Professional Documents

Culture Documents

04 93453 - Quality Control Plan PDF

04 93453 - Quality Control Plan PDF

Uploaded by

Sara mamdouhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 93453 - Quality Control Plan PDF

04 93453 - Quality Control Plan PDF

Uploaded by

Sara mamdouhCopyright:

Available Formats

Date: 03/31/20 Code:

PROCESS CONTROL PRG-009-L

Page 1 of 11

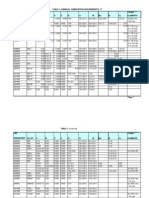

5.11. Finished product control

a) Tiles (baseboards, steps, flashing...): they will be subjected (as

established by UNE-EN 14411) to tests in an accredited

laboratory.The following table establishes the acceptance criteria by

variables or by attributes as appropriate, as well as the established

limit values.

Inspection by

attributes

Inspection by mean value

Sample

Initial initial+

sample second Initial sample Initial sample +second

Condition

Limit value

Frequency

Acceptanc

Acceptanc

e number

e number

rejection

rejection

for the

number

number

Sample

Condition second Condition

size

criteria intake criteria rejection

sample condition

Anion-

Exchange 7 Annual 23 mean1≥23 mean1<23 mean2≥23 mean2<23

breakage

Resistance to

therma

l choc 5 Annual Compliant 0 2 1 2

Resistance to:

the frost 10 Annual Compliant 0 1

Resistance to

impact 5 Annual 0 2 1 2

Water

absorption 5 Annual 0.5 Mean1≤0.5 Mean1>0.5 mean2≤0.5 average2>0

.5

Coefficient of

linear Declared

thermal 1 Annual Value

expansion

*The conduct of these tests is optional and will depend on whether there

have been significant changes affecting these properties or on the

decision of the Technical Director.

- will be subjected to the following internal tests with the minimum

periodicity marked by each particular instruction:

Determination of absorption (according to IP-0062)

Frost resistance (according to IP-6458)

Flexural strength (according to IP-6455)

Cerámica Mayor S.A.

Date: 03/31/20 Code:

PROCESS CONTROL PRG-009-L

Page 2 of 11

b) Facade: they will undergo the following tests annually in an

accredited laboratory

Inspection by

attributes

Inspection by mean value

Sample

Initial initial+

sample second Initial sample Initial sample +second

Condition

Limit value

Frequency

Acceptanc

Acceptanc

e number

e number

rejection

rejection

for taking

number

number

Sample

Condition second Condition

size

criteria sample criteria rejection

condition

Anion-

Exchange 7 Annual 17 mean1≥17 mean1<17 mean2≥17 mean2<17

breakage

Resistance to

therma

l choc 5 Annual Compliant 0 2 1 2

Resistance to:

the frost 10 Annual Compliant 0 1

Resistance to

impact 5 Annual 0 2 1 2

Water Decl

absorption 5 Annual ared

Value

**The conduct of these tests is optional and will depend on whether there

have been significant changes affecting these properties or on the

decision of the Technical Director.

- They will be subjected to the following internal tests with the

minimum periodicity marked by each particular instruction:

i. Determination of absorption (according to IP-0062)

ii. Frost resistance (according to IP-6458)

iii. Flexural strength (according to IP-6455)

iv. Flexural strength after freezing (according to IP-6457)

Cerámica Mayor S.A.

Date: 03/31/20 Code:

PROCESS CONTROL PRG-009-L

Page 3 of 11

c) Tiles (from external supplier...): they will be submitted or the

supplier company will supply (as established by UNE-EN 14411) to

tests in an accredited laboratory. The following table establishes the

acceptance criteria by variables or by attributes as appropriate, as

well as the limit values established in the event that the tests are

carried out by Cerámica Mayor.

Inspection by

attributes

Inspection by mean value

Sample

Initial initial+

sample second Initial sample Initial sample +second

Condition

Limit value

Frequency

Acceptanc

Acceptanc

e number

e number

rejection

rejection

for the

number

number

Sample

Condition second Condition

size

criteria intake criteria rejection

sample condition

Anion-

Exchange 7 Annual 23 mean1≥23 mean1<23 mean2≥23 mean2<23

breakage

Resistance to

therma

l choc 5 Annual Compliant 0 2 1 2

Resistance to:

the frost 10 Annual Compliant 0 1

Resistance to

impact 5 Annual 0 2 1 2

Water

absorption 5 Annual 0.5 Mean1≤0.5 Mean1>0.5 mean2≤0.5 average2>0

.5

Coefficient of

expansion Declared

linear thermal 1 Annual Value

*The conduct of these tests is optional and will depend on whether there

have been significant changes affecting these properties or on the

decision of the Technical Director.

5.12. Packaging.

Following the classification, the material is packaged as detailed in each of the

corresponding IPs.

5.13. Storage.

Finally, the material goes into storage until it is sold.

5.14. Finish

The material, either after sorting or storage, may undergo an additional step of

surface finishing, cutting or grinding. This surface finishing procedure may be

Cerámica Mayor S.A.

Date: 03/31/20 Code:

PROCESS CONTROL PRG-009-L

Page 4 of 11

outsourced. This

Cerámica Mayor S.A.

You might also like

- Itp TransformerDocument2 pagesItp TransformerDwi Mulyanti DwimulyantishopNo ratings yet

- The Cnidaria, Past, Present and Future: Stefano Goff Redo Zvy Dubinsky EditorsDocument842 pagesThe Cnidaria, Past, Present and Future: Stefano Goff Redo Zvy Dubinsky Editorscuentas cuentasNo ratings yet

- Inspection and Test Plan (Shunt Reactor)Document5 pagesInspection and Test Plan (Shunt Reactor)adi yudhaNo ratings yet

- Inspeksi Trafo - Sabtu SiangDocument24 pagesInspeksi Trafo - Sabtu SiangJAN OJANNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Uop Sulfolane Process: Thomas J. Stoodt and Antoine NegizDocument12 pagesUop Sulfolane Process: Thomas J. Stoodt and Antoine NegizBharavi K S100% (1)

- Manual Operasi DS700 Auto Stator TesterDocument4 pagesManual Operasi DS700 Auto Stator TesterAgus SupriyantoNo ratings yet

- The Scope of This Exercise Is Limited To Induction Cap Sealing MachineDocument5 pagesThe Scope of This Exercise Is Limited To Induction Cap Sealing MachinejaimurugeshNo ratings yet

- 2 Inspection FormatsDocument40 pages2 Inspection FormatsSatish ReddyNo ratings yet

- SGB-FR-QA-01.08-001 - Form Approval Release Dan Exceptional Release - 0.0Document2 pagesSGB-FR-QA-01.08-001 - Form Approval Release Dan Exceptional Release - 0.0Siti SalsabilNo ratings yet

- Section 9: Excitation TransformerDocument2 pagesSection 9: Excitation TransformerManjunathRangishettyNo ratings yet

- Form Native CTDocument1 pageForm Native CTFendi ahmadNo ratings yet

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDocument5 pagesInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNo ratings yet

- MBCI01Document2 pagesMBCI01THILAKKUMARNo ratings yet

- Section 13: Generator Bus Duct and Bus BarDocument2 pagesSection 13: Generator Bus Duct and Bus BarManjunathRangishettyNo ratings yet

- L&T QapDocument2 pagesL&T Qapsriram.5230No ratings yet

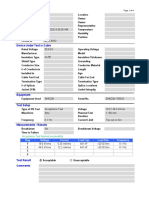

- Formate 20 - Capacitive Voltage TransformerDocument5 pagesFormate 20 - Capacitive Voltage Transformermayur dhandeNo ratings yet

- 907S Electrical Test Check ListDocument1 page907S Electrical Test Check Listjairo enrique silva rNo ratings yet

- Npar Tests: Npar Tests /K-S (Normal) P - PR P - Po K - PR K - Po /missing AnalysisDocument2 pagesNpar Tests: Npar Tests /K-S (Normal) P - PR P - Po K - PR K - Po /missing AnalysisVivin MarscellaNo ratings yet

- IOMQC Collapsible Jerry CansDocument13 pagesIOMQC Collapsible Jerry CansNibasB.ApuNo ratings yet

- HVA Report IS1-C.B-R2: Acceptance Test Finished SuccessfullyDocument1 pageHVA Report IS1-C.B-R2: Acceptance Test Finished SuccessfullyAhmed RabaaNo ratings yet

- DatasheetDocument2 pagesDatasheetLima LogictelNo ratings yet

- 2305-0-15702-Po 14459702Document3 pages2305-0-15702-Po 14459702Alfonso LopezNo ratings yet

- In-Process Inspection Report For Infant Incubator Parts9Document1 pageIn-Process Inspection Report For Infant Incubator Parts9Hilario AlinabonNo ratings yet

- Blant Test Report - 3 Phase TransformerDocument2 pagesBlant Test Report - 3 Phase TransformerEngr. Rik2xNo ratings yet

- 5.1form Test - SWG - 22-33kVDocument55 pages5.1form Test - SWG - 22-33kVfild225No ratings yet

- Scan 16 Jun 2022Document1 pageScan 16 Jun 2022pirates kingNo ratings yet

- 7 Grm155r71e104ke14 01a-1984358 PDFDocument32 pages7 Grm155r71e104ke14 01a-1984358 PDFrakeeNo ratings yet

- 12A. QA-NPD-12 Sani Molds Switch Base ACE-023-01 21-06-2019Document8 pages12A. QA-NPD-12 Sani Molds Switch Base ACE-023-01 21-06-2019delightplasticsNo ratings yet

- Output SPSSDocument3 pagesOutput SPSSEva IrmalaNo ratings yet

- Mcti - CBF Current Check RelayDocument2 pagesMcti - CBF Current Check RelayTHILAKKUMARNo ratings yet

- 08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EDocument6 pages08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EdelightplasticsNo ratings yet

- 1414-Pvb-Fcc-Icl-Pvsk-001-01 MV TXDocument4 pages1414-Pvb-Fcc-Icl-Pvsk-001-01 MV TXNoorNo ratings yet

- PC 5kpi (S)Document2 pagesPC 5kpi (S)bullxyzNo ratings yet

- Messrs.: Specification For ApprovalDocument5 pagesMessrs.: Specification For Approvalg_1234No ratings yet

- IOMQC GeneralDocument11 pagesIOMQC GeneralNibasB.ApuNo ratings yet

- Quality Plan - CapacitorsDocument2 pagesQuality Plan - Capacitorssmart solutionee100% (1)

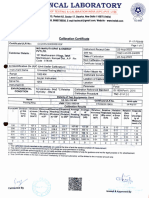

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- Aux Transformer TestDocument4 pagesAux Transformer TestEngr Fahimuddin QureshiNo ratings yet

- GOCOANT PPT 2021 - All MachinesDocument40 pagesGOCOANT PPT 2021 - All MachinesMohd RazaNo ratings yet

- PatientMonitor - CheckForm2 Rev.Document2 pagesPatientMonitor - CheckForm2 Rev.DickyNo ratings yet

- ELECT-TIC-2.6 (Continuity and Insulation Resistance Test)Document3 pagesELECT-TIC-2.6 (Continuity and Insulation Resistance Test)Muhammad Irfan100% (1)

- In-Process Inspection Report For Infant Incubator PartsDocument1 pageIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNo ratings yet

- Test Procedure PB273 - CDocument12 pagesTest Procedure PB273 - Cadi yudhaNo ratings yet

- MU UCT SoilDocument4 pagesMU UCT SoilemygeolabnorthNo ratings yet

- Shunt Reactor TestDocument10 pagesShunt Reactor TestEngr Imtiaz Hussain GilaniNo ratings yet

- Quenching and Tempering Check Sheet - Issue 1Document8 pagesQuenching and Tempering Check Sheet - Issue 1Sakthi VelNo ratings yet

- Maintaining Accuracy and Repeatability in The Ultimate Quest For Process PerfectionDocument36 pagesMaintaining Accuracy and Repeatability in The Ultimate Quest For Process PerfectionyardsonNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- In-Process Inspection Report For Infant Incubator PartsDocument4 pagesIn-Process Inspection Report For Infant Incubator PartsHilario AlinabonNo ratings yet

- Road Embankment ITPDocument6 pagesRoad Embankment ITPMahendraSinghNo ratings yet

- Factory Acceptance Test Document 20000075: Machine InformationDocument4 pagesFactory Acceptance Test Document 20000075: Machine Informationastojadin1873No ratings yet

- Test Report FormDocument7 pagesTest Report Formmyo kyawNo ratings yet

- Uji ValitditasDocument4 pagesUji ValitditasThomas Brilian DanikaNo ratings yet

- Commissioning Services Department Commissioning Manual Factory Type and Routine TestsDocument19 pagesCommissioning Services Department Commissioning Manual Factory Type and Routine Testsm khNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetMed CHNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetNsma AlaaNo ratings yet

- Packaging Code: GQM2195C2E470FB12 - (0805, C0G:EIA, 47pF, DC250V) Reference SheetDocument27 pagesPackaging Code: GQM2195C2E470FB12 - (0805, C0G:EIA, 47pF, DC250V) Reference SheetyogiNo ratings yet

- iSTM - Auto Sequential TestorDocument3 pagesiSTM - Auto Sequential TestorAakash PandyaNo ratings yet

- Mhob 04-Pw Protection (Translay) RelayDocument1 pageMhob 04-Pw Protection (Translay) RelayTHILAKKUMARNo ratings yet

- Adaptive Tests of Significance Using Permutations of Residuals with R and SASFrom EverandAdaptive Tests of Significance Using Permutations of Residuals with R and SASNo ratings yet

- Updated CV (Hussein Soliman)Document1 pageUpdated CV (Hussein Soliman)Sara mamdouhNo ratings yet

- CV Mohamed Eid.Document1 pageCV Mohamed Eid.Sara mamdouhNo ratings yet

- Saudi Importing Electrical Devices CompaniesDocument30 pagesSaudi Importing Electrical Devices CompaniesSara mamdouhNo ratings yet

- ArchitectureDocument10 pagesArchitectureSara mamdouhNo ratings yet

- عرض سعر شركة الجبيلي للاستشاراتDocument1 pageعرض سعر شركة الجبيلي للاستشاراتSara mamdouhNo ratings yet

- Research ProposalDocument16 pagesResearch Proposaljasvinder_sidhu100% (1)

- Analysis Report Client Address: Sample No: 29466 Report Date: 2022-03-23Document2 pagesAnalysis Report Client Address: Sample No: 29466 Report Date: 2022-03-23venkateshNo ratings yet

- SSRN Id4601234Document40 pagesSSRN Id4601234tNo ratings yet

- KTC 4370 ADocument2 pagesKTC 4370 AMambo Music PlusNo ratings yet

- Aerodynamics Tutorial IistDocument2 pagesAerodynamics Tutorial IistShubham MauryaNo ratings yet

- 1 Periodical Test Earth and Life Science 11Document3 pages1 Periodical Test Earth and Life Science 11GERRY CHEL LAURENTENo ratings yet

- Generic Vs Column & DetectorDocument4 pagesGeneric Vs Column & Detectorfazlul.qc.ndclNo ratings yet

- Electrostatics PowerPointDocument37 pagesElectrostatics PowerPointpunithaNo ratings yet

- Post Lab DiscussionDocument80 pagesPost Lab DiscussionDan ManaigNo ratings yet

- C1 - Atoms, Molecules and Stoichiometry (Structure Question) ANSWERDocument6 pagesC1 - Atoms, Molecules and Stoichiometry (Structure Question) ANSWERJosh, LRTNo ratings yet

- 2022 Intro To Org Chem Tutorial Section B AnsDocument17 pages2022 Intro To Org Chem Tutorial Section B AnsLow Jia YingNo ratings yet

- Chimica 2 2014 RGB 33-37 PDFDocument6 pagesChimica 2 2014 RGB 33-37 PDFMary Grace VelitarioNo ratings yet

- CH 14 Nuclear Chemistry PDFDocument28 pagesCH 14 Nuclear Chemistry PDFShivam KansagaraNo ratings yet

- Chapter 6. Equilibrium Based Separation Processes: 6.1 Study ObjectivesDocument17 pagesChapter 6. Equilibrium Based Separation Processes: 6.1 Study ObjectivesMaarifa KidogeNo ratings yet

- Wall Wash Test Procedures On Chemical TankersDocument3 pagesWall Wash Test Procedures On Chemical TankersPavel Viktor100% (1)

- Computer Science Exam PreviousDocument12 pagesComputer Science Exam PreviousAmanSaroyNo ratings yet

- Form 2 Chapter 9 HeatDocument46 pagesForm 2 Chapter 9 HeatAmer MalekNo ratings yet

- Magnetism: Arvind Singh Heer Msc-I (Sem-Ii) Inorganic Chemistry Mithibai CollegeDocument15 pagesMagnetism: Arvind Singh Heer Msc-I (Sem-Ii) Inorganic Chemistry Mithibai CollegeMUHAMMAD NADEEMNo ratings yet

- Tatabunan Integrated School Talalora Samar Third Periodical Examination Science - Grade 8Document2 pagesTatabunan Integrated School Talalora Samar Third Periodical Examination Science - Grade 8Tinay TinayNo ratings yet

- z.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Document6 pagesz.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Sutarno -No ratings yet

- Aquatech FEWADocument6 pagesAquatech FEWAMohamed ZaghloulNo ratings yet

- Refining ProcessDocument22 pagesRefining Processramadoss_alwar7307No ratings yet

- RocimaDocument2 pagesRocimaسلطان ابوالعلا0% (1)

- Table 1 Chemical Composition Requirements, %: UNS DesignationDocument5 pagesTable 1 Chemical Composition Requirements, %: UNS DesignationQuraNo ratings yet

- Detergents (Anionic Surfactants, MBAS)Document1 pageDetergents (Anionic Surfactants, MBAS)Anggun SaputriNo ratings yet

- Hill1987 PDFDocument8 pagesHill1987 PDFWillbrynner MarquesNo ratings yet

- SRP Booklet 2011Document24 pagesSRP Booklet 2011mekanshNo ratings yet

- Tutorial PDFDocument81 pagesTutorial PDFFilipe SaboiaNo ratings yet