Professional Documents

Culture Documents

End Sem PPP 2021 1

End Sem PPP 2021 1

Uploaded by

S SaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

End Sem PPP 2021 1

End Sem PPP 2021 1

Uploaded by

S SaiCopyright:

Available Formats

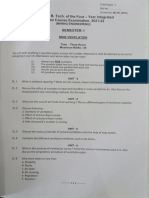

MECHANICAL ENGINEERING DEPARTMENT

NATIONAL INSTITUTE OF TECHNOLOGY, ROURKELA-8

END- SEMESTER EXAMINATION, June 2021

SESSION: 2020-2021, SEMESTER: SPRING

B.TECH.: 4th SEMESTER, Mechanical Engineering

SUBJECT: Primary Production Processes (ME-2202) (ME)

FULL MARKS: 50

Duration of Examinations: 2 Hours It contains 2 pages and 4 questions

Answer ALL Questions

All parts of a question (i, ii, iii etc) should be answered at one place.

Answer should be brief and to-the-point and be supplemented with neat sketches.

Any missing data or wrong data may be assumed suitably giving proper justification.

1. Solve (any four) 4x4 30 minutes

i) A copper block of size 200x100x50 mm is to be made by casting. Find the dimensions of the wooden

pattern assuming machining allowance of 1 mm on top surface only, shaking allowance of 2.0 mm on

length and width, shrinkage allowance of 5% and taper allowance of 3 degree.

ii) An aluminum billet of 50 mm thickness is to be decreased to thickness of 30 mm in a rolling process by

number of passes. The radius of roll is 500 mm, Find the minimum number of passes required, if bite angle

is 10 degree.

iii) A hole of 30mm diameter is to be made on a copper sheet of 10 mm thickness by punching. The shear

strength of the material is 250 MPa. What is the cutting force required? Find the diameter of punch and die

if the clearance is 2 mm.

iv) The arc length-arc voltage characteristic of a DC arc welding is given by V=10+40L where V is the arc

voltage and L is the arc length in mm. The static V-I characteristic of the power source is given by a straight

line with open circuit voltage (OCV) of 90 volts and short-circuit current of 400 A. Determine the optimum

arc length for maximum power.

v) A cylindrical steel block of diameter 30 mm and height 60 mm is to be forged by a press to a height of 20

mm. True stress-strain curve of the steel follow = 350 ε0.38MPa, µ=0.0. If the capacity of the press is

400 kN, is it possible to forge the work piece?

MECHANICAL ENGINEERING DEPARTMENT

NATIONAL INSTITUTE OF TECHNOLOGY, ROURKELA-8

END- SEMESTER EXAMINATION, June 2021

SESSION: 2020-2021, SEMESTER: SPRING

B.TECH.: 4th SEMESTER, Mechanical Engineering

SUBJECT: Primary Production Processes (ME-2202) (ME)

FULL MARKS: 50

Duration of Examinations: 2 Hours It contains 2 pages and 4 questions

Answer ALL Questions

All parts of a question (i, ii, iii etc) should be answered at one place.

Answer should be brief and to-the-point and be supplemented with neat sketches.

Any missing data or wrong data may be assumed suitably giving proper justification.

2. A. Practical Application: Describe how to manufacture the following components: (any five) 1x5

Total 30 minutes

i) Big sewage/drain pipes. ii) Turbine blades.

iii) Self-lubricated Babbitt bearings for automobiles iv) Head of the bolt

v) Daily use aluminum utensils vi) collapsible tubes like that for toothpaste and shaving cream.

B. Industrial problem: Propose a suitable Solution (any five) 1x5

vii) To weld Railway lines at remote areas. viii) The sheets manufactured by rolling are wavy

ix) Wrinkles are found on the flange of a cup manufactured by deep drawing x) Found cracks at

corner points of a casted wheel xi) Pitting marks are observed on the surface of a forged wrench

xii) When two mild steel flat are welded by single V butt joint, found to be curved upward.

MECHANICAL ENGINEERING DEPARTMENT

NATIONAL INSTITUTE OF TECHNOLOGY, ROURKELA-8

END- SEMESTER EXAMINATION, June 2021

SESSION: 2020-2021, SEMESTER: SPRING

B.TECH.: 4th SEMESTER, Mechanical Engineering

SUBJECT: Primary Production Processes (ME-2202) (ME)

FULL MARKS: 50

Duration of Examinations: 2 Hours It contains 2 pages and 4 questions

Answer ALL Questions

All parts of a question (i, ii, iii etc) should be answered at one place.

Answer should be brief and to-the-point and be supplemented with neat sketches.

Any missing data or wrong data may be assumed suitably giving proper justification.

3. Answer all questions in brief (any Ten) 1.5x10 30 minutes

I. What is the use of chill and chaplets in casting?

II. Difference between forehand and backhand gas welding process?

III. What is flux? Why it is essential to use in welding?

IV. Essential good properties of molding sand.

V. Fettling process for casting.

VI. What is a non-transferred type plasma arc welding? What is its advantage?

VII. Differentiate between conventional strain and true-strain

VIII. Steps followed in investment casting.

IX. What are specific merits of cold working over hot working?

X. Differentiate between coining and embossing.

XI. What is ironing in a sheet metal operation?

MECHANICAL ENGINEERING DEPARTMENT

NATIONAL INSTITUTE OF TECHNOLOGY, ROURKELA-8

END- SEMESTER EXAMINATION, June 2021

SESSION: 2020-2021, SEMESTER: SPRING

B.TECH.: 4th SEMESTER, Mechanical Engineering

SUBJECT: Primary Production Processes (ME-2202) (ME)

FULL MARKS: 50

Duration of Examinations: 2 Hours It contains 2 pages and 4 questions

Answer ALL Questions

All parts of a question (i, ii, iii etc) should be answered at one place.

Answer should be brief and to-the-point and be supplemented with neat sketches.

Any missing data or wrong data may be assumed suitably giving proper justification.

4. A. Draw free hand sketches (any five) 1x5 Total 30 minutes

i) Hot chamber die casting.

ii) Cross section of a sand mould which is ready for pouring, and label the various parts.

iii) Different zones of carburizing flame used in oxy-acetylene gas welding.

iv) Different components of an ultrasonic welding set-up.

v) 3 stand 4 high tandem/ continuous rolling mill.

vi) Show the flash and gutter in a forging die set-up.

B. Know How/Mechanics knowledge Test: Describe with diagram (any four) 1x4

vii) Difference between Brazing and soldering?

viii) How Oxy-acetylene cutting torch is different from welding torch? Show by diagram.

ix) Why parts manufactured by forming processes have better mechanical properties than produced

by casting and machining? Explain by a diagram.

x) Show the sequence of forging operations to manufacture a crane hook.

xi) Shear angle is provided on which part of the punching operation? How it is specified?

xii) What is roll bending defect? How it can be minimized.

-●-

You might also like

- University Institute of Engineering & Technology Kurukshetra University, KurukshetraDocument3 pagesUniversity Institute of Engineering & Technology Kurukshetra University, KurukshetraagogNo ratings yet

- 2k19 5th Sem Papers - Watermark-1Document15 pages2k19 5th Sem Papers - Watermark-1Vishal kumarNo ratings yet

- 304 Building ServicesDocument2 pages304 Building Serviceslima chakkuNo ratings yet

- 2018 Ques 5th SemDocument15 pages2018 Ques 5th SemVishal kumarNo ratings yet

- QP End Term Basic ManufacturingDocument3 pagesQP End Term Basic ManufacturingAtul GaurNo ratings yet

- MP Assignment-VIDocument1 pageMP Assignment-VIRaja HarisNo ratings yet

- Question of Manufacturing ProcessDocument4 pagesQuestion of Manufacturing ProcessRounak AgrawalNo ratings yet

- 2-1 PT (Nov 2009 Regular)Document4 pages2-1 PT (Nov 2009 Regular)micmechNo ratings yet

- DesDocument33 pagesDesKiran RatnaNo ratings yet

- Answer BDA30502 - FINAL 012015Document11 pagesAnswer BDA30502 - FINAL 012015SmithNo ratings yet

- Mech3002y 3 2010 2 PDFDocument5 pagesMech3002y 3 2010 2 PDFKeshav GopaulNo ratings yet

- Me 5 PT 2021Document3 pagesMe 5 PT 2021SameerNo ratings yet

- Enrollment NoDocument4 pagesEnrollment Nojenilpatel1709No ratings yet

- Mech 204 Takehome Exam 1 of 2020Document2 pagesMech 204 Takehome Exam 1 of 2020Manuel Tikongyin WundengbaNo ratings yet

- Regular: BalconiesDocument10 pagesRegular: BalconiesPrachi SomaniNo ratings yet

- Questionns Primary MFGDocument3 pagesQuestionns Primary MFGRajib MandalNo ratings yet

- Important Instructions To Examiners:: (Autonomous)Document22 pagesImportant Instructions To Examiners:: (Autonomous)Pramod DhaigudeNo ratings yet

- Mody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyDocument3 pagesMody Institute of Technology and Science, Lakshmangarh Faculty of Engineering and TechnologyVikrant SharmaNo ratings yet

- Adobe Scan 06 Sept 2023Document8 pagesAdobe Scan 06 Sept 2023Sumit PrajapatNo ratings yet

- R10 JanuaDry - 2014Document4 pagesR10 JanuaDry - 2014sivaenotesNo ratings yet

- Cse 215 - Engineering Drawing IiiDocument3 pagesCse 215 - Engineering Drawing IiiWol Monydeng BolditNo ratings yet

- Zeal Polytechnic, Pune.: Third Year (Ty) Diploma in Civil Engineering Scheme: I Semester: VDocument31 pagesZeal Polytechnic, Pune.: Third Year (Ty) Diploma in Civil Engineering Scheme: I Semester: Vpratikshapawar66440No ratings yet

- Answers Should Be Written in QCAB Format Only.: InstructionsDocument73 pagesAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiNo ratings yet

- QPME3103D-Machine Tools and CNC SystemsDocument2 pagesQPME3103D-Machine Tools and CNC SystemsNeya SebastianNo ratings yet

- Alliance College of Engineering and Design: Bachelor of Technology (Batch: 2018 - 22)Document2 pagesAlliance College of Engineering and Design: Bachelor of Technology (Batch: 2018 - 22)PandiiitmNo ratings yet

- MP Assignment 1 2022-23Document1 pageMP Assignment 1 2022-23KirtanNo ratings yet

- Mech3002y 3 2011 2 PDFDocument5 pagesMech3002y 3 2011 2 PDFKeshav GopaulNo ratings yet

- M 057Document3 pagesM 057Nixon Joe EmmanuelNo ratings yet

- MM3304Document2 pagesMM3304xipah14997No ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Muhammad FirdawsNo ratings yet

- Tools Design Question Paper 2021 CVSRDocument2 pagesTools Design Question Paper 2021 CVSRRadha Krishna100% (1)

- Module Code PRDT01C04Document9 pagesModule Code PRDT01C04Sherif El-soudyNo ratings yet

- Answer: Answer Five Questions From Part BDocument2 pagesAnswer: Answer Five Questions From Part BpalreddyNo ratings yet

- Fourth Year B.Arch. Building Construction & Materials (Paper - Iv)Document43 pagesFourth Year B.Arch. Building Construction & Materials (Paper - Iv)Tanaya ChiplunkarNo ratings yet

- 4Document69 pages4RAM NAIDU CHOPPANo ratings yet

- MT R07, Sup, AprilMay - 2012Document34 pagesMT R07, Sup, AprilMay - 2012N Dhanunjaya Rao BorraNo ratings yet

- HTTPSWWW Examinations iearchiveexampapers2022LC027ALP000EV PDFDocument12 pagesHTTPSWWW Examinations iearchiveexampapers2022LC027ALP000EV PDFWeres DiwetNo ratings yet

- B.arch (2015 Pattern)Document49 pagesB.arch (2015 Pattern)Attarwala Abdulqadir Hashim FaridaNo ratings yet

- TIE 3213 Assignment 2 (2020) PDFDocument2 pagesTIE 3213 Assignment 2 (2020) PDFphillip chirongwe0% (1)

- Trial For Final Exam 1Document4 pagesTrial For Final Exam 1Mamadil SelatanNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Priyadharshan RNo ratings yet

- Production Technology (Mechanical Engineering)Document4 pagesProduction Technology (Mechanical Engineering)andhracollegesNo ratings yet

- NR 410303 Production TechnologyDocument5 pagesNR 410303 Production TechnologySrinivasa Rao GNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Muhammad FirdawsNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)gowrisankarNo ratings yet

- PP 2021Document2 pagesPP 2021GuriNo ratings yet

- Answer All Questions: Define Machinability of MetalDocument1 pageAnswer All Questions: Define Machinability of MetalBIBIN CHIDAMBARANATHANNo ratings yet

- MTC1501 Assignment 1 2022 S2Document4 pagesMTC1501 Assignment 1 2022 S2Andile ButheleziNo ratings yet

- 9A01405 Building Planning and DrawingDocument4 pages9A01405 Building Planning and DrawingsivabharathamurthyNo ratings yet

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulNo ratings yet

- Final-Term Examination - First Semester 2018/2019Document3 pagesFinal-Term Examination - First Semester 2018/2019Hossam MohamedNo ratings yet

- Measurement of Building Works Trial QuestionsDocument3 pagesMeasurement of Building Works Trial QuestionsBAGUMA NELSON100% (1)

- Masinde Muliro University of Science and Technology (Mmus'O: FirstDocument2 pagesMasinde Muliro University of Science and Technology (Mmus'O: FirstMarlene EsipilaNo ratings yet

- Adobe Scan Apr 19, 2023Document7 pagesAdobe Scan Apr 19, 2023sonu kumarNo ratings yet

- ME204Document2 pagesME204raja93satNo ratings yet

- MP Assignment-IVDocument1 pageMP Assignment-IVRaja HarisNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential AP/APR2010/QSD282Document4 pagesUniversiti Teknologi Mara Final Examination: Confidential AP/APR2010/QSD282Pangiran ShafiqNo ratings yet

- International Institute of Managemant & Technical Studies: Machine DrawingDocument2 pagesInternational Institute of Managemant & Technical Studies: Machine DrawingyekahNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNo ratings yet

- W-c-ss-014 Steel Coating Works SpecificationsDocument23 pagesW-c-ss-014 Steel Coating Works SpecificationswanroselanNo ratings yet

- D65PX-12 M Sead001202Document221 pagesD65PX-12 M Sead001202Carlos Israel Gomez100% (7)

- Bio Data Khan 074Document3 pagesBio Data Khan 074Saoud KhanNo ratings yet

- AWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingDocument65 pagesAWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingPubcrawlNo ratings yet

- ASMEDocument2 pagesASMEdenisNo ratings yet

- API 570 ResponsibilitiesDocument6 pagesAPI 570 Responsibilitiesapply19842371No ratings yet

- A Review of Non-Destructive Evaluation Techniques for Butt-Fusion Welded High Density Polyethylene Joints 2Document15 pagesA Review of Non-Destructive Evaluation Techniques for Butt-Fusion Welded High Density Polyethylene Joints 2ДејанNo ratings yet

- Seminar TopicsDocument22 pagesSeminar TopicsAnilKotthurNo ratings yet

- Method Statement With Jsa For Piping Work (Rev 1) (28!08!2019)Document55 pagesMethod Statement With Jsa For Piping Work (Rev 1) (28!08!2019)Pradip PaulNo ratings yet

- The Influence of Steel Chemistry & Surface Coatings On Resistance Spot Weld Strength and Failure MechanismsDocument14 pagesThe Influence of Steel Chemistry & Surface Coatings On Resistance Spot Weld Strength and Failure MechanismsDolfredNo ratings yet

- Mason Airconditioning Health and Safety PDFDocument48 pagesMason Airconditioning Health and Safety PDFXe XeNo ratings yet

- MTU 2000 M94 OperationDocument153 pagesMTU 2000 M94 OperationDimas Saputro100% (1)

- ClapeDocument302 pagesClapecastibraNo ratings yet

- Hastelloy C-2000 Welding Data: General InformationDocument1 pageHastelloy C-2000 Welding Data: General Informationtuna61No ratings yet

- Steel Capacity of Headed Studs Loaded in ShearDocument10 pagesSteel Capacity of Headed Studs Loaded in ShearMallesh NenkatNo ratings yet

- A Report Guide To Literature in The Field of Electromagnetic Testing - Volume IiDocument207 pagesA Report Guide To Literature in The Field of Electromagnetic Testing - Volume IileonabrahamzapruderNo ratings yet

- Corrosión PDFDocument292 pagesCorrosión PDFsangonote67% (3)

- NDT & WeldingDocument3 pagesNDT & WeldingSoham SahaNo ratings yet

- RioPipeline2017 2515 Rio Pipeline 2017 United MininDocument9 pagesRioPipeline2017 2515 Rio Pipeline 2017 United MininJose Anisio SilvaNo ratings yet

- Welding PDFDocument22 pagesWelding PDFFaisalTahirRambeNo ratings yet

- Fronius Perfect WeldingDocument4 pagesFronius Perfect Weldingjhi jklNo ratings yet

- CE5611 Connections - Part 2 (Compatibility Mode)Document37 pagesCE5611 Connections - Part 2 (Compatibility Mode)koksoon chongNo ratings yet

- Aquatherm Blue Pipe PDFDocument164 pagesAquatherm Blue Pipe PDFAnonymous 4MwmDaNbNo ratings yet

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriNo ratings yet

- WeldcalculatorDocument36 pagesWeldcalculatorDeerendra KaranthNo ratings yet

- 1910.255 Resistance WeldingDocument2 pages1910.255 Resistance WeldingAlfredo VSNo ratings yet

- Brochure Iqfvjl Iil PPRC Brochure CompressedDocument25 pagesBrochure Iqfvjl Iil PPRC Brochure CompressedZAHID IQBALNo ratings yet

- M655 Arc Reach Wire FeedersDocument8 pagesM655 Arc Reach Wire FeedersAlexis Bardales EspinozaNo ratings yet

- 1final Syllabus-CIVIL - (1st To 8th Semester)Document130 pages1final Syllabus-CIVIL - (1st To 8th Semester)kishan singhNo ratings yet