Professional Documents

Culture Documents

Final Extra Work Boq

Final Extra Work Boq

Uploaded by

chetanjtOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Extra Work Boq

Final Extra Work Boq

Uploaded by

chetanjtCopyright:

Available Formats

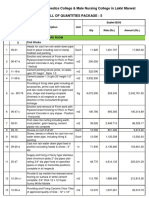

BOQ - Extra Work Bungalow For Mr.

Prasanna

TOTAL 3,80,559.44

SR.N ITEM DESCRIPTION UNIT Additional RATE BOQ AMOUNT

O. Qty

Providing second class Burnt Brick masonry with conventional/ I.S.

type bricks in cement mortar 1:6 in foundations and plinth of inner

1 walls/ in plinth external walls including bailing out water manually , Cumt 6.09 8219.9 50059.191

striking joints on unexposed faces, raking out joints on exposed

faces and watering etc. Complete

Providing sand faced plaster externally in cement mortar using

approved screened sand, in all positions including base coat of 15

mm thick in cement mortar 1:4 using waterproofing compound at

2 1 kg per cement bag curing the same for not less than 2 days and Sqmt 15.9 693.42 11,025.38

keeping the surface of the base coat rough to receive the sand

faced treatment 6 to 8 mm thick in cement mortar 1:4 finishing the

surface by taking out grains and curing for fourteen days

scaffolding etc.complete..

Providing internal cement plaster 12mm thick in single coat in

3. cement mortar 1:4 without neeru Sqmt 27.06 306.31 8,288.75

finish to concrete or brick surfaces, in all positions including

scaffolding and curing etc. complete..

4 Store Room Roof & Duct area (11.02 & 5) Sqmt 16.02

structural steel MT 0.4005 110000 44,055.00

roofing tile Sqmt 16.02 1240 19,864.80

fixing labour Sqmt 16.02 215 3,444.30

Providing and laying Cast in situ/Ready Mix cement concrete M-25

of trap / granite /quartzite/ gneiss metal for R.C.C. columns as per

detailed designs and drawings or as directed including steel

centering, formwork, cover blocks compacting and roughening if

5 special finish is to be provided and curing etc. complete. Cumt 0.6 15081.71 9,049.03

(Excluding reinforcement and structural steel).with fully automatic

micro processor based PLC

with SCADA enabled reversible Drum Type mixer/ concrete Batch

mix plant (Pan mixer) etc. complete. With fine aggregate (

Crushed sand VSI Grade finely washed etc).

Providing and laying Cast in situ/Ready Mix cement concrete M-25

of trap/ granite / quartzite/ gneiss metal for R.C.C. slabs and

landings as per detailed designs and drawings including steel

centering, formwork, cover blocks, compaction, finishing the

formed surfaces with cement mortar 1:3 of sufficient minimum

6 thickness to give a smooth and even surface or roughening if Cumt 6.37 16105.7 1,02,593.31

special finish is to be provided and curing etc.

complete.(Excluding reinforcement and structural steel).with fully

automatic micro processor based PLC with SCADA enabled

reversible Drum Type mixer/ concrete Batch mix plant (Pan mixer)

etc. complete. With fine aggregate ( Crushed sand VSI Grade

finely washed

Providing and etc).

fixing in position TMT - FE - 500 bar reinforcement of

various diameters for R.C.C. pile caps, footings, foundations, slabs,

beams columns, canopies, staircase, newels, chajjas, lintels pardis,

7 copings, fins, arches etc. as per detailed designs, drawings and MT 0.56 76964.2 43099.952

schedules. including cutting, bending, hooking the bars, binding

with wires or tack welding and supporting as required complete.

8 Demolision Work LS 1 25000 25000

10 Providing & Fixing Of Window frame Work SQ.M 17.65 3650 64427.72

11 Extra Exacavtion work CUMT 236.72 210 49711.20

You might also like

- NU - Urban Breach Handbook - TEBCDocument13 pagesNU - Urban Breach Handbook - TEBCiagaruNo ratings yet

- Cooling Tower Inspection ChecklistDocument9 pagesCooling Tower Inspection Checklistmohammed_hatem100% (1)

- BOQ - Extra Work Bungalow For Mr. Prasanna - 25!03!23Document1 pageBOQ - Extra Work Bungalow For Mr. Prasanna - 25!03!23chetanjtNo ratings yet

- Prassanna Sir Bunglow Extra - 25!02!23-R2-FINALDocument9 pagesPrassanna Sir Bunglow Extra - 25!02!23-R2-FINALchetanjtNo ratings yet

- Swimming Pool - VaijyanathDocument11 pagesSwimming Pool - VaijyanathchetanjtNo ratings yet

- Outdoor Kitchen r2 2510Document18 pagesOutdoor Kitchen r2 2510chetanjtNo ratings yet

- Tender CaDocument4 pagesTender CaThatCreepyGuy ForeverNo ratings yet

- Revise - BOQ - FIRST FLOOR TGDocument34 pagesRevise - BOQ - FIRST FLOOR TGdan_geplNo ratings yet

- R.C.C Project Upto Plinth Level: Abstract SheetDocument10 pagesR.C.C Project Upto Plinth Level: Abstract SheetVivÊk Síngh PâlNo ratings yet

- Mr. Prasanna Bungalow DC 150422Document51 pagesMr. Prasanna Bungalow DC 150422chetanjtNo ratings yet

- Ministry of Physical Infrastructure DevelopmentDocument25 pagesMinistry of Physical Infrastructure DevelopmentrahulNo ratings yet

- viewNitPdf 3536507 Part3Document5 pagesviewNitPdf 3536507 Part3pkb_999No ratings yet

- G Load Abstrack Sheet Final MARMIKDocument9 pagesG Load Abstrack Sheet Final MARMIKMarmik JavareNo ratings yet

- Estimate Saraf RashmiDocument12 pagesEstimate Saraf RashmiAbhiraj AbhirajNo ratings yet

- BOQ HouseDocument2 pagesBOQ Housezain Ishaq100% (1)

- Estimate 3Document8 pagesEstimate 3Shrikant KaleNo ratings yet

- Tal. & Dist. Ratnagiri ON C.T.S. 660/5, S. NO. 358 1/5 A 10, FOR MRS. KULKARNI SUREKHA ShrikanthDocument5 pagesTal. & Dist. Ratnagiri ON C.T.S. 660/5, S. NO. 358 1/5 A 10, FOR MRS. KULKARNI SUREKHA ShrikanthSojwal VelyeNo ratings yet

- CL 38-02 BillDocument1 pageCL 38-02 Billvishal bhiseNo ratings yet

- 1-Factory Shed 5.8.21Document72 pages1-Factory Shed 5.8.21Harsh Bhavsar100% (1)

- Abstract EstimateDocument5 pagesAbstract EstimateAB XEROXNo ratings yet

- EWS PintalDocument2 pagesEWS PintaljitendraNo ratings yet

- CHINMAYA MissionDocument7 pagesCHINMAYA Missionakhil joshyNo ratings yet

- Estimate 2Document11 pagesEstimate 2Shrikant KaleNo ratings yet

- Chinmaya MissionDocument26 pagesChinmaya Missionakhil joshyNo ratings yet

- Measurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 TotalDocument19 pagesMeasurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 Totaldan12345_007No ratings yet

- Proposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IDocument27 pagesProposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IHusen GhoriNo ratings yet

- Boq For Barra - Ii S.N. Description Unit QTY Rate AmountDocument8 pagesBoq For Barra - Ii S.N. Description Unit QTY Rate AmountManish SinghNo ratings yet

- Noida - Chauganpur AnganbadiDocument5 pagesNoida - Chauganpur AnganbadiManish SinghNo ratings yet

- Lakki College Pkg-5 Main Gate & Guard RoomDocument11 pagesLakki College Pkg-5 Main Gate & Guard RoomFarhan AshrafNo ratings yet

- BOQDocument25 pagesBOQBILAL HAJINo ratings yet

- NEW Estimate D.S.R. of Law CollegeDocument28 pagesNEW Estimate D.S.R. of Law Collegerony bhandNo ratings yet

- Estimation of Boundary Wall at Rajshahi.Document3 pagesEstimation of Boundary Wall at Rajshahi.HabibNo ratings yet

- Abstract Sheet For, Proposed Construction of Bhaktniwas, at Paithan, Dis AurangabadDocument51 pagesAbstract Sheet For, Proposed Construction of Bhaktniwas, at Paithan, Dis AurangabadShaikh ImranNo ratings yet

- SR - No. Description Rate UnitDocument52 pagesSR - No. Description Rate UnitSumit JainNo ratings yet

- Quatation - 05.12.09Document8 pagesQuatation - 05.12.09Jason Fisher100% (1)

- JetithorDocument8 pagesJetithorRupesh HundeNo ratings yet

- Boq For Proposed Rooms and Resturant at Tah.-Kamptee, Dist.-Nagpur. Belonging To: - Mr. Sumit Agarwal and MR - Ramji SharmaDocument3 pagesBoq For Proposed Rooms and Resturant at Tah.-Kamptee, Dist.-Nagpur. Belonging To: - Mr. Sumit Agarwal and MR - Ramji SharmaAnkishaBhendeNo ratings yet

- 22c871 3Document35 pages22c871 3shubham kumarNo ratings yet

- Nanoshi Samajik SabhagrahDocument4 pagesNanoshi Samajik SabhagrahAkshay NaikNo ratings yet

- Control Room at OHTDocument12 pagesControl Room at OHTTechnowisdom ConsultantsNo ratings yet

- Rate For Chemical StoreDocument8 pagesRate For Chemical Storeabdullah rahmanNo ratings yet

- Abstract Sheet - Ap Sir - MR Tambve Sir PDF 2Document7 pagesAbstract Sheet - Ap Sir - MR Tambve Sir PDF 2sabale xeroxNo ratings yet

- JSR UpdatedDocument23 pagesJSR UpdatedFullertron IndiaNo ratings yet

- Schedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDocument2 pagesSchedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDada Chandan Das A&R DevelopersNo ratings yet

- Provn of 02x TRG Shed at 21 GNRDocument9 pagesProvn of 02x TRG Shed at 21 GNRdevdutt sharmaNo ratings yet

- AbstractDocument4 pagesAbstractShaikh ImranNo ratings yet

- Abstract Sheet 2Document12 pagesAbstract Sheet 2Shravan NigadeNo ratings yet

- Schedule BDocument43 pagesSchedule Bhardik sorathiyaNo ratings yet

- 20-Ce-190 Bill of QuantitiesDocument7 pages20-Ce-190 Bill of QuantitiesEng TariqNo ratings yet

- Po SM InfraDocument5 pagesPo SM InfraAvi DantkaleNo ratings yet

- Parking Shed Quotation RV00Document2 pagesParking Shed Quotation RV00venky 934No ratings yet

- 1 - Comilla Lot1-02 BOQ BrahmanbariaDocument28 pages1 - Comilla Lot1-02 BOQ BrahmanbariajgnmoqjidncpobeimuNo ratings yet

- 1.HQ Building - 03.01.2022 - STR - Compound Wall AbDocument2 pages1.HQ Building - 03.01.2022 - STR - Compound Wall Abnitesh.salvi12No ratings yet

- Takhat E Akbari BoqDocument14 pagesTakhat E Akbari Boqsubcircle amritsarNo ratings yet

- Detailed Estimate, Fire TankDocument2 pagesDetailed Estimate, Fire Tankanish kvNo ratings yet

- EstimationDocument4 pagesEstimationArif AbbihalNo ratings yet

- Bab-E-Pakistan Complex Project Walton Lahore: Construction of New Masjid (1-No)Document36 pagesBab-E-Pakistan Complex Project Walton Lahore: Construction of New Masjid (1-No)muhammad iqbalNo ratings yet

- Lakki College Pkg-5 InfrastructureDocument24 pagesLakki College Pkg-5 InfrastructureFarhan AshrafNo ratings yet

- BOQ MS StaircaseDocument1 pageBOQ MS StaircaseSajid AliNo ratings yet

- Lift Core at BaddaDocument2 pagesLift Core at BaddaMasud AbidNo ratings yet

- Super Final MH ESTIMATEDocument214 pagesSuper Final MH ESTIMATEIshor ThapaNo ratings yet

- The RhythmDocument5 pagesThe RhythmchetanjtNo ratings yet

- Sale Area StatementDocument1 pageSale Area StatementchetanjtNo ratings yet

- Outdoor Kitchen r2 2510Document18 pagesOutdoor Kitchen r2 2510chetanjtNo ratings yet

- Swimming Pool - VaijyanathDocument11 pagesSwimming Pool - VaijyanathchetanjtNo ratings yet

- Bhakti Brick Jali CatalougeDocument19 pagesBhakti Brick Jali CatalougechetanjtNo ratings yet

- Break To God's Own Country Kerala - Revised 1Document9 pagesBreak To God's Own Country Kerala - Revised 1chetanjtNo ratings yet

- Booklet - Religeous Use Masjid 1685537115859Document49 pagesBooklet - Religeous Use Masjid 1685537115859chetanjtNo ratings yet

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- Oxford One Earth FRW Parking Lobby MS Door BOQDocument2 pagesOxford One Earth FRW Parking Lobby MS Door BOQRohit KumarNo ratings yet

- INTERNSHIPDocument31 pagesINTERNSHIPStalan JonathanNo ratings yet

- Flexural Strength Masonry PrismsDocument10 pagesFlexural Strength Masonry PrismsMuhammadAboubakarFarooqNo ratings yet

- BLEEDINGDocument2 pagesBLEEDINGbookNo ratings yet

- 3 Bedroom Flat Quotation For Dupe-1Document2 pages3 Bedroom Flat Quotation For Dupe-1Amos EmmanuelNo ratings yet

- Draft 3rd Revision of IRC-8 - Type Design For Distance Markers On Roads and HighwaysDocument15 pagesDraft 3rd Revision of IRC-8 - Type Design For Distance Markers On Roads and HighwaysPERNo ratings yet

- Vol 3 - MEP SpecsDocument119 pagesVol 3 - MEP SpecsAbdulaziz Al-FarsiNo ratings yet

- Topm Fit-Out GuidelinesDocument31 pagesTopm Fit-Out GuidelinesJohn Ian Avanzado InocencioNo ratings yet

- Creaton Pv-Autarq. Solar Roof Tiles Powered by Autarq.: All Benefits at A GlanceDocument2 pagesCreaton Pv-Autarq. Solar Roof Tiles Powered by Autarq.: All Benefits at A GlanceMatteo FrongilloNo ratings yet

- Geofill LD Abandonment SpecDocument3 pagesGeofill LD Abandonment SpecMerluza, Ullys M.No ratings yet

- Design of Bamboo Reinforced Concrete Water TankDocument5 pagesDesign of Bamboo Reinforced Concrete Water TankkalpanaadhiNo ratings yet

- BS 1722-10 1999Document29 pagesBS 1722-10 1999thushtikaNo ratings yet

- Interlocking & Curb Stone Rev.1Document3 pagesInterlocking & Curb Stone Rev.1Shaddy Joseph Endrawes100% (1)

- KONE TranSys DX Visual Options-Factsheet Soisof 222-WEB tcm59-86413Document2 pagesKONE TranSys DX Visual Options-Factsheet Soisof 222-WEB tcm59-86413YANETH ALCANTARANo ratings yet

- Medium and Techniques of The ArtDocument10 pagesMedium and Techniques of The ArtprincessyeshacNo ratings yet

- Tribal Museum BhopalDocument1 pageTribal Museum Bhopalrakshitha bandiNo ratings yet

- What Is ScaffoldDocument47 pagesWhat Is Scaffoldkolli.99995891No ratings yet

- www.P65Warnings - Ca.gov www.P65Warnings - Ca.gov www.P65Warnings - Ca.govDocument1 pagewww.P65Warnings - Ca.gov www.P65Warnings - Ca.gov www.P65Warnings - Ca.govhrithikvNo ratings yet

- English Wordmeanings Class 12 SDCDocument24 pagesEnglish Wordmeanings Class 12 SDCDIPANSHU PRASADNo ratings yet

- PT. Bondor IndonesiaDocument27 pagesPT. Bondor Indonesiabangun.budiono.spotifyNo ratings yet

- DEC Infrastructure Projects India PVT LtdTrial Balance577448Document943 pagesDEC Infrastructure Projects India PVT LtdTrial Balance577448DEC InfraNo ratings yet

- 06 ME 36A/ 06 ME 46A: Model Question PaperDocument2 pages06 ME 36A/ 06 ME 46A: Model Question PaperRavi karanNo ratings yet

- User Manual: International Industry of Metallic Formwork SystemsDocument9 pagesUser Manual: International Industry of Metallic Formwork Systemsjachoijachoi100% (1)

- Preparation: Bill of MaterialsDocument8 pagesPreparation: Bill of MaterialsJJ TevesNo ratings yet

- CSI Color Hardener: Technical Data Sheet 1.0509DSDocument2 pagesCSI Color Hardener: Technical Data Sheet 1.0509DSAyman MohamedNo ratings yet

- Slab On GradeDocument2 pagesSlab On GradeVistash Buhary100% (1)

- Chapter 1 Fundamentals Concrete TechnologyDocument50 pagesChapter 1 Fundamentals Concrete Technologyaman sudiNo ratings yet