Professional Documents

Culture Documents

DM-BSB60-SA Manual SB-60-SA

DM-BSB60-SA Manual SB-60-SA

Uploaded by

Pedro MartinezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DM-BSB60-SA Manual SB-60-SA

DM-BSB60-SA Manual SB-60-SA

Uploaded by

Pedro MartinezCopyright:

Available Formats

Single Bottom Sea Valve

SB-60-SA

Operation and Installation Manual

SKIPPER Electronics AS Telephone: +47 23 30 22 70

Enebakkveien 150 Telefax: +47 23 30 22 71

P. O. Box 151, Manglerud E-mail: support@skipper.no Document no: DM-BSB60-SA

0612 Oslo, Norway Co. reg. no: NO-965378847-MVA Rev 1003A

www.skipper.no Date: 2014-08-06

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

Weitergabe sowie vervielfältigung dieser unterlage, verwertung Copying of this document, and giving it to others and the use

und mitteilung ihres inhaltes nicht gestattet, soweit nicht or communication of contents thereof, are forbidden without

ausdrücklich zugestanden. Zuwiderhandlungen verpflichten zu express authority. Offenders are liable to the payment of

schadenersatz. damages.

Toute communication ou reproduction de ce document, Sin nuestra expresa autorización, queda terminantemente

toute exploitation ou communication de ou son contenu sont prohibida la reproducción total o parcial de este documento,

interdites, sauf autorisation expresse. Tout manquement à asì como su uso indebido y/o su exhibición o comunicación

cette règle est illicite et expose son auteur au versement de a terceros. De los infractores Se exigirá el correspondiente

dommeges et intèrèts. resarcimiento de daños y perjuicios.

Date: 2014-08-06 Page 2 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

Contents

1. Installation..............................................................................................................................4

2. Space considerations...........................................................................................................6

3. Welding the bottom flange.............................................................................................7

4. Sea Valve assembly................................................................................................................8

5. Assembling of first extension tube and sensor...................................................9

6. Sensor installation............................................................................................................10

7. Clamp Unit mounting..........................................................................................................11

8. Final assembly.......................................................................................................................12

9. Sensor removal.....................................................................................................................13

10. Re-installation....................................................................................................................14

11. EML224 Sensor........................................................................................................................15

12. EML224 Single Bottom.......................................................................................................16

Date: 2014-08-06 Page 3 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

SKIPPER SB (Single Bottom) Sea Valve 60 mm

1. Installation

The SKIPPER SB Sea Valve 60 mm is used for installation of EML224 Speed Log.

Caution!

Be aware that the Sea Valve contains high precision parts and therefore proper

handling when mounting is essential for the final result.

When handling the Sea Valve, all lifting devices must be attached on the outside of the

valve. It is very important to not insert any chains, wire, rope or any other device into

the valve chamber. This to avoid damaging and any kind of pollution of the Sea Valve.

The SKIPPER SB Sea Valve 60 mm is delivered partly assembled for transport. The parts necessary for final

assembly will be found packed in a box delivered with the Sea Valve. First of all, it must be decided where

the Sea Valve should be installed. Normally, this will be in the fore part of the ship, in the centerline, or as

close to the centerline as possible. Optimal system operation is achieved by fitting the transducer/sensor as

deep as possible on the hull.

• The active surface of the sensor must be installed with front face a maximum of +/-1 degree to the ships

horizontal plane. (Speed Logs).

Do not mount transducers close to the bow thruster propeller outlets, or aft of other hull installations (outlets,

vents or other protruding details) who may create aeration or turbulence.

It is necessary to select a part of the hull that is submerged and free from turbulence and aeration under all

load and speed conditions, and to avoid positions where air is trapped in heavy weather.

If a flat, horizontal section is not available for transducer fitting, the shipyard must construct a suitable bed.

Welding seams in this area should be smoothed and rounded off, in order not to create turbulence or aeration

at speed.

Protect the active element of the transducer/sensors during transport and installation, and

do not paint the surface.

The Sea Valve should be placed in a service accessible place, large enough for installation and disassembly

of the sensor unit. See drawing: “Space considerations”.

Date: 2014-08-06 Page 4 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

Important

”Sensors for Speed Logs are delivered with a fixed cable. Attention must be taken to allow easy

replacement/pulling of new cable during maintenance”.

SKIPPER Electronics AS will recommend installation positions if GA-drawings (General

arrangements), lines drawings and frame drawings are made available for study.

Condition.

The welding to hull structures and structural support of the items may be subject to separate approval by

classification societies for each installation on board a ship.

Note: All “Item (X)” references on the following pages, can be found on drawing EML224 Single Bottom.

Date: 2014-08-06 Page 5 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

2. Space considerations

The Sea Valve should be placed in a service accessible place, large enough for installation and disassembly

of the sensor unit.

Date: 2014-08-06 Page 6 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

3. Welding the bottom flange

• When the position has been decided, a 187 mm hole is cut in the hull.

• Disassemble the Sea Valve.

• The bottom flange, Item (1) is welded into the hull. Standard welding practice, methods and procedures

should be observed, but may vary. (See welding notes).

Attention:

The bottom flange is a part of the Sea Valve that is machined with high accuracy and it should be

protected after mounting to avoid damage to the bottom flange surfaces. This to avoid leakage. If the

valve is pre-mounted, be shure to protect the valve from being polluted by welding debris.

WELDING NOTES!

All bottom parts and flanges for welding are precisely machined parts. During welding of these parts

to the ship’s hull plates, careful attention must be paid to avoid construction strain on the bottom

parts and flanges.

• Let parts cool down during welding.

• Over heating may change fit and form and result in non-conformity with intended sensor/

transducer.

• Welding to thick hull steel plates will exert high stress on bottom parts and flanges.

• Especially care must be taken during welding of stainless steel flanges.

• Work must be performed by a qualified and certified welder.

Welding the bottom flange in ships’s hull

Date: 2014-08-06 Page 7 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

4. Sea Valve assembly

Sea Valve assembly. (Orientation not necessary).

• Place 1.5 mm Klingersil gasket, Item (37) on top of Bottom Flange, Item (1).

• Then place the Ball Valve element on top of the Bottom Flange. The 12 mm nuts and washers should be

mounted and tightened. (Align parts before tighten nuts).

• Place a 1.5 mm Klingersil gasket on top of the Ball Valve element.

• Mount the intermediate element, Item (12) on top of the Ball Valve element.

• All 4 bolts, Item (33) and washers, Item (38) should be mounted, and tightened. (Align parts before

tighten bolts).

Date: 2014-08-06 Page 8 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

5. Assembling of first extension tube and sensor

Date: 2014-08-06 Page 9 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

6. Sensor installation

• Place the O-ring, Item (36) in the groove on top of the Intermediate Element, Item (12). Apply grease to

the O-ring.

• Insert the 2 thread bolts, Item (16) through the flange and secure with 2 x M12 counter nuts, Item (28).

Torque 98 Nm.

• Lower the Sensor and Top Flange carefully down to the top of Intermediate Element, Item (12).

The sensors sensitive area must be handled with care.

Date: 2014-08-06 Page 10 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

7. Clamp Unit mounting

• Mount Top Flange, Item (13). Secure with 2 each washers and nuts. Torque: 98 Nm.

Clamp unit to be mounted in the following order:

• 2 x M12 nuts, Item (28).

• Clamp unit, Item (15).

• 2 x M12 nuts, Item (28) with spring washer, Item (29).

Date: 2014-08-06 Page 11 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

8. Final assembly

Open Ball Valve, lower sensor unit and

Extention tube.

Forward (Ahead)

Protect sensor!

• When launching ship, lift sensor 50 mm.

• When dry docking ship, lift sensor 50 mm.

• After the ship is afloat, it is necessary to let the air out of the Sea Valve. Loosen the nut M50, let the air

out and tighten nut again.

• Check that the transducer sensor housing, when fully inserted, is flush with the lower surface of the

bottom flange.

Date: 2014-08-06 Page 12 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

9. Sensor removal

Date: 2014-08-06 Page 13 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

10. Re-installation

Forward (Ahead) 2

4

1 3

Date: 2014-08-06 Page 14 of 16

SKIPPER Electronics AS SB-60-SA Operation and Installation Manual

11. EML224 Sensor

Premounted by SKIPPER

Electronics

Date: 2014-08-06 Page 15 of 16

Date: 2014-08-06

7 29 28 15 16 13 19 12 42 1

SKIPPER Electronics AS

39

2

20 30

36 37 37

33 38

21

19 28 28 29 28 29 35

18

A

20 31 17

32 22

12. EML224 Single Bottom

* 37 2 gasket DB-1042-00 ZOA-1028

*) Mounted partly on Valve or in mounting Kit: SB-60-M-KIT

22 1 Washer DB-2040-00 DB-2040 ) Spare parts in service Kit: Module-SB-DB-S-KIT.1042A

* 21 1 Nut M28 DB-2039-00 DB-2039

* 20 1 gasket DB-2038-00 DB-2038

* 19 2 Washer DB-2037-00 DB-2037

18 1 Nut M50 DB-2036-00 DB-2036

17 2 gasket DB-2035-00 DB-2035

* 16 2 Thread Bolt M12x285 SB-6027-00 SB-6027 42 1 Ball Valve PN16 A4 St.steel ZCC-02001

* 15 1 Clamp unit DB-1033-00 DB-1033

13 1 Top flange DB-1031-00 DB-1031 39 2 Screw M12x40 DIN933 A4 St.steel ZOA-01065

12 1 Intermediate Element DB-1021-00 DB-1021 38 4 Spring Washer M16 DIN 127B A4 St.steel ZOA-01035

* 36 1 O-ring 105,0 x 4,00 Nitril ZOA-01029

(NBR 70 shore)

35 4 Washer M12 DIN125 A4 St.steel ZOA-01048

* 7 1 Extention Tube - 0.5m DB-2026-01 DB-2026 33 4 Screw M16x40 DIN933 A4 St.steel ZOA-01034

* 32 2 Spring Washer M8 DIN 127B A4 St.steel

* 31 2 Screw M8 x 30 DIN 933 A4 St.steel ZOA-01083

* 30 2 Screw M4 x 8 DIN 7991 A4 St.steel ZOA-01069

2 1 EMl224 Sensor EMl224Sg-00 EMl224Sg * 29 10 Spring Washer M12 DIN 127B A4 St.steel ZOA-01066

1 1 Bottom flange SB-1022-00 SB-1022 * 28 12 Nut M12 DIN934 A4 St.steel ZOA-01023

IT QTy. DESCRIPTION

EM DWg. NO. PART. NO. IT QTy.

EM DESCRIPTION MATERIAl PART. NO. 02 101012 01

SB-60-SA Operation and Installation Manual

Page 16 of 16

You might also like

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- RHRS-2005RC - River Radar - Installation Manual PDFDocument41 pagesRHRS-2005RC - River Radar - Installation Manual PDFGeta Enache83% (6)

- Road Construction Quality Control Plan Sample PDFDocument26 pagesRoad Construction Quality Control Plan Sample PDFQaqc AbbasNo ratings yet

- Professional Cloud Service Manager - Course Book - SampleDocument25 pagesProfessional Cloud Service Manager - Course Book - SampleMyScribd_ielts100% (3)

- King Servo SM292Document5 pagesKing Servo SM292splynNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 8400jf Fountain Owners Manual KascoDocument17 pages8400jf Fountain Owners Manual KascoSouth Santee Aquaculture100% (1)

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- Sacado Da Net - SB-100-SB Operation and Installation ManualDocument18 pagesSacado Da Net - SB-100-SB Operation and Installation ManualRafael ReisNo ratings yet

- DB-60-SA Operation and Installation Manual: Double Bottom Sea ValveDocument21 pagesDB-60-SA Operation and Installation Manual: Double Bottom Sea ValveJean-Guy PaulNo ratings yet

- DB-100-SB OpIn DM-BDB-100-SB Rev 1003A 2015-11-25Document21 pagesDB-100-SB OpIn DM-BDB-100-SB Rev 1003A 2015-11-25Seamen 777No ratings yet

- ETNSLB Operation and Installation ManualDocument12 pagesETNSLB Operation and Installation ManualsonotiumNo ratings yet

- Installation, Operation & Maintenance Manual - Original VersionDocument11 pagesInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqNo ratings yet

- SC 360apr-Th-M 04 1-6Document6 pagesSC 360apr-Th-M 04 1-6Ivaylo Ivanov100% (1)

- DB-100-SA OpIn DM-BDB-100-SA Rev 1003A 20151125 PDFDocument21 pagesDB-100-SA OpIn DM-BDB-100-SA Rev 1003A 20151125 PDFSeamen 777No ratings yet

- RD36kV CEB MANUALDocument31 pagesRD36kV CEB MANUALsbjamdadeNo ratings yet

- Color Video Sounder FCV-667/668 Installation ManualDocument29 pagesColor Video Sounder FCV-667/668 Installation ManualOdair Fernandes de BritoNo ratings yet

- Sx90transducer ReplacementDocument14 pagesSx90transducer ReplacementLEANDRO DELOS SANTOSNo ratings yet

- Multilingual Installation Manual: Advansea S400 Wind Masthead UnitDocument72 pagesMultilingual Installation Manual: Advansea S400 Wind Masthead UnitMartin NiNo ratings yet

- Sony Playstation 3 Cecha00 Cecha01 Sm-Ps3-0013e-02Document45 pagesSony Playstation 3 Cecha00 Cecha01 Sm-Ps3-0013e-02naoyakatsu100% (2)

- SIMRAD SAL R1a Installation ManualDocument30 pagesSIMRAD SAL R1a Installation ManualPalaKhartikeyanNo ratings yet

- 8' MPV User's Manual For Side Port PDFDocument20 pages8' MPV User's Manual For Side Port PDFdavibrenoNo ratings yet

- HRS1 Heading Sensor Installation ManualDocument20 pagesHRS1 Heading Sensor Installation ManualPrinceBabuNo ratings yet

- Foote-Jones Parallel Shaft Helical Reducer ManualDocument18 pagesFoote-Jones Parallel Shaft Helical Reducer ManualbwelzNo ratings yet

- Installation Instructions Owner'S Guide &: StructurescanDocument8 pagesInstallation Instructions Owner'S Guide &: StructurescanOlegNo ratings yet

- GC-GCA Manual PDFDocument14 pagesGC-GCA Manual PDFKholoud OwidaNo ratings yet

- 028120-SPL-006 Linepipe and Riser Handling Rev. CDocument5 pages028120-SPL-006 Linepipe and Riser Handling Rev. CRokan PipelineNo ratings yet

- SGC 650 Manual 30.engDocument26 pagesSGC 650 Manual 30.engluckystrike9008No ratings yet

- Foote-Jones Spiral Bevel Helical ReducerDocument21 pagesFoote-Jones Spiral Bevel Helical Reducerbwelz100% (1)

- Humminbird Wide Optic ManualDocument32 pagesHumminbird Wide Optic ManualLaurent Chandezon50% (2)

- CSH7 Ime-DDocument58 pagesCSH7 Ime-DnimsNo ratings yet

- Hummingbird 300TX ManualDocument28 pagesHummingbird 300TX ManualDale Wells100% (1)

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- User Guide 80S H EnglishDocument48 pagesUser Guide 80S H Englishpapum2013No ratings yet

- Skipper Transducer DWG - ESN100Document11 pagesSkipper Transducer DWG - ESN100Komar ElectricNo ratings yet

- Manual Propeller Shaft Earthing System Althen SensorsDocument12 pagesManual Propeller Shaft Earthing System Althen SensorsAndrewNo ratings yet

- Kasco Half HPPond Aerator Owners ManuelDocument24 pagesKasco Half HPPond Aerator Owners ManuelDeepak JoyNo ratings yet

- Ib Aa04 301Document16 pagesIb Aa04 301shadow21No ratings yet

- DM-BETNST-SA StandardTank InMan 2013-05-15Document12 pagesDM-BETNST-SA StandardTank InMan 2013-05-15Irina IrinaNo ratings yet

- Manual Sonda Humminbird 350txDocument28 pagesManual Sonda Humminbird 350txJose Meseguer BañoNo ratings yet

- Servicemanual Panasonic kv-s2048cDocument139 pagesServicemanual Panasonic kv-s2048cRalf KöhlerNo ratings yet

- SC 15TW-Stainless Steel 13Document44 pagesSC 15TW-Stainless Steel 13roherneville100% (1)

- HumminbirdWide3DVistaUsersManual465808 891224972Document38 pagesHumminbirdWide3DVistaUsersManual465808 891224972Radojko TomitoNo ratings yet

- Installation, Operating, & Maintenance Instructions: Model 8392-02 Sidewinder (Brass) Model 8492-02 Sidewinder (Aluminum)Document6 pagesInstallation, Operating, & Maintenance Instructions: Model 8392-02 Sidewinder (Brass) Model 8492-02 Sidewinder (Aluminum)Jean Jacques ouandaNo ratings yet

- Jwe 2400cua InstallDocument23 pagesJwe 2400cua Installmkbower43No ratings yet

- BEL Technical Manual 4 Side Port LDocument18 pagesBEL Technical Manual 4 Side Port LgulfengsolutionsNo ratings yet

- Side Power Thruster SE170 - 250TC IP Ignition ProtectedDocument20 pagesSide Power Thruster SE170 - 250TC IP Ignition ProtectedkloostNo ratings yet

- ROSOV Manual - L & TDocument122 pagesROSOV Manual - L & TMuneeshNo ratings yet

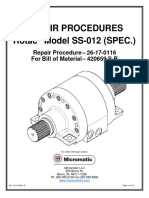

- Roatary Actuators - Micromatic Repair Manual - 26-17-0116Document10 pagesRoatary Actuators - Micromatic Repair Manual - 26-17-0116tungNo ratings yet

- Installation Instructions & Reference GuideDocument19 pagesInstallation Instructions & Reference GuideАртемNo ratings yet

- MNV20052 1210 (SS)Document16 pagesMNV20052 1210 (SS)wikijeg975No ratings yet

- CH37 Ime-CDocument69 pagesCH37 Ime-Chimu100bdctgNo ratings yet

- Factory Alarm Tvss - IvdDocument39 pagesFactory Alarm Tvss - IvdRohn J JacksonNo ratings yet

- Repair Manual - SS-001 Thru SS-130Document15 pagesRepair Manual - SS-001 Thru SS-130AlexandrNo ratings yet

- Panasonic KV s1025c S SMDocument119 pagesPanasonic KV s1025c S SMFrancisco Rodriguez MartinezNo ratings yet

- Linear 2 Manual CompleteDocument115 pagesLinear 2 Manual CompleteDjvionico PerezNo ratings yet

- EC - OI-II, EC-01 Electronics Internatonal IncDocument47 pagesEC - OI-II, EC-01 Electronics Internatonal IncRenato ParetaNo ratings yet

- KochDocument181 pagesKochRichard FelipNo ratings yet

- Side-Power: SXP80/185T & SXP100/185T External Sternthruster AssemblyDocument16 pagesSide-Power: SXP80/185T & SXP100/185T External Sternthruster AssemblyLin LinNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Managing Complex Work Systems Via Crowdworking Platforms: How Deutsche Bank Explores AI Trends and The Future of Banking With JovotoDocument10 pagesManaging Complex Work Systems Via Crowdworking Platforms: How Deutsche Bank Explores AI Trends and The Future of Banking With JovotoCarlos Alberto Chavez AznaranNo ratings yet

- RTN 980L V100R009 Quick Installation GuideDocument30 pagesRTN 980L V100R009 Quick Installation GuideMuhammad AdilNo ratings yet

- QQ 2222Document4 pagesQQ 2222wesleybsNo ratings yet

- Exponential Smoothing Example:: Single Years Quarter Period Sales Avg A (T) /avgDocument6 pagesExponential Smoothing Example:: Single Years Quarter Period Sales Avg A (T) /avgchikomborero maranduNo ratings yet

- Manual Zodiac D-One BT - 18.08.23Document31 pagesManual Zodiac D-One BT - 18.08.23martonbiro07No ratings yet

- Symantec Data Center Security Server Monitoring Edition and Server Advanced 6.8 Overview GuideDocument20 pagesSymantec Data Center Security Server Monitoring Edition and Server Advanced 6.8 Overview GuideĐình Khánh BùiNo ratings yet

- Global Work in A Rapidly Changing World: Implications For MNEs and IndividualsDocument14 pagesGlobal Work in A Rapidly Changing World: Implications For MNEs and IndividualsKhondoker AliNo ratings yet

- Battery Tester Bt3554-50: Next Battery: No. 2 Pass! Next Battery: No. 3Document4 pagesBattery Tester Bt3554-50: Next Battery: No. 2 Pass! Next Battery: No. 3ppNo ratings yet

- 2 Master Boot Record (MBR) PDFDocument2 pages2 Master Boot Record (MBR) PDFDarmoni LaishramNo ratings yet

- 4 - 01 - Product Catalog For 450connectDocument100 pages4 - 01 - Product Catalog For 450connectAdil MuradNo ratings yet

- 8I Heating and Cooling Multiple Choice TestDocument3 pages8I Heating and Cooling Multiple Choice Testapi-369814690% (10)

- Drawbar Pull vs. Rim Pull - MCM - Multi Construction MachinesDocument1 pageDrawbar Pull vs. Rim Pull - MCM - Multi Construction Machinesمهدي وجيه كمال100% (1)

- GG CoC GR V6 enDocument35 pagesGG CoC GR V6 enDaniel PintoNo ratings yet

- Database Administration Level - 3 Practical Exam Level 3: Filed Name Data Type SizeDocument3 pagesDatabase Administration Level - 3 Practical Exam Level 3: Filed Name Data Type SizeGammee Bekele100% (3)

- Popular Electricity - 1909 - 09Document140 pagesPopular Electricity - 1909 - 09sezaroNo ratings yet

- Samsung ML-1610 Service Manual - 03 - System OverviewDocument31 pagesSamsung ML-1610 Service Manual - 03 - System OverviewiraklitospNo ratings yet

- PLC C200HDocument3 pagesPLC C200HRidho AkbarNo ratings yet

- Automated Excel DetailsDocument10 pagesAutomated Excel DetailsPrashant mhamunkarNo ratings yet

- Google and AWS CloudComputing PDFDocument16 pagesGoogle and AWS CloudComputing PDFDP MulluruNo ratings yet

- Backtesting-MethodsDocument14 pagesBacktesting-MethodsDL SantosNo ratings yet

- Series: Compact Leak Detector With Continuous FlowDocument2 pagesSeries: Compact Leak Detector With Continuous FlowDrikus OdendaalNo ratings yet

- Travel Allowance Excel July 2021Document2 pagesTravel Allowance Excel July 2021HarDik PatelNo ratings yet

- Phishing Detection Using Heuristic BasedDocument6 pagesPhishing Detection Using Heuristic BasedArun PanikarNo ratings yet

- 5 Natiora MahagagaDocument13 pages5 Natiora MahagagaSafidiniaina Lahatra RasamoelinaNo ratings yet

- Spin Valves - KnifeDocument8 pagesSpin Valves - KnifePablo HurtubiaNo ratings yet

- Aggregate Lab Internal Audit Practice AidDocument8 pagesAggregate Lab Internal Audit Practice AidTesfuNo ratings yet

- IMSVA AMEA Partner Case Submission Handbook1.1Document55 pagesIMSVA AMEA Partner Case Submission Handbook1.1devendarNo ratings yet

- Build Hat Serial ProtocolDocument17 pagesBuild Hat Serial ProtocolDozer KamilNo ratings yet