Professional Documents

Culture Documents

Method of Test For Evaluation of Freshly Mixed Self-Consolidating Concrete by Slump Flow

Method of Test For Evaluation of Freshly Mixed Self-Consolidating Concrete by Slump Flow

Uploaded by

I MixOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Test For Evaluation of Freshly Mixed Self-Consolidating Concrete by Slump Flow

Method of Test For Evaluation of Freshly Mixed Self-Consolidating Concrete by Slump Flow

Uploaded by

I MixCopyright:

Available Formats

Ministry of Transportation, Ontario Test Method LS-438 Rev. No.

25

Laboratory Testing Manual Date: 09 08 01 Page 1 of 2

METHOD OF TEST FOR

EVALUATION OF FRESHLY MIXED SELF-CONSOLIDATING CONCRETE

BY SLUMP FLOW

1. SCOPE

This test method covers procedures for determining slump flow of self-consolidating concrete (SCC).

The procedure is suitable for use in the laboratory or in the field, and is used as a measure of flowa-

bility and segregation resistance of SCC.

Note 1: This method is based on the test method outlined in the Precast/Prestressed Concrete

Institute and EFNARC (European Federation of Producers and Contractors of Specialist Products for

Structures) guidelines.

2. RELEVANT DOCUMENTS

2.1 Interim Guidelines for the Use of Self-Consolidating Concrete in Precast/Prestressed

Concrete Institute Member Plants, Precast/Prestressed Concrete Institute, TR-6-03, April

2003

2.2 Specification and Guidelines for Self-Compacting Concrete, EFNARC, February 2002

2.3 CAN/CSA A 23.2-5C, Slump and Slump Flow of Concrete

3. DEFINITIONS

3.1 Flowability is a measure of SCC’s ability to completely fill formwork without entrapped air

pockets.

3.2 Self-Consolidating Concrete (SCC) is highly flowable yet stable concrete that can spread

readily into place, fill the formwork, and encapsulate the reinforcement without any mechanical

consolidation and without undergoing segregation or excessive bleeding.

4. APPARATUS

The test equipment shall be according to CSA A23.2-5C with the additional requirement that the

surface of the base plate shall be smooth.

Note 2: Base plates made of steel, plastic, or that are plastic-coated are suitable.

5. SLUMP FLOW PROCEDURE

5.1 Follow the slump flow procedure of CSA A 23.2-5C with the following exceptions:

5.1.1 Measure and record air temperature of the testing environment and of the plastic concrete.

5.1.2 Position base plate on which the slump flow will be tested so that it is fully supported, flat,

and level.

5.1.3 Remove all excess water on the base plate using a squeegee or a sponge.

Ministry of Transportation, Ontario Test Method LS-438 Rev. No. 25

Laboratory Testing Manual Date: 09 08 01 Page 2 of 2

Note 3: Removing excess water is important in order to determine the Visual Stability Index in Step

5.15 below. Excess water will inhibit the accurate assessment of the outside edge of the slump flow

patty.

5.1.4 The slump cone may be used in the inverted position (small opening of the mould facing

down) provided that it is demonstrated that test results do not differ from those obtained with the

cone in the standard upright position.

5.1.5 Following completion of the slump flow test, determine the Visual Stability Index rating.

5.1.6 Rate the stability of the mixture in 0.5 increments by visual examination using the guidelines

provided in Table 1.

Table 1

Visual Stability Index

Rating Criteria

0 No evidence of segregation in the slump flow patty or in the mixer drum or wheelbarrow.

1 No halo or aggregate pile in the slump flow patty but some slight bleeding or air

bubbles on the surface of the concrete in the mixer drum or wheelbarrow.

2 A slight halo (<10 mm) at the perimeter of the slump flow patty and/or aggregate pile in

the slump flow patty and highly noticeable bleeding in the mixer drum and wheel-

barrow.

3 Clearly segregating by evidence of a large halo (>10mm) at the perimeter of the slump

flow patty and/or large aggregate pile in the centre of the concrete patty and a thick

layer of paste on the surface of the resting concrete in the mixer drum or wheelbarrow.

6. REPORT

Reporting shall be according to CSA A23.2-5C and, in addition, concrete and air temperatures and

the Visual Stability Index shall be reported.

You might also like

- World Bank CV - FormatDocument8 pagesWorld Bank CV - Formatmanojkumarmurlidhara100% (2)

- Astm C 940-16-2Document3 pagesAstm C 940-16-2reni100% (1)

- Assignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueDocument8 pagesAssignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueRahul SarkarNo ratings yet

- ASTM C1260 - 14 Reactividad en BarrasDocument5 pagesASTM C1260 - 14 Reactividad en BarrasFrancisco QuiñonezNo ratings yet

- Slimhole CementingDocument33 pagesSlimhole CementingTariqNo ratings yet

- Astm C1611M-05Document6 pagesAstm C1611M-05manil_5100% (2)

- Control Valve Test ProcedureDocument5 pagesControl Valve Test ProcedureMark Haizlip100% (3)

- Astm d5641Document4 pagesAstm d5641Walther LaricoNo ratings yet

- SAT Subject Tests: Math Level 2Document2 pagesSAT Subject Tests: Math Level 2Б. МолорNo ratings yet

- A Tall Man Executes A Jig - Irving LaytonDocument3 pagesA Tall Man Executes A Jig - Irving LaytonRolf AuerNo ratings yet

- Infiltration Rate of in Place Pervious Concrete: Standard Test Method ForDocument3 pagesInfiltration Rate of in Place Pervious Concrete: Standard Test Method ForRafael Reinheimer SantosNo ratings yet

- Astm C939 PDFDocument4 pagesAstm C939 PDFSrihariKyatamNo ratings yet

- WSDOT Test Method For ASTM C 939: Flow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Document4 pagesWSDOT Test Method For ASTM C 939: Flow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Anshoriy LubisNo ratings yet

- Water Retention of Hydraulic Cement-Based Mortars and PlastersDocument4 pagesWater Retention of Hydraulic Cement-Based Mortars and PlastersMohammed FasilNo ratings yet

- Standard Test Method For Slump Flow of SCCDocument6 pagesStandard Test Method For Slump Flow of SCCPris Twins TobingNo ratings yet

- Vacume Box Test ProcedureDocument5 pagesVacume Box Test ProcedureFarhan Sheikh100% (3)

- Determining The Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk DiffusionDocument8 pagesDetermining The Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk DiffusionAhmed AlzubaidiNo ratings yet

- Astm C 939Document4 pagesAstm C 939FABIAN FIENGO100% (1)

- Astm c939 Flow ConeDocument5 pagesAstm c939 Flow ConeScribdTranslationsNo ratings yet

- Astm C1403 - 2015 PDFDocument5 pagesAstm C1403 - 2015 PDFGrebelAndrésAmarantoMercado100% (1)

- ASTM C151C151M. Obsoleta2018Document4 pagesASTM C151C151M. Obsoleta2018JAIME CARDONA DIAZ DIAZNo ratings yet

- Activity of ClayDocument6 pagesActivity of ClayAsep TheaNo ratings yet

- Procedure For Vaccum Box TestDocument5 pagesProcedure For Vaccum Box Testdheerendrakumar110No ratings yet

- Slump Flow of Self-Consolidating Concrete: Standard Test Method ForDocument6 pagesSlump Flow of Self-Consolidating Concrete: Standard Test Method Foroscargon19100% (1)

- C939Document3 pagesC939Alexandru PoenaruNo ratings yet

- Flow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Document3 pagesFlow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Aung Kyaw100% (1)

- ASTM C1701 C1701M 17aDocument1 pageASTM C1701 C1701M 17aKarnalPreethNo ratings yet

- Mechanical Integrity 2018 - Brian GravesDocument106 pagesMechanical Integrity 2018 - Brian GravesHosamMohamedNo ratings yet

- Astm C 1611Document6 pagesAstm C 1611kevin suarez grisalesNo ratings yet

- AIPPL - Procedure For Vacuum Box TestingDocument7 pagesAIPPL - Procedure For Vacuum Box Testingdheerendrakumar110No ratings yet

- Slump Flow of Self-Consolidating Concrete: Standard Test Method ForDocument6 pagesSlump Flow of Self-Consolidating Concrete: Standard Test Method ForbilalNo ratings yet

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocument6 pagesSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- LS-414 - Rev 34 - May 2020Document3 pagesLS-414 - Rev 34 - May 2020ming_zhu10No ratings yet

- SPE-186113-MS Using A Resin-Only Solution To Complete A Permanent Abandonment Operation in The Gulf of MexicoDocument7 pagesSPE-186113-MS Using A Resin-Only Solution To Complete A Permanent Abandonment Operation in The Gulf of Mexicoizzatislam.mohdnoorNo ratings yet

- ASTM1506, Water Retention of Mortar TestDocument4 pagesASTM1506, Water Retention of Mortar TestTabish Islam100% (2)

- Astm D5641 D5641M 16Document2 pagesAstm D5641 D5641M 16Samer MohamedNo ratings yet

- Full Water and Air Leak Test Procedure - Atmospheric Pressure TankDocument11 pagesFull Water and Air Leak Test Procedure - Atmospheric Pressure TankSreetharan SNo ratings yet

- ProTech2Ch4 PDFDocument39 pagesProTech2Ch4 PDFweldsvNo ratings yet

- C940.28412 Expansion and Bleeding of Freshly Mixed Grouts ForDocument3 pagesC940.28412 Expansion and Bleeding of Freshly Mixed Grouts ForSabine Alejandra Kunze HidalgoNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- Determining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Document5 pagesDetermining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)smanoj354No ratings yet

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- Hydrocyclone Testing ExtractDocument15 pagesHydrocyclone Testing ExtractKu Esyra HaniNo ratings yet

- Astm C1602 C1602M 22Document4 pagesAstm C1602 C1602M 22عبدالمعز المليانNo ratings yet

- BS1881-116 1983Document11 pagesBS1881-116 1983gagokapala100% (1)

- Norma ASTM C156Document5 pagesNorma ASTM C156Jony GutiérrezNo ratings yet

- Visual Stability Index (VSI) of Self-Consolidating Concrete (SCC)Document6 pagesVisual Stability Index (VSI) of Self-Consolidating Concrete (SCC)Waleed AhmedNo ratings yet

- Autoclave Expansion of Portland Cement: Standard Test Method ForDocument4 pagesAutoclave Expansion of Portland Cement: Standard Test Method ForSebastián RodríguezNo ratings yet

- Microsoft Word - Rec.114 - NEW June 2010 - Zoe WrightDocument2 pagesMicrosoft Word - Rec.114 - NEW June 2010 - Zoe WrightJony DarkoNo ratings yet

- Vaccum Box Test ProcedureDocument3 pagesVaccum Box Test ProcedureAJOJOY009No ratings yet

- Lime For Use in Soil StabilisationDocument14 pagesLime For Use in Soil Stabilisationpranjalsingj75No ratings yet

- Static Segregation of Self-Consolidating Concrete Using Column TechniqueDocument4 pagesStatic Segregation of Self-Consolidating Concrete Using Column Techniquebilal100% (1)

- WSDOT Test Method For ASTM C 939: Flow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Document1 pageWSDOT Test Method For ASTM C 939: Flow of Grout For Preplaced-Aggregate Concrete (Flow Cone Method)Corey HeffernanNo ratings yet

- ASTM-C-939-02-Flow of Grout For Preplaced Aggregate-Concrete (Flow Cone Method)Document3 pagesASTM-C-939-02-Flow of Grout For Preplaced Aggregate-Concrete (Flow Cone Method)Sundara NayakanNo ratings yet

- CRD c662Document6 pagesCRD c662Veio MacieiraNo ratings yet

- LB3-46 ForkliftsDocument10 pagesLB3-46 ForkliftsWalidbenrhoumaNo ratings yet

- Vaccum Box Procedure KOD GEN PRO 001Document4 pagesVaccum Box Procedure KOD GEN PRO 001Totan KarNo ratings yet

- Lime Stabilisation. NZTA - WWW - Nzta.govt - NZDocument6 pagesLime Stabilisation. NZTA - WWW - Nzta.govt - NZDave ChaterNo ratings yet

- AASHTO R60-12 (2020) - Sampling Freshly Mixed ConcreteDocument5 pagesAASHTO R60-12 (2020) - Sampling Freshly Mixed ConcreteErnesto Oscar VidelaNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

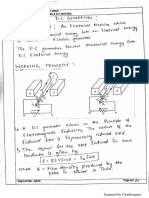

- 18ele M4Document37 pages18ele M4I MixNo ratings yet

- Dispersion of Carbon Fibers in Cement Based Compos - 2017 - Construction and BuiDocument8 pagesDispersion of Carbon Fibers in Cement Based Compos - 2017 - Construction and BuiI MixNo ratings yet

- 3 Hinged ArchDocument3 pages3 Hinged ArchI MixNo ratings yet

- 01 - CementDocument59 pages01 - CementI MixNo ratings yet

- Kulkarni 2003Document7 pagesKulkarni 2003I MixNo ratings yet

- Wind Load Calculation For TrussDocument16 pagesWind Load Calculation For Trusssujan100% (1)

- Hive Fleet Leviathan v3Document16 pagesHive Fleet Leviathan v3CarlosFerraoNo ratings yet

- Rail Kala Rang P.A.System Materials: SL - No Description Qty RemarksDocument12 pagesRail Kala Rang P.A.System Materials: SL - No Description Qty Remarksk vandanaNo ratings yet

- Enamelled Copper WireDocument8 pagesEnamelled Copper WireNNN MMMNo ratings yet

- Activity 5 Educational OrganizationDocument4 pagesActivity 5 Educational OrganizationRaymart NaagNo ratings yet

- Google Algorithm UpdatesDocument8 pagesGoogle Algorithm UpdatesMalik RayyanNo ratings yet

- Portland Slag Cement - Specification: Indian StandardDocument11 pagesPortland Slag Cement - Specification: Indian Standardদেবীসা দুর্গা সিনহাNo ratings yet

- The Resonance Escape ProbabilityDocument7 pagesThe Resonance Escape ProbabilityMohammad RamzyNo ratings yet

- Diagonals of TilesDocument2 pagesDiagonals of TileskheyNo ratings yet

- Skills Test 3 & 4 Skills Test 12Document3 pagesSkills Test 3 & 4 Skills Test 12Candelaria LuqueNo ratings yet

- Lista de Errores Tajima All ModelsDocument10 pagesLista de Errores Tajima All ModelsCesar EspinozaNo ratings yet

- Conexión para Programación de Memorias de Forma ExternaDocument24 pagesConexión para Programación de Memorias de Forma ExternaAntonii SoliizsNo ratings yet

- LBR JWB Sesi 1 - Medika Adijaya - 2021Document11 pagesLBR JWB Sesi 1 - Medika Adijaya - 2021NahmaKidsNo ratings yet

- Emaux SC Series Pump User Manual EnglishDocument2 pagesEmaux SC Series Pump User Manual EnglishAlex PalaciosNo ratings yet

- Assignment 1 - Topographic Maps - 22 - Mauro AlessiDocument5 pagesAssignment 1 - Topographic Maps - 22 - Mauro AlessiMauro AlessiNo ratings yet

- CH 02Document104 pagesCH 02Tabish NomanNo ratings yet

- Brochure OOS Gretha REV2.1 PDFDocument4 pagesBrochure OOS Gretha REV2.1 PDFVovchenko AlexandrNo ratings yet

- Gender & Society 2Document7 pagesGender & Society 2John Roasa100% (1)

- HiFly - A340 9H SUNDocument8 pagesHiFly - A340 9H SUNGustavo QueirozNo ratings yet

- Sex OnlineDocument15 pagesSex OnlineAlessandro ZarrellaNo ratings yet

- Study Material: Free Master Class SeriesDocument21 pagesStudy Material: Free Master Class SeriesTinku SinglaNo ratings yet

- Sikadur 752: Low Viscosity Epoxy Resin InjectionDocument2 pagesSikadur 752: Low Viscosity Epoxy Resin InjectionMike AlarNo ratings yet

- PDMS Course SyllabusDocument3 pagesPDMS Course SyllabusBalu MuruganNo ratings yet

- Biofuels Annual - Tokyo - Japan - JA2022-0109Document19 pagesBiofuels Annual - Tokyo - Japan - JA2022-0109magijNo ratings yet

- 【奥纬咨询】Will Web3 Reinvent Insurance - 【洞见研报DJyanbao.com】Document39 pages【奥纬咨询】Will Web3 Reinvent Insurance - 【洞见研报DJyanbao.com】dafei sunNo ratings yet

- Understanding Regression Equations Interpreting Regression Tables PDFDocument20 pagesUnderstanding Regression Equations Interpreting Regression Tables PDFCaro SánchezNo ratings yet