Professional Documents

Culture Documents

Aux Trafo

Aux Trafo

Uploaded by

jalaj bisenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aux Trafo

Aux Trafo

Uploaded by

jalaj bisenCopyright:

Available Formats

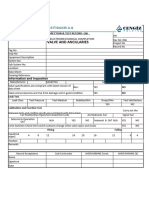

Document No.

F04(PRJ(SOL)-P-01)/14-3 PRE-COMMISSIONING TEST REPORT FOR

Revision No. 02 AUXILIARY TRANSFORMER

Date: 16.12.2020

PRE-COMMISSIONING TESTS FOR AUXILIARY TRANSFORMER

I. GENERAL DETAILS

DETAILS

Project: 50 MW SOLAR PLANT,HASAPUR Sub-Station: ICR-02

Feeder name: AUX TRAFO LOA/PO No.:

Make: NORTEX Type: DRY TYPE

Sr. No.: 20976396 Year of Manufacture: 2022

Rated Capacity: 7 KVA Rated Voltage: 800 V

Rated Current: HV SIDE-5.05 A

Vector Group: NA

LV SIDE-30.4 A

Cooling Type: AN Rated Frequency: 50 Hz

Type of Neutral Grounding: SOLID Type of Tap Changer: NA

Voltage Variation: NA Oil Quantity: NA

Date of Receipt at site: Date of Completion of Erection:

Date of Commissioning: Date of Loading:

II. CHECK LISTS OF ELECTRICAL TESTS CARRIED OUT FOR AUXILIARY TRANSFORMER

Sl. Performed Test Results

Name of Tests

No. (Yes/No) (Ok/Not Ok)

1 Pre-Commissioning Checks YES OK

2 Voltage Ratio Test YES OK

3 Vector Group Test & Polarity Check NO -

4 Magnetic Balance Test NO -

5 Insulation Resistance Measurement YES OK

6 Measurement of Winding Resistance YES OK

7 Protection and Alarm Tests NO -

Signature: Signature: Signature: Signature: Signature:

Name: RATIKANT

Name: Name: Kashyap Patel Name: Name:Gowtham

SAHOO

Designation: Erection Designation: Erection Designation: Quality

Designation: Testing Er. Designation: Testing Er.

Er. Er. Er.

Organization: Main Organization: Akshar

Organization: Renew Organization: Renew Organization: Renew

Bidder Leepant

Sheet No

Document No.

F04(PRJ(SOL)-P-01)/14-3 PRE-COMMISSIONING TEST REPORT FOR

Revision No. 02 AUXILIARY TRANSFORMER

Date: 16.12.2020

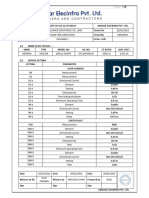

III. PRE-COMMISSIONING CHECKS:

Sl. Status Remarks

Description

No YES NO Deficiencies

1 Transformer is free from visible defects on physical inspection YES

2 All fittings as per out line General Arrangement Drawing YES

3 Check Main Tank has been provided with double earthing -

All nuts and bolts are tightened correctly as per specified torque (as

4 -

per manufacturers recommendation) (ERECTION REPORT ENCLOSED)

5 Check tightness of Terminal at cable YES

6 Check leveling of Transformer and its accessories YES

YES REVIWED AS

Erection Completion Certificate along with list of outstanding activities

7 PER ERECTION

reviewed(ERECTION REPORT ENCLOSED)

CHECK LIST

8 Any Paint removed / scratched in transit has been touched up YES

9 Bushings are clean and free from physical damages -

10 Check oil leakage through any Joints / Valves etc. -

11 Check oil drain valves are properly closed and locked -

12 Check oil level in Main Tank & Conservator tank -

Check oil level at conservator matches with oil temperature of -

13

transformer

14 Check OTI and WTI pockets and replenish the oil, if required -

15 Check all valves for their opening & closing Sequence -

16 Check the color of the breather silica gel (blue when dry) -

17 Check availability of oil in the breather cup -

Check all rollers are locked and tack welded with rails (wherever -

18

applicable)

Check no debris, loose T & P and oil strains on and around the -

19

Transformer

Check door seals of Marshaling Box is intact and all cable gland plates

20 YES

unused holes are sealed

21 Check that pressure relief device is correctly mounted -

22 Check that permanent and adequate lighting arrangements are ready -

23 Check that labeling and identification is permanent and satisfactory -

Check that Buchholz Relay is correctly mounted with arrow pointing

24 -

towards conservator

25 Check cables are properly fixed and ensure cable entry at the bottom YES

26 Ensure all Power and Control cable Terminals are Tightened YES

Check all cables and Ferrules are provided with Number as per Cable

27 YES

Schedule (Cross Ferruling to be checked)

28 Check that all cables are correctly glanded. YES

Signature: Signature: Signature: Signature: Signature:

Name: RATIKANT

Name: Name: Kashyap Patel Name: Name:Gowtham

SAHOO

Designation: Erection Designation: Erection Designation: Quality

Designation: Testing Er. Designation: Testing Er.

Er. Er. Er.

Organization: Main Organization: Akshar

Organization: Renew Organization: Renew Organization: Renew

Bidder Leepant

Sheet No

Document No.

F04(PRJ(SOL)-P-01)/14-3 PRE-COMMISSIONING TEST REPORT FOR

Revision No. 02 AUXILIARY TRANSFORMER

Date: 16.12.2020

Check external cabling from Junction Box to Relay / Control Panel

29 -

completed

Check that air has been released from the Radiators and their

30 -

headers / Buchholz relay / Main tank/Bushing chambers etc.

31 Check Fire Protection System is adequate & ready -

Check that all radiator bank valves on top and bottom headers are

32 -

open

33 Calibration of OTI & WTI performed as per procedure -

34 Equipment is cleaned and free from dust/dirt foreign materials etc. -

35 Equipment is free from all visible defects on physical inspection. -

36 Check tightness of each cable termination. -

37 Check all the fuse/ MCB. -

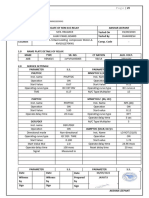

IV. INSULATION RESISTANCE MEASUREMENT:

(Using 5000 Volts Megger)

Make & Sl. No. of Testing Kit : FLUKE & 2560001

Date of Last Calibration of Kit : 16/07/2022

Ambient Temp in ºC : 300C

Date of Testing : 19/10/2022

PHASE

CORE UNIT

R – Phase Y – Phase B - Phase

PRIMARY – EARTH GΩ >1 GΩ >1 GΩ >1 GΩ

PRIMARY – SECONDARY GΩ >1 GΩ

SECONDARY- EARTH GΩ >1 GΩ

V. Ratio Test:

Make & Sl. No. of testing kit : FLUKE & 37911953WS

Date of last calibration of the kit : 18/07/2022

Ambient temp in ºC : 300C

Date of Testing : 19/10/2022

Tap Applied HV Voltage(V) LV Measured Voltage(V)

Position 1U1V 1V1W 1W1U 2U-2N

- 406.0 406.0 406.0 118.6

Signature: Signature: Signature: Signature: Signature:

Name: RATIKANT

Name: Name: Kashyap Patel Name: Name:Gowtham

SAHOO

Designation: Erection Designation: Erection Designation: Quality

Designation: Testing Er. Designation: Testing Er.

Er. Er. Er.

Organization: Main Organization: Akshar

Organization: Renew Organization: Renew Organization: Renew

Bidder Leepant

Sheet No

Document No.

F04(PRJ(SOL)-P-01)/14-3 PRE-COMMISSIONING TEST REPORT FOR

Revision No. 02 AUXILIARY TRANSFORMER

Date: 16.12.2020

VI. MEASUREMENT OF WINDING RESISTANCE:

Make &Sl. No. of testing kit : FLUKE & 37911953WS

Date of last calibration of kit : 18/07/2022

Ambient temp in ºC : 300C

Date of Testing : 19/10/2022

WINDING RESISTANCE (HV) LV SIDE

Tap Position

1U-1V 1V-1W 1W-1U 2U-2N

3.3 3.4 6.3 0.5

VII. ALL ELECTRICAL TEST RESULTS COMPARED WITH FACTORY TEST RESULTS & FOUND TO BE IN ORDER

Date of Testing : YES NO REMARKS

√

i. Phase marking & Continuity Sequence check.

YES NO

√

VIII. FINAL DOCUMENTATION REVIEW

i. Factory test results are available

YES NO

√

ii. Final documents of Pre- Commissioning checks reviewed and approved.

YES NO

√

iii. Document regarding spares equipment, O&M manuals etc. available at site.

YES NO

√

iv. After modification, if any, “As built Drawings” are available at site.

YES NO

√

Signature: Signature: Signature: Signature: Signature:

Name: RATIKANT

Name: Name: Kashyap Patel Name: Name:Gowtham

SAHOO

Designation: Erection Designation: Erection Designation: Quality

Designation: Testing Er. Designation: Testing Er.

Er. Er. Er.

Organization: Main Organization: Akshar

Organization: Renew Organization: Renew Organization: Renew

Bidder Leepant

Sheet No

You might also like

- Shop Manual: 4D98E 4D106 S4D106Document204 pagesShop Manual: 4D98E 4D106 S4D106Julio Alvarado Morales100% (1)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- Service Manual: Seer21 Split UnitDocument102 pagesService Manual: Seer21 Split UnitGabriel GuerreroNo ratings yet

- Abb Rec670 Acse Relay TestDocument10 pagesAbb Rec670 Acse Relay Testm khNo ratings yet

- SDV, BDV, Esdv ChecklistDocument2 pagesSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Check List of P443Document10 pagesCheck List of P443nassarkiNo ratings yet

- ACSBDocument6 pagesACSBjalaj bisenNo ratings yet

- SWGR Feeder - Functional TestDocument13 pagesSWGR Feeder - Functional TestChheng KimhokNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDocument8 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNo ratings yet

- LCC Bus Coupler - Functional TestDocument7 pagesLCC Bus Coupler - Functional TestAmr ElkadyNo ratings yet

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDocument12 pagesAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNo ratings yet

- Sel-487v Relay Test For CapacitorDocument21 pagesSel-487v Relay Test For CapacitorSentaNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDocument6 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- LCC Bus Section - Functional TestDocument10 pagesLCC Bus Section - Functional TestAmr ElkadyNo ratings yet

- Name of Substation: SEC - COA Contract No.: 4000043193 Diffrential, Distance and Def Relay Micom P546Document13 pagesName of Substation: SEC - COA Contract No.: 4000043193 Diffrential, Distance and Def Relay Micom P546Anonymous dH3DIEtzNo ratings yet

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Document1 pagePackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirNo ratings yet

- 57-Power Transformer Installation ChecklistDocument4 pages57-Power Transformer Installation Checklistprithiviraj50% (2)

- Mvtp11-Ct Supervision RelayDocument2 pagesMvtp11-Ct Supervision RelayTHILAKKUMARNo ratings yet

- Aux RelayDocument1 pageAux RelaysupermannonNo ratings yet

- HT CableDocument3 pagesHT Cablejalaj bisenNo ratings yet

- Abb Rec670 Busbar High ImpDocument4 pagesAbb Rec670 Busbar High Impm khNo ratings yet

- ElectroMechanical Completion VALVE and ANCILLARIESDocument1 pageElectroMechanical Completion VALVE and ANCILLARIEShuseyinyuksel1903No ratings yet

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- 50 MVA Trfo-2Document6 pages50 MVA Trfo-2p m yadavNo ratings yet

- 7sa Line Distance Relay TestDocument34 pages7sa Line Distance Relay Testsubhasish sarkarNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelNo ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- Coating PanDocument2 pagesCoating Pankashifurrahaman8No ratings yet

- Fakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERDocument1 pageFakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERkarimiNo ratings yet

- Laminar Air FlowDocument2 pagesLaminar Air Flowkashifurrahaman8No ratings yet

- Function Test 132kv Avc PanelDocument9 pagesFunction Test 132kv Avc PanelratheeshkumardNo ratings yet

- Transformer Diff - p643Document20 pagesTransformer Diff - p643rajeshNo ratings yet

- Abb Rec670 Cap Bank ProtnDocument11 pagesAbb Rec670 Cap Bank ProtnRatheesh KumarNo ratings yet

- 50mva TRAFO#1 BAY#106Document19 pages50mva TRAFO#1 BAY#106Balaji DevathaNo ratings yet

- Site Test Report For Potential Transformer: StepcDocument2 pagesSite Test Report For Potential Transformer: StepcRAM SHANMUGAMNo ratings yet

- Isolator & Earth Switch - For SwitchayrdDocument6 pagesIsolator & Earth Switch - For SwitchayrdSindhuKumarNo ratings yet

- Siemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019Document12 pagesSiemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019SARAVANAN ANo ratings yet

- Fakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERDocument1 pageFakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERkarimiNo ratings yet

- PM Check List - CB & BusbarDocument7 pagesPM Check List - CB & BusbarRizky VidiyanaNo ratings yet

- Interlock - Intertrip Between HANDWA GIS & HQC-SS-31 GISDocument2 pagesInterlock - Intertrip Between HANDWA GIS & HQC-SS-31 GISJeba JosephNo ratings yet

- 44BC Line 1 7SD522Document12 pages44BC Line 1 7SD522BalajiNo ratings yet

- Fakoor Sanat Tehran: 1. General Data & InformationDocument6 pagesFakoor Sanat Tehran: 1. General Data & Informationkarimi-15No ratings yet

- TUV RE EE CL 105 Transformer TestingDocument1 pageTUV RE EE CL 105 Transformer TestingfarhanNo ratings yet

- Ref615 - Oc Ef Relay TestDocument8 pagesRef615 - Oc Ef Relay TestMeghavahinaNo ratings yet

- NDT Inspection PlanDocument7 pagesNDT Inspection Planasif712No ratings yet

- Sterling and Wilson Commissioning Test Report For Ups DOC. No.: REV. No.: 00 Page No: 1 of 2 ProjectDocument2 pagesSterling and Wilson Commissioning Test Report For Ups DOC. No.: REV. No.: 00 Page No: 1 of 2 Projectsamwel kariukiNo ratings yet

- 7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDDocument8 pages7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDAnonymous dH3DIEtzNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Numerical Line Differential Protection Relay 7Sd522Document27 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Numerical Line Differential Protection Relay 7Sd522Rajesh Sawale100% (1)

- Load Shedding - Function TestDocument9 pagesLoad Shedding - Function TestratheeshkumardNo ratings yet

- 7ut - Transformer Diff Relay TestDocument25 pages7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- 11 KV HT Panel ReportDocument66 pages11 KV HT Panel ReportVishakha PandeyNo ratings yet

- ICL-021-BatteryDocument1 pageICL-021-BatteryKham NguyenNo ratings yet

- 80MVAR Reactor Test ReportDocument28 pages80MVAR Reactor Test ReportSARAVANAN ANo ratings yet

- Field Service Report For Pump: Service Work Order NoDocument1 pageField Service Report For Pump: Service Work Order Noadizindwan15No ratings yet

- VFD Panel CommissioningDocument3 pagesVFD Panel Commissioningabdelmalek boudjemaaNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- HT CableDocument3 pagesHT Cablejalaj bisenNo ratings yet

- Bay 1Document52 pagesBay 1jalaj bisenNo ratings yet

- Trafo Bay - 5 CTDocument6 pagesTrafo Bay - 5 CTjalaj bisenNo ratings yet

- LT Panel IC-2Document2 pagesLT Panel IC-2jalaj bisenNo ratings yet

- 7SR1206 Ic-1Document2 pages7SR1206 Ic-1jalaj bisenNo ratings yet

- Bus Bar CRM & IrDocument1 pageBus Bar CRM & Irjalaj bisenNo ratings yet

- 12 - 5 MW Relay-2 FinalDocument11 pages12 - 5 MW Relay-2 Finaljalaj bisenNo ratings yet

- Design, Engineering, Testing & CommissioningDocument4 pagesDesign, Engineering, Testing & Commissioningjalaj bisenNo ratings yet

- SANS1874 2022 Ed4Document47 pagesSANS1874 2022 Ed4GomolemoGumzNtlailaneNo ratings yet

- Unit 6 NotesDocument18 pagesUnit 6 Notesरितेश हरोडेNo ratings yet

- Monopile Foundations Under Complex Cyclic Lateral LoadingDocument239 pagesMonopile Foundations Under Complex Cyclic Lateral Loadingking sunNo ratings yet

- GTP Technology Selection ReportDocument56 pagesGTP Technology Selection ReportEmad El GebesyNo ratings yet

- Riciclo Batterie LitioDocument57 pagesRiciclo Batterie LitiomattiaNo ratings yet

- 03 Current TransformersDocument34 pages03 Current Transformersmohsin awan100% (1)

- Fuse Box Location E39Document2 pagesFuse Box Location E39T. HankitiwatNo ratings yet

- Snag ListDocument4 pagesSnag ListMd. Emtiaz HossainNo ratings yet

- 512 Au 5 Re 9 ZNFDocument1 page512 Au 5 Re 9 ZNFAngel Gabriel GalvánNo ratings yet

- Testing of Relays and Detailed ProcedureDocument30 pagesTesting of Relays and Detailed Proceduresetyo nugrohoNo ratings yet

- NRB 0282-0754 HDocument8 pagesNRB 0282-0754 HZvonimir PerasovićNo ratings yet

- Jamaica - Central America and The Caribbean - RE - SPDocument4 pagesJamaica - Central America and The Caribbean - RE - SPnfitzpatrick743No ratings yet

- Checklist For Installation of Sprinkler SystemDocument1 pageChecklist For Installation of Sprinkler Systembeho2000No ratings yet

- DOL, Rotor Resistance and Star To Delta StarterDocument8 pagesDOL, Rotor Resistance and Star To Delta StarterRAMAKRISHNA PRABU GNo ratings yet

- ZORO 6 in - TSBDocument36 pagesZORO 6 in - TSBRashida MajeedNo ratings yet

- Jurnal FIX Moh. Arnata A. GonibalaDocument10 pagesJurnal FIX Moh. Arnata A. Gonibalaanti panicNo ratings yet

- IRZ-400 Series Control Stations For Rod PumpsDocument3 pagesIRZ-400 Series Control Stations For Rod PumpsCesar VellorinNo ratings yet

- Physics Basics Material (CBSE)Document20 pagesPhysics Basics Material (CBSE)Syambabu Mathangi100% (1)

- Dimensional Data For Valves and Actuators Book 3: OrbitDocument52 pagesDimensional Data For Valves and Actuators Book 3: OrbitZeeshan SajidNo ratings yet

- Assignment 3Document9 pagesAssignment 3PUBG SlayerNo ratings yet

- Turbine Engine Operation, Maintenance, Inspection, and OverhaulDocument27 pagesTurbine Engine Operation, Maintenance, Inspection, and OverhaulDaiben SulitNo ratings yet

- Mostadam For Residential Buildings O+E Manual - 0Document180 pagesMostadam For Residential Buildings O+E Manual - 0Héctor RodalNo ratings yet

- Terex: System Specification SheetDocument1 pageTerex: System Specification SheetMaylson SenaNo ratings yet

- 5 - ch.1 Current Situation Electric Vehicle ASEAN 2611Document32 pages5 - ch.1 Current Situation Electric Vehicle ASEAN 2611NurMazhariyaUlmiNo ratings yet

- Disaster Risk Readiness and Reduction Module 9 - The Elements of Fire Triangle What'S inDocument4 pagesDisaster Risk Readiness and Reduction Module 9 - The Elements of Fire Triangle What'S inKimchiiNo ratings yet

- IH process-SOPDocument2 pagesIH process-SOPSelvakumar MNo ratings yet

- Model Predictive Control Energy Management Strategy of Fuel Cell Hybrid Electric VehicleDocument8 pagesModel Predictive Control Energy Management Strategy of Fuel Cell Hybrid Electric VehicleJ MrNo ratings yet

- ESRS E5 Delegated-Act-2023-5303-Annex-1 - enDocument12 pagesESRS E5 Delegated-Act-2023-5303-Annex-1 - enDimitris VrachoritisNo ratings yet