Professional Documents

Culture Documents

Boq For The Proposed 8 No. Classroom Block Revised

Boq For The Proposed 8 No. Classroom Block Revised

Uploaded by

SalamiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boq For The Proposed 8 No. Classroom Block Revised

Boq For The Proposed 8 No. Classroom Block Revised

Uploaded by

SalamiCopyright:

Available Formats

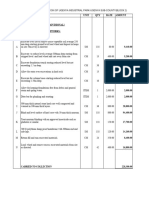

REVISED BOQ FOR THE PROPOSED 8 CLASSROOMS BLOCK

ITEM DESCRIPTION UNIT QUANTITY RATE AMOUNT

PROPOSED CONSTRUCTION OF 8

CLASSROOM BLOCK

EXCAVATIONS AND EARTH

WORKS

Clear site of shrubs, bush and dispose the

A SM 400.00

arising materials

Excavate the site to remove all top soil to

B 200mm depth and dump the materials at SM 400.00

approved dumping site

Excavate for foundation footing starting at

C stripped levels to depth not exceeding CM 110.00

1500mm

D Ditto column bases ditto CM 100.00

Return, fill and ram selected excavated

E material in layers of 150mm thick around CM 140.70

foundations.

Load and dispose surplus excavated material

F in municipal dumping site distance not CM 69.30

exceeding 100m away

Approve 1000mm thick hardcore filling well

G compacted and consolidated in layers of CM 300.00

150mm thick layer.

Approve hardcore backfilling well compacted

H CM 0.00

and consolidated in layers of 150mm thick.

50mm thick approved murram blinding to

I SM 340.00

surface of hardcore

'Rentokil" or other equal and approved

J SM 340.00

insecticide treatment to murram surface

Damp proof membrane

1000 Gauge polythene or other equal and

approved plastic sheet damp proof membrane

K SM 340.00

laid over blinding(measured nett - allow for

laps)

TOTAL CARRIED FORWARD TO

LL/1

COLLECTION

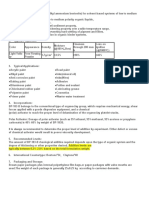

ITEM DESCRIPTION UNIT QUANTIT RATE AMOUNT

CONCRETE WORKS

Vibrate reinforced concrete(1:2:4)

20mm aggregate as described in : bs 81110

A Column base CM 39.00

column starters CM 4.10

B Foundation footing CM 25.00

C Column CM 15.00

D First floor beams CM 17.00

E Ring beams CM 15.00

F 150mm thick ground floor slab CM 54.00

G 150mm thick first floor slab CM 54.00

H 125 mm thick staircase waist CM 2.00

I 150mm staicase landing CM 3.00

J Ramp waist and landing CM 5.00

Sawn formwork as described to:-

K Collum bases SM

L Column SM 250.00

M vertical sides of foundation footing SM

Vertical edge of concrete floor slab 75-

N LM 100.00

150mm high

O Sides and soffits of ring beams first floor SM 140.00

P Sides and soffits of beams SM 150.00

Q soffits of slabs SM 337.00

soffits of sloping sides of stairs waists

T SM 4.00

landings and the sides of stairs

Open raking string edge to staircase 300 mm

U high (extreme) cut and fitted to SM 4.00

profile of treads and riser.

Wall raking string to edge of slopping

V SM 10.00

waist 150-225 mm high (provision)

W Soffits of sloping sides of ramp SM 25.00

50mm thick concrete (1:4:8)

blinding

A Culumn bases SM 100.00

B Foundation footing SM 30.00

BRC mesh A142 in one layer laid concrete

floor slab High tensile square twisted

C SM 360.00

reinforcement bar to B.S 4461 including

cutting hooks; spacer blocks and binding wire:

High Tensile Reinforcement Bars to

B.S 4461 including cutting, Bendinng and

all necessary Spacer Blocks: ( provisional)

D 20mm diameter bar KG 4400.00

E 16mm diameter bar KG 3,520.00

F 12mm diameter bar KG 2,860.00

G 8mm diameter bar KG 2,200.00

H 10mm diameter bar KG 4,620.00

TOTAL CARRIED FORWARD TO

LL/2

COLLECTION

ITEM DESCRIPTION UNIT QUANTIT RATE AMOUNT

WALLING

Smooth machine dressed quarry stone or

other equal and approved walling in

cement:sand (1:4)mortar:-

200mm Thick rough chiselled dressed natural

stone walling bedded and jointed in cement

A and sand (1:3) mortar and reinforced with and SM 160.00

including 20 swg x 25 mm wide hoopiron in

every alternate course

200mm thick dressed on one side natural

stonewalling above general ground level laid

B with (1;4)cement sand mortar with hoop iron SM 780.00

in every sencond course. (use undressed for

sub-structure)

Approved 200mm wide damp proof couse laid

C to breaking jionts with 150mm laps in LM 150.00

cement:sand (1:3) mortar

TOTAL CARRIED FORWARD TO

LL/3

COLLECTION

1 Brought forward from LL/1

2 Brought forward from LL/2

3 Brought forward from LL/3

COLLECTION 01

ITEM DESCRIPTION UNIT QUANTIT RATE AMOUNT

ROOFING WORK

Supply and fix onto timber purlins with

approved nails gauge 30 I.T.4 box profile

A SM 500.00

galvanized iron sheets as per Galsheet or

equivalent manufacturer

Ridge cap to match item (A) above LM 30.00

The following in sawn treated cypruss

or equivalent including hoisting and

placing in position approximately

3.50Metres above ground level

B 150 x 50 mm rafter LM 600.00

C 100 x 50 mm tie beam LM 400.00

D 75 x 50 mm purlin LM 400.00

E 200 x 25 mm fascial board LM 120.00

200 x 225mm wrot cypruss fascia or

H LM

burge boad

I 100 x 50 mm sawn cypress wall plate LM 100.00

Knot, prime stop prepare and one undercoat

J and two finshing coats of gloss paint to general LM 140.00

surface of wood 200- 300 mm girth.

K

Roof water goods

Supply and fix 140mm half round gutter

(pvc)

L prefabricated with fixed with screwed joints LM 140.00

on approved 140mm gutter support c/w

brackets

brackets

N Extra for closed ends NO 6.00

Supply and fix 100mm diameter

P LM 35.00

downpipe with brackets to wall

Q Extra for 100mm diameter spigot outlet NO 5.00

Extra for swan neck and rainwater shoe

R NO 5.00

Labour in:

Raking cutting Galvanised iron plain

S LM 10.00

sheet

TOTAL CARRIED FORWARD TO

LL/4

COLLECTION

Description UNIT QUANTITY RATE AMOUNT

ITEM

ELEMENT NO. 4

WINDOWS

Supply and fix the following Ex-shop standard

welded mild steel casement windows

comprising of standard 25 x 25 x 3 mm Z

section framing: complete with approved Brass

fasteners, stays and all other necessary iron

mongery: including 75 mm perforated mild

steel permanent vent and hood at the top

infilled with mosquito wiregauze and all

primed in one coat red oxide primer before

delivery to site and all welds ground smooth

including fixing lugs to masonary and/or

beams bedded in cement and sand (1:3) mortar

and pointing all round with mastic.

NOTE:

All reference to ideal casement catalogue but

the tenderer may supply any other equal and

approved to the satisfaction of the Project

manager.

Window overall size 1500 mm x 1500 high to

A Architects detail NO 48.00

mm high to the

B Ditto, 1400 mmx 1500mm NO

Ditto. 2600 mm x 1500 mm.

C Supply and fix brass metal stays and fasteners

to existing window casements

D Fasteners NO 96.00

E Stays NO 96.00

GLAZING

4mm thick glass Clear sheet in panes not

F exceeding 0.50 and glazing with putty to SM 108.00

metal as:

Burglarproofing Grills

Galvanised mild steel grille framed with 40 x

25 x 3 mm thick R.H.S. Sections including

assembly and fixing to opening cutting and SM 108.00

pinning lugs to concrete or blockwork and

bedding frame in cement and sand mortar

1500 mm x 1500 mm high with R10

H burglarproofing in varied approved

patterns;curves

I Ditto, 1400 mmx 1500mm

J Ditto. 2600 mm x 1500 mm.

DOORS

50mm thick single leaf wrot cypress panel

door size 900x2100mm high fitted with 100 x

A. NO 8.00

50mm grooved frames and painted with clear

furnish ready to be fixed to position

1600mm wide x 2400mm high overall mild

steel panelled double door comprising of 75 x

50 x 6mm thickmild steel framing all round

,1.6mm thick mild steel sheet welded to 75 x

B 50 x6 mm thick angle bracings top and middle NO

rails complete with handles purpose made

hinges and all necessary accessories including

priming with one coat of red oxide primer

before delivery to site

Painting

Prepare and apply one undercoat

and two finishing coats gloss oil paint to:-

C General surfaces of Metal SM 27.00

Carried to collection

TOTAL CARRIED FORWARD TO LL/5

ITEM DESCRIPTION UNIT QUANTIT RATE AMOUNT

FLOOR FINNISHING

30mm thick cement sand (1:3) screed

A trowelled smooth comprising of 3 mm SM 800.00

finishing coat

15 mm thick two coat cement and sand (1:3)

plaster trowelled smooth comprising of 12mm

backing and 3 mm finishing coat on:

B Ditto Staircase and ramp Landing SM 30.00

C Ditto Sloping of Staircase string SM 3.05

Internal wall finishes

D 12mm thick cement sand (1:4)rendering SM 900.00

Prepare and apply one.undercoats and two

E finishing coats of plastic emulsion SM 900.00

ai t to rendered rface.

External finishes wall finishes

B Labour and material for keying external SM 600.00

Bag wash to the external ring beams SM 113.00

CEILING FINISHES

A Extra over walling for key pointing along SM

12mm thick chipboard ceiling fixed with clout

nails on 50x50mm grade 1 cypress brandering

B SM 400.00

at 600mm centres

clout nails with V-Joint onto timber

D 75mm by 25mm wrot cypress cornice LM 400.00

Prepare and apply one undercoat and two

E SM 400.00

finishingcoat of emulsion paint on

Balustrades and railings

25mm x 25mm X 3mm S.H.S railings on

A LM 240.00

sides of veranda walkway

Ditto 100mm Dia C.H.S LM 70.00

TOTAL CARRIED FORWARD TO

LL/6

COLLECTION

SUB- TOTAL

1 Brought forward from COLLECTION 01

2 Brought forward from LL/4

3 Brought forward from LL/5

4 Brought forward from LL/6

SUB - TOTAL 1 FOR BUILDERS WORK

PROVISIONAL SUMS

Allow prime cost (P.C) sum of Kshs.

500,000 for the resident engineers

A Miscelleneous account to be spent in whole PC SUM

or part as directed by the resident Engineer

against receipts during supervission works

Provide a prime cost sum of kenya shillings

five hundred thousand (500, 000.00) for

B Sum 1.00

Electrical works to be executed by a

licensed Electrical Sub-Contractor

Allow a prime cost sum of Kenya shillings

C Hundred thousand (Kshs.200,000)only for Sum 1.00

material test

Allow a prime cost sum of Kenya shillings

Hundred thousand (Kshs.25,000)only for

D Sum 1.00

erection of

publicity sign board

Allow a prime cost sum of Kenya shillings

Hundred thousand

E sum 1.00

(Kshs.200,000)only for hoarding to be

measured on day works basis

SUB - TOTAL 2 = TOTAL 1 + PC SUM

ADD 1.5% FOR CONTINGENCIES

SUB TOTAL 3

ADD 14%VAT

GRAND TOTAL SUM CARRIED TO

FORM OF BID

You might also like

- Bills of Quantities For Standard Residential House - 2 Bedroom-Type ADocument13 pagesBills of Quantities For Standard Residential House - 2 Bedroom-Type AIsabelle FG79% (29)

- Bills of Quantities For Standard Residential House - 2 Bedroom-Type A PDFDocument13 pagesBills of Quantities For Standard Residential House - 2 Bedroom-Type A PDFHammad SalahuddinNo ratings yet

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)

- 4 Bedroom BoqDocument13 pages4 Bedroom BoqNana Barima75% (4)

- Vibrated Reinforced Concrete Class 25 (Mix 1:1.5:3) (20Mm AGGREGATES) As Described InDocument11 pagesVibrated Reinforced Concrete Class 25 (Mix 1:1.5:3) (20Mm AGGREGATES) As Described InMasambu Hillary100% (2)

- Codigos QR Beybalde ACTIVIDADn3 - 335f99d4cc68ea7Document60 pagesCodigos QR Beybalde ACTIVIDADn3 - 335f99d4cc68ea7Farid Enrique Mejia Viana100% (10)

- Flat 2021 - UnpricedDocument12 pagesFlat 2021 - UnpricedCharles M. EvansNo ratings yet

- South Horr Police StationDocument18 pagesSouth Horr Police Stationcliff machukaNo ratings yet

- BQ SampleDocument51 pagesBQ SampleShamsul Bahrin Sulaiman100% (2)

- Poultry House Construction GuidelinesDocument4 pagesPoultry House Construction GuidelinesChangamkia Works100% (1)

- Bills of Quantities KMTC For 4no Classrooms PDFDocument18 pagesBills of Quantities KMTC For 4no Classrooms PDFabdul100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Module - 5 - Late Twentieth Century & The New MillenniumDocument181 pagesModule - 5 - Late Twentieth Century & The New MillenniumAlex100% (1)

- Tender For Expansion of Narok Referral Mortuary and Construction of Ambulation BlockDocument23 pagesTender For Expansion of Narok Referral Mortuary and Construction of Ambulation BlockO SNo ratings yet

- Excel Substructure WorksDocument18 pagesExcel Substructure Workssngunjiri60No ratings yet

- Measured Works - August - 2019 - RevisedDocument34 pagesMeasured Works - August - 2019 - RevisedFelistaNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- Rwathia April 2023Document76 pagesRwathia April 2023michael100% (1)

- 1254 Revised BOQDocument20 pages1254 Revised BOQAnthony MainaNo ratings yet

- Njagi Substructures Boq 2020Document76 pagesNjagi Substructures Boq 2020michaelNo ratings yet

- PlinthsDocument1 pagePlinthsPNN1No ratings yet

- X4o0Z5CxUpSv - BOQ FOR LITENDocument19 pagesX4o0Z5CxUpSv - BOQ FOR LITENsunjeyNo ratings yet

- Unpriced REVISED BQ IFAD RIAT UpgradingDocument28 pagesUnpriced REVISED BQ IFAD RIAT UpgradingJKROSSNo ratings yet

- Roof ConstructionDocument1 pageRoof ConstructionPNN1No ratings yet

- Boq As DoneDocument40 pagesBoq As Doneogongorichard82100% (1)

- Industrial Park 2Document14 pagesIndustrial Park 2Zack DaveNo ratings yet

- Click Here To Download Boq 1Document20 pagesClick Here To Download Boq 1emanNo ratings yet

- Proposed Residential For MR GitauDocument30 pagesProposed Residential For MR GitauBob MbuguaNo ratings yet

- South Horr Police Station 3Document18 pagesSouth Horr Police Station 3cliff machukaNo ratings yet

- Karen Perimeter Wall - MusdenDocument7 pagesKaren Perimeter Wall - MusdenpeterNo ratings yet

- KUJARIBUDocument1,098 pagesKUJARIBUMike LitoriesNo ratings yet

- Bills of Quantities Boundary Wall Juja FarmDocument10 pagesBills of Quantities Boundary Wall Juja FarmDiana Mwongeli100% (1)

- Ecosan Late - Boq Dibo NewDocument16 pagesEcosan Late - Boq Dibo Newpaulobiga2018No ratings yet

- Bills of Quantities For 2 Bedroom HouseDocument54 pagesBills of Quantities For 2 Bedroom HousePerry LendorNo ratings yet

- Naf 2 Bed Boq OnlyDocument22 pagesNaf 2 Bed Boq Onlyuche ekeNo ratings yet

- Proposed Godown at Gikomba Market - BQ-1Document28 pagesProposed Godown at Gikomba Market - BQ-1michaelNo ratings yet

- Talai Primary Ablution Block BQDocument10 pagesTalai Primary Ablution Block BQDennis KigenNo ratings yet

- Proposed Apartment Development at Eastleigh. NairobiDocument32 pagesProposed Apartment Development at Eastleigh. NairobimichaelNo ratings yet

- Bedele HallDocument57 pagesBedele Hallfayisamamo126No ratings yet

- BoQ 33 - 11 KV SUBSTATION - 01Document13 pagesBoQ 33 - 11 KV SUBSTATION - 01Ricky ChangNo ratings yet

- Bill of Quantities OlvrDocument8 pagesBill of Quantities OlvrOliver Otieno100% (1)

- DGT-321-L-CW-WS-001Document18 pagesDGT-321-L-CW-WS-001mohan890No ratings yet

- PROPOSED SINGLE GRADE 9 HOUSE TYPE A1 Bungale ADocument10 pagesPROPOSED SINGLE GRADE 9 HOUSE TYPE A1 Bungale ARic ReeNo ratings yet

- Builders Works Bill of QuantitiesDocument14 pagesBuilders Works Bill of QuantitieserickNo ratings yet

- Adnan B QDocument9 pagesAdnan B QKevin AtutiNo ratings yet

- Piling Works: Item Description Unit Qty Rate Amount (RM)Document8 pagesPiling Works: Item Description Unit Qty Rate Amount (RM)Suhaimi SuibNo ratings yet

- Bills of Quantities MR, MarcelDocument11 pagesBills of Quantities MR, MarcelDiana MwongeliNo ratings yet

- BQ C6 Permata PDFDocument42 pagesBQ C6 Permata PDFzulNo ratings yet

- ISMAEL Kisumu Apartments - BILLS & Cost AnalysisDocument125 pagesISMAEL Kisumu Apartments - BILLS & Cost AnalysisFrancis OdongoNo ratings yet

- Kimanthi Mwiki BQDocument76 pagesKimanthi Mwiki BQmichaelNo ratings yet

- Tanked Basement: Sectional Plan A - ADocument9 pagesTanked Basement: Sectional Plan A - ASAMSON WERESONNo ratings yet

- BQ C6 PermataDocument42 pagesBQ C6 PermataGnabBangNo ratings yet

- Tower BOQ 1 With Rates1Document14 pagesTower BOQ 1 With Rates1skalema340% (1)

- Bills of Quantities For Pit Latrine PDFDocument6 pagesBills of Quantities For Pit Latrine PDFdogg100% (1)

- BQ Wall Samburu - ExelDocument25 pagesBQ Wall Samburu - ExelsatejaNo ratings yet

- WallFenceBillOfQuantities (BOQ) - 1Document35 pagesWallFenceBillOfQuantities (BOQ) - 1Myless MukendiNo ratings yet

- Balcad BOQ - Construction of ClassroomsDocument10 pagesBalcad BOQ - Construction of ClassroomscabdirazaakNo ratings yet

- Proposed Log Office Block Concept 1Document6 pagesProposed Log Office Block Concept 1Hunk RolandNo ratings yet

- ChamaDocument73 pagesChamasarcozy922No ratings yet

- Bill Nr. 1 Residential QuartersDocument68 pagesBill Nr. 1 Residential QuartersJudyNo ratings yet

- BillingDocument10 pagesBillingJoseph EzekielNo ratings yet

- Art & Design IGCSE 0400 Portfolio GuidelineDocument10 pagesArt & Design IGCSE 0400 Portfolio GuidelinedaemoniumNo ratings yet

- Perancangan Busana Ready To Wear Menggunakan Metode Zero Waste Dengan Kombinasi Tenun BaduyDocument8 pagesPerancangan Busana Ready To Wear Menggunakan Metode Zero Waste Dengan Kombinasi Tenun BaduyREZA MAULINANo ratings yet

- But Is It Art?: Watch Full ProgrammeDocument10 pagesBut Is It Art?: Watch Full Programmeyoyo igoNo ratings yet

- Multimedia Questions and Answers 2021Document142 pagesMultimedia Questions and Answers 2021Jean d'Amour ISHIMO100% (2)

- Sarah WaldoDocument2 pagesSarah WaldorobthegermanNo ratings yet

- Sacred Spaces AP Art History Study GuideDocument46 pagesSacred Spaces AP Art History Study GuideFriend LuckeyNo ratings yet

- Warhol Ten TakesDocument105 pagesWarhol Ten TakesAra OsterweilNo ratings yet

- 20 Century Art StylesDocument52 pages20 Century Art StylesIrān Brotamonte100% (3)

- Bentona BP 183 B ChinaDocument2 pagesBentona BP 183 B Chinaoptimus_1404No ratings yet

- Catalogue: Facing BricksDocument82 pagesCatalogue: Facing BricksBipu1978No ratings yet

- SAS-5 and 6-Week 4-SOCSCI 104Document4 pagesSAS-5 and 6-Week 4-SOCSCI 104Bench RodriguezNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet

- 1st Summative AssessmentDocument4 pages1st Summative AssessmentAngelina TagleNo ratings yet

- Juego de LogaritmosDocument15 pagesJuego de LogaritmosSALGADO JORDYNo ratings yet

- Ancient Egyptian Theological TotemDocument14 pagesAncient Egyptian Theological TotemLogan HurtNo ratings yet

- FIght For Kindness Zetafonts 2022 EditionDocument66 pagesFIght For Kindness Zetafonts 2022 EditionTURBONo ratings yet

- ED - 2021 - 2nd Paper 183-2023Document3 pagesED - 2021 - 2nd Paper 183-2023md tanimNo ratings yet

- Unit 2 What Is This ?Document6 pagesUnit 2 What Is This ?Hoang HaNo ratings yet

- 2a 2d Design Introduction PDFDocument11 pages2a 2d Design Introduction PDFVijay VermaNo ratings yet

- Basilica Cistern HoDocument4 pagesBasilica Cistern HoRichie Juls Bacalso100% (1)

- 8 Principles of Art by Zoey Katke 1 1Document9 pages8 Principles of Art by Zoey Katke 1 1api-548442050No ratings yet

- Beginning of FuturismDocument18 pagesBeginning of FuturismKomal LakhyaniNo ratings yet

- 9.1đáp Án Chi Tiết Trật Tự Tính TừDocument4 pages9.1đáp Án Chi Tiết Trật Tự Tính Từnguyen hoangNo ratings yet

- Pictures of Paint Defects 1Document2 pagesPictures of Paint Defects 1manuel castilloNo ratings yet

- LAS Contemporary-Arts Grade-12 Week-2Document7 pagesLAS Contemporary-Arts Grade-12 Week-2esterlitaNo ratings yet

- MATERI TRAINING PT INATEX 13 Maret 21Document66 pagesMATERI TRAINING PT INATEX 13 Maret 21RiparazanNo ratings yet

- Brice Marden Paintings On MarbleDocument7 pagesBrice Marden Paintings On MarbleAnne PesceNo ratings yet

- Ebook Artistic Places 1St Edition Susie Hodge Online PDF All ChapterDocument69 pagesEbook Artistic Places 1St Edition Susie Hodge Online PDF All Chapterjuana.scott160100% (11)