Professional Documents

Culture Documents

Induction Shop

Induction Shop

Uploaded by

neerajbhayal34560 ratings0% found this document useful (0 votes)

7 views3 pagesThe document describes various coating processes at a tungsten carbide plant including thermal spray coating, zinc arc coating, and a Kuka robot control system. Thermal spray coating involves spraying melted or heated coating materials onto a surface using plasma, arc, or combustion flame heating. It can provide thick coatings from 20 microns to several mm in thickness with hardness levels between 980 to 1440 HV. Zinc arc coating sprays molten zinc droplets onto a surface for corrosion resistance, increased hardness, and smooth roughness. An example coating process uses zinc coating on a 530mm diameter drawing block with 5 minutes for loading, 22 minutes for setting up, and 7 minutes for the coating process.

Original Description:

Original Title

Induction shop

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes various coating processes at a tungsten carbide plant including thermal spray coating, zinc arc coating, and a Kuka robot control system. Thermal spray coating involves spraying melted or heated coating materials onto a surface using plasma, arc, or combustion flame heating. It can provide thick coatings from 20 microns to several mm in thickness with hardness levels between 980 to 1440 HV. Zinc arc coating sprays molten zinc droplets onto a surface for corrosion resistance, increased hardness, and smooth roughness. An example coating process uses zinc coating on a 530mm diameter drawing block with 5 minutes for loading, 22 minutes for setting up, and 7 minutes for the coating process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

7 views3 pagesInduction Shop

Induction Shop

Uploaded by

neerajbhayal3456The document describes various coating processes at a tungsten carbide plant including thermal spray coating, zinc arc coating, and a Kuka robot control system. Thermal spray coating involves spraying melted or heated coating materials onto a surface using plasma, arc, or combustion flame heating. It can provide thick coatings from 20 microns to several mm in thickness with hardness levels between 980 to 1440 HV. Zinc arc coating sprays molten zinc droplets onto a surface for corrosion resistance, increased hardness, and smooth roughness. An example coating process uses zinc coating on a 530mm diameter drawing block with 5 minutes for loading, 22 minutes for setting up, and 7 minutes for the coating process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

Induction shop

TC PLANT (tungsten carbide palnt)

TC PLANT UNITS

-THERMAL SPRAY COATING

- ZINC ARC COATING

-KUKA ROBOT CONTROL

-WET DUST COLLECTOR

-EXHOUST FAN

-CHILLER (freeze tech)

-POWDER FEEDER

-ACOUSTIC CHAMBER

* THERMAL SPRAY COATING

~ Thermal spraying techniques are coating processes in which melted (or

heated) materials are sprayed onto a surface. The "feedstock" (coating

precursor) is heated by electrical (plasma or arc) or chemical means

(combustion flame).

~ Thermal spraying can provide thick coatings (approx. thickness range is 20

microns to several mm

~ Thermal spray hardness level- 980 to 1440 HV(vicker)

~ Define load is 0.3 kg

~ temperature is approximately is 1500degree celcius

~ Exhoust are run at a speed of 8000rpm

~ Exhoust can create pressure of 160 CFM

Operation – Tungsten Carbide thermal spray

FEED POWDER- Tungsten carbide

PRICE - 8000 Rupees per kg

DEPOSIT RATE – 70%

BY -KUKA ROBOT ( kuka robot has 6 axis and turn table has 2 axis of rotation

overall 8 axis of rotation )

COMPONENT NAME – Drum Block

DIAMETER- 530mm

SETTING TIME – 25 minute

LOADING TIME – 1minute

OPERATION TIME -17 minute (15-20 times coated by machine in a interval of

15 minute for 0.3 mm of coating is complete)

APPLICATION –

This technique is mostly used to produce coatings on structural materials. Such

coatings provide protection against high temperatures (for example thermal

barrier coatings for exhaust heat management), corrosion, erosion, wear

* ZINC COATING SPRAY

Zinc spray, which is also referred to as metallizing, is done by melting zinc

powder or zinc wire in a flame or electric arc and projecting the molten zinc

droplets by air or gas onto the surface to be coated. The zinc used is nominally

99.5% pure or better and the corrosion resistance of the coating produced by

this technique is approximately equal to the hot-dip galvanized coating.

APPLICATION

- Rust and Corrosion resistance

- Increase hardness

- Smooth roughness

OPERATION -ZINC COATING

COMPONENT NAME- Drawing Block

DIAMETER – 530mm

LOADING TIME - 5 minute

SETTING TIME - 22 minute

PROCESS TIME - 7 minute

You might also like

- ControTrace Vs Jacketed Piping enDocument3 pagesControTrace Vs Jacketed Piping enYoung-seok Hwang100% (1)

- D0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Document18 pagesD0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Surya Darma100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- It May Be Necessary To Perform Surface Treatments in Order ToDocument30 pagesIt May Be Necessary To Perform Surface Treatments in Order ToSunil SharmaNo ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- Technical Characteristics and Reference Standards: Zintek® in The Building IndustryDocument2 pagesTechnical Characteristics and Reference Standards: Zintek® in The Building Industryapi-112807037No ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Report On TransformersDocument34 pagesReport On TransformersAnkit Sharma0% (1)

- 04 Lloyd Insulation SDocument39 pages04 Lloyd Insulation SBalson VijaishNo ratings yet

- Steel Melt Shop 2 Process .Document50 pagesSteel Melt Shop 2 Process .Rahul Pandey0% (2)

- Forging PresentationDocument17 pagesForging PresentationRakesh PuriNo ratings yet

- 08 Preheating, PWHT & Sand Blasting - PaintingDocument23 pages08 Preheating, PWHT & Sand Blasting - PaintingFasil ParuvanathNo ratings yet

- Information - Roofing SheetDocument5 pagesInformation - Roofing SheetRajeev RanjanNo ratings yet

- Vermiculite ExfoliationDocument4 pagesVermiculite ExfoliationPeyman KhNo ratings yet

- E 1605 SikaCor 255 277Document6 pagesE 1605 SikaCor 255 277emanuelluca@yahoo.comNo ratings yet

- LloydDocument125 pagesLloydpartha070No ratings yet

- Gas TurbineDocument93 pagesGas TurbineShubhankit Porwal100% (3)

- E Radmax I Complete SectionDocument20 pagesE Radmax I Complete SectionJunita MagdalenaNo ratings yet

- Thornton Vessel Shop PresentationDocument30 pagesThornton Vessel Shop PresentationChris CarterNo ratings yet

- AnnelingDocument31 pagesAnnelingSatyam Singh100% (1)

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDocument9 pagesIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNo ratings yet

- Indian Railways Presented by Y.K.Jha Sse/Nc/AiiwDocument9 pagesIndian Railways Presented by Y.K.Jha Sse/Nc/Aiiwdhanalakshmi k sNo ratings yet

- An 10 001 Thermal Paste Application ENGDocument6 pagesAn 10 001 Thermal Paste Application ENGEuge VillarNo ratings yet

- Sinter PlantDocument38 pagesSinter PlantRahul Pandey75% (4)

- Fabrication of Heavy Wall Reactors in Crmo V PlatesDocument24 pagesFabrication of Heavy Wall Reactors in Crmo V PlatesDinesh Vaghela100% (1)

- Neeraj NT PCDocument33 pagesNeeraj NT PCClash ClanNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- A Summer Training Presentation 0N National Thermal Power Plant Kahalgaon (Bihar)Document42 pagesA Summer Training Presentation 0N National Thermal Power Plant Kahalgaon (Bihar)Abhishek KarnNo ratings yet

- Plasma Spray Coating MethodDocument28 pagesPlasma Spray Coating Methodvijay9994No ratings yet

- Painting Insulation CPDocument4 pagesPainting Insulation CPvinothNo ratings yet

- Evaluation-3 PPT HardikDocument31 pagesEvaluation-3 PPT Hardikdevendrakumar marsoniaNo ratings yet

- Highway Specification & Maintenance Lecture 37811682168295597938Document19 pagesHighway Specification & Maintenance Lecture 37811682168295597938Gaylan BarwariNo ratings yet

- Trasformatori SGBDocument24 pagesTrasformatori SGBst_calvoNo ratings yet

- Unit-II Coating of SuperalloysDocument36 pagesUnit-II Coating of SuperalloysJ JhansibaiNo ratings yet

- Heating Up of KilnsDocument74 pagesHeating Up of KilnsMehmet C100% (5)

- "Thermal Spray Coatings": Presented By: Swarup Satyajit Nanda Roll No-27628 Guided By: Mrs Swarnalata BeheraDocument31 pages"Thermal Spray Coatings": Presented By: Swarup Satyajit Nanda Roll No-27628 Guided By: Mrs Swarnalata Beherasujit_sekharNo ratings yet

- Abrasive Jet MachiningDocument6 pagesAbrasive Jet Machiningpatel ketan71% (7)

- Bitumen Test-Part BDocument31 pagesBitumen Test-Part Bபிரபாகரன் முனிசாமிNo ratings yet

- Spinning Training ReprotDocument62 pagesSpinning Training ReprotPranav Sharma100% (2)

- Updated GeneralDocument24 pagesUpdated GeneralMOHAMMED HANEEFNo ratings yet

- A Novel Cryogenic Grinding System For Recycling Scrap Tire PeelsDocument11 pagesA Novel Cryogenic Grinding System For Recycling Scrap Tire Peelssing_rNo ratings yet

- Windsichter CTC 4Document12 pagesWindsichter CTC 4LuisFernándezNo ratings yet

- Brochuras 01Document68 pagesBrochuras 01Anatoliy VinogradovNo ratings yet

- A New Die Material For Longer Service LifeDocument12 pagesA New Die Material For Longer Service LifeLuis SantosNo ratings yet

- Wrought TiAl BladesDocument6 pagesWrought TiAl BladesamvitaNo ratings yet

- Vertical Roller Mills KTM enDocument6 pagesVertical Roller Mills KTM enJoko Dewoto100% (1)

- Bhel (Transformer) Major TrainingDocument33 pagesBhel (Transformer) Major TrainingArpitSinghNo ratings yet

- Steam Turbine Basic Training - Module 2Document61 pagesSteam Turbine Basic Training - Module 2Ahtsham Ahmad100% (4)

- PKR MillsDocument37 pagesPKR Millsnetygen1No ratings yet

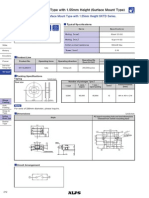

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Primary Met Final SpreadsDocument5 pagesPrimary Met Final SpreadsPablo GarciaNo ratings yet

- 04 LloydDocument107 pages04 LloydAgung Pramu AjiNo ratings yet

- ZRC 3 07Document2 pagesZRC 3 07groelzjNo ratings yet

- Study of Furnace of WRMDocument18 pagesStudy of Furnace of WRMkranthi chaitanyaNo ratings yet

- InternshipDocument41 pagesInternshipMin Kyaw HtetNo ratings yet

- OVDT Vs CRT - GeneralDocument24 pagesOVDT Vs CRT - Generaljaiqc100% (1)

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Projects For PythonDocument3 pagesProjects For Pythonneerajbhayal3456No ratings yet

- Important Questions For PythonDocument1 pageImportant Questions For Pythonneerajbhayal3456No ratings yet

- Excell AI ToolsDocument1 pageExcell AI Toolsneerajbhayal3456No ratings yet

- Jee Main 2024 Shift1 Maths Jan27Document6 pagesJee Main 2024 Shift1 Maths Jan27neerajbhayal3456No ratings yet

- RACDocument3 pagesRACneerajbhayal3456No ratings yet