Professional Documents

Culture Documents

WPS Mig 2

WPS Mig 2

Uploaded by

rafetguzelsoyCopyright:

Available Formats

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- As Series - Installation Operation and Maintenance Manua1 - 1Document35 pagesAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Lengo Savings Plan PremierDocument9 pagesLengo Savings Plan PremierPado DjochieNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- TunnelTalk Annual Review 2019 2020Document50 pagesTunnelTalk Annual Review 2019 2020Mohamed SalehNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- New Build - 270Ft LCT Listing IDDocument13 pagesNew Build - 270Ft LCT Listing IDrafetguzelsoy100% (1)

- HR Practices of Marks and Spencer Selfri PDFDocument46 pagesHR Practices of Marks and Spencer Selfri PDFbalach100% (1)

- Multiple Pregnancy LectureDocument33 pagesMultiple Pregnancy Lecturefarid_nchep100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PQR - 1Document1 pagePQR - 1janardan.sfeNo ratings yet

- Wps PQR PipexlsxDocument190 pagesWps PQR PipexlsxIshwarNo ratings yet

- Aditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Document1 pageAditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Anand MakasanaNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- WPS Mig 1Document1 pageWPS Mig 1rafetguzelsoyNo ratings yet

- Barge Supports Detail Design Drawings - 03-April - 2021 - For ConstructionDocument49 pagesBarge Supports Detail Design Drawings - 03-April - 2021 - For ConstructionrafetguzelsoyNo ratings yet

- 5000 05 17 0 00 354 16m Patrol Boat Presentation - DefDocument2 pages5000 05 17 0 00 354 16m Patrol Boat Presentation - DefrafetguzelsoyNo ratings yet

- HTTPWWW Moratex Euplikitww201034tww20103-4art5enDocument5 pagesHTTPWWW Moratex Euplikitww201034tww20103-4art5enrafetguzelsoyNo ratings yet

- Pontoon BoatsDocument2 pagesPontoon BoatsrafetguzelsoyNo ratings yet

- 3060tundra GaDocument7 pages3060tundra GarafetguzelsoyNo ratings yet

- TANKSAN KatalogDocument35 pagesTANKSAN KatalografetguzelsoyNo ratings yet

- NEW BUILD - 15m Self Propelled Barge. Listing IDDocument4 pagesNEW BUILD - 15m Self Propelled Barge. Listing IDrafetguzelsoyNo ratings yet

- NEW BUILD - Houseboat HB 39 Listing IDDocument7 pagesNEW BUILD - Houseboat HB 39 Listing IDrafetguzelsoyNo ratings yet

- NEW BUILD - General-Cargo / Cargo-Training (SF45) Listing IDDocument4 pagesNEW BUILD - General-Cargo / Cargo-Training (SF45) Listing IDrafetguzelsoyNo ratings yet

- NEW 41m Landing Craft Listing ID - : Description Date Launched Length Beam Draft Location Broker PriceDocument4 pagesNEW 41m Landing Craft Listing ID - : Description Date Launched Length Beam Draft Location Broker PricerafetguzelsoyNo ratings yet

- Confined Space Hazards Assessment FormDocument3 pagesConfined Space Hazards Assessment FormAhmed El-sherpiniNo ratings yet

- Oh S Risk RegisterDocument83 pagesOh S Risk RegisterJacob YeboaNo ratings yet

- Sewerage SystemDocument11 pagesSewerage Systemhajjiyare2016100% (1)

- Travel AgencyDocument10 pagesTravel AgencySisu SuominenNo ratings yet

- Bottled Water Report July-Sep, 2018 (Final)Document23 pagesBottled Water Report July-Sep, 2018 (Final)umerjaved86No ratings yet

- AUBF - Lec Chapter 3 4 5 COMPLETE - Transes 1Document18 pagesAUBF - Lec Chapter 3 4 5 COMPLETE - Transes 1Princess Eve OlowanNo ratings yet

- Chloe Ting - 2 Weeks Shred Challenge - Free Workout Program PDFDocument1 pageChloe Ting - 2 Weeks Shred Challenge - Free Workout Program PDFvalentina9echeniqueNo ratings yet

- PNLE NursingDocument631 pagesPNLE NursingLenaj Ebron50% (2)

- Funda Test DrillDocument32 pagesFunda Test DrillNurseRiemNo ratings yet

- ABC mg7 (1) - Bonding in Complexes - CrystalfieldtheoryDocument50 pagesABC mg7 (1) - Bonding in Complexes - CrystalfieldtheoryAdistaNo ratings yet

- 5 Public Goods Merit Goods Private GoodsDocument14 pages5 Public Goods Merit Goods Private Goodserni inaNo ratings yet

- BSMMU Result Obstetrics and Gynaecology July 2019Document1 pageBSMMU Result Obstetrics and Gynaecology July 2019Abid Hasan ZiKonNo ratings yet

- DD Cen TS 12037-2003Document34 pagesDD Cen TS 12037-2003DoicielNo ratings yet

- Small BuildingDocument5 pagesSmall BuildingasddasswxlNo ratings yet

- 2015 VN Single InverterDocument29 pages2015 VN Single InverterMinhvan LeNo ratings yet

- Basic Principles of Ultrasonic Testing: Theory and PracticeDocument42 pagesBasic Principles of Ultrasonic Testing: Theory and PracticeMuhammad Ramdhan Nurghodan100% (2)

- MCQ in Genetics With AnswersDocument6 pagesMCQ in Genetics With AnswersAkram Niazi100% (8)

- 370 HRDocument3 pages370 HRMritunjay SrivastavaNo ratings yet

- Laporan Harian OverhoulDocument234 pagesLaporan Harian OverhoulRosyadNo ratings yet

- 7 Day Ruqyah Detox Programme - Shaykh 'Adil Ibn Tahir Al-Muqbil - FacebookDocument2 pages7 Day Ruqyah Detox Programme - Shaykh 'Adil Ibn Tahir Al-Muqbil - FacebookR.RNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Multiple Choice: Chapter 2, Lesson 1: The Atmosphere Student Test BankDocument4 pagesMultiple Choice: Chapter 2, Lesson 1: The Atmosphere Student Test BankMAYRA CRUZNo ratings yet

- ĐỀ SỐ 33 - DEDocument4 pagesĐỀ SỐ 33 - DE27. Minh PhươngNo ratings yet

- 10ME6307 Advanced Thermodynamics and Combustion IA 2 QPDocument2 pages10ME6307 Advanced Thermodynamics and Combustion IA 2 QPDeepakNo ratings yet

- Rohan Jaiswal Final ProjectDocument64 pagesRohan Jaiswal Final Projectsanjeev ranaNo ratings yet

WPS Mig 2

WPS Mig 2

Uploaded by

rafetguzelsoyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Mig 2

WPS Mig 2

Uploaded by

rafetguzelsoyCopyright:

Available Formats

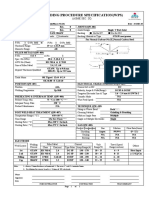

AD ASTRA MARITIME GEMI VE PERSONEL

ISLETMECILIGI SAN TIC LTD STI. WPS No. 1-1-11

Rev. No. 0

Date:

PQR No.

WELDING PROCEDURE SPECIFICATION (WPS)

PREHEAT (QW-406) GAS (QW-408)

o

Preheat Temp., Min. 10 C Percent Composition

o

Interpass Temp., Max. 260 C Gas(es) Mixture Flow Rate

Preheat Maintenance - Shielding Ar 100,00% 25-35 CFH

( Continuous or special heating where applicable should be recorded) Trailing N/A

Backing N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current, AC or DC DC Polarity (EP) Reverse

Amps (Range) 90-400 Volts (Range) 15-35

Tungsten Electrode Size and Type AISI316

Mode of Metal Transfer for MIG Short Circuiting

( Spray arc, Short circuiting arc, etc.)

Wire Feed rate 70 - 630 IPM

TECHNIQUE (QW-410)

String or Weave Bead Either , but weave preferred

Orifice or Gas Cup Size

Initial and interpass Cleaning Wire Brushing & Grinding

Method of Back Gouging None

Oscillation N/A

Contact Tube to Work Distance 6 mm to 10 mm for MIG

Multiple or Single Pass (Per side) Multiple

Multiple or Single Electrodes Single

Travel Speed (Range) 7-30 Inch per minute

Peening N/A

Other In Short circuiting, spatter is caused by excess voltage; in spray, spatter is caused by

not enough voltage.

Filler Metal Current

Weld Layer(s) Process Amp. Range/ Volt Range Travel Speed Range (IPM)

Class Size Polarity Type Wire feed rate

90-100/120 to

Root Pass MIG 2,4 DCRP 140 ipm 15-18 7-10

100-130/70 to

Hot Pass MIG 2,4 DCRP 125 ipm 15-18 7-10

316L

230-300/420 to

Fill MIG 2,4 DCRP 630 ipm 27-33 10-25

250-410/280 to

Cap MIG 2,4 DCRP 560 ipm 27-35 13-30

PREPARED BY: APPROVED BY: CLIENT APPROVAL:

Name : Name : Name :

Designation : QC - MECHANICAL Designation : TECHNICAL MANAGER Designation :

Signature : Signature : Signature :

Page 2 of 2

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- As Series - Installation Operation and Maintenance Manua1 - 1Document35 pagesAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Lengo Savings Plan PremierDocument9 pagesLengo Savings Plan PremierPado DjochieNo ratings yet

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- TunnelTalk Annual Review 2019 2020Document50 pagesTunnelTalk Annual Review 2019 2020Mohamed SalehNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- New Build - 270Ft LCT Listing IDDocument13 pagesNew Build - 270Ft LCT Listing IDrafetguzelsoy100% (1)

- HR Practices of Marks and Spencer Selfri PDFDocument46 pagesHR Practices of Marks and Spencer Selfri PDFbalach100% (1)

- Multiple Pregnancy LectureDocument33 pagesMultiple Pregnancy Lecturefarid_nchep100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PQR - 1Document1 pagePQR - 1janardan.sfeNo ratings yet

- Wps PQR PipexlsxDocument190 pagesWps PQR PipexlsxIshwarNo ratings yet

- Aditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Document1 pageAditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)Anand MakasanaNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- WPS Mig 1Document1 pageWPS Mig 1rafetguzelsoyNo ratings yet

- Barge Supports Detail Design Drawings - 03-April - 2021 - For ConstructionDocument49 pagesBarge Supports Detail Design Drawings - 03-April - 2021 - For ConstructionrafetguzelsoyNo ratings yet

- 5000 05 17 0 00 354 16m Patrol Boat Presentation - DefDocument2 pages5000 05 17 0 00 354 16m Patrol Boat Presentation - DefrafetguzelsoyNo ratings yet

- HTTPWWW Moratex Euplikitww201034tww20103-4art5enDocument5 pagesHTTPWWW Moratex Euplikitww201034tww20103-4art5enrafetguzelsoyNo ratings yet

- Pontoon BoatsDocument2 pagesPontoon BoatsrafetguzelsoyNo ratings yet

- 3060tundra GaDocument7 pages3060tundra GarafetguzelsoyNo ratings yet

- TANKSAN KatalogDocument35 pagesTANKSAN KatalografetguzelsoyNo ratings yet

- NEW BUILD - 15m Self Propelled Barge. Listing IDDocument4 pagesNEW BUILD - 15m Self Propelled Barge. Listing IDrafetguzelsoyNo ratings yet

- NEW BUILD - Houseboat HB 39 Listing IDDocument7 pagesNEW BUILD - Houseboat HB 39 Listing IDrafetguzelsoyNo ratings yet

- NEW BUILD - General-Cargo / Cargo-Training (SF45) Listing IDDocument4 pagesNEW BUILD - General-Cargo / Cargo-Training (SF45) Listing IDrafetguzelsoyNo ratings yet

- NEW 41m Landing Craft Listing ID - : Description Date Launched Length Beam Draft Location Broker PriceDocument4 pagesNEW 41m Landing Craft Listing ID - : Description Date Launched Length Beam Draft Location Broker PricerafetguzelsoyNo ratings yet

- Confined Space Hazards Assessment FormDocument3 pagesConfined Space Hazards Assessment FormAhmed El-sherpiniNo ratings yet

- Oh S Risk RegisterDocument83 pagesOh S Risk RegisterJacob YeboaNo ratings yet

- Sewerage SystemDocument11 pagesSewerage Systemhajjiyare2016100% (1)

- Travel AgencyDocument10 pagesTravel AgencySisu SuominenNo ratings yet

- Bottled Water Report July-Sep, 2018 (Final)Document23 pagesBottled Water Report July-Sep, 2018 (Final)umerjaved86No ratings yet

- AUBF - Lec Chapter 3 4 5 COMPLETE - Transes 1Document18 pagesAUBF - Lec Chapter 3 4 5 COMPLETE - Transes 1Princess Eve OlowanNo ratings yet

- Chloe Ting - 2 Weeks Shred Challenge - Free Workout Program PDFDocument1 pageChloe Ting - 2 Weeks Shred Challenge - Free Workout Program PDFvalentina9echeniqueNo ratings yet

- PNLE NursingDocument631 pagesPNLE NursingLenaj Ebron50% (2)

- Funda Test DrillDocument32 pagesFunda Test DrillNurseRiemNo ratings yet

- ABC mg7 (1) - Bonding in Complexes - CrystalfieldtheoryDocument50 pagesABC mg7 (1) - Bonding in Complexes - CrystalfieldtheoryAdistaNo ratings yet

- 5 Public Goods Merit Goods Private GoodsDocument14 pages5 Public Goods Merit Goods Private Goodserni inaNo ratings yet

- BSMMU Result Obstetrics and Gynaecology July 2019Document1 pageBSMMU Result Obstetrics and Gynaecology July 2019Abid Hasan ZiKonNo ratings yet

- DD Cen TS 12037-2003Document34 pagesDD Cen TS 12037-2003DoicielNo ratings yet

- Small BuildingDocument5 pagesSmall BuildingasddasswxlNo ratings yet

- 2015 VN Single InverterDocument29 pages2015 VN Single InverterMinhvan LeNo ratings yet

- Basic Principles of Ultrasonic Testing: Theory and PracticeDocument42 pagesBasic Principles of Ultrasonic Testing: Theory and PracticeMuhammad Ramdhan Nurghodan100% (2)

- MCQ in Genetics With AnswersDocument6 pagesMCQ in Genetics With AnswersAkram Niazi100% (8)

- 370 HRDocument3 pages370 HRMritunjay SrivastavaNo ratings yet

- Laporan Harian OverhoulDocument234 pagesLaporan Harian OverhoulRosyadNo ratings yet

- 7 Day Ruqyah Detox Programme - Shaykh 'Adil Ibn Tahir Al-Muqbil - FacebookDocument2 pages7 Day Ruqyah Detox Programme - Shaykh 'Adil Ibn Tahir Al-Muqbil - FacebookR.RNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Multiple Choice: Chapter 2, Lesson 1: The Atmosphere Student Test BankDocument4 pagesMultiple Choice: Chapter 2, Lesson 1: The Atmosphere Student Test BankMAYRA CRUZNo ratings yet

- ĐỀ SỐ 33 - DEDocument4 pagesĐỀ SỐ 33 - DE27. Minh PhươngNo ratings yet

- 10ME6307 Advanced Thermodynamics and Combustion IA 2 QPDocument2 pages10ME6307 Advanced Thermodynamics and Combustion IA 2 QPDeepakNo ratings yet

- Rohan Jaiswal Final ProjectDocument64 pagesRohan Jaiswal Final Projectsanjeev ranaNo ratings yet