the manual before usage.

stable flow.

Keep your energy costs in check: sustainable

The no-heater solution solution

Some membrane N2 generators use a feed air heater to boost

performance. However, these heaters use a lot of energy,

inflating your operational costs. The NGM+ doesn’t require a

heater to reach maximum capacity. The result: a substantial

reduction in your running costs.

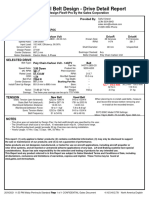

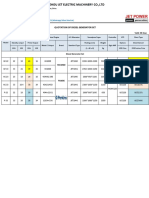

Technical specifications

Nitrogen - FND * Dimensions (W x D x H) Weight

Type

95% 96% 97% 98% 99% 99.5% mm in kg lbs

FND Nm³/h 25 21 17.2 13.4 9.6 7.1

NGM 7+ 820 x 772 x 2090 32 x 30 x 82 228 503

FND Scfm 14.5 12.3 10.1 7.9 5.7 4.2

FND Nm³/h 49 42 34 27 19.3 14.2

NGM 14+ 820 x 772 x 2090 32 x 30 x 82 251 553

FND Scfm 29 25 20 15.8 11.3 8.4

FND Nm³/h 74 63 52 40 29 21

NGM 21+ 820 x 1470 x 2090 32 x 58 x 82 472 1041

FND Scfm 44 37 30 24 17 12.6

FND Nm³/h 99 84 69 54 39 28

NGM 28+ 820 x 1470 x 2090 32 x 58 x 82 499 1100

FND Scfm 58 49 41 32 23 16.8

FND Nm³/h 123 105 86 67 48 36

NGM 35+ 820 x 1470 x 2090 32 x 58 x 82 553 1219

FND Scfm 73 62 51 39 28 21

FND Nm³/h 148 125 103 81 58 43

NGM 42+ 820 x 1470 x 2090 32 x 58 x 82 576 1270

FND Scfm 87 74 61 47 34 25

FND Nm³/h 173 146 121 94 67 50

NGM 49+ 820 x 1470 x 2090 32 x 58 x 82 617 1360

FND Scfm 102 86 71 55 40 29

FND Nm³/h 198 167 138 107 77 57

NGM 56+ 820 x 1470 x 2090 32 x 58 x 82 642 1415

FND Scfm 116 98 81 63 45 34

FND Nm³/h 222 188 155 121 87 64

NGM 63+ 820 x 1470 x 2090 32 x 58 x 82 688 1517

FND Scfm 131 111 91 71 51 38

FND Nm³/h 247 209 172 134 96 71

NGM 70+ 820 x 1470 x 2090 32 x 58 x 82 713 1572

FND Scfm 145 123 101 79 57 42

*

FND: Free Nitrogen Delivery

Reference conditions:

- Compressed air effective inlet pressure: 8 bar(g)/116 psi(g) Options

- Ambient air temperature: 20°C/68°F

- Feed air pressure dewpoint: 3°C/37°F

• Feed air quality (PDP) monitoring & interception

Performance: • Nitrogen quality (PDP) monitoring

- Nitrogen capacity/air consumption can vary up to +/- 5% • Nitrogen digital flow meter

- Inlet air PDP to be at least 10°C/18°F lower than inlet

temperature • Oil filter service indicator

- Outlet nitrogen quality [1:2:1] according to ISO 8573-1:2010 • Exhaust vent kit

• Room oxygen alarm (wall mount)

www.atlascopco.com

You might also like

- CS5000 English ManualDocument35 pagesCS5000 English ManualTaufan Justvands75% (4)

- ASTM E519 Standard Test Method For Diagonal Tension in Masonry AssemblagesDocument5 pagesASTM E519 Standard Test Method For Diagonal Tension in Masonry AssemblagesFélix LlamosasNo ratings yet

- CPA 15 User ManualDocument48 pagesCPA 15 User ManualTaufan Justvands86% (7)

- VulkanCoupling (Wartsila)Document37 pagesVulkanCoupling (Wartsila)Denisse100% (2)

- LP Series Limpsfield Combustion Operating and Maintenance Manual Iss3Document63 pagesLP Series Limpsfield Combustion Operating and Maintenance Manual Iss3hoangtien1991No ratings yet

- Airman Pds185s 5c2 PMDocument30 pagesAirman Pds185s 5c2 PMTaufan Justvands50% (2)

- Mam 200Document24 pagesMam 200Taufan JustvandsNo ratings yet

- Mam Ky02sDocument34 pagesMam Ky02sTaufan Justvands67% (3)

- Oxygen Generators Range Atlas CopcoDocument1 pageOxygen Generators Range Atlas CopcoAhmad SayedNo ratings yet

- NGP+8-130 enDocument2 pagesNGP+8-130 enwilliambach2018No ratings yet

- Hydrotrac GFT: Track Drives For Mini-And Medium ExcavatorsDocument6 pagesHydrotrac GFT: Track Drives For Mini-And Medium Excavatorsamrsaleh79No ratings yet

- Flyer N2 ENDocument2 pagesFlyer N2 ENRohan SandesaraNo ratings yet

- Quality and Worry Free Ownership: Extended Warranty Protect 5 - Our Total CommitmentDocument3 pagesQuality and Worry Free Ownership: Extended Warranty Protect 5 - Our Total CommitmentEhsan ZiyaeiNo ratings yet

- Safe Transition With YANMARDocument4 pagesSafe Transition With YANMARJosé Manuel PérezNo ratings yet

- Stage V EnglishDocument4 pagesStage V EnglishLacatusu MirceaNo ratings yet

- Stage V EnglishDocument4 pagesStage V EnglishLacatusu MirceaNo ratings yet

- Drift Sensitvity Coefficient & Interstory Drift Is Attached. - All Detailing Rules Including Beam-Column Joint Details Have Already Been IncludedDocument3 pagesDrift Sensitvity Coefficient & Interstory Drift Is Attached. - All Detailing Rules Including Beam-Column Joint Details Have Already Been IncludedEyerusNo ratings yet

- DC - FDN Uprouting SheetDocument1 pageDC - FDN Uprouting SheetMeetNo ratings yet

- GD - 8pp - FM30-150 - RS - AUS - 0519 v3Document8 pagesGD - 8pp - FM30-150 - RS - AUS - 0519 v3Andres AlejandroNo ratings yet

- 010 Chapter 8Document5 pages010 Chapter 8xiaomiNo ratings yet

- (Dd0eff91 8517 432e A0db D39ed010873e) - Data Sheet Id FanDocument16 pages(Dd0eff91 8517 432e A0db D39ed010873e) - Data Sheet Id FanRajendra NinganuriNo ratings yet

- Wind Load & Blow Off Calculation NMML1Document14 pagesWind Load & Blow Off Calculation NMML1Ankit AgarwalNo ratings yet

- Xe-90/145M Series ControllersDocument2 pagesXe-90/145M Series Controllersmario InzaghiNo ratings yet

- Omega J1065 Fisa Tehnica MotorDocument2 pagesOmega J1065 Fisa Tehnica MotorAdrian StiubeNo ratings yet

- PLANOFLEXDocument3 pagesPLANOFLEXDaniel PerezNo ratings yet

- Dokumen - Tips - Tecnotest Mod 488 Manual Mod 488 Manual Owners Manual Instructions Book UsersDocument2 pagesDokumen - Tips - Tecnotest Mod 488 Manual Mod 488 Manual Owners Manual Instructions Book UsersMircoNo ratings yet

- Tabla de Equivalencias de Aceros NormadosDocument1 pageTabla de Equivalencias de Aceros NormadosGASTÓN ANDRÉS BALTIERRA CARTESNo ratings yet

- Portable Nitrogen Generation Systems 2935 9490 00Document2 pagesPortable Nitrogen Generation Systems 2935 9490 00GuptaNo ratings yet

- AOL-gasket MachineDocument20 pagesAOL-gasket Machinegiussepi2No ratings yet

- Alliance DPF ProgramDocument23 pagesAlliance DPF ProgramWayneNo ratings yet

- Deutz Power SystemsDocument4 pagesDeutz Power SystemsRudiNo ratings yet

- ES - Model W-W1911Document2 pagesES - Model W-W1911SANRAJ TECHNONo ratings yet

- Lapp Pro531870engbDocument5 pagesLapp Pro531870engbbarttijmensen1234No ratings yet

- CFM 4 PolesDocument1 pageCFM 4 Polesbk1826702No ratings yet

- Drive Design KPOC X-2612 & 2622Document1 pageDrive Design KPOC X-2612 & 2622FazliJaafarNo ratings yet

- PMV - pmv2 2023 UpdateDocument6 pagesPMV - pmv2 2023 Updatesyifanuraprilia857No ratings yet

- L30-L75 Fixed Speed Rotary Screw Compressor BrochureDocument2 pagesL30-L75 Fixed Speed Rotary Screw Compressor BrochureSpark ElectricNo ratings yet

- L-Series: Advanced Technology. Inspired Simplicity. First Class ServiceabilityDocument2 pagesL-Series: Advanced Technology. Inspired Simplicity. First Class Serviceabilitywilber fernando nina chambillaNo ratings yet

- Rose 6.0 600W VawtDocument8 pagesRose 6.0 600W Vawtcjve2012No ratings yet

- DWX-53DC: Primary InformationDocument29 pagesDWX-53DC: Primary InformationTín ĐăngNo ratings yet

- Filtro Hidráulico Pi1941 MahleDocument5 pagesFiltro Hidráulico Pi1941 MahleHIDRAFLUIDNo ratings yet

- Elettrotek Kabel-FLEXIFESTOONDocument18 pagesElettrotek Kabel-FLEXIFESTOONsales-admin.bdgNo ratings yet

- Eng CD 55PC0211 HDocument1 pageEng CD 55PC0211 HEhsan pour sarabiNo ratings yet

- 20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaDocument3 pages20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaAsh mohamedNo ratings yet

- Samsung Gt-b5310 Service ManualDocument78 pagesSamsung Gt-b5310 Service ManualashrafNo ratings yet

- EC 40 40 MM, Brushless, 120 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 120 Watt: Part NumbersLeonardo LeoNo ratings yet

- Material List: 2.1. Table of AbbreviationsDocument7 pagesMaterial List: 2.1. Table of AbbreviationsHOANG DANNo ratings yet

- GV-300W Greef Wind Turbine Catalgouev1Document8 pagesGV-300W Greef Wind Turbine Catalgouev1JOE FUNGNo ratings yet

- BLWMWcMVT7UAxnWXzvV7 MTG Brochure October 2021 PDFDocument4 pagesBLWMWcMVT7UAxnWXzvV7 MTG Brochure October 2021 PDFatemtutemNo ratings yet

- Broadband Radar System Installation: Radome Mounting and DimensionsDocument10 pagesBroadband Radar System Installation: Radome Mounting and DimensionsVasile NicolaeNo ratings yet

- Petrol State CableDocument1 pagePetrol State CableVladimir SpasenovskiNo ratings yet

- Driven Too Holder With Coromant Capto 92856Document48 pagesDriven Too Holder With Coromant Capto 92856Prerak PatelNo ratings yet

- Twin Clutch SST Overhaul: Group 22DDocument20 pagesTwin Clutch SST Overhaul: Group 22Djose alvarezNo ratings yet

- PD4 Piston Direct Oil Free Data Sheet ENDocument2 pagesPD4 Piston Direct Oil Free Data Sheet ENCioz NguyenNo ratings yet

- Home Products Service Solutions Download About Us ForumDocument1 pageHome Products Service Solutions Download About Us ForumEduardo QuiñonesNo ratings yet

- Cim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDocument2 pagesCim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDaniel B. BalmoriNo ratings yet

- Ahu SpecDocument40 pagesAhu SpecVuTranNo ratings yet

- Renner Scroll LineDocument1 pageRenner Scroll LineAriantoNo ratings yet

- Chain DriveDocument1 pageChain Drivevaibhavd123No ratings yet

- Enhancing Gas Turbine Performance by Correct Washing ProceduresDocument24 pagesEnhancing Gas Turbine Performance by Correct Washing ProceduresAbdulhameed HamadNo ratings yet

- Air Filter ElementDocument30 pagesAir Filter ElementKrupesh PatelNo ratings yet

- Sony CDXGT-770 Service ManualDocument54 pagesSony CDXGT-770 Service ManualSantiago MendezNo ratings yet

- Manual de Servicio Samsung Gt-S3350Document64 pagesManual de Servicio Samsung Gt-S3350jhonathan28No ratings yet

- MWM TCG 2020V16 Engine Technical SpecificationDocument8 pagesMWM TCG 2020V16 Engine Technical Specificationudelmark0% (1)

- DGS Replacement Procedure 28KA3122A&BDocument20 pagesDGS Replacement Procedure 28KA3122A&Bofon OML102No ratings yet

- Hertz Equipment Catalog enDocument48 pagesHertz Equipment Catalog enTaufan JustvandsNo ratings yet

- Lingyu-Air Dryer-2023Document23 pagesLingyu-Air Dryer-2023Taufan JustvandsNo ratings yet

- Brochure DHHDocument16 pagesBrochure DHHTaufan Justvands100% (1)

- Hertz Compressor Catalog enDocument57 pagesHertz Compressor Catalog enTaufan JustvandsNo ratings yet

- Catalogue-Dalian Pipro Technology Co., Ltd.Document24 pagesCatalogue-Dalian Pipro Technology Co., Ltd.Taufan JustvandsNo ratings yet

- G 7-11 Instruction Book EN WuxiDocument90 pagesG 7-11 Instruction Book EN WuxiTaufan JustvandsNo ratings yet

- Company Profile Agya MakmurDocument10 pagesCompany Profile Agya MakmurTaufan JustvandsNo ratings yet

- Spiralair C2CDocument8 pagesSpiralair C2CTaufan JustvandsNo ratings yet

- En SATA Catalog Product Catalogue 2023 221205 241786 Uid 63e126bf522efDocument164 pagesEn SATA Catalog Product Catalogue 2023 221205 241786 Uid 63e126bf522efTaufan JustvandsNo ratings yet

- PiPro 2021 V2Document12 pagesPiPro 2021 V2Taufan JustvandsNo ratings yet

- Brochure-Dryer FX SeriesDocument2 pagesBrochure-Dryer FX SeriesTaufan JustvandsNo ratings yet

- BMED Duplex SPC 2-7.5HP Scroll Air NFPA EN 4107851186Document1 pageBMED Duplex SPC 2-7.5HP Scroll Air NFPA EN 4107851186Taufan JustvandsNo ratings yet

- LW-50D-VSD Screw Air CompressorDocument8 pagesLW-50D-VSD Screw Air CompressorTaufan JustvandsNo ratings yet

- Reciprocating Air CompressorsDocument4 pagesReciprocating Air CompressorsTaufan JustvandsNo ratings yet

- Product Catalogue: Compressed Air System DistributorDocument6 pagesProduct Catalogue: Compressed Air System DistributorTaufan JustvandsNo ratings yet

- Omega Air-Rdp - en - 950376 - 06-2020 - A4Document8 pagesOmega Air-Rdp - en - 950376 - 06-2020 - A4Taufan JustvandsNo ratings yet

- LW-30D Screw Air CompressorDocument9 pagesLW-30D Screw Air CompressorTaufan JustvandsNo ratings yet

- Company Profile Agya Makmur 2020Document32 pagesCompany Profile Agya Makmur 2020Taufan JustvandsNo ratings yet

- ELGi DryerDocument4 pagesELGi DryerTaufan JustvandsNo ratings yet

- Airman Sas Serie Catalog 1Document4 pagesAirman Sas Serie Catalog 1Taufan JustvandsNo ratings yet

- RB8ES202Document2 pagesRB8ES202Taufan JustvandsNo ratings yet

- Airman Sas Serie CatalogDocument8 pagesAirman Sas Serie CatalogTaufan JustvandsNo ratings yet

- GA 11 22 PackDocument44 pagesGA 11 22 PackTaufan JustvandsNo ratings yet

- 11 75 KW EG Series Screw Compressor 6181 DomesticDocument12 pages11 75 KW EG Series Screw Compressor 6181 DomesticTaufan JustvandsNo ratings yet

- EN 73 (V3) Manual Code 01 94 00 115Document133 pagesEN 73 (V3) Manual Code 01 94 00 115Taufan Justvands67% (3)

- Projectile MotionDocument25 pagesProjectile MotionWendy TangNo ratings yet

- Rac Notes (By D Deepak)Document32 pagesRac Notes (By D Deepak)Desh DeepakNo ratings yet

- How To Calculate The Nominal Values of Over Pin or Ball Measurement of Teeth For Various Types of GearingDocument4 pagesHow To Calculate The Nominal Values of Over Pin or Ball Measurement of Teeth For Various Types of GearingROYAL LION GAMERNo ratings yet

- Under Carriage of Construction EquipmentDocument19 pagesUnder Carriage of Construction EquipmentBhawesh SthaNo ratings yet

- List of Contents For Gs-15Document13 pagesList of Contents For Gs-15Kalai SelvanNo ratings yet

- CatalogueDocument208 pagesCatalogueASHOK SUTHARNo ratings yet

- Ashrae Hvac 2001 Fundamentals HandbookgttDocument7 pagesAshrae Hvac 2001 Fundamentals HandbookgttOğuzhan KocaoğluNo ratings yet

- Calculation ExampleDocument20 pagesCalculation Examplepavankumar0001No ratings yet

- Ce2202 - Mechanics of FluidsDocument3 pagesCe2202 - Mechanics of FluidsPrashant GaradNo ratings yet

- Harmonised Standards Under Directive 2014 68 EU For Pressure EquipmentDocument24 pagesHarmonised Standards Under Directive 2014 68 EU For Pressure EquipmentciekawskiNo ratings yet

- Aalborg Av 6nDocument2 pagesAalborg Av 6nAmit SarkarNo ratings yet

- Mechanical Engineering S6 - RemovedDocument149 pagesMechanical Engineering S6 - RemovedAnish SukumaranNo ratings yet

- Machanical System DesignDocument4 pagesMachanical System DesignGreyphen GreyNo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- Pinza para Lámina TBLDocument3 pagesPinza para Lámina TBLÓscar RodríguezNo ratings yet

- Robustness of Car Parks Against Localised Fire (Robustfire)Document143 pagesRobustness of Car Parks Against Localised Fire (Robustfire)Batuhan DerNo ratings yet

- Temperature Analysis in The Fused Deposition Modeling ProcessDocument5 pagesTemperature Analysis in The Fused Deposition Modeling ProcessAffan SadiqNo ratings yet

- Uponor Infrastructure: Uponor Gravity Sewer SystemsDocument20 pagesUponor Infrastructure: Uponor Gravity Sewer Systemsarjun 11No ratings yet

- C1100 D5 Technical SpecificationDocument4 pagesC1100 D5 Technical SpecificationmnezamiNo ratings yet

- Solid Control Fact SheetDocument13 pagesSolid Control Fact SheetEbi ImmortalNo ratings yet

- Culvert 1Document104 pagesCulvert 1rahulgehlot2008No ratings yet

- GRP Unit DescriptionDocument2 pagesGRP Unit DescriptionTuấn NeoNo ratings yet

- Earthquake Engineering: Job InformationDocument27 pagesEarthquake Engineering: Job Informationpablo naragNo ratings yet

- Dana-Off-highway-condensed-specs Cajas Automaticas Generales PDFDocument34 pagesDana-Off-highway-condensed-specs Cajas Automaticas Generales PDFAlonso Fernando0% (1)

- Chapter 5Document7 pagesChapter 5joshdax2No ratings yet

- 345B SN 55S01001 & 76L01801 & Up-2Document271 pages345B SN 55S01001 & 76L01801 & Up-2A AhmedNo ratings yet

- Liebherr LTM 1250Document4 pagesLiebherr LTM 1250Kunal GalaNo ratings yet

- Grip. Reinforcement. Strength.: Perfect Better HighDocument12 pagesGrip. Reinforcement. Strength.: Perfect Better HighTentu VenkataramanaNo ratings yet

- Norma SAE J1273Document10 pagesNorma SAE J1273mrioitaNo ratings yet