Professional Documents

Culture Documents

IngersollRand T30

IngersollRand T30

Uploaded by

SERGIO CELIS ARIZAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IngersollRand T30

IngersollRand T30

Uploaded by

SERGIO CELIS ARIZACopyright:

Available Formats

Type 30 Reciprocating Compressors

The Ingersoll Rand Type 30 was introduced in 1929 and is still one of the world Specifications

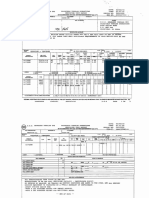

Model Motor Pressure Receiver Piston Dimensions Weight

leaders in heavy duty applications, where reliability, efficiency, durability and Max Displacement cm

kW hp bar g Litres l/min cfm LxWxH kg

maintenance are of paramount importance to the customer. Value Package

T30/200/3 V 2.2 3.0 11 200 290 10.2 162 x 68 x 122 140

T30/X/3 V 2.2 3.0 14 - 290 10.2 125 x 80 x 85 90

T30/200/4 V 3.0 4.0 11 200 387 13.7 162 x 68 x 122 145

T30/X/4 V 3.0 4.0 14 - 362 12.8 125 x 80 x 85 95

T30/200/5.5 V 4.0 5.5 11 200 523 18.5 162 x 68 x 122 170

2-Stage Lubricated T30/X/5.5 V 4.0 5.5 14 - 523 18.5 125 x 80 x 85 115

Designed for heavy shop or industrial use, such as automotive service and T30/200/7.5 V 5.5 7.5 11 200 702 24.8 162 x 68 x 122 180

T30/X/7.5 V 5.5 7.5 14 - 657 23.2 125 x 80 x 85 135

body shops, machine shops, construction, car washes and manufacturing

T30/200/10 V 7.5 10.0 11 200 1013 35.8 162 x 80 x 145 235

lines, Ingersoll Rand’s T30 2-stage lubricated compressors, with their cast T30/X/10 V 7.5 10.0 14 - 1013 35.8 125 x 80 x 85 185

iron cylinders, provide the quality and performance that are required in T30/500/15 V 11.0 15.0 11 500 1441 50.9 210 x 90 x 165 425

T30/X/15 V 11.0 15.0 14 - 1292 45.6 155 x 85 x 110 295

these applications. T30/500/20 V 15.0 20.0 11 500 1713 60.5 210 x 90 x 165 435

T30/X/20 V 15.0 20.0 14 - 1713 60.5 155 x 85 x 110 300

T30/500/25 V 18.5 25.0 11 500 2620 92.5 210 x 90 x 165 580

T30/X/25 V 18.5 25.0 14 - 2620 92.5 155 x 85 x 110 460

T30/500/30 V 22.0 30.0 11 500 2932 103.5 210 x 90 x 165 600

T30/X/30 V 22.0 30.0 14 - 2932 103.5 155 x 85 x 110 480

Premium Package

T30/200/3 P 2.2 3.0 11 200 290 10.2 162 x 78 x 122 180

T30/X/3 P 2.2 3.0 14 - 290 10.2 125 x 95 x 85 130

T30/200/4 P 3.0 4.0 11 200 387 13.7 162 x 78 x 122 195

T30/X/4 P 3.0 4.0 14 - 362 12.8 125 x 95 x 85 145

T30/200/5.5 P 4.0 5.5 11 200 523 18.5 162 x 68 x 122 220

T30/X/5.5 P 4.0 5.5 14 - 523 18.5 125 x 95 x 85 165

T30/200/7.5 P 5.5 7.5 11 200 702 24.8 162 x 68 x 122 230

T30/X/7.5 P 5.5 7.5 14 - 657 23.2 125 x 95 x 85 185

T30/200/10 P 7.5 10.0 11 200 1013 35.8 162 x 80 x 145 300

T30/X/10 P 7.5 10.0 14 - 1013 35.8 125 x 95 x 85 250

T30/500/15 P 11.0 15.0 11 500 1441 50.9 210 x 90 x 165 500

T30/X/15 P 11.0 15.0 14 - 1292 45.6 155 x 100 x 110 370

The T30 2-stage lubricated range comprises of Value and Premium packages, T30/500/20 P 15.0 20.0 11 500 1713 60.5 210 x 90 x 165 510

making choosing the correct machine and configuration even easier to suit T30/X/20 P 15.0 20.0 14 - 1713 60.5 155 x 100 x 110 375

T30/500/25 P 18.5 25.0 11 500 2620 92.5 210 x 90 x 165 655

your customer’s requirements. Both packages come in either an 11 bar g T30/X/25 P 18.5 25.0 14 - 2620 92.5 155 x 100 x 110 535

receiver mounted or 14 bar g base-mounted configuration. T30/500/30 P 22.0 30.0 11 500 2932 103.5 210 x 90 x 165 675

T30/X/30 P 22.0 30.0 14 - 2932 103.5 155 x 100 x 110 555

The Value package provides an economic and dependable solution for

those customers simply focused on a reliable compressed air solution

and is ideal for commercial, automotive and light industrial applications.

The Premium package enhances durability and performance by offering

all the features of the Value package plus a number of additional features

that provide increased reliability, lower maintenance and an overall Totally dependable in the most

higher quality of performance. The additional features include an

air-cooled aftercooler, low oil level switch and an auto-condensate drain

demanding and exacting environments.

(on receiver mounted units) that make the Premium package ideally

suited for manufacturing and more heavy duty industrial applications.

8 Continually Moving Forward Continually Moving Forward 9

High Pressure Non-lubricated

The Ingersoll Rand T30 high pressure units, used in industries such as refuelling Ingersoll Rand T30 Non-lubricated piston compressors, used in industries such

stations, beverage plants, power stations and engine starting, are a series of as textiles, packaging and chemical, do not have oil in the cylinders and are

base-mounted piston compressors that can provide your customer with designed for applications where air free from oil is required. The non-lubricated

pressures as high as 345 bar g. Consistent with the 2-stage lubricated range, units use Teflon rings and rider bands to achieve cooling in the compression area.

the high pressure units offer reliability, durability and ease of maintenance. The T30 non-lubricated compressor is available in both receiver mounted and

base-mounted configurations.

Specifications Specifications

Model Bare Motor Pressure Receiver Piston Revolutions Dimensions Weight Model Bare Motor Pressure Receiver Piston Revolutions Dimensions Weight

Unit Max Displacement per minute LxWxH Unit Max Displacement per minute LxWxH

kW hp bar g Litres l/min rpm cm kg kW hp bar g Litres l/min rpm cm kg

High Pressure Non-lubricated

231X30 231 2.2 3.0 35 N/A 211 670 87 x 51 x 51 100 23ANLE20 23ANL 1.5 2.0 6.9 200 230 730 137 x 51 x 108 170

7T2X100 7T2 8.5 12.5 35 N/A 1050 820 124 x 67 x 84 275 235HNLE30 235HNL 2.2 3.0 6.9 200 310 490 143 x 54 x 107 210

15T2X200-35 15T2 15 20 35 N/A 1471 950 143 x 84 x 87 415 235HNLF40 235HNL 3.0 4.0 6.9 270 450 710 146 x 54 x 111 232

15T2X200-70 15T2 15 20 70 N/A 1230 790 143 x 84 x 87 415 5T2NLH100 5T2NL 7.5 10 8.6 500 1010 900 187 x 63 x 153 475

15T4X200 15T4 15 20 241 N/A 988 930 150 x 78 x 108 505 10T3NLH150 10T3NL 11 15 8.6 500 1500 670 187 x 69 x 192 615

H15T4X200 H15T4 15 20 345 N/A 988 930 150 x 78 x 108 525 10T3NLH200 10T3NL 15 20 8.6 500 2000 890 187 x 69 x 192 630

23ANLX20 23ANL 1.5 2.0 6.9 N/A 230 730 80 x 48 x 59 84

235HNLX30 235HNL 2.2 3.0 6.9 N/A 310 490 92 x 56 x 58 127

235HNLX40 235HNL 3.0 4.0 6.9 N/A 450 710 92 x 56 x 58 127

Oil-less 5T2NLX55 5T2NL 4.0 5.5 8.6 N/A 640 570 128 x 63 x 82 227

Ingersoll Rand T30 Oil-less compressors are designed for the tough 5T2NLX100 5T2NL 7.5 10 8.6 N/A 1010 900 128 x 63 x 82 252

10T3NLX150 10T3NL 11 15 8.6 N/A 1500 670 154 x 79 x 115 360

requirements of industries demanding oil-free air such as pharmaceuticals,

10T3NLX200 10T3NL 15 20 8.6 N/A 2000 890 154 x 79 x 115 380

electronics, medical and food processing. T30 Oil-less compressors do not

have oil in the system and cooling is carried out by using special materials, Vacuum

ensuring 100% oil-free air for your customers application. The higher Ingersoll Rand T30 Vacuum compressors are designed for vacuum

investment costs of an Oil-less compressor are repaid due to the lower applications such as food packaging, processing plants, vacuum cleaning

running costs of the complete compression system, including maintenance, and printing industries.

supervision and also during operation, with downtime virtually eliminated.

A maximum vacuum of over 99% (754 mm Hg) is available with these units,

T30 Oil-less compressors are available in both receiver mounted and

depending on customer requirements. Units are available in a base-mounted

base-mounted configurations.

configuration only.

Specifications Specifications

Model Bare Motor Pressure Receiver Piston Revolutions Dimensions Model Bare Motor Vacuum Receiver Piston Revolutions Dimensions Weight

Unit Max Displacement per minute LxWxH Unit Max Displacement per minute LxWxH

kW hp bar g Litres l/min rpm cm kW hp mm Hg bar g Litres l/min rpm cm kg

Oil-less Vacuum

OL5F55 OL5 4.0 5.5 8.6 270 690 820 146 x 64 x 112 V235X20 V235 1.5 2.0 737 97.0 - 510 790 83 x 46 x 48 95

OL5X55 OL5 4.0 5.5 8.6 - 690 820 106 x 54 x 59 V235TX20 V235T 1.5 2.0 752 98.9 - 255 790 83 x 46 x 48 95

OL5F75 OL5 5.5 7.5 8.6 270 930 1100 146 x 64 x 112 V244X30 V244 2.2 3.0 737 97.0 - 900 790 88 x 56 x 53 148

OL5X75 OL5 5.5 7.5 8.6 - 930 1100 106 x 54 x 59 V244TX30 V244T 2.2 3.0 753 99.1 - 450 790 88 x 56 x 53 148

OL10H100 OL10 7.5 10 8.6 500 1430 1135 187 x 70 x 129 V255X55 V255 4.0 5.5 737 97.0 - 1730 770 92 x 63 x 61 173

OL10X100 OL10 7.5 10 8.6 - 1430 1135 128 x 66 x 65 V255TX55 V255T 4.0 5.5 754 99.2 - 870 770 92 x 63 x 61 173

OL15H200 OL15 15 20 8.6 500 1900 945 187 x 70 x 129 7VX75 7V 5.5 7.5 737 97.0 - 2800 900 122 x 65 x 72 260

OL15X200 OL15 15 20 8.6 - 1900 945 128 x 66 x 65 7VTX75 7VT 5.5 7.5 753 99.1 - 1400 900 122 x 65 x 72 260

OL25VH300 OL25 22 30 8.6 500 3300 1100 220 x 115 x 216 15VX100 15V 7.5 10 742 97.0 - 3600 770 137 x 79 x 88 325

OL25X300 OL25 22 30 8.6 - 3300 1100 185 x 94 x 116 15VTX100 15VT 7.5 10 754 99.2 - 2400 770 137 x 79 x 88 325

10 Continually Moving Forward Continually Moving Forward 11

You might also like

- Kubota Bx2200 Exploded Parts ManualDocument266 pagesKubota Bx2200 Exploded Parts Manualgregfortkamp75% (28)

- Essential Statistics 1st Edition by Navidi and Monk ISBN Test BankDocument41 pagesEssential Statistics 1st Edition by Navidi and Monk ISBN Test Banknancy100% (31)

- 380engine Parts ManualDocument108 pages380engine Parts Manualkokila infraltdNo ratings yet

- Daikin ASP 31-29 All Products Data-Performance CatalogDocument156 pagesDaikin ASP 31-29 All Products Data-Performance CatalogGiang Nguyễn HươngNo ratings yet

- Technical Data Sheet 15cdv6Document2 pagesTechnical Data Sheet 15cdv6mahmood750No ratings yet

- HHF-1600HL Mud PumpDocument7 pagesHHF-1600HL Mud PumpSERGIO CELIS ARIZA100% (1)

- 2018 Book ModernAgeEnvironmentalProblems PDFDocument244 pages2018 Book ModernAgeEnvironmentalProblems PDFJINA MARCELA MARTINEZ LARANo ratings yet

- MAXAM-Mining-Catalog-02 2021 v2 LoResDocument20 pagesMAXAM-Mining-Catalog-02 2021 v2 LoResQaibak safarNo ratings yet

- Off-Highway Tyre SolutionsDocument9 pagesOff-Highway Tyre SolutionsJamal HabbasNo ratings yet

- BATISTA Produtos NovosDocument3 pagesBATISTA Produtos NovosTruck Center ModeloNo ratings yet

- Fisher - Anchor Bolt FAZDocument9 pagesFisher - Anchor Bolt FAZlazar_maria18No ratings yet

- Tubular Frame Power Unit D & 10 SeriesDocument4 pagesTubular Frame Power Unit D & 10 SeriesluisedonossaNo ratings yet

- Cellpack Cross Section Table DINA5 ENDocument2 pagesCellpack Cross Section Table DINA5 ENHadiNo ratings yet

- SNT Autopart Oil Seal Catalog For HINODocument53 pagesSNT Autopart Oil Seal Catalog For HINOpaatgeral15No ratings yet

- TeDa HMDocument1 pageTeDa HMChachou MohamedNo ratings yet

- Combibox Program Schedule: AttachmentsDocument8 pagesCombibox Program Schedule: AttachmentsremeenNo ratings yet

- Size Rating Type Rim O.D. S.W. T.D. Tread Compound TMPH/ TKPH Infl. P. L.C.C. L.IDocument1 pageSize Rating Type Rim O.D. S.W. T.D. Tread Compound TMPH/ TKPH Infl. P. L.C.C. L.IHilman X FajarNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- TRELLEBORG Pneumatic T 900 English PDFDocument2 pagesTRELLEBORG Pneumatic T 900 English PDFMaynor RuizNo ratings yet

- I Ec Quick Reference Dimensional ChartDocument2 pagesI Ec Quick Reference Dimensional ChartGamma RohkmatullohNo ratings yet

- Tabela TorqueDocument2 pagesTabela TorqueFlorin DumbravaNo ratings yet

- HY13 1590 010 TE SeriesDocument30 pagesHY13 1590 010 TE SeriesCarlos Augusto Oliveira DrapeNo ratings yet

- LINERDocument78 pagesLINEREleazar PavonNo ratings yet

- Parker TC-SeriesDocument18 pagesParker TC-SeriesSam MarmorNo ratings yet

- Installation Note: Valid For: DN Part NumberDocument4 pagesInstallation Note: Valid For: DN Part NumberJhonny Mayo RodriguezNo ratings yet

- PROJECT: Habit Burger Subject: Date: 8/31/2019Document2 pagesPROJECT: Habit Burger Subject: Date: 8/31/2019muth sokvisalNo ratings yet

- Torque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteDocument6 pagesTorque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteEsraa HarazNo ratings yet

- Three Phase Electric MotorsDocument10 pagesThree Phase Electric MotorsFaye KimNo ratings yet

- Heavy Duty Diesel1Document2 pagesHeavy Duty Diesel1Rolando GuijarroNo ratings yet

- Zaranda en CascadaDocument2 pagesZaranda en CascadaJuan Gabriel Galvis ZuluagaNo ratings yet

- CMD CouplingsDocument45 pagesCMD CouplingsSalgado_e_BentoNo ratings yet

- Catalogo 2022 Itr PneusDocument82 pagesCatalogo 2022 Itr PneusRonaldo Pereira CostaNo ratings yet

- Cricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Document2 pagesCricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Dwi Agus DermawanNo ratings yet

- Amafilter Cricketfilter For Wet Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Wet Cake Discharge 20210414virus40No ratings yet

- Shield Vibration Isolaion Product SheetDocument19 pagesShield Vibration Isolaion Product SheetVikin WangNo ratings yet

- Poro : For Groups With Spacer Coupling Add TD Dimensidn " M " Ond "E " The Oimensidn XDocument1 pagePoro : For Groups With Spacer Coupling Add TD Dimensidn " M " Ond "E " The Oimensidn XGUIVER3577No ratings yet

- Lote Pecas - Suspensao PDFDocument1 pageLote Pecas - Suspensao PDFtoninhomelotti_53173No ratings yet

- Suyesh Foundry Pvt. LTD.: Vendorwise Defectwise Rejection Summary From 01-May-24 To 31-May-24Document1 pageSuyesh Foundry Pvt. LTD.: Vendorwise Defectwise Rejection Summary From 01-May-24 To 31-May-24aniket patilNo ratings yet

- Submersible Agitator Pumps: Toyo DPDocument2 pagesSubmersible Agitator Pumps: Toyo DPBasit Edu0% (1)

- Portable Hose Hydro Test PumpDocument2 pagesPortable Hose Hydro Test PumpkamaraniNo ratings yet

- Elektra S EngDocument9 pagesElektra S Engnarendra kumarNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- Block Roller 2Document1 pageBlock Roller 2Juan Ismael Grave LolNo ratings yet

- SMT Power Inductor: HMR1042B, 1045, 1050, 1055 & 1075B TypeDocument1 pageSMT Power Inductor: HMR1042B, 1045, 1050, 1055 & 1075B TypeSilvio SchwanckNo ratings yet

- BRK Applicable Excavator KTR 02Document3 pagesBRK Applicable Excavator KTR 02Frans BobyNo ratings yet

- Kei Wire Flex List Price 27-5-2024Document8 pagesKei Wire Flex List Price 27-5-2024Skyhill EnterprisesNo ratings yet

- 100 Ton JPBR - 1030 ManualDocument19 pages100 Ton JPBR - 1030 ManualKanul RiyazNo ratings yet

- Copper Tubes, Coils & Solder Fittings (Inch & Metric)Document43 pagesCopper Tubes, Coils & Solder Fittings (Inch & Metric)dffgfdg dfgdgNo ratings yet

- Bond Formula Calculation: Ultratech Cemco Awarpur Cement Mill-1Document1 pageBond Formula Calculation: Ultratech Cemco Awarpur Cement Mill-1anand singhNo ratings yet

- Lista Catalogo Discos de Freno Corven ExcelDocument22 pagesLista Catalogo Discos de Freno Corven ExcelMundo RepuestosNo ratings yet

- 3 Way Electrical Control Valve: TYPE 7562EDocument13 pages3 Way Electrical Control Valve: TYPE 7562EAhmed EmamNo ratings yet

- Elektra 315 EngDocument8 pagesElektra 315 EngNitesh SinghNo ratings yet

- FRAD - Putnicki ProgramDocument152 pagesFRAD - Putnicki ProgramBoban TimotijevicNo ratings yet

- Suyesh Foundry Pvt. LTD.: Vendorwise Defectwise Rejection Summary From 01-Apr-24 To 30-Apr-24Document1 pageSuyesh Foundry Pvt. LTD.: Vendorwise Defectwise Rejection Summary From 01-Apr-24 To 30-Apr-24aniket patilNo ratings yet

- Parker TB Series CatalogDocument26 pagesParker TB Series CatalogLuka JelovčanNo ratings yet

- Accutherm Riello Gi Emme 300 - 900 Series Package Dual Fuel Burner 130930105241Document8 pagesAccutherm Riello Gi Emme 300 - 900 Series Package Dual Fuel Burner 130930105241Ruben David Ibañez RetamalNo ratings yet

- Solideal 4L I3Document2 pagesSolideal 4L I3Benjamin romeroNo ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- JCB 3CX 4 S MasterDocument24 pagesJCB 3CX 4 S MasterManuals Catalogs100% (2)

- M/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsDocument8 pagesM/1000 Heavy Duty Cylinders, Double Acting: Medium: Operating Pressure: Operating Temperature: MaterialsBahador YazdiNo ratings yet

- Lista de Precios Cauchos FGDocument1 pageLista de Precios Cauchos FGMiriam GonzálezNo ratings yet

- 5555555555555Document46 pages5555555555555Tommy CamposNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Certified Test Report Date Time: Serial NoDocument5 pagesCertified Test Report Date Time: Serial NoSERGIO CELIS ARIZANo ratings yet

- CAM218780565 140 PROMAX Premium Hydraulic AW46 Product Bulletin PDFDocument2 pagesCAM218780565 140 PROMAX Premium Hydraulic AW46 Product Bulletin PDFSERGIO CELIS ARIZANo ratings yet

- DataSheet TD2Document2 pagesDataSheet TD2SERGIO CELIS ARIZANo ratings yet

- Api 602Document52 pagesApi 602SERGIO CELIS ARIZANo ratings yet

- Financial Analysis of Hero CyclesDocument106 pagesFinancial Analysis of Hero CyclesD Attitude Kid50% (12)

- Consumable Parts Doosan DX800Document2 pagesConsumable Parts Doosan DX800Adi MNo ratings yet

- Layout of AutomobileDocument3 pagesLayout of AutomobileTyler Derdun33% (3)

- Og 23 2203 1801 00005279Document16 pagesOg 23 2203 1801 00005279Mahika PardeshiNo ratings yet

- 07-Feed dx680Document56 pages07-Feed dx680pedrojrandrade100% (1)

- T135HC Jupiter-Mx Stand & FootrestDocument2 pagesT135HC Jupiter-Mx Stand & FootresterikanandaNo ratings yet

- Tractor Lift / Lower Control Installation & Instruction ManualDocument10 pagesTractor Lift / Lower Control Installation & Instruction ManualLina Delgado OsorioNo ratings yet

- ترموستاتDocument6 pagesترموستاتali chivaeiNo ratings yet

- Polovne GumeDocument6 pagesPolovne GumeNikolaNo ratings yet

- 412CRO412CROCH63Document468 pages412CRO412CROCH63252nd PAS100% (1)

- Cessna Emergency Rescue Access and Fire Fighting Procedures - PropjetDocument16 pagesCessna Emergency Rescue Access and Fire Fighting Procedures - PropjetMaurice FiechterNo ratings yet

- SP18-02 SSH SSV Split Shaft PTO ServiceDocument20 pagesSP18-02 SSH SSV Split Shaft PTO ServiceABEL FRANCISCO NAVAS NAJERANo ratings yet

- Koganei Air-Piloted Valves FeaturesDocument4 pagesKoganei Air-Piloted Valves Featuresluthfie4uNo ratings yet

- Bloque de MotorDocument4 pagesBloque de MotorJackson GiraldoNo ratings yet

- Service Letter SL2018-664/PRP: Risk of Breakage of Cylinder Liner Lifting ToolDocument22 pagesService Letter SL2018-664/PRP: Risk of Breakage of Cylinder Liner Lifting ToolWing On WongNo ratings yet

- John Pump CharacheristicDocument20 pagesJohn Pump CharacheristicjohnNo ratings yet

- GLA45AMG 156 133 Oil ChangeDocument2 pagesGLA45AMG 156 133 Oil ChangeJoan Callau FuentesNo ratings yet

- Kid Trax Power Wheels 6v To 12v UpgradeDocument7 pagesKid Trax Power Wheels 6v To 12v UpgradeGazza TNo ratings yet

- Manual Checklist 3094Document2 pagesManual Checklist 3094MARTIN GONZALEZNo ratings yet

- Story of GFGFDocument3,455 pagesStory of GFGFZoro ShresthaNo ratings yet

- TRX Anchoring ComponentsDocument2 pagesTRX Anchoring Componentsanthony1007765No ratings yet

- SIM Newton's Three Laws of MotionDocument34 pagesSIM Newton's Three Laws of MotionLyn Campos AndradeNo ratings yet

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- Company Overview: Leading Global Manufacturer of Pushing, Pulling, Lifting, and Rotating SolutionsDocument8 pagesCompany Overview: Leading Global Manufacturer of Pushing, Pulling, Lifting, and Rotating Solutionsj24maybe5963No ratings yet

- Operating Instructions: Diesel Engine 12V2000M94 16V2000M94Document153 pagesOperating Instructions: Diesel Engine 12V2000M94 16V2000M94michelNo ratings yet

- Simbolos Hidraulicos Din Iso 1219 PDFDocument15 pagesSimbolos Hidraulicos Din Iso 1219 PDFcrtpoint3No ratings yet

- Mode Selection For D375A-6Document2 pagesMode Selection For D375A-6alcowo100% (3)