Professional Documents

Culture Documents

Steam Trap-1

Steam Trap-1

Uploaded by

Krishna PATELOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Trap-1

Steam Trap-1

Uploaded by

Krishna PATELCopyright:

Available Formats

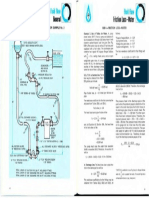

STEAM AND CONDENSATE SYSTEMS 145

5 psi (receiver) + 7.5 psi (riser) + 2 psi (pipe) = 14.5 psi over 75% of the steam rate shown (the square root of

60/100). The cost of wasted steam far outweighs the

or the differential pressure driving the condensate flow cost of proper maintenance to repair the malfunctions,

through the trap is 30 – 14.5 = 15.5 psi. and comprehensive steam trap maintenance programs

From Table 6.12 we see that a Model C trap will have proven to be among the most attractive energy

handle 2100 lb/hr at 15-psi differential pressure; this conservation investments available in large process

would then be the correct choice. plants. Most types of steam traps can be repaired, and

some have inexpensive replaceable elements for rapid

6.4.4 Maintaining Steam Traps for Efficient Operation turnaround.

Steam traps can and do malfunction in two

ways. They may stick in the closed position, causing Table 6.13 Annual Cost of Steam Leaks

—————————————————————————

condensate to back up into the steam system, or they

Steam

may stick open, allowing live steam to discharge into

Wasted per

the condensate system. The former type of malfunc-

Leak Diame- Month Cost per Cost per

tion is usually quickly detectable, since flooding of a a b

ter (in.) (lb) Month Yearb

process heater with condensate will usually so degrade —————————————————————————

its performance that the failure is soon evidence by a 1/16 13,300 $40 $480

significant change in operating conditions. This type 1/8 52,200 156 1,890

of failure can have disastrous effects on equipment 1/4 209,000 626 7,800

by producing damaging water hammer and causing 1/2 833,000 2,500 30,000

—————————————————————————

process streams to back up into other equipment. aBased on 100-psig differential pressure across the orifice.

Because of these potential problems, steam traps are bBased on steam value of $3/1000 lb. Cost will scale in direct

often designed to fail in the open position; for this proportion for other steam values.

reason, they are among the biggest energy wasters in

an industrial plant. Broad experience in large process

plants using thousands of steam traps has shown that, A major problem facing the energy conservation

typically, from 15 to 60% of the traps in a plant may manager is diagnosis of open traps. The fact that a trap

be blowing through, wasting enormous amounts of is blowing through can often be detected by a rise in

energy. Table 6.13 shows the cost of wasted 100-psig temperature at the condensate receiver, and it is quite

steam (typical of many process plant conditions) for easy to monitor this simple parameter. There are also

leak diameters characteristic of steam trap orifices. At several direct methods for checking trap operation. Fig-

higher steam pressures, the leakage would be even ure 6.15 shows the simplest approach for open conden-

greater; the loss rate does not go down in direct pro- sate systems where traps drain directly to atmospheric

portion at lower steam pressures but declines at a rate pressure. In proper normal operation, a stream of con-

proportional to the square root of the pressure. For densate drains from the line together with a lazy cloud

example, a 1/8-in. leak in a system at 60 psig, instead of flash steam, produced as the condensate throttles

of the 100 psig shown in the table, would still waste across the trap. When the trap is blowing through, a

Table 6.14 Operating Sounds of Various Types of Steam Traps

Trap Proper Operation Malfunctioning

Disk type (impulse of Opening and snap-closing of Rapid chattering of disk as

thermodynamic) disk several times per minute steam blows through

Mechanical type (bucket) Cycling sound of the bucket as Fails open—sound of steam

it opens and closes blowing through

Fails closed—no sound

Thermostatic type Sound of periodic discharge if Fails closed—no sound

medium to high load;

possibly no sound if light

load; throttled discharge

You might also like

- Surge Analysis ReportDocument22 pagesSurge Analysis ReportAh Leng LauNo ratings yet

- LPG Calculation Restaurnat RoshnDocument3 pagesLPG Calculation Restaurnat RoshnKrishna PATELNo ratings yet

- Dissertation RPSDocument35 pagesDissertation RPSRaghvendra Pratap Singh100% (1)

- Condensate Return CEPDocument8 pagesCondensate Return CEPrvkumar61100% (1)

- ANSI HI 10.6-2010 Air Operated Pump Tests PDFDocument28 pagesANSI HI 10.6-2010 Air Operated Pump Tests PDFKhanh PhamNo ratings yet

- Guide For Sea Trials PDFDocument111 pagesGuide For Sea Trials PDFnawkong67% (3)

- The Importance of Intensive Steam Trap ManagementDocument4 pagesThe Importance of Intensive Steam Trap ManagementRobert MontoyaNo ratings yet

- Prevention of Water HammerDocument6 pagesPrevention of Water HammerHabshanaNo ratings yet

- Topic 10 Gas-Liquid Systems: Considerations For Chemists & Engineers Working in Process DevelopmentDocument12 pagesTopic 10 Gas-Liquid Systems: Considerations For Chemists & Engineers Working in Process DevelopmentSasitharan MNo ratings yet

- Facts at Your Fingertips-200904-Energy Efficiency in Steam SystemsDocument1 pageFacts at Your Fingertips-200904-Energy Efficiency in Steam Systemsonizuka-t2263No ratings yet

- Sizing Steam TrapsDocument4 pagesSizing Steam Trapsjesus_manrique2753No ratings yet

- Water Hammer in Condensate LinesDocument5 pagesWater Hammer in Condensate LinesAatish Chandrawar100% (1)

- SPE 56705 Chemical Defoamer Reduction With New Internals in The Mars TLP SeparatorsDocument5 pagesSPE 56705 Chemical Defoamer Reduction With New Internals in The Mars TLP SeparatorsRégis OngolloNo ratings yet

- Table 5-5 Demand Weight of Fixtures, in Fixture Units: 123 Chapter 5 - Cold-Water SystemsDocument2 pagesTable 5-5 Demand Weight of Fixtures, in Fixture Units: 123 Chapter 5 - Cold-Water SystemsAkhilNo ratings yet

- Vent Away Condensate Pump Frustrations in A FlashDocument6 pagesVent Away Condensate Pump Frustrations in A FlashBramJanssen76100% (1)

- Water Hammer: The Number One Problem in A Steam SystemDocument4 pagesWater Hammer: The Number One Problem in A Steam Systemarodriguez2757No ratings yet

- WatsonDocument6 pagesWatsonLanang Delonix Regia SugiartoNo ratings yet

- 14.4.sizing Condensate Return LinesDocument18 pages14.4.sizing Condensate Return LinesBayu100% (1)

- B.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationDocument16 pagesB.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationTrần Vũ HạNo ratings yet

- Optimising Nitrogen Utilisation in Refinery OperationsDocument7 pagesOptimising Nitrogen Utilisation in Refinery Operationsamir.alishahi.hsn24No ratings yet

- WEIR - Technical Bulletin - Hazards of Blocked PipesDocument6 pagesWEIR - Technical Bulletin - Hazards of Blocked PipesWesley MendesNo ratings yet

- Sizing Drain and Condensate Lines To TrapsDocument18 pagesSizing Drain and Condensate Lines To TrapsMubarik Ali100% (1)

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- Flash SteamDocument10 pagesFlash Steamsayansaesue2514No ratings yet

- Lack of Compressor Capacity Analysis of The Symptoms PDFDocument31 pagesLack of Compressor Capacity Analysis of The Symptoms PDFNor Firdaus Yunus100% (1)

- Condenser Vacuum MarEDocument4 pagesCondenser Vacuum MarEMayeiaElenorNo ratings yet

- Steam Trap Inspection Guide PDFDocument8 pagesSteam Trap Inspection Guide PDFchanayire100% (1)

- Manual Boiler Feed IND 20 PDFDocument1 pageManual Boiler Feed IND 20 PDFHicham IdrisiNo ratings yet

- Chapter 7: Oil Vapor Diffusion Pumps: Theory of OperationDocument9 pagesChapter 7: Oil Vapor Diffusion Pumps: Theory of OperationGyu BotNo ratings yet

- Waterhammer PDFDocument4 pagesWaterhammer PDFsbalu12674No ratings yet

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32No ratings yet

- Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Document1 pagePages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Ghasem BashiriNo ratings yet

- Steam TrapsDocument5 pagesSteam TrapsAdel Suker100% (1)

- A Guide To Sizing Condensate Lines To and From Steam TrapsDocument20 pagesA Guide To Sizing Condensate Lines To and From Steam TrapsGeovannyNo ratings yet

- Chapter 10Document4 pagesChapter 10Santosh Kumar GembaliNo ratings yet

- Testing Steam Traps: IndexDocument3 pagesTesting Steam Traps: IndexArturo RockNo ratings yet

- Goulds-Paper StockDocument10 pagesGoulds-Paper StockDavid Alejandro GomezNo ratings yet

- Unit Operations Lab, CHE 322 Spring 2021Document5 pagesUnit Operations Lab, CHE 322 Spring 2021Fahad NoumanNo ratings yet

- Steam Management (Spirax Sarco)Document31 pagesSteam Management (Spirax Sarco)Heru PramudyaNo ratings yet

- Brochure Ventiladores OeldeDocument6 pagesBrochure Ventiladores OeldeJorge CarignanoNo ratings yet

- Gas TurbineDocument7 pagesGas TurbineBadadmasi MaiwdaNo ratings yet

- STEAM USE in CORRUGATORS PDFDocument3 pagesSTEAM USE in CORRUGATORS PDFArtur SilvaNo ratings yet

- Proper Sizing of Steam Header Drains Prevents Water InductionDocument7 pagesProper Sizing of Steam Header Drains Prevents Water InductionmhdsolehNo ratings yet

- 3 B3 ArcuriDocument28 pages3 B3 ArcurijoesuhreNo ratings yet

- A Set of Miscellaneous Losses .: Other Losses in TurbinesDocument30 pagesA Set of Miscellaneous Losses .: Other Losses in TurbinesKvvPrasadNo ratings yet

- StallDocument16 pagesStallbhalchandrak1867100% (3)

- Crude Unit Startup Consequences of High Liquid LevelDocument4 pagesCrude Unit Startup Consequences of High Liquid LevelAlessio ScarabelliNo ratings yet

- COND Cleaning and Leakage Inspection PDFDocument11 pagesCOND Cleaning and Leakage Inspection PDFprakashNo ratings yet

- Steam Blowing ProcessDocument15 pagesSteam Blowing Processprincemech2004No ratings yet

- High-Efficiency Desliming by Use of Hydraulic Water Additions 2Document6 pagesHigh-Efficiency Desliming by Use of Hydraulic Water Additions 2rolandoh1No ratings yet

- Turbine MaintainanceDocument9 pagesTurbine Maintainanceer_sanjaypatel100% (2)

- 5 Common Misconceptions Lyo2Document3 pages5 Common Misconceptions Lyo2DholakiaNo ratings yet

- Fingerprints in Vacuum SystemsDocument4 pagesFingerprints in Vacuum SystemsBenjamin BrownNo ratings yet

- (EE) - Steam Traps and Steam TrapingDocument94 pages(EE) - Steam Traps and Steam Trapingrajpratik1561No ratings yet

- Armstrong Solving StallDocument9 pagesArmstrong Solving StallsaverrNo ratings yet

- Report of A Seminar Held at The Ashrae Annual Meeting 1979Document4 pagesReport of A Seminar Held at The Ashrae Annual Meeting 1979Gavriel CarvalhoNo ratings yet

- Unique Piping Vibration Issue in A Centrifugal Compressor 1692540928Document16 pagesUnique Piping Vibration Issue in A Centrifugal Compressor 1692540928logicloverNo ratings yet

- Importance of Maintaining Valve RecordsDocument5 pagesImportance of Maintaining Valve Recordsmuthu kujmarNo ratings yet

- Exergy Analysis of A 10,000 M /day Tajoura SWRO Desalination PlantDocument7 pagesExergy Analysis of A 10,000 M /day Tajoura SWRO Desalination Plantchengawy7No ratings yet

- Improved Steam Condenser Gas Removal SystemDocument7 pagesImproved Steam Condenser Gas Removal Systemtfernandes.x18No ratings yet

- EvapcoPiping EvapCond131A PDFDocument12 pagesEvapcoPiping EvapCond131A PDFManuel BalanNo ratings yet

- SR-1054 Serie 40 Applications 2010-10Document14 pagesSR-1054 Serie 40 Applications 2010-10Carlos GutierrezNo ratings yet

- EnglishDocument19 pagesEnglishKrishna PATELNo ratings yet

- SustainableDocument1 pageSustainableKrishna PATELNo ratings yet

- Tag 1Document1 pageTag 1Krishna PATELNo ratings yet

- Plumbing Notes, Legend, & Abbreviations: Project Code: 1110Document1 pagePlumbing Notes, Legend, & Abbreviations: Project Code: 1110Krishna PATELNo ratings yet

- Fire Pump Page 57 96Document41 pagesFire Pump Page 57 96Krishna PATELNo ratings yet

- Deo Coat 8110Document2 pagesDeo Coat 8110Krishna PATELNo ratings yet

- 2-Water Systems (Compatibility Mode)Document33 pages2-Water Systems (Compatibility Mode)Krishna PATELNo ratings yet

- CP 342 2 1974 Centralized Hot Water SupplyDocument30 pagesCP 342 2 1974 Centralized Hot Water SupplyKrishna PATELNo ratings yet

- Fire Hydrant Internal-Page-175-191Document18 pagesFire Hydrant Internal-Page-175-191Krishna PATELNo ratings yet

- Plumbing List of Drawings: Project Code: 1110Document1 pagePlumbing List of Drawings: Project Code: 1110Krishna PATELNo ratings yet

- Portable Fire Extinguisher-Page-147-212Document64 pagesPortable Fire Extinguisher-Page-147-212Krishna PATELNo ratings yet

- Plumbing List of Drawings: Project Code: 1110Document1 pagePlumbing List of Drawings: Project Code: 1110Krishna PATELNo ratings yet

- Chapter-2 Reel Rubber Hose-Page-161-171Document13 pagesChapter-2 Reel Rubber Hose-Page-161-171Krishna PATELNo ratings yet

- Chapter 1 Manual Extingyisher-147-158Document13 pagesChapter 1 Manual Extingyisher-147-158Krishna PATELNo ratings yet

- Panoramic ElevatorsDocument4 pagesPanoramic ElevatorsKrishna PATELNo ratings yet

- Auto Cad S5Document1 pageAuto Cad S5Krishna PATELNo ratings yet

- Auto Cad S-1Document1 pageAuto Cad S-1Krishna PATELNo ratings yet

- Auto Cad S-2Document1 pageAuto Cad S-2Krishna PATELNo ratings yet

- Manning CoefficientDocument1 pageManning CoefficientKrishna PATELNo ratings yet

- Pipe SizeDocument2 pagesPipe SizeKrishna PATELNo ratings yet

- VISCOSITYDocument1 pageVISCOSITYKrishna PATELNo ratings yet

- Auto Cad Short L - MDocument1 pageAuto Cad Short L - MKrishna PATELNo ratings yet

- Fluid FlowDocument1 pageFluid FlowKrishna PATELNo ratings yet

- Fluid Flow General - 1Document1 pageFluid Flow General - 1Krishna PATELNo ratings yet

- Other Fluids CharacteristicsDocument1 pageOther Fluids CharacteristicsKrishna PATELNo ratings yet

- Friction Loss WaterDocument1 pageFriction Loss WaterKrishna PATELNo ratings yet

- Fluid Pipe InstallationDocument1 pageFluid Pipe InstallationKrishna PATELNo ratings yet

- Fluid Flow Part-2Document1 pageFluid Flow Part-2Krishna PATELNo ratings yet

- Fitting CoefficientDocument1 pageFitting CoefficientKrishna PATELNo ratings yet

- Differential Pressure Switch RH3Document2 pagesDifferential Pressure Switch RH3Jairo ColeccionistaNo ratings yet

- GP-03!06!01 Piping For InstrumentsDocument18 pagesGP-03!06!01 Piping For Instrumentsabenitech100% (1)

- KSB Datasheet PDFDocument19 pagesKSB Datasheet PDFWogayehuGizawNo ratings yet

- MECHATRONICS Notes PDFDocument69 pagesMECHATRONICS Notes PDFsivakrishna nadakuduru100% (1)

- Delta BarDocument20 pagesDelta BarMorteza alizadehNo ratings yet

- PCS-3 Ferguson PCS 3000 Controller User GuideDocument20 pagesPCS-3 Ferguson PCS 3000 Controller User GuideojrfgmrfNo ratings yet

- CHAPTER 2 DCN3113-StudentDocument18 pagesCHAPTER 2 DCN3113-StudentAja_ajazaiNo ratings yet

- 3 PressureDocument10 pages3 PressureRishabh KaushikNo ratings yet

- 3KXP200011R1001-DS 266GST Ast en C 06 2012Document32 pages3KXP200011R1001-DS 266GST Ast en C 06 2012onutocsNo ratings yet

- Piping and Instrumentation Diagrams PDFDocument34 pagesPiping and Instrumentation Diagrams PDFsaravanan aathiNo ratings yet

- ASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFDocument89 pagesASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFFabiano Lebkuchen100% (2)

- Weksler TermometrosDocument94 pagesWeksler TermometrosjhobanybernalNo ratings yet

- C3 PDFDocument4 pagesC3 PDFJesus Mac LeodNo ratings yet

- Spray Scrubber Simulation Setup and Static Pressure Measurement LocationsDocument14 pagesSpray Scrubber Simulation Setup and Static Pressure Measurement LocationsAhmad Anas Nagoor GunnyNo ratings yet

- CASO Expert TrainingDocument166 pagesCASO Expert TrainingDalila AmmarNo ratings yet

- Mechanical Measurements and Instrumentation Digital MaterialDocument256 pagesMechanical Measurements and Instrumentation Digital MaterialSai Praneeth100% (1)

- Datos Tecnicos Quemador OVENPAK 400 PDFDocument8 pagesDatos Tecnicos Quemador OVENPAK 400 PDFIsaias de la CruzNo ratings yet

- 4 Semester: Biju Patnaik University of Technology, OdishaDocument27 pages4 Semester: Biju Patnaik University of Technology, OdishaSunil NepakNo ratings yet

- DPI610 615LP (16jan02)Document4 pagesDPI610 615LP (16jan02)bertan dağıstanlıNo ratings yet

- 1 3 Vacuum MeasurementDocument8 pages1 3 Vacuum Measurementmanikandaprabhu100% (1)

- ManometreDocument6 pagesManometreAbdo KouNo ratings yet

- Fluid MechanicsDocument182 pagesFluid Mechanicsreddy331No ratings yet

- FM & HM Lab Lab ManualDocument75 pagesFM & HM Lab Lab ManualvenkiteshksNo ratings yet

- Scadapack 4203 PDFDocument7 pagesScadapack 4203 PDFFelix VelasquezNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument46 pagesGascalc 5.0: Calculation ReferenceCésar Sandoval100% (1)

- Fluid Mechanics and Hydralics Machines PDFDocument4 pagesFluid Mechanics and Hydralics Machines PDFkalikadeviNo ratings yet

- Thermo NewDocument78 pagesThermo NewYa100% (1)

- Ccims Close-Coupled Instrument Mounting Solutions: Parker WorldwideDocument4 pagesCcims Close-Coupled Instrument Mounting Solutions: Parker WorldwideXavierNo ratings yet