Professional Documents

Culture Documents

RESP003VDM

RESP003VDM

Uploaded by

NIEL TANEDOOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RESP003VDM

RESP003VDM

Uploaded by

NIEL TANEDOCopyright:

Available Formats

ASSOC.

PIP

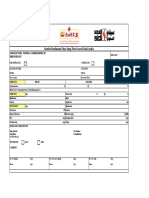

DATA SHEET RESP003V-DM

RESP003V

VERTICAL CENTRIFUGAL PUMPS FOR PAGE 1 OF 4

WATER SERVICE (SI UNITS) FEBRUARY 2004

ISSUED FOR: PROPOSAL PURCHASE AS BUILT

FACILITY NAME/LOCATION:

ITEM NAME: PURCHASER/LOCATION:

ITEM TAG NO.: JOB NO:

SERVICE: PURCHASER ORDER NO.:

UNIT: SUPPLIER/LOCATION:

P&ID NO.: SUPPLIER ORDER/SERIAL NOS.: /

DATA PROVIDED BY: PURCHASER SUPPLIER u SUPPLIER IF NOT BY PURCHASER

PURCHASERS REFERENCES DESIGN OPERATING/INSTALLATION DATA

PUMP MFR: FIGURE 1 CLOSED SUCTION SYSTEM

SIZE & TYPE:

SERIAL NO.: AT NOZZLES CL:

DRIVER TYPE: TOTAL SUCTION HEAD: M

THIS DATA SHEET COVERS: PUMP(S) TOTAL DIFF. HEAD: M

PUMP MARK NO(S).: TOTAL DISCH. HEAD: M

PUMPS OF IDENTICAL TYPE AND SIZE IN OPERATION:

NOZZLE CL ABOVE

DATUM: M

DRIVER DATA SHEET: DATUM ELEVATION: M

GEAR UNIT DATA SHEET: NPSHA AT DATUM: M

LUBE OIL SYSTEM DATA SHEET:

DESIGN OPERATING DATA BARREL WALL THICKN: mm

SERVICE BARREL OD: mm

CONTINUOUS INTERMITTENT STANDBY BARREL LENGTH: M

ATTENDED UNATTENDED CL 1ST STAGE IMPELLER TO

PUMP FUNCTION: CL SUCTION NOZZLE: M

INDIVIDUALLY IN SERIES IN PARALLEL

UPSTREAM OF PUMP NO(S).

DOWNSTREAM OF PUMP NO(S). MOUNTED ON:

LIQUID CHARACTERISTICS CONCRETE

LIQUID PUMPED: TDS: MG/L STRUCTURAL STEEL

NORMAL FLOW TEMPERATURE: °C FIGURE 2 OPEN SUCTION SYSTEM TYPE:

MAX. FLOW TEMPERATURE: °C CONCENTRIC RISER COLUMN

RELATIVE DENSITY AT NORMAL FLOW TEMP.: SIDE DISCHARGE PIPE

VISCOSITY AT FLOW TEMPERATURE: MPA.S,mm2/S

VAPOR PRESSURE AT NORMAL FLOW TEMP.: KPA(ABS) NOZZLE CL ABOVE

VAPOR PRESSURE AT MAXIMUM FLOW TEMP.: KPA(ABS) DATUM: M

TSS: NONE MG/L UNKNOWN DATUM ELEVATION: M

CHARACTER OF SOLIDS: PULPY GRITTY HARD SOFT

GAS IN FLUID: NONE VOL. % UNKNOWN

PRINCIPAL CORROSIVES: STATIC LEVEL: M

PH: CL: MG/L

RATED OPERATING CONDITIONS

RATED CAPACITY: M3/HR PUMPING LEVEL: M

TOTAL DIFFERENTIAL HEAD: M

VISCOSITY CORRECTION FACTORS CQ; CH; CE:

SUCTION SYSTEM: CLOSED OPEN MIN. LIQUID LEVEL: M

FOR CLOSED SUCTION SYSTEMS: ENTER DATA ON FIG. 1

NPSH AVAILABLE AT SUCTION FLG.:

AT RATED CAPACITY: M

AT 120% OF RATED CAPACITY: M CL FIRST STAGE: M

RATED SUCTION PRESSURE: KPA(ABS)

MAX. SUCT. PR. AT RATED CAP: KPA(ABS)

MAX. SUCT. PR. AT SHUT OFF: KPA(ABS)

RATED DISCHARGE PRESSURE: KPA(ABS) BOTTOM OF SUMP/TANK: M

MAX. DISCH. PR. AT RATED CAP.: KPA(ABS)

FOR OPEN SUCTION SYSTEMS: ENTER DATA ON FIG. 2

RATED DISCHARGE PRESSURE: KPA(ABS)

SITE CONDITIONS MOUNTED ON:

INDOOR OUTDOOR UNDER ROOF CONCRETE

ONSHORE COASTAL OFFSHORE STRUCTURAL STEEL

ELECTRICAL AREA CLASS: DIV GROUP

NO. DATE REVISION DESCRIPTION BY APVD.

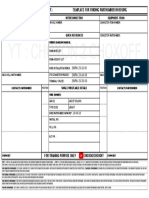

ASSOC. PIP

DATA SHEET RESP003V-DM

RESP003V

VERTICAL CENTRIFUGAL PUMPS FOR PAGE 2 OF 4

WATER SERVICE (SI UNITS) FEBRUARY 2004

PERFORMANCE DATA PUMP CONSTRUCTION DATA (CONT’D)

u DRIVER NAMEPLATE POWER RATING: KW FORCES AND MOMENTS

u RATED SPEED OF DRIVER: RPM ALLOWABLE FORCES AND MOMENTS:

SUCTION: DISCHARGE: EACH NOZZLE:

MIN. CONT. 100% 120% FX: N FX: N MX: N,M.

STABLE FLOW OF RATED CAPACITY FY: N FY: N MY: N,M.

BOWL ASSEMBLY HEAD: M FZ: N FZ: N MZ: N,M.

COLUMN LOSS: M

EFFICIENCY: % MISC. CONNECTIONS: QUANTITY SIZE TYPE

REQUIRED POWER: KW BARREL VENT:

VEL IN COLUMN: M/S BARREL DRAIN:

NPSHR FOR CLOSED SUCT. SYSTEM AT CL 1ST ST. IMPELLER: SEAL LIQUID INLET:

3% DH ON WATER: M SEAL LIQUID DRAIN:

NPSHR FOR OPEN SUCT. SYSTEM AT CL 1ST ST. IMPELLER: STUFFING BOX VENT:

3% DH ON WATER: M

MIN. SUBM. REQ’D: M PRESSURES

MAX. ALOW WORK HYDROTEST

SHUT-OFF HEAD AT ACTUAL IMPELLER DIAMETER: M PRESSURES: PRESS. AT °C PRESSURE

AT MAXIMUM IMPELLER DIAMETER: M BOWL ASSEMBLY: KPA(GA)

CAPACITY AT END OF CURVE: M3/HR COLUMN ASSEMBLY: KPA(GA)

TOTAL DIFF. HEAD AT END OF CURVE: M HEAD ASS’Y (DISCH.): KPA(GA)

RATIO-SHUT-OFF HEAD/RATED HEAD: HEAD ASS’Y (SUCT.): KPA(GA)

RATIO-END OF CURVE CAPACITY RATED CAP: SUCTION BARREL: KPA(GA)

MINIMUM CONTINUOUS STABLE FLOW: M3/HR MECHANICAL SEAL: KPA(GA)

MINIMUM CONTINUOUS THERMAL FLOW: M3/HR

MAXIMUM OPR. TIME AT SHUT-OFF: S

FIRST CRIT. SPEED DRY: RPM SHAFT DATA

FIRST CRIT. SPEED WET: RPM SHAFT DIAMETER AT MECHANICAL SEAL SLEEVE: mm

MAX. ALLOWABLE SPEED: RPM SHAFT DIAMETER AT BEARINGS: mm

MAX. UPTHRUST: N TOTAL ROTOR LIFT: mm

MAX . DOWNTHRUST: N SHAFT COUPLING: KEYED OTHER:

MAX. POWER FULL CURVE ACTUAL IMP. DIAM.: KW

POWER AT SHUT OFF HEAD: KW SHAFT SEALING

PACKED STUFFING BOX PACKING MATERIAL:

PUMP CONSTRUCTION DATA PROVIDED WITH LANTERN RING: YES NO

PUMP BOWL TYPE: SEALING ARRANGEMENT

SINGLE VOLUTE DOUBLE VOLUTE THROUGH SEALING DEAD ENDED SEAL

QUADRANT VOLUTE DIFFUSER FLUSHED WITH:

THREADED BOWLS BOLTED BOWLS LIQUID PUMPED FOREIGN LIQUID

LINE SHAFT: GREASE BLEED OFF

OPEN ENCLOSED MECHANICAL SEAL, API CODE:

FLANGED THREADED API CODE MA’L 3RD LETTER:

THRUST BEARING IN: 4TH LETTER:

PUMP DRIVER 5TH LETTER:

SUCTION STRAINER: MAKE:

BASKET CONE MANUFACTURER MATERIAL CODE:

NONE MODEL:

BARREL INSULATION: PIPING FOR PRIMARY SEAL PLAN:

YES, PROVISIONS, ONLY NO PIPING FOR THROTTLE BUSHING OR

THICKNESS: mm AUXILIARY SEAL PLAN:

u INTERMEDIATE TRANSMISSION:

RIGHT ANGLE GEARBOX RATIO: COOLING WATER PIPING PLAN:

DIRECTION OF ROTATION: VIEWED FROM ABOVE CYCLONE SEPARATOR: YES NO

CW CCW FLOW ORIFICE IN SEAL FLUSH SUPPLY LINE: YES NO

SEAL LEAKAGE PIPING WITH ORIFICE: YES NO

NOZZLES: SIZE RATING FACING LOCATION BUFFER LIQUID SYSTEM: YES NO

SUCTION: REQ'D PRESS.: KPA(GA) FLOW: L/S

DISCHARGE: CARTRIDGE DESIGN: YES NO

ASSOC. PIP

DATA SHEET RESP003V-DM

RESP003V

VERTICAL CENTRIFUGAL PUMPS FOR PAGE 3 OF 4

WATER SERVICE (SI UNITS) FEBRUARY 2004

PUMP CONSTRUCTION DATA (CON’T) PUMP CONSTRUCTION DATA (CON’T)

STUFFING BOX DATA MATERIALS OF CONSTRUCTION

STUFFING BOX: INTERNAL EXTERNAL BOWLS: ASTM

INBOARD OUTBOARD IMPELLERS ASTM

INSIDE DIAMETER: mm WEAR RING BOWL: ASTM

DEPTH: mm WEAR RING IMPELLER: ASTM

DISTANCE FACE OF STUFFING BOX mm BEARING BOWL ASSEMBLY: ASTM

FLANGE TO NEAREST OBSTRUCTION: SHAFT, BOWL ASSEMBLY: ASTM

LINE SHAFT (OIL LUB0): ASTM

IMPELLER DATA LINE SHAFT (SELF LUB0): ASTM

CLOSED SEMI ENCLOSED OPEN BEARINGS, LINE SHAFT: ASTM

KEY FITTED COLLET FITTED SHAFT SLEEVE: ASTM

RISER COLUMN AND SHAFT ENC. TUBE: ASTM

FIRST FOLLOW NOZZLE HEAD: ASTM

NUMBER OF STAGES: STAGE STAGES MOTOR SUPPORT & MOUNTING FLANGE: ASTM

ACTUAL DIAMETER: mm SUCTION BARREL: ASTM

MAXIMUM DIAMETER: mm SUCTION STRAINER: ASTM

MINIMUM DIAMETER: mm GLAND/MECH. SEAL FLANGE: ASTM

SINGLE/DOUBLE SUCTION: LANTERN RING: ASTM

TOTAL EYE AREA IMPELLER: CM2 SEAL & VENT PIPING/FITTINGS: ASTM

VANE ANGLE AT IMPELLER EXIT: BOLTING MATL, STUDS/BOLTS: ASTM

NUMBER OF VANES: NUTS: ASTM

ACTUAL PERIPHERAL SPEED: M/S MECH. SEAL SPRINGS: ASTM

PATTERN NUMBER: MECH. SEAL OTHER METAL PARTS: ASTM

PRECISION CAST: YES/NO

CUT WATER DIAMETER: mm NOISE SPECIFICATION

SPECIFIC SPEED: MAXIMUM ALLOWABLE SOUND LEVEL

SUCTION SPECIFIC SPEED AT 3% DH: AT 1 M DISTANCE: DBA

WIDTH IMPELLER DISCH.: mm GUARANTEED MINIMUM: DBA

WEAR RINGS: PUMP: DBA

IMPELLER: YES NO CASE OPEN DRIVER: DBA

CLEARANCES INBOARD: mm COMPLETE TRAIN: DBA

DESIGN OUTBOARD: mm

LINE SHAFT BEARINGS AND LUBRICATION

GUIDE BEARING SPAN: M

OPEN LINESHAFT BEARINGS, LUBR’D BY MED. PUMPED

ENCLOSED LINESHAFT BEARINGS

LUBRICATED BY: WATER (EXTERNAL SUPPLY)

OIL (EXTERNAL SUPPLY)

OIL RESERVOIR CONTENT: M3

MIN. L. O. SUPPLY: M3/WEEK

INDIVIDUAL BEARING L.O. SUPPLY: YES NO

LUBRICANTS

LINESHAFT BEARINGS:

LIQUID PUMPED WATER

OIL GREASE

MOTOR BEARINGS:

OIL GREASE

COUPLING

RIGID ADJUSTABLE SPACER TYPE

SPACER LENGTH: mm

HOLLOW SHAFT DRIVER

ASSOC. PIP

DATA SHEET RESP003V-DM

RESP003V

VERTICAL CENTRIFUGAL PUMPS FOR PAGE 4 OF 4

WATER SERVICE (SI UNITS) FEBRUARY 2004

UTILITIES DRAWINGS

ELECTRIC POWER:

AC/DC AVAILABLE VOLTS PHASE/HZ DRAWING REQUIRED

MAIN ELECTRIC DRIVER: NUMBER YES NO

CONTROLS AND PROTECTION: DIMENSIONAL DRAWING OF COMPLETELY

OTHER: ASSEMBLED UNIT:

AIR: OPER. & MAINT. INSTRUCTIONS:

CONTROLS AND PROTECTION: AVAILABLE KPA(GA) CROSS SECTION DRAWING WITH PART NO’S.:

OTHER: AVAILABLE KPA(GA) MECHANICAL SEAL DRAWING:

PRESS. INLET OUTLET BILLS OF MATERIALS:

AVAILABLE COOLING AVAIL. KPA(GA) °C °C COMPLETED PUMP DATA SHEET:

WATER: REQ'D. KPA(GA) °C °C AUXILIARY PIPING DRAWING:

WELL WATER TREATED WATER SEA WATER CERTIFIED TEST CURVE AND DATA:

ONCE THROUGH SYSTEM CLOSED LOOP SYSTEM RECOMMENDED SPARES LIST:

INSTR. WIRING DIAGRAM:

INSTRUMENTATION & CONTROLS SPEED TORQUE CURVE:

SHAFT SEAL LEAKAGE CONTROL: YES NO COLD ALIGNMENT CURVE:

ELECTRICAL PNEUMATIC DATA L. & T. VIBRATION ANALYSIS:

PRES. SWITCH MAKE: MODEL:

PRESSURE SETTING “SHUTDOWN”: KPA(GA) MISCELLANEOUS

LEVEL SWITCH MAKE: MODEL: PURCHASER’S PAINT SPECIFICATION:

TIME DELAY SETTING: S CONTR. ORIFICE: mm SUPPLER'S STANDARD PAINT:

INSPECTION AND TESTS

SUPPLIER’S STANDARD SHOP TEST

WITN'D OBSR'D CERT'D NONE

AS FOLLOWS:

HYDROSTATIC TEST:

WATER:

KEROSENE:

RUNNING TEST (MIN. 4 HOURS):

PERFORMANCE TEST:

MEASURE DP ACROSS STUFFING BOX:

NPSH TEST:

DISMANTLING:

RADIOGRAPHIC EXAM IMPELLER:

DYE PENETRANT EXAM IMPELLER:

DYNAMIC BALANCE IMPELLER(S):

DYNAMIC BALANCE ROTOR:

DYNAMIC BALANCE COUPLING:

VIBRATION MEASUREMENTS:

TESTS TO BE CARRIED OUT WITH:

ACTUAL DRIVER

SUPPLIER’S DRIVER

TESTS TO BE CARRIED OUT AT:

RATED SPEED

DERATED SPEED: RPM

MASSES

PUMP: KG

PUMP ROTATING ASSEMBLY: KG

BARREL: KG

COUPLING: KG

DRIVER ROTATING ASSEMBLY: KG

TOTAL MASS PUMP, DRIVER, COUPLING, BARREL, BASE: KG

You might also like

- F.tr.03.Tool History CardDocument2 pagesF.tr.03.Tool History CardSaurabh60% (5)

- Example Pump Selection: Equipment Data SheetDocument4 pagesExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNo ratings yet

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- 11 D Equipment Data SheetDocument4 pages11 D Equipment Data SheetFernando RomeroNo ratings yet

- Principles of TurbomachineryDocument276 pagesPrinciples of TurbomachineryNavneet PAndeNo ratings yet

- PIPE ProblemsDocument8 pagesPIPE ProblemsNelson Naval Cabingas100% (3)

- German Atv-Dvwk Rules and Standards: Standard ATV-DVWK-A 134E Planning and Construction of Wastewater Pumping StationsDocument42 pagesGerman Atv-Dvwk Rules and Standards: Standard ATV-DVWK-A 134E Planning and Construction of Wastewater Pumping StationsMehmet Emre Bastopcu100% (1)

- RESP003VDDocument8 pagesRESP003VDParag WadekarNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- RESP003SDDocument4 pagesRESP003SDParag WadekarNo ratings yet

- Centrifugal Pump Data Sheet: Operating Conditions Site and Utility Data (Cont.)Document1 pageCentrifugal Pump Data Sheet: Operating Conditions Site and Utility Data (Cont.)dante eyzaguirreNo ratings yet

- KI SV F005, REV.02 Start Up Data SheetDocument1 pageKI SV F005, REV.02 Start Up Data SheetMark Anthony CaguioaNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Client: Contract: Job / Project TitleDocument10 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- Nrs Mod 5 Data Innovation ReportDocument1 pageNrs Mod 5 Data Innovation ReportBrahmananda ChakrabortyNo ratings yet

- P - Id Scan FileDocument16 pagesP - Id Scan FileCua Tran VanNo ratings yet

- Example Pump Selection: Hoja de Datos de EquiposDocument2 pagesExample Pump Selection: Hoja de Datos de EquiposAlonso DIAZNo ratings yet

- Environmental MonitoringDocument1 pageEnvironmental MonitoringResearcherNo ratings yet

- Structural Damage Report Form: SDR NoDocument2 pagesStructural Damage Report Form: SDR NoDewin Silva100% (1)

- Data PDFDocument30 pagesData PDFBernardo Ramos RojasNo ratings yet

- TOF-036 Formato de Pipe Repair Inspeciton ReportDocument2 pagesTOF-036 Formato de Pipe Repair Inspeciton ReportRodrigoNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- SAMPLE Defect SheetDocument2 pagesSAMPLE Defect SheetshafanyNo ratings yet

- Weld MapDocument7 pagesWeld Maprian1099No ratings yet

- 002 - Repair - Trough Thickness-PQR - Rev.1Document2 pages002 - Repair - Trough Thickness-PQR - Rev.1Ricardo NapitupuluNo ratings yet

- SPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETDocument1 pageSPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETgopuvinu4uNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- Pueblo Viejo Project Barrick Gold - Dominican Republic CM 001Document6 pagesPueblo Viejo Project Barrick Gold - Dominican Republic CM 001Silvia Quispe CerinNo ratings yet

- Silverline Borehole PumpsDocument48 pagesSilverline Borehole PumpsBradley PortNo ratings yet

- HD BombasDocument3 pagesHD BombasingearroyoNo ratings yet

- Datasheet Pump - 3205ABDocument2 pagesDatasheet Pump - 3205ABprocess1plecoNo ratings yet

- PMCM Form-074 Megger TestingDocument1 pagePMCM Form-074 Megger TestingAbnar KumplishaNo ratings yet

- HRP Ii WPS LGP 332Document4 pagesHRP Ii WPS LGP 332RohiNo ratings yet

- Flow Element: Base Maximum Flow Min Flow Property MethodDocument4 pagesFlow Element: Base Maximum Flow Min Flow Property Methodscploperation.2x50 CommonNo ratings yet

- PDS Centrifugal PumpsDocument3 pagesPDS Centrifugal Pumpsrupawer56No ratings yet

- Fire Pumps Data SheetDocument1 pageFire Pumps Data SheetSalim BakhshNo ratings yet

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiNo ratings yet

- AGITATORDATA HWPDocument1 pageAGITATORDATA HWPbrat.jose2023No ratings yet

- 545 7489 (EAG349) - Process FlowDocument1 page545 7489 (EAG349) - Process FlowDurai NaiduNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- 24191000-1, LACT Unit As BuiltDocument7 pages24191000-1, LACT Unit As BuiltAtty AttyNo ratings yet

- Co2 Cylinder Master Assembly: Data SheetDocument19 pagesCo2 Cylinder Master Assembly: Data SheetLaxmanDungraniNo ratings yet

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiNo ratings yet

- F-034 (Piping Dismantling Format)Document1 pageF-034 (Piping Dismantling Format)Rajeev KumarNo ratings yet

- Sample Drawing Oil Water SeparatorDocument9 pagesSample Drawing Oil Water SeparatorTemoteo L Pupa IIINo ratings yet

- Mechanical Sales, Inc.: Fire Pump Test WorksheetDocument1 pageMechanical Sales, Inc.: Fire Pump Test WorksheetAhmed El MorsyNo ratings yet

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 pagesSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarNo ratings yet

- Ns2-Xg02-p1lac-120001 (Các Thông Số) Cần Đo) for BfbpDocument5 pagesNs2-Xg02-p1lac-120001 (Các Thông Số) Cần Đo) for BfbpPHAM PHI HUNGNo ratings yet

- Iv-0633-20 Cross Over 48988KDocument1 pageIv-0633-20 Cross Over 48988Kivan dario benavides bonillaNo ratings yet

- Boeing PN Template by ChoxonDocument1 pageBoeing PN Template by ChoxonMuhammad ShoaibNo ratings yet

- Fe-7151 Case 3 PDFDocument1 pageFe-7151 Case 3 PDFSureshNo ratings yet

- fLOW 3265 PDFDocument1 pagefLOW 3265 PDFSureshNo ratings yet

- Flow Element: Base Maximum Flow Normal Flow Property MethodDocument1 pageFlow Element: Base Maximum Flow Normal Flow Property MethodSureshNo ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Fe-7151 Case 1 PDFDocument1 pageFe-7151 Case 1 PDFSureshNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- Motor Operated Valves2Document2 pagesMotor Operated Valves2Kareem HelmyNo ratings yet

- Material Receiving Accomplished Data at Jana-Zamil VesselsDocument6 pagesMaterial Receiving Accomplished Data at Jana-Zamil VesselsNIEL TANEDONo ratings yet

- L - FA - Niel T. - WK03 - After Inst. Cable Glanding, Sealing & TerminationDocument1 pageL - FA - Niel T. - WK03 - After Inst. Cable Glanding, Sealing & TerminationNIEL TANEDONo ratings yet

- L - FA - Niel T. - WK04 - FA After Control Cable Glanding, Sealing & TerminationDocument1 pageL - FA - Niel T. - WK04 - FA After Control Cable Glanding, Sealing & TerminationNIEL TANEDONo ratings yet

- L - FA - Niel T. - wk#13 - Contractors Monitoring & Measuring DeviceDocument1 pageL - FA - Niel T. - wk#13 - Contractors Monitoring & Measuring DeviceNIEL TANEDONo ratings yet

- L - FA - Niel T. - WK03 - FA After Inst. Cable Glanding, Sealing & TerminationDocument1 pageL - FA - Niel T. - WK03 - FA After Inst. Cable Glanding, Sealing & TerminationNIEL TANEDONo ratings yet

- L - FA - Niel T. - WK04 - NPCC PLB 648 Quality System DeliverablesDocument1 pageL - FA - Niel T. - WK04 - NPCC PLB 648 Quality System DeliverablesNIEL TANEDONo ratings yet

- L - FA - Niel T. - wk#04 - ICCP Cable Reel Storage & PreservationDocument1 pageL - FA - Niel T. - wk#04 - ICCP Cable Reel Storage & PreservationNIEL TANEDONo ratings yet

- Lbe Week #01Document2 pagesLbe Week #01NIEL TANEDONo ratings yet

- K Twin ImpellerDocument9 pagesK Twin ImpellerMehdi BeygNo ratings yet

- Design Production and Testing of A Single Stage Centrifugal PumpDocument10 pagesDesign Production and Testing of A Single Stage Centrifugal PumpCat MaNo ratings yet

- Balakumaran CVDocument4 pagesBalakumaran CVjohn MNo ratings yet

- Pump GuidelinesDocument205 pagesPump GuidelinesSyedNadeemAhmed100% (1)

- Pit Ot Tube Pump TechnologyDocument12 pagesPit Ot Tube Pump TechnologymariasofiarossiNo ratings yet

- Experiment Centrifugal PumpDocument14 pagesExperiment Centrifugal PumpmahabubNo ratings yet

- Process Equipment Design and DrawingDocument35 pagesProcess Equipment Design and DrawingKutty Krishnan MankaraNo ratings yet

- Submersible Pumps GuidelinesDocument5 pagesSubmersible Pumps GuidelinesJanneth Herrera FloresNo ratings yet

- Centrifugal PUMP SPECIFICATIONDocument6 pagesCentrifugal PUMP SPECIFICATIONAlvin Smith100% (1)

- SRAC Publication No. 453 Recirculating Aquaculture Tank Production Systems A Review of Current Design Practice PDFDocument12 pagesSRAC Publication No. 453 Recirculating Aquaculture Tank Production Systems A Review of Current Design Practice PDFmabrarahmedNo ratings yet

- Fluid Mechanics PDFDocument59 pagesFluid Mechanics PDFsunny chaurasiaNo ratings yet

- 11-Pump Affinity LawsDocument13 pages11-Pump Affinity Lawspratheesh100% (1)

- RRB Junior Engineer JE Mechanical Previous Question Papers - Indian ShoutDocument8 pagesRRB Junior Engineer JE Mechanical Previous Question Papers - Indian ShoutPavitar Papii80% (5)

- PUMPS IN Unit 11 (P)Document1 pagePUMPS IN Unit 11 (P)Mizanul HoqueNo ratings yet

- Internship Report 2022Document25 pagesInternship Report 2022trick masterNo ratings yet

- US Seal MFG Catalog 1010Document210 pagesUS Seal MFG Catalog 1010Juntas Homocineticas Ever0% (1)

- FRISTAM FP enDocument2 pagesFRISTAM FP enAhmed Hassan Abd ElhafezNo ratings yet

- Epfl TH4642Document159 pagesEpfl TH4642Davide AbdelalNo ratings yet

- Fluid MechanicsDocument9 pagesFluid Mechanicsjayasimha bmNo ratings yet

- Understanding Pump Curves PDFDocument2 pagesUnderstanding Pump Curves PDFumairgul841No ratings yet

- Educspace - Pumps - Problems SetDocument3 pagesEducspace - Pumps - Problems SetMatthew John SyNo ratings yet

- Fluid TransportationDocument63 pagesFluid TransportationAijaz Ahmed Khoso100% (1)

- Ebara Stainless Steel Centrifugal PumpDocument3 pagesEbara Stainless Steel Centrifugal PumpHelda MhptNo ratings yet

- PumpsDocument46 pagesPumpsDr. Rachid djoudjouNo ratings yet

- Sizing and Specifying Pumps R2Document27 pagesSizing and Specifying Pumps R2royNo ratings yet

- Brosur MT Rev.13092019Document2 pagesBrosur MT Rev.13092019gheghe mahardikaNo ratings yet

- Data Sheet For Centrifugal PumpsDocument2 pagesData Sheet For Centrifugal PumpsgffNo ratings yet