Professional Documents

Culture Documents

Xuwinazawuduloxigabepepen

Xuwinazawuduloxigabepepen

Uploaded by

mohamed elmasryCopyright:

Available Formats

You might also like

- Data Analytics Case Study Q&ADocument3 pagesData Analytics Case Study Q&Agisizzlah54% (13)

- Handbook For Process Safety in Laboratories and Pilot Plants A Risk Based Approach Ccps Center For Chemical Process Safety Full ChapterDocument68 pagesHandbook For Process Safety in Laboratories and Pilot Plants A Risk Based Approach Ccps Center For Chemical Process Safety Full Chapterclinton.choi969100% (6)

- Risk Assessment For Road HaulageDocument4 pagesRisk Assessment For Road Haulagenkem_sunday100% (1)

- En 1050 Risk - AssessmentDocument22 pagesEn 1050 Risk - AssessmentWillian Siqueira Sartori100% (1)

- Question 2 - Toward CertiDocument12 pagesQuestion 2 - Toward CertiFazlee KanNo ratings yet

- Risk Management for Engineering Projects: Procedures, Methods and ToolsFrom EverandRisk Management for Engineering Projects: Procedures, Methods and ToolsNo ratings yet

- Guidelines On Workplace Traffic Safety ManagementDocument22 pagesGuidelines On Workplace Traffic Safety Managementr_sadekarNo ratings yet

- HSE Assignment 3 FinalDocument21 pagesHSE Assignment 3 FinalLuqman HakimNo ratings yet

- Hazards and Effects Management ProcessDocument12 pagesHazards and Effects Management ProcessrwerwerwNo ratings yet

- Safe Work Method StatementDocument2 pagesSafe Work Method Statementbuddyhello1No ratings yet

- Landscape Ecology and Enivornment and EiaDocument26 pagesLandscape Ecology and Enivornment and EiaparvathabaskarNo ratings yet

- The 5 Key Steps in Working Safely at Height in MEWPsDocument2 pagesThe 5 Key Steps in Working Safely at Height in MEWPsDee ReyesNo ratings yet

- E-Fact 02 - Preventing Vehicle Accidents in ConstructionDocument9 pagesE-Fact 02 - Preventing Vehicle Accidents in ConstructionAntonio LeiteNo ratings yet

- Hazard Identification & Risk Assessment (Hira)Document23 pagesHazard Identification & Risk Assessment (Hira)Ked KubenNo ratings yet

- Mobile Elevating Work PlatformsDocument2 pagesMobile Elevating Work PlatformsParmod Rana100% (1)

- Richards Krab 60safety01Document2 pagesRichards Krab 60safety01Anonymous UebIaD8A8CNo ratings yet

- In The Line of Fire Lifting Operations: What's The Risk?Document3 pagesIn The Line of Fire Lifting Operations: What's The Risk?Muhammad KhalidNo ratings yet

- Best Practice Guide For MEWPsDocument33 pagesBest Practice Guide For MEWPsAlbaTraining100% (1)

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

- MEWPsDocument4 pagesMEWPsAivarasNo ratings yet

- Car Parking PDFDocument2 pagesCar Parking PDFSajid HussainNo ratings yet

- Unit 4 HvpeDocument12 pagesUnit 4 HvpeRamNo ratings yet

- Road Haulage Company: Example Risk Assessment For ADocument3 pagesRoad Haulage Company: Example Risk Assessment For ASayed Abbas100% (1)

- Safe Work Method Statement (SWMS) 012-F01Document7 pagesSafe Work Method Statement (SWMS) 012-F01Sokha RunNo ratings yet

- Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For ADocument5 pagesMotor Vehicle Mechanical Repair Workshop: Example Risk Assessment For AKimmy Lyons100% (1)

- Era Motor Vehicle RepairDocument5 pagesEra Motor Vehicle RepairMuhammad Saqib AsifNo ratings yet

- Procena RizikaDocument25 pagesProcena RizikaDave CNo ratings yet

- Safe Use of MEWP 241008Document3 pagesSafe Use of MEWP 241008Ojo OgboadayegbeNo ratings yet

- Risk Assessment and Control For Main Hazards in Reverse Osmosis Desalination PlantsDocument11 pagesRisk Assessment and Control For Main Hazards in Reverse Osmosis Desalination PlantsassurendranNo ratings yet

- Mewp DMDocument20 pagesMewp DMmohanraj2purushothamNo ratings yet

- Indg 383Document20 pagesIndg 383Jose De Jeus MalibranNo ratings yet

- Risk RegisterDocument37 pagesRisk RegisterSufiyan Farooq100% (1)

- Preliminary Hazard AnalysisDocument75 pagesPreliminary Hazard AnalysisDoru ToaderNo ratings yet

- Accident Investigation and Prevention in The WorkplaceDocument14 pagesAccident Investigation and Prevention in The WorkplaceNanang RizalNo ratings yet

- Accident Investigation and Prevention Qatar Mar 21Document14 pagesAccident Investigation and Prevention Qatar Mar 21shamusiNo ratings yet

- Guidance To Operators - Navigational Risk AssessmentDocument9 pagesGuidance To Operators - Navigational Risk AssessmentAleksandr PipchenkoNo ratings yet

- Safe Use of Work PlatformsDocument5 pagesSafe Use of Work PlatformsFrancis Enriquez TanNo ratings yet

- The Use of Hazop Techniques in Applied Hazard ProcessesDocument72 pagesThe Use of Hazop Techniques in Applied Hazard Processesamidi5555913No ratings yet

- Excavation SWMS 1Document8 pagesExcavation SWMS 1azlinaz100% (2)

- WTS Management Info SheetDocument5 pagesWTS Management Info SheetbodZkeeNo ratings yet

- General Guide For Cranes: What Is A Crane?Document18 pagesGeneral Guide For Cranes: What Is A Crane?Eyanya MtilaNo ratings yet

- Anup 000768Document8 pagesAnup 000768rhp1989No ratings yet

- S Barnes: MOD Risk Assessment FormDocument4 pagesS Barnes: MOD Risk Assessment FormRazvan EulNo ratings yet

- Manual Handling 2Document20 pagesManual Handling 2swiezaplesnNo ratings yet

- Practical Alternatives To Using StepladdersDocument18 pagesPractical Alternatives To Using StepladdersBazzer1947No ratings yet

- COSWP-RA GuidanceDocument5 pagesCOSWP-RA Guidancesanu909No ratings yet

- NASCDocument16 pagesNASCbalasubramaniamNo ratings yet

- Unit 4Document55 pagesUnit 4Emmanuel JoshuaNo ratings yet

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 pagesHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineNo ratings yet

- WSH Guidelines On Safe Use of MachineryDocument72 pagesWSH Guidelines On Safe Use of MachinerySofias TrendyNo ratings yet

- Project ReportDocument52 pagesProject ReportShishir DewanganNo ratings yet

- Penyusunan Rencana Manajemen Keselamatan Lalu Lintas Proyek Tol Pandaan - MalangDocument6 pagesPenyusunan Rencana Manajemen Keselamatan Lalu Lintas Proyek Tol Pandaan - MalangicaaaaaaaaaaaaaNo ratings yet

- MH MethodologyDocument7 pagesMH Methodologyimran ahemadNo ratings yet

- NASC SG7 19 Risk Assessments Method Statements RAMSDocument16 pagesNASC SG7 19 Risk Assessments Method Statements RAMSDoru-Mihai VlasNo ratings yet

- Risk Assessmet and Method StatementDocument5 pagesRisk Assessmet and Method StatementDareen BaredNo ratings yet

- SG6 22 Management of Manual Handling in The Scaffolding IndustryDocument16 pagesSG6 22 Management of Manual Handling in The Scaffolding Industryscythe.shooterNo ratings yet

- Guidance Note 018 RAMS Guidance Final 030818Document18 pagesGuidance Note 018 RAMS Guidance Final 030818Vishu KumarNo ratings yet

- Mangement of Road Risk.Document37 pagesMangement of Road Risk.Muhammad AsimNo ratings yet

- Aviation Risk and Safety Management: Methods and Applications in Aviation OrganizationsFrom EverandAviation Risk and Safety Management: Methods and Applications in Aviation OrganizationsNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Adventurer's Guide to Risk Management: Fictional Tales about Risk ManagementFrom EverandAdventurer's Guide to Risk Management: Fictional Tales about Risk ManagementNo ratings yet

- Certified Software Quality Engineer (CSQE) Body of KnowledgeDocument10 pagesCertified Software Quality Engineer (CSQE) Body of KnowledgeMrTheroMorphNo ratings yet

- Ford - Risk TakingDocument13 pagesFord - Risk TakingChloe OberlinNo ratings yet

- Cchem Applicant RequirementsDocument11 pagesCchem Applicant RequirementsbukkysuccessNo ratings yet

- Internal Control QuestionnaireDocument19 pagesInternal Control QuestionnaireIchsanNo ratings yet

- The Technical Basis Forthe NRC's Guidelines Forexternal Risk CommunicationDocument112 pagesThe Technical Basis Forthe NRC's Guidelines Forexternal Risk CommunicationEnformableNo ratings yet

- Appendix EaDocument3 pagesAppendix EaUsman AhmadNo ratings yet

- Center For Information Integrity ResearchDocument23 pagesCenter For Information Integrity ResearchYogesh JadhavNo ratings yet

- BCom Computers CBCSDocument42 pagesBCom Computers CBCSnaganathNo ratings yet

- Final Term Exam: Accounting Information System: Submitted ToDocument9 pagesFinal Term Exam: Accounting Information System: Submitted ToFarjad AliNo ratings yet

- FMI Long Questions EditedDocument7 pagesFMI Long Questions EditedChanna KeshavaNo ratings yet

- Insurance, Definition of InsuranceDocument3 pagesInsurance, Definition of InsuranceRK VermaNo ratings yet

- 5806en PDFDocument94 pages5806en PDFSofian AmaraNo ratings yet

- HSBC Index Tracker Fund Product RangeDocument4 pagesHSBC Index Tracker Fund Product RangeKaushalya-FrankMunroNo ratings yet

- Grand Bargain AgreementDocument16 pagesGrand Bargain AgreementRuby GarciaNo ratings yet

- Why Mutual Fund?: AMFI IAP (Association of Mutual Funds India Investor Awareness Program)Document30 pagesWhy Mutual Fund?: AMFI IAP (Association of Mutual Funds India Investor Awareness Program)swapnil deokarNo ratings yet

- MPIUA FilingDocument184 pagesMPIUA FilingCape Cod TimesNo ratings yet

- Comparation of Audit ApproachDocument1 pageComparation of Audit Approachrio HENRYNo ratings yet

- Ergonomics STDDocument51 pagesErgonomics STDRamesh Maverick100% (1)

- RBI For Power Plants PDFDocument13 pagesRBI For Power Plants PDFOsu AmpawanonNo ratings yet

- Value Engineering VA - VEDocument146 pagesValue Engineering VA - VEactivedeen100% (1)

- CLARIANT March 2024 FY Roadshow Presentation 202403Document56 pagesCLARIANT March 2024 FY Roadshow Presentation 202403leticia.meneguzziNo ratings yet

- Chapter 3 Credit ManagementDocument37 pagesChapter 3 Credit ManagementTwinkle FernandesNo ratings yet

- Organisational Culture and ClimateDocument53 pagesOrganisational Culture and ClimateAzim Samnani100% (3)

- SPM 2 Marks ReferDocument13 pagesSPM 2 Marks ReferpavithrasubburajNo ratings yet

- Thesis On Rewards and Employee PerformanceDocument5 pagesThesis On Rewards and Employee Performancevaj0demok1w2100% (2)

- Pimco Dynamic Multi Asset FundDocument4 pagesPimco Dynamic Multi Asset Fundtgpmfq48trNo ratings yet

Xuwinazawuduloxigabepepen

Xuwinazawuduloxigabepepen

Uploaded by

mohamed elmasryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Xuwinazawuduloxigabepepen

Xuwinazawuduloxigabepepen

Uploaded by

mohamed elmasryCopyright:

Available Formats

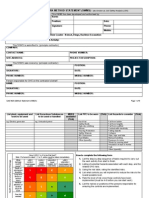

Risk assessment for manlift operation

Using manlift risk assessment. Risk assessment for lifting operation.

20 Planning and preparation are the first steps, starting with safe work: to reduce the risk of accidents and accidents - in order to increase employees' safety and invest in the right procedures than someone will leave the land.

This two -story diary describes the method during the planning process, captured by Manlift security experts - Wim Van Meer and Robert Cavaleri. All working stations should be identified and allowed using potential risks and risks if anyone uses a mobile working platform (MeWP), such as nests with shoulders or scissors.

A comprehensive risk assessment should include the following main areas: at the last minute, it checks the choice of MEWP inspection and assessing the risk of personal protective measures (OOP). Anyone who acquires proper training and experience is also known as a competent person from a legal point of view. Manlift can advise you with the risk

of carrying, but it is very important that the risk assessment actually performs your competent person. You have a legal and moral obligation to carefully assess the risk of the site. This means that employees, colleagues and other suppliers working in the same area can identify and solve potential risks. It also includes determining the potential risk

and risk level of each danger. Risk assessment should be specially applied to each place and application - a universal approach cannot be used. The main stages of risk assessment are: identification of danger - which can harm the decision, what can be damaged and how it can occur as a risk assessment, and take proper preventive measures, make

sure: shallow wells and holes, including those that areMay 20 planning and preparation is the first steps to take place in complete safety: reduce the risk of incidents and accidents - improve the safety of employees and invest in the right procedures before someone leaves work.

This two -part journal describes the approach to the planning process recorded by key security experts Manlift \ xe2 \ x80 \ x99, Wim van Meer and Robert Cavaleri. All jobs must identify possible threats and prevent them before the use of a mobile work platform (PEMP), such as a dart or lifting basket. The threat assessment must cover the following

key areas: Survey on -site and risk assessment of appropriate SME control measures before selecting individual protective equipment (PPE). Last minute test and risk assessment of the site survey and risk assessment and risk assessment should be externally performed. .

A person with appropriate training and experience, also known as a legally competent person. Manlift can make recommendations on the risks to be taken, but it is important that your competent person really has a risk assessment. You have a legal and regulatory obligation to assess the site. It identifies and eliminates potential risks to employees, co

-workers and other subcontractors working in the same area. It also means possible threats and the determination of the risk level of each threat.

The risk assessment must be adapted to each place and application. There is no unique approach. The main stages of the risk assessment are: Identifying the danger - anything that can cause harm. Decide who could be injured and how this could happen. Evaluate the risks and take appropriate precautions. Pay attention to your discoveries. Check

and update your risk assessment regularly. Possible threats to consider: shallow pits and pits, including those hiding water, ice, mud and debris.To ensure you have an emergency rescue plan that includes people in the area, working nearby and training to use a ground control device and emergency response system. To prevent the operator from

being hit on the head by an obstacle, many unwanted lifts and scissors are now equipped with a secondary protective device. There are differences in how these devices work and it is therefore even more important to understand local prevention. This is the key part of risk assessment when it comes to identifying threats caused by overhead objects.

In particular, the environment is constantly evolving. Therefore, be prepared to update your risk assessment if the situation develops, for example if other contractors or construction equipment are working in the same area as your MEWP. Choosing the right MEWP for site investigations and risk assessment allows you to choose the most suitable

MEWP for safe and efficient work at heights. Some of the key considerations are: What is the job? Does the platform work internally or both? What platform and size do you need? How many residents will be in the cart or platform? What size and distance do you need? What are the conditions on the soil or soil surface? Do the operators have adequate

training and qualifications? Are there any obstacles on the ground and in height?

What are the MEWP maintenance requirements? Is it noise pollution or exhaust emissions? The main advantages of choosing an optimal aerial lift are as follows: ensuring the safety of operators and passengers, ensuring the safety of other employees on site, completing the task in the most effective way, reducing the operator's ability to reduce

probability of damage to equipment. For advice on pre-use testing, good PPE selection and last minute checks, read part two of our blog. Vim Van Mayor is a group of Sheq my(MEWP) Spend time creating your organization ** Safe Use Plan **. Read further ...

There are many furniture lifting platforms (MEWP) that operate in northern climate when there is extreme temperature in North America and Europe. Read further ... To get more information about equipment including managers, safe use procedures, hazard estimates and specifications, visit Flexhire Info HUB HUB

You might also like

- Data Analytics Case Study Q&ADocument3 pagesData Analytics Case Study Q&Agisizzlah54% (13)

- Handbook For Process Safety in Laboratories and Pilot Plants A Risk Based Approach Ccps Center For Chemical Process Safety Full ChapterDocument68 pagesHandbook For Process Safety in Laboratories and Pilot Plants A Risk Based Approach Ccps Center For Chemical Process Safety Full Chapterclinton.choi969100% (6)

- Risk Assessment For Road HaulageDocument4 pagesRisk Assessment For Road Haulagenkem_sunday100% (1)

- En 1050 Risk - AssessmentDocument22 pagesEn 1050 Risk - AssessmentWillian Siqueira Sartori100% (1)

- Question 2 - Toward CertiDocument12 pagesQuestion 2 - Toward CertiFazlee KanNo ratings yet

- Risk Management for Engineering Projects: Procedures, Methods and ToolsFrom EverandRisk Management for Engineering Projects: Procedures, Methods and ToolsNo ratings yet

- Guidelines On Workplace Traffic Safety ManagementDocument22 pagesGuidelines On Workplace Traffic Safety Managementr_sadekarNo ratings yet

- HSE Assignment 3 FinalDocument21 pagesHSE Assignment 3 FinalLuqman HakimNo ratings yet

- Hazards and Effects Management ProcessDocument12 pagesHazards and Effects Management ProcessrwerwerwNo ratings yet

- Safe Work Method StatementDocument2 pagesSafe Work Method Statementbuddyhello1No ratings yet

- Landscape Ecology and Enivornment and EiaDocument26 pagesLandscape Ecology and Enivornment and EiaparvathabaskarNo ratings yet

- The 5 Key Steps in Working Safely at Height in MEWPsDocument2 pagesThe 5 Key Steps in Working Safely at Height in MEWPsDee ReyesNo ratings yet

- E-Fact 02 - Preventing Vehicle Accidents in ConstructionDocument9 pagesE-Fact 02 - Preventing Vehicle Accidents in ConstructionAntonio LeiteNo ratings yet

- Hazard Identification & Risk Assessment (Hira)Document23 pagesHazard Identification & Risk Assessment (Hira)Ked KubenNo ratings yet

- Mobile Elevating Work PlatformsDocument2 pagesMobile Elevating Work PlatformsParmod Rana100% (1)

- Richards Krab 60safety01Document2 pagesRichards Krab 60safety01Anonymous UebIaD8A8CNo ratings yet

- In The Line of Fire Lifting Operations: What's The Risk?Document3 pagesIn The Line of Fire Lifting Operations: What's The Risk?Muhammad KhalidNo ratings yet

- Best Practice Guide For MEWPsDocument33 pagesBest Practice Guide For MEWPsAlbaTraining100% (1)

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

- MEWPsDocument4 pagesMEWPsAivarasNo ratings yet

- Car Parking PDFDocument2 pagesCar Parking PDFSajid HussainNo ratings yet

- Unit 4 HvpeDocument12 pagesUnit 4 HvpeRamNo ratings yet

- Road Haulage Company: Example Risk Assessment For ADocument3 pagesRoad Haulage Company: Example Risk Assessment For ASayed Abbas100% (1)

- Safe Work Method Statement (SWMS) 012-F01Document7 pagesSafe Work Method Statement (SWMS) 012-F01Sokha RunNo ratings yet

- Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For ADocument5 pagesMotor Vehicle Mechanical Repair Workshop: Example Risk Assessment For AKimmy Lyons100% (1)

- Era Motor Vehicle RepairDocument5 pagesEra Motor Vehicle RepairMuhammad Saqib AsifNo ratings yet

- Procena RizikaDocument25 pagesProcena RizikaDave CNo ratings yet

- Safe Use of MEWP 241008Document3 pagesSafe Use of MEWP 241008Ojo OgboadayegbeNo ratings yet

- Risk Assessment and Control For Main Hazards in Reverse Osmosis Desalination PlantsDocument11 pagesRisk Assessment and Control For Main Hazards in Reverse Osmosis Desalination PlantsassurendranNo ratings yet

- Mewp DMDocument20 pagesMewp DMmohanraj2purushothamNo ratings yet

- Indg 383Document20 pagesIndg 383Jose De Jeus MalibranNo ratings yet

- Risk RegisterDocument37 pagesRisk RegisterSufiyan Farooq100% (1)

- Preliminary Hazard AnalysisDocument75 pagesPreliminary Hazard AnalysisDoru ToaderNo ratings yet

- Accident Investigation and Prevention in The WorkplaceDocument14 pagesAccident Investigation and Prevention in The WorkplaceNanang RizalNo ratings yet

- Accident Investigation and Prevention Qatar Mar 21Document14 pagesAccident Investigation and Prevention Qatar Mar 21shamusiNo ratings yet

- Guidance To Operators - Navigational Risk AssessmentDocument9 pagesGuidance To Operators - Navigational Risk AssessmentAleksandr PipchenkoNo ratings yet

- Safe Use of Work PlatformsDocument5 pagesSafe Use of Work PlatformsFrancis Enriquez TanNo ratings yet

- The Use of Hazop Techniques in Applied Hazard ProcessesDocument72 pagesThe Use of Hazop Techniques in Applied Hazard Processesamidi5555913No ratings yet

- Excavation SWMS 1Document8 pagesExcavation SWMS 1azlinaz100% (2)

- WTS Management Info SheetDocument5 pagesWTS Management Info SheetbodZkeeNo ratings yet

- General Guide For Cranes: What Is A Crane?Document18 pagesGeneral Guide For Cranes: What Is A Crane?Eyanya MtilaNo ratings yet

- Anup 000768Document8 pagesAnup 000768rhp1989No ratings yet

- S Barnes: MOD Risk Assessment FormDocument4 pagesS Barnes: MOD Risk Assessment FormRazvan EulNo ratings yet

- Manual Handling 2Document20 pagesManual Handling 2swiezaplesnNo ratings yet

- Practical Alternatives To Using StepladdersDocument18 pagesPractical Alternatives To Using StepladdersBazzer1947No ratings yet

- COSWP-RA GuidanceDocument5 pagesCOSWP-RA Guidancesanu909No ratings yet

- NASCDocument16 pagesNASCbalasubramaniamNo ratings yet

- Unit 4Document55 pagesUnit 4Emmanuel JoshuaNo ratings yet

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 pagesHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineNo ratings yet

- WSH Guidelines On Safe Use of MachineryDocument72 pagesWSH Guidelines On Safe Use of MachinerySofias TrendyNo ratings yet

- Project ReportDocument52 pagesProject ReportShishir DewanganNo ratings yet

- Penyusunan Rencana Manajemen Keselamatan Lalu Lintas Proyek Tol Pandaan - MalangDocument6 pagesPenyusunan Rencana Manajemen Keselamatan Lalu Lintas Proyek Tol Pandaan - MalangicaaaaaaaaaaaaaNo ratings yet

- MH MethodologyDocument7 pagesMH Methodologyimran ahemadNo ratings yet

- NASC SG7 19 Risk Assessments Method Statements RAMSDocument16 pagesNASC SG7 19 Risk Assessments Method Statements RAMSDoru-Mihai VlasNo ratings yet

- Risk Assessmet and Method StatementDocument5 pagesRisk Assessmet and Method StatementDareen BaredNo ratings yet

- SG6 22 Management of Manual Handling in The Scaffolding IndustryDocument16 pagesSG6 22 Management of Manual Handling in The Scaffolding Industryscythe.shooterNo ratings yet

- Guidance Note 018 RAMS Guidance Final 030818Document18 pagesGuidance Note 018 RAMS Guidance Final 030818Vishu KumarNo ratings yet

- Mangement of Road Risk.Document37 pagesMangement of Road Risk.Muhammad AsimNo ratings yet

- Aviation Risk and Safety Management: Methods and Applications in Aviation OrganizationsFrom EverandAviation Risk and Safety Management: Methods and Applications in Aviation OrganizationsNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Adventurer's Guide to Risk Management: Fictional Tales about Risk ManagementFrom EverandAdventurer's Guide to Risk Management: Fictional Tales about Risk ManagementNo ratings yet

- Certified Software Quality Engineer (CSQE) Body of KnowledgeDocument10 pagesCertified Software Quality Engineer (CSQE) Body of KnowledgeMrTheroMorphNo ratings yet

- Ford - Risk TakingDocument13 pagesFord - Risk TakingChloe OberlinNo ratings yet

- Cchem Applicant RequirementsDocument11 pagesCchem Applicant RequirementsbukkysuccessNo ratings yet

- Internal Control QuestionnaireDocument19 pagesInternal Control QuestionnaireIchsanNo ratings yet

- The Technical Basis Forthe NRC's Guidelines Forexternal Risk CommunicationDocument112 pagesThe Technical Basis Forthe NRC's Guidelines Forexternal Risk CommunicationEnformableNo ratings yet

- Appendix EaDocument3 pagesAppendix EaUsman AhmadNo ratings yet

- Center For Information Integrity ResearchDocument23 pagesCenter For Information Integrity ResearchYogesh JadhavNo ratings yet

- BCom Computers CBCSDocument42 pagesBCom Computers CBCSnaganathNo ratings yet

- Final Term Exam: Accounting Information System: Submitted ToDocument9 pagesFinal Term Exam: Accounting Information System: Submitted ToFarjad AliNo ratings yet

- FMI Long Questions EditedDocument7 pagesFMI Long Questions EditedChanna KeshavaNo ratings yet

- Insurance, Definition of InsuranceDocument3 pagesInsurance, Definition of InsuranceRK VermaNo ratings yet

- 5806en PDFDocument94 pages5806en PDFSofian AmaraNo ratings yet

- HSBC Index Tracker Fund Product RangeDocument4 pagesHSBC Index Tracker Fund Product RangeKaushalya-FrankMunroNo ratings yet

- Grand Bargain AgreementDocument16 pagesGrand Bargain AgreementRuby GarciaNo ratings yet

- Why Mutual Fund?: AMFI IAP (Association of Mutual Funds India Investor Awareness Program)Document30 pagesWhy Mutual Fund?: AMFI IAP (Association of Mutual Funds India Investor Awareness Program)swapnil deokarNo ratings yet

- MPIUA FilingDocument184 pagesMPIUA FilingCape Cod TimesNo ratings yet

- Comparation of Audit ApproachDocument1 pageComparation of Audit Approachrio HENRYNo ratings yet

- Ergonomics STDDocument51 pagesErgonomics STDRamesh Maverick100% (1)

- RBI For Power Plants PDFDocument13 pagesRBI For Power Plants PDFOsu AmpawanonNo ratings yet

- Value Engineering VA - VEDocument146 pagesValue Engineering VA - VEactivedeen100% (1)

- CLARIANT March 2024 FY Roadshow Presentation 202403Document56 pagesCLARIANT March 2024 FY Roadshow Presentation 202403leticia.meneguzziNo ratings yet

- Chapter 3 Credit ManagementDocument37 pagesChapter 3 Credit ManagementTwinkle FernandesNo ratings yet

- Organisational Culture and ClimateDocument53 pagesOrganisational Culture and ClimateAzim Samnani100% (3)

- SPM 2 Marks ReferDocument13 pagesSPM 2 Marks ReferpavithrasubburajNo ratings yet

- Thesis On Rewards and Employee PerformanceDocument5 pagesThesis On Rewards and Employee Performancevaj0demok1w2100% (2)

- Pimco Dynamic Multi Asset FundDocument4 pagesPimco Dynamic Multi Asset Fundtgpmfq48trNo ratings yet