Professional Documents

Culture Documents

Bushing Monitoring

Bushing Monitoring

Uploaded by

chandraippa2Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bushing Monitoring

Bushing Monitoring

Uploaded by

chandraippa2Copyright:

Available Formats

The 19th International Symposium on High Voltage Engineering, Pilsen, Czech Republic, August, 23 – 28, 2015

BUSHING MONITORING TO PROTECT POWER TRANSFORMER

AGAINST BUSHING FAILURES

1* 1 1

S. Coenen , T. Stirl , B. Dolata

1

Alstom Grid GmbH, Rheinstr. 73, 41065 Moenchengladbach, Germany

*Email: <Sebastian.coenen@alstom.com>

Abstract: High voltage condenser bushings of power transformers, according to their

construction and age, are amongst the most endangered components from all operating

equipment used. In the past, off-line measurements like the measurement of bushing

insulator capacitances and measurement of the dissipation factor were carried out for

determining the operational state. Today, modern microprocessor and computer

technology makes it possible to carry out the measurements and analysis continuous

within a monitoring concept. The monitoring of the electrical measurement quantities is

achieved by a voltage measurement consisting of a bushing adaptor, directly connected

to the measurement tap of the bushing and connected voltage sensor. The output signal

of one phase is compared with two remaining phases. Short and long term grid

unbalances can be filtered by certain algorithms. The paper discusses the preconditions

when modern bushing monitoring solutions are ready to protect bushing from failures

caused by breakdown of layers. The thresholds criteria can be distinguished by the

design of condenser bushings as the measured voltage jump caused by breakdown of

capacitive layers is depending on the number of layers. As the resulting dielectric stress

on the remaining layers increases, the operation of the bushing leads to increased risk for

failure, i.e. at least a warning should be generated automatically. The breakdown of

further layer might lead in a cascade breakdown ending with a catastrophic bushing

failure, i.e. an alarm should be generated and the transformer should be de-energised.

1 INTRODUCTION analyse conditions and to initiate subsequent

actions.

Today, utilities focus, on one hand, on improving or

maintaining system security by preventing outages,

and on the other, reducing operation and

maintenance costs of their assets. Both objectives

rely on information about asset conditions. As

such, an increasing number of power transmission

and power generation utilities are equipping their

power transformers with continuous on-line

monitoring systems. Step-by-step, this equipment

becomes a standard configuration of power Figure 1: Example of expert system with alarm

transformers. message caused by increased bushing

capacitance of transformer 1. Information and

A power transformer consists of several recommendations for service and maintenance can

components: transformer tank with active part and be displayed and data can be correlated to further

oil-paper insulation, conservator, cooling unit, on- information or other transformers

load tap changer and bushings, to mention some.

These components can be fitted with various The next step to prevent failures could be an

sensors, which are integrated into one monitoring automatic activation of protection by means of a

IED (Intelligent Electronic Device) by means of continuous on-line monitoring system. The paper

analogue or digital signals and different protocols, discusses the preconditions when modern bushing

building a comprehensive on-line condition monitoring solutions are ready to protect bushing

monitoring and expert system. against failures caused by breakdown of layers.

The thresholds criteria can be distinguished by the

Raw data acquired from a wide range of demand- design of condenser bushings as the measured

specific selectable sensors are analysed by means voltage jump caused by breakdown of capacitive

of implemented models, and stored in the on-line layers is depending on the number of layers. As

condition monitoring and expert system. Data the resulting dielectric stress on the remaining

acquisition and processing alone are of limited layers increases, the operation of the bushing

value. An expert system, see Figure 1, included in leads to increased risk for failure, i.e. at least a

the monitoring device becomes a powerful tool to warning should be generated automatically. The

breakdown of further layer might lead in a cascade

breakdown ending with a catastrophic bushing 2.2 Bushing capacitance C and dielectric

failure, i.e. an alarm should be generated and the dissipation factor tanδ

transformer should be de-energised.

The measurement of the bushing capacitance C

2 BUSHINGS and the dielectric dissipation factor tan δ, see

Figure 2, are important parameters for evaluating

High voltage condenser bushings of power trans- the operational state of a high voltage bushing.

formers, according to their construction and age, The dissipation factor is obtained from

are amongst the most endangered components tan δ = 1/RωC. In the case of a new resin-bonded

from all operating equipment used. In the past, off- paper bushing, it is in the range 0.5 ... 0.7 %. In the

line measurements like the measurement of case of resin-impregnated bushings, it is in the

bushing insulator capacitances and measurement range 0.25 ... 0.45 %, and for oil-impregnated

of the dissipation factor were carried out bushings, values between 0.25 ... 0.5 % are

successfully for determining the operational state. normal.

Today, modern microprocessor and computer

technology makes it possible to carry out these

procedures on-line with the help of a monitoring

system.

2.1 Capacitive controlled insulator bushings

In the voltage range from 110 kV upwards, modern

bushings are generally designed with closely

stepped capacitive control layers [1]. The insulator

body is manufactured in a coil winding process.

The basic insulating systems of capacitive Figure 2: Equivalent circuit diagram and vector

controlled high voltage bushings can be classified diagram of the dielectric loss factor tan δ

as:

Dielectric losses in the insulation result in a

• Resin-bonded paper bushings (RBP) capacitive loss current in the dielectric material.

• Resin-impregnated paper bushings (RIP) The reason for this can be found in the electrical

• Resin-impregnated synthetic bushings (RIS) properties of the insulation structure [1].

• Oil-impregnated paper bushings (OIP)

Depending on the ageing, the bushing capacitance

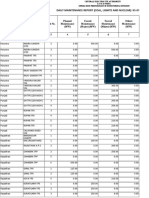

The inner insulation structure of resin-bonded and the tan δ can change. Table 1 shows guide

paper bushings consists of resin-coated material, values for tan δ and capacitance values as

which is glued under high temperature and examples for resin-bonded paper bushings. When

pressure in normal ambient conditions. In the case these limiting values are reached, continued

of resin-impregnated bushings, the insulator operation is not recommended.

consists of crepe paper with wrapped aluminium

coatings. This is dried and impregnated in vacuum. Table 1: Limit values for the dielectric loss factor

A resin-impregnated synthetic bushing the major tan δ and capacitive increase Δ C for resin-bonded

insulation consists of a core wound from synthetics paper bushings [6]

subsequently impregnated with a curable resin. In

the case of oil-impregnated bushings, the UN [kV] tan [%] C [%]

insulating body consists of kraft paper with 123 2.0 20

wrapped aluminium or graphite coatings, which are 245 1.5 15

dried and oil-impregnated in vacuum. The outer 420 1.0 10

insulation structure is generally made up of

porcelain or, more recently, of silicon.

For protection purpose periodic off-line testing of

What is common to all constructions is that they bushings is not sufficient and those changings

are subjected to very high mechanical, electrical need to be detected during operation of power

and thermal stresses during operation. This results transformers with on-line monitoring systems.

in ageing and hence to a change in the operational When detecting those changes, the protection of

state [2]. Thus, partial breakdowns in the insulation bushings and transformers can only be guaranteed

system can affect the operational safety to such an by direct de-energization of the transformer.

extent that further safe operation is not guaranteed Therefore the discussion is necessary to involve

any more [3, 4]. bushing monitoring into the protection devices of

power transformers. The possibility of false alarms

by external environmental influences, the

necessary and achievable accuracy is discussed in

the following. A focus of discussion in the following The voltage sensor, see Figure 3 right, essentially

is also on the reliability and acceptability of consists of a capacitance CM, which normally has

threshold values. values of 1...2 µF, see sketch in Figure 4.

Other reasons for a change in the values of tan δ

and Δ C are external environmental influences like

moisture and dirt on the outside on the porcelain.

An increase in the Δ C can also be caused by an

oil-impregnation in the case of resin-bonded paper

bushings. Apart from a consideration of the

absolute values of tan δ and Δ C, an analysis of

the trend is of great importance.

Thus, an increase in the Δ C for all bushing types

indicates partial breakdowns between control

layers (Table 2). Hence, for instance, if one of the

60 control layers of a typical 420 kV bushing

Figure 4: Sketch of bushing and equivalent circuit

breaks down, its capacitance changes by a value

diagram of the bushing and the voltage sensor

of 1.7 %. A short-circuit between two control layers

does not directly result in bushing failure, but the

Since CM >> C2 (with C2 ≈ 300 pF), I2 is practically

likelihood of a complete break-down of the

0. The resistance R terminates the connected

insulation raises with increasing number of

coaxial cable with a surge impedance of 50 Ω. The

defective layers and a safe operation of the

potential divider ratio between C1 and CM is

bushing and the whole transformer cannot be

dimensioned that a measurement voltage UM of

guaranteed any more.

57 V AC is set. In addition, there is an overvoltage

suppressor (Ü) installed, which protects the sensor

Table 2: Increase in capacitance delta C in case of

and the cable from overvoltages, and as there are

a partial breakdown between control layers for oil-

no electronic components used in the sensor at the

impregnated bushings.

bushing, this measurement procedure is not

sensitive to electromagnetic emission. Another

UN [kV] Number of control layers [n] C [%] advantage of the technology used is in the high

123 28 3.6 signal-to-noise ratio owing to the transmission of a

245 42 2.4 voltage signal of about 57 V AC.

420 60 1.7

3.1 OPERATING VOLTAGES AND

OVERVOLTAGES

Hence the internal design of bushings defines the

thresholds of change in capacity for generating trip For the measurement of operating voltages, the

signals and in the following a suitable capacitive voltage sensor already described is

measurement set-up with reachable accuracy is used. In addition overvoltages can also be

presented. detected. Transient overvoltages represent a

significant endangerment potential for the

3 MONITORING VALUES insulation. Therefore, the detection and evaluation

of these transients is of great significance for the

The monitoring of the electrical measurement evaluation of the bushing insulator reliability [5] and

quantities is achieved with a voltage adaptor and besides this also for the insulation system of the

voltage sensor. The adaptor is connected directly active part of the transformer.

to the measurement tap of the bushing, see

Figure 3, left. This design allows a reliable Overvoltages can be caused by lightning impulses

measurement with a bandwidth of up to 2 MHz. and switching actions, e. g. the switching on of

overhead lines and chokes. In particular, bushings

of transformers in GIS or HVDC-switchgear are

subjected to fast transient overvoltages. Since their

size and shape are often not known, there can be

a failure of operating equipment, which can be

avoided by taking specific countermeasures.

Furthermore, information about the amplitude of

overvoltages and the combination with the on-line

measures and analysing data of e.g. transient

Figure 3: Bushing voltage adaptor fitting for

overvoltage monitoring modules is of great

different types of bushings and voltage sensor with

importance in case of root cause analysis after the

adopted measuring capacity

occurrence of a damage.

Figure 5 shows, as an example, three-phase very high resolution in terms of time in order to

operating voltages on the 275 kV bushings of a achieve this accuracy. In this case, the sampling

185 MVA generator transformer together with rate is 10 µs, to detect the zero crossing of the

detected overvoltages recorded over a period of 4 50/60 Hz AC voltage.

days.

For the acquisition of the Δ tan δ, an accuracy of at

least ± 0.15 % must be reached. The reason for

this is that the dissipation factor for the various

types of construction of bushings moves in the

range of about 0.5 % and a maximum warning

threshold has to be assumed at about 0.7 %. In the

case of offline measurements, it is in keeping with

the current state-of-the-art to determine the

dissipation factor using a reference capacitance

and a reference voltage. These aids are not

available on-line. Rather, in the case of an on-line

measurement, as in the process described here,

the voltage of another phase is used as a

reference.

Different types of interpretation methods (e.g.

Figure 5: Continuously monitored 3-phase change of dissipation factor vs. sum current

operating voltages (phases L1, L2, L3) with phasor) with their advantages and disadvantages

overvoltages, voltage fluctuations and network are discussed in [7, 9] and it is the authors opinion

asymmetries (period 4 days) that the tan δ value cannot be a protection criteria.

As there is no comparable link to internal design

What can be seen are some voltage spikes in the which allows a clear threshold. A condition

graph, which are caused by the overvoltages that assessment by tan δ measurements needs the

occur. In addition voltage fluctuations in the line consultancy of an expert, like e.g. PD

voltage and network asymmetries of up to 1 % can measurement analysis, and an automatic tripping

be clearly seen from the graph. is not meaningful. Furthermore there are no case

studies known to the authors, where only the

3.2 Change of Capacity – Δ C change of on-line measured tan δ values indicated

a bushing failure.

The monitoring of the change in the bushing

capacitances (Δ C) is achieved by means of a 4 CASE STUDIES

three-phase voltage measurement. Here, the

output signal of the presented voltage sensor is 4.1 350 MVA, 420 kV Transformer

compared with the two remaining phases. The

result of the algorithm is based on an averaging in The effect of a partial flashover of 2 layers of a

order to eliminate voltage fluctuations in the 420 kV bushing is depicted in Figure 6. The 3-

network in this manner. The influences of phase operating voltages (phase L1, L2, L3)

temperature can be compensated by the three- together with overvoltages of the 350 MVA

phase measurement principle. In consequence, the regulating transformer are shown.

relative change in capacitance is used for

determining the Δ C. This method has also proven

itself over a prolonged time in the field [7] also

impressing through its high signal-to-noise ratio.

Hence the change of capacity can be chosen as

protection criteria and two available case studies

will demonstrate in the following that possibility.

3.3 Change of dissipation factor – tan δ

The measurement of the phase angle between the

three phases makes it possible to detect changes

in the dielectric dissipation (loss) factor tan δ. The

difficulty in the measurement technique is in being

able to detect even very slight changes. For

example, a change in the loss factor tan δ by 0.1 % Figure 6: Detection of partial flashover of 420 kV

means that the phase angle changes by 0.057 °. bushing and avoidance of collateral damage of

The measurement data has to be recorded with a 350 MVA regulating transformer, 3-phase

operating voltages (phase L1, L2, L3) with In Figure 7 it can be seen that overvoltages have

overvoltages (large figure), identified by change of been detected prior to the fault, which might have

capacitance Δ C (small figure) been a possible root cause for the bushing failure.

Therefore comprehensive monitoring systems can

On 27.11.2004 after only 1 ½ years of bushing be used to correlate transient overvoltages and

operation a warning was generated automatically capacity change of bushings for a deeper

by the on-line monitoring system identified by a understanding of those additional dielectric

change in the bushing capacitance by 3.6 % stresses.

(Figure 6, small figure).

In case the monitoring system would have been

After switching off the transformer an off-line used to protect the bushing with appropriate

measurement was performed and proved the on- thresholds, the system might have protected the

line determined value. The bushing was shipped to transformer for that unscheduled tripping by raising

the manufacturer who also confirmed the result. a warning 3 days in advance and an alarm 6 hours

Due to the installation of an on-line monitoring in advance with a possible de-energization of the

system a collateral damage could be prevented. In transformer.

addition the system indicated that the transformer

has been affected by overvoltages which could 5 CONCLUSION

have been the most probable reason for the

damage. The focus in this paper was to demonstrate how

capacitive controlled bushings can be protected by

4.2 850 MVA, 400 kV Transformer on-line monitoring devices. The underlying

principle of the measurement technique is based

In the evening of 28th of June 2013 a 850 MVA, on the use of a capacitive voltage sensor that is

400/27kV transformer, manufactured in 2000, was installed at the measurement tap of the bushing. In

tripped due to a catastrophic bushing failure of high this manner, the operational voltages can be

voltage side in phase V. Analysing the measured, and deriving therefrom, overvoltages

measurement data of the monitoring system and transient voltages can be detected.

reveals that the catastrophic failure was detectable

approximately 3 days in advance, see Figure 7. The change in the bushing capacitance as the

most important characteristic quantity for

determining the operational state can be analyzed

reliably on this basis. Hence the change of

capacitance can be chosen as protection criteria

and thresholds are clear distinguished by bushings

internal design and number of layers.

Practical examples have shown that the change in

the dielectric dissipation factor can be acquired,

but provides less information than the

recommended simple on-line monitoring of the

Figure 7: Increase of measured voltage (phase to change in the bushing capacitance. Hence the

ground voltage measurement on bushing test tap change of tan δ is not seen as protection criteria as

at high voltage side) on a failed bushing of a possible threshold are not linkable to internal

850 MVA transformer design and there is no case study available for

bushing failures linked to only tan δ changes.

On 26th of June, the voltage measurement on Tan δ monitoring might still be used to monitor the

phase V showed a voltage rise of approx. 2.5 % bushing condition on a long time period, i.e.

what correlates to one layer breakdown in the monitor the aging of bushings.

condenser bushing. Beginning approximately 6

hours in advance of the trip a cascade breakdown Case studies demonstrated, that a critical damage

inside the bushing occurs and the voltage rose up of a 350 MVA grid coupling transformer could be

to additional 15 % of nominal voltage. However, in avoided by a detection of a partial flashover of

this case the alarm management functionality of layers of a bushing indicated by a change in the

the on-line condition monitoring system was not bushing capacitance. Another collateral damage of

implemented into the SCADA system. The active an 850 MVA transformer bushing might have been

use of the bushing monitoring functionality would prevented in case the bushing monitoring system

have avoided that major bushing failure and the based on capacitive voltage measurements would

unscheduled outage. Due to that experience the have been authorized to trip the transformer.

utility decided to implement from now on the

bushing monitoring into the active alarm For certain types of bushings in case of certain

management. chance of on-line monitored capacity automated

alarming and tripping of transformers seems to

become feasible. This article aims to start

discussions between bushing and transformer

manufacturer and users about thresholds, concrete

preconditions and subsequent actions including

automated tripping.

This article states that the monitoring principal

which it´s so far used technology might be a base

for future development of protection devices, as

the specification for protection devices is different

to monitoring devices, e.g. real time

communication.

REFERENCES

[1] D. Kind, H. Kärner: “High voltage Insulation

Technology”, Friedr. Vieweg & Sohn,

Braunschweig, 1982

[2] ”An International Survey on Failures of Large

Power Transformers in Service”, CIGRE

Working Group 12.05, Electra, No. 88, 1983

[3] K. Widmaier: “Bushing – a very highly stressed

compo-nent”, MICAFIL Symposium, Stuttgart,

2002

[4] [8] R. Krump, H. Frielingsdorf: “Dry type

Bushings for Operation under difficult

Conditions”, Transform, Munich, 2001

[5] S. Tenbohlen, T. Stirl et al.: “Experience-based

Evaluation of Economic Benefits of On-line

Monitoring Systems for Power Transformers”,

CIGRE Session 2002, paper 12-110, Paris,

2002

[6] S. Tenbohlen et al.: “Enhanced Diagnosis of

Power Transformers using On- and Off-line

Methods: Results, Examples and Future

Trends”, CIGRE Session 2000, paper 12-204,

Paris, 2000

[7] T. Stirl, et al.: “On-line Condition Monitoring

and Diagnosis for Power Transformers their

Bushings, Tap Changer and Insulation

System”, CMD 2006, Korea 2006

[8] F. Lachman et al.: „On-Line Diagnostics of

High Voltage Bushings and Current

Transformers Using the Sum Current method“,

IEEE Transactions on Power Delivery, Vol. 15,

No. 1, January 2000

[9] J. Watson et al.: “Interpretation of Data from

On-line Bushing Monitoring Systems”, Cigre

Session 2014, paper A2-111, Paris 2014

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Electrical Installation Certificate - GreenDocument7 pagesElectrical Installation Certificate - GreenAnas Kabar100% (2)

- Eaton Guide To Circuit Protection & ControlDocument72 pagesEaton Guide To Circuit Protection & ControlGuruxyzNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- LS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureDocument24 pagesLS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureBharath Nadimpalli100% (1)

- Cahier Technique: Protection of MV/LV Substation TransformersDocument37 pagesCahier Technique: Protection of MV/LV Substation TransformersDheeraj Yadav100% (1)

- 22 - Altenhuber - Guidance For The Application of Low Voltage FusesDocument10 pages22 - Altenhuber - Guidance For The Application of Low Voltage FusesRagowo Tri WicaksonoNo ratings yet

- The Design Basics of Motor Protection Circuit BreakerDocument15 pagesThe Design Basics of Motor Protection Circuit BreakerKI OHNo ratings yet

- Protection of MV LV Substation Transformers PDFDocument37 pagesProtection of MV LV Substation Transformers PDFmatanveerNo ratings yet

- Coordination of LV Protection DevicesDocument44 pagesCoordination of LV Protection Deviceslsanchezorjuela100% (1)

- ImportantDocument72 pagesImportantSanda NeumanNo ratings yet

- Protection of Distribution Grid Having DGDocument16 pagesProtection of Distribution Grid Having DGiftikhar395No ratings yet

- WP012003EN Fin Apr2016Document12 pagesWP012003EN Fin Apr2016GustavoGamezNo ratings yet

- Melrose - Transformer Maintenance Section (Read-Only) (Compatibility Mode)Document32 pagesMelrose - Transformer Maintenance Section (Read-Only) (Compatibility Mode)ECB_MktNo ratings yet

- Design HDocument7 pagesDesign HJohn Mark DalidaNo ratings yet

- Unconventional Diagnostic Methods For Testing Generator Stator WindingsDocument8 pagesUnconventional Diagnostic Methods For Testing Generator Stator WindingsJakariya JakariyaNo ratings yet

- Comparison Between High Impedance and Low Impedance Bus Differential ProtectionDocument15 pagesComparison Between High Impedance and Low Impedance Bus Differential Protectionpop papNo ratings yet

- Monitoring of Dielectric Losses at Capacitor-Type Bushings: Dnedelcut@icmetDocument9 pagesMonitoring of Dielectric Losses at Capacitor-Type Bushings: Dnedelcut@icmetBlack JasmineNo ratings yet

- Basic Selection of MV Public Distribution NetworksDocument24 pagesBasic Selection of MV Public Distribution NetworksBanyar AungNo ratings yet

- TRABTECH Basics: Basic Knowledge On Surge ProtectionDocument24 pagesTRABTECH Basics: Basic Knowledge On Surge ProtectionMisko PiskoNo ratings yet

- Component Protection For Electrical SystemsDocument32 pagesComponent Protection For Electrical Systemsgeorgel1980No ratings yet

- Technical Solutions For The Increased Integration of Renewable Generation Into LV - and MV Grid Structures - Uwe KaltenbornDocument5 pagesTechnical Solutions For The Increased Integration of Renewable Generation Into LV - and MV Grid Structures - Uwe KaltenbornAjay krishnan NilakantanNo ratings yet

- Reactive Power Compensation Using A Voltage Source GeneratorDocument10 pagesReactive Power Compensation Using A Voltage Source GeneratorkubikNo ratings yet

- General Rules of Electrical Installation Design: Chapter ADocument20 pagesGeneral Rules of Electrical Installation Design: Chapter AMuhammad Mahfud Rosyidi100% (1)

- LV DESGIN FOR TRAINING Manual FinalDocument8 pagesLV DESGIN FOR TRAINING Manual FinalBehailu Mulugeta100% (1)

- Circuit BreakerDocument32 pagesCircuit BreakerOsama SalemNo ratings yet

- Electrical Shop in A Ship Repair Yard PDFDocument21 pagesElectrical Shop in A Ship Repair Yard PDFBachhanChaubey100% (1)

- EIG A Electrical DesignDocument20 pagesEIG A Electrical DesignMahmoud FakhereddinNo ratings yet

- 21 Guide Using International StandardsDocument9 pages21 Guide Using International Standardslebsework1801No ratings yet

- Arduino Based Short Circuit Protection SDocument5 pagesArduino Based Short Circuit Protection SReena ExpNo ratings yet

- Lightning Protection of SCADA and Telemetry System PDFDocument7 pagesLightning Protection of SCADA and Telemetry System PDFkaruna88No ratings yet

- General Rules of Electrical Installation Design: Chapter ADocument20 pagesGeneral Rules of Electrical Installation Design: Chapter Agenial72No ratings yet

- IDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHDocument58 pagesIDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHbmwr1100s_055542No ratings yet

- Cahier Technique No. 203: Basic Selection of MV Public Distribution NetworksDocument24 pagesCahier Technique No. 203: Basic Selection of MV Public Distribution NetworksnbnbNo ratings yet

- Industrial Power System Design by Benigno S JimenezDocument11 pagesIndustrial Power System Design by Benigno S JimenezmjpadzNo ratings yet

- EE 466 Power System Protection: University of HailDocument22 pagesEE 466 Power System Protection: University of Hailselvithimmarajan@gmail.comNo ratings yet

- An Electronic Control Unit For Reducing Contact Bounce in Electromagnetic ContactorsDocument10 pagesAn Electronic Control Unit For Reducing Contact Bounce in Electromagnetic ContactorsAbirami RajagopalNo ratings yet

- Earthing Systems in LV - Schneider 172Document30 pagesEarthing Systems in LV - Schneider 172anon_568723957No ratings yet

- Trigged Current Limiters ApplicationsDocument6 pagesTrigged Current Limiters ApplicationsVíctor RojasNo ratings yet

- Ngts - 3 24 10Document41 pagesNgts - 3 24 10akmezimNo ratings yet

- Investigation On PolarizationDocument6 pagesInvestigation On PolarizationDécio HanashiroNo ratings yet

- Practical Examples Using Dachcz RegulationsDocument11 pagesPractical Examples Using Dachcz RegulationsrvasilevaNo ratings yet

- Tarea ProteccionesDocument8 pagesTarea Proteccionesjuan carlos moreno morenoNo ratings yet

- Application Guide: General PointsDocument71 pagesApplication Guide: General PointsWaseem MohammedNo ratings yet

- Soccomac Application GuideDocument71 pagesSoccomac Application GuideNoli OtebaNo ratings yet

- SBEF and REFDocument8 pagesSBEF and REFadhyartha100% (1)

- Relay Protection Systems (Print Out)Document27 pagesRelay Protection Systems (Print Out)windpower btNo ratings yet

- Discrimination SchneiderElectricDocument244 pagesDiscrimination SchneiderElectricaldodarNo ratings yet

- Ichveps2017-Condition Monitoring Metal Clad Switchgear - KHDocument24 pagesIchveps2017-Condition Monitoring Metal Clad Switchgear - KHbmwr1100s_055542No ratings yet

- Power Quality Improvement For Non Linear Ffe96ec1Document6 pagesPower Quality Improvement For Non Linear Ffe96ec1Muhammad AzisNo ratings yet

- Medium-Voltage Electrical System ProtectionDocument8 pagesMedium-Voltage Electrical System ProtectiontechtricNo ratings yet

- Relay Using GuidelinesDocument14 pagesRelay Using GuidelinesSahil RajputNo ratings yet

- Mastering All Sub-Assemblies of An MV Circuit Breaker and Racking Truck System Ensures Reliability and RobustnessDocument10 pagesMastering All Sub-Assemblies of An MV Circuit Breaker and Racking Truck System Ensures Reliability and Robustnesstechhustler2No ratings yet

- Ableitstrom TI en 26 PDFDocument7 pagesAbleitstrom TI en 26 PDFrizhaypNo ratings yet

- 18 - Aizam - HV IT in TNB Substations - Paper PDFDocument5 pages18 - Aizam - HV IT in TNB Substations - Paper PDFbcqbaoNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Correlation - Between - Lightning - Impacts - and Line OutagesDocument11 pagesCorrelation - Between - Lightning - Impacts - and Line Outageschandraippa2No ratings yet

- Political cartooning in India with special reference to AssamDocument12 pagesPolitical cartooning in India with special reference to Assamchandraippa2No ratings yet

- When satire is seriousDocument8 pagesWhen satire is seriouschandraippa2No ratings yet

- 577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1Document7 pages577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1chandraippa2No ratings yet

- Religious Nationalism and Political ComiDocument1 pageReligious Nationalism and Political Comichandraippa2No ratings yet

- 500kv Shunt Reactor Bushing FailureDocument7 pages500kv Shunt Reactor Bushing Failurechandraippa2No ratings yet

- Anaerobic Digestion Process TechnologicaDocument14 pagesAnaerobic Digestion Process Technologicachandraippa2No ratings yet

- Cartoonish claims depiction of religion in editorial cartoonsDocument16 pagesCartoonish claims depiction of religion in editorial cartoonschandraippa2No ratings yet

- 2022 Experiencesandchallengesin IEC61850 ProcessbusDocument18 pages2022 Experiencesandchallengesin IEC61850 Processbuschandraippa2No ratings yet

- To Love Is To ThinkDocument1 pageTo Love Is To Thinkchandraippa2No ratings yet

- VietnamDocument1 pageVietnamchandraippa2No ratings yet

- Prasthaavana of Kannada Markandeya PuraanaDocument5 pagesPrasthaavana of Kannada Markandeya Puraanachandraippa2No ratings yet

- Study of Katha UpanishadDocument73 pagesStudy of Katha Upanishadchandraippa2No ratings yet

- Marigold Garden - Pictures and RhymesDocument68 pagesMarigold Garden - Pictures and Rhymeschandraippa2No ratings yet

- Everything You Need To Know About Small Language Models (SLM) and Its ApplicationsDocument3 pagesEverything You Need To Know About Small Language Models (SLM) and Its Applicationschandraippa2No ratings yet

- On-Sets A Vintage Set Theory GameDocument5 pagesOn-Sets A Vintage Set Theory Gamechandraippa2No ratings yet

- Sanskrit Has Had Profound Influence On World LanguagesDocument3 pagesSanskrit Has Had Profound Influence On World Languageschandraippa2No ratings yet

- Divine Order and Divine Evil in The Tamil Tale of RamaDocument20 pagesDivine Order and Divine Evil in The Tamil Tale of Ramachandraippa2No ratings yet

- A Set Theory WorkbookDocument162 pagesA Set Theory Workbookchandraippa2No ratings yet

- Preface To Narayaneeyam-trans-SwamiTapasyanandaDocument36 pagesPreface To Narayaneeyam-trans-SwamiTapasyanandachandraippa2No ratings yet

- Teaching Aids For Set Concept Instruction in Kindergarten TeachersDocument7 pagesTeaching Aids For Set Concept Instruction in Kindergarten Teacherschandraippa2No ratings yet

- A Poet's Daily RoutineDocument2 pagesA Poet's Daily Routinechandraippa2No ratings yet

- A BowlDocument1 pageA Bowlchandraippa2No ratings yet

- Fratricide Among The MonkeysDocument8 pagesFratricide Among The Monkeyschandraippa2No ratings yet

- Beyond The Still LifeDocument2 pagesBeyond The Still Lifechandraippa2No ratings yet

- 9 4676 Enfaces Specialized System Classification Analysis FaultsDocument2 pages9 4676 Enfaces Specialized System Classification Analysis Faultschandraippa2No ratings yet

- Electromagnetic Compatibility in Various Kinds of Substations in Croatian Transmission Networks and Mitigation MeasuresDocument7 pagesElectromagnetic Compatibility in Various Kinds of Substations in Croatian Transmission Networks and Mitigation Measureschandraippa2No ratings yet

- PLOTINUS - Andrew SmithDocument159 pagesPLOTINUS - Andrew Smithchandraippa2100% (1)

- Sinvert - 600 SiemensDocument2 pagesSinvert - 600 SiemensLuis Álvarez JátivaNo ratings yet

- PPTDocument24 pagesPPTGuntur GopiNo ratings yet

- Solar Power Plant in Iit HyderabadDocument9 pagesSolar Power Plant in Iit HyderabadHimanshu VermaNo ratings yet

- Cascade Arrangements of TransformersDocument3 pagesCascade Arrangements of TransformerstutorrituNo ratings yet

- Manual Lms 4Document156 pagesManual Lms 4svatantrayabhinava0% (1)

- Automatic Battery Chargers Full: 5A, 10A, 15A, 20ADocument3 pagesAutomatic Battery Chargers Full: 5A, 10A, 15A, 20Amuhammad arifNo ratings yet

- Omron Vs Mini j7Document177 pagesOmron Vs Mini j7Güray ÖZÜERLER100% (1)

- Universal Mining School Great BritainDocument162 pagesUniversal Mining School Great BritainVeshwan Varma100% (3)

- Summary of Insulation Coordination StandardDocument7 pagesSummary of Insulation Coordination StandardAhsan MubashirNo ratings yet

- How I Was Forced Into IncestDocument2 pagesHow I Was Forced Into IncestDebolina DeyNo ratings yet

- ATSSDocument8 pagesATSSGeorge AniborNo ratings yet

- Abb Goes OffshoreDocument12 pagesAbb Goes OffshoreНемања КатићNo ratings yet

- RPET Quality ReportDocument22 pagesRPET Quality ReportMOAHMMED ABDUR RAB AZADNo ratings yet

- "National Thermal Power Corporation Anta (Raj.) ": A Report On Practical Training Taken atDocument8 pages"National Thermal Power Corporation Anta (Raj.) ": A Report On Practical Training Taken atArpan PorwalNo ratings yet

- MCBDocument6 pagesMCBvicky gosaviNo ratings yet

- Dstatcom Project ReportDocument43 pagesDstatcom Project ReportMahendar Mahe100% (3)

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun Sirimangkalo100% (1)

- Indian Power Plants Performance AnalysisDocument4 pagesIndian Power Plants Performance AnalysisLeanmark MayahleNo ratings yet

- Boq Template (2-In Low Tension)Document2 pagesBoq Template (2-In Low Tension)virudalaNo ratings yet

- Daily Maintenance Report (Coal, Lignite and Nuclear) 05-07-2020Document18 pagesDaily Maintenance Report (Coal, Lignite and Nuclear) 05-07-2020Data CentrumNo ratings yet

- 3UG46251CW30 Datasheet enDocument6 pages3UG46251CW30 Datasheet enragkaraNo ratings yet

- Installation Guide FCP 106Document52 pagesInstallation Guide FCP 106Ivan KurniadiNo ratings yet

- Project ProposalDocument4 pagesProject ProposalAkhtar AliNo ratings yet

- M624 MBATech Electrical Subrat Sharma Final ReportDocument64 pagesM624 MBATech Electrical Subrat Sharma Final ReportJosef MorganNo ratings yet

- In Fine On Heat Pump Web in Ar 1657122562261Document31 pagesIn Fine On Heat Pump Web in Ar 1657122562261Dejan MitrovićNo ratings yet

- U389A and U389B Electric Meters For Active EnergyDocument4 pagesU389A and U389B Electric Meters For Active Energyiskandarn_el5735No ratings yet

- One-Line Diagram - OLV1 (Load Flow Analysis) : Wind Turbine GeneratorDocument2 pagesOne-Line Diagram - OLV1 (Load Flow Analysis) : Wind Turbine GeneratorSupratno ArhamNo ratings yet