Professional Documents

Culture Documents

Tts HC Siderolling Bulk

Tts HC Siderolling Bulk

Uploaded by

Anurag JhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tts HC Siderolling Bulk

Tts HC Siderolling Bulk

Uploaded by

Anurag JhaCopyright:

Available Formats

Side rolling hatch covers

for bulk vessels

TTS side rolling hatch covers are of a simple, cost-effective construction

and are designed to ensure that the requirements of owners and regulatory

authorities – for instance IACS UR S21A – in respect of the manoeuvring,

cleating and tightening of the hatch cover panels are met in full.

SIDE ROLLIN G H ATCH COVE RS FO R BULK VESSELS

Our product development continually reduces manufacturing its closed position. At the same time the cover is cleated by

time while ensuring a low weight of cover and maintaining self-engaging auto cleats.

strength requirements. Two alternative cleating systems are:

One operation method for side rolling hatch covers is • The Snap Lock cleat for manual operation from deck when

by rack and pinion where a rack is located transversely in high coamings are required

the centre of the underside of each panel. A hydraulically • Customised hydraulic cleatings available on request

operated pinion drive is positioned on the outside of the side

coaming where it engages in the rack. When two panels are Complementing the side rolling hatch covers are two types of

fitted each has its own rack and pinion drive system allowing seal. These are the square seal type for dry bulk carriers and

independent operation. the double lip seal for use on OBO and Ore/Oil ships carrying

Other operating drive systems are available including a liquid cargoes. All types have been designed by TTS to suit

hydraulic motor-driven chain drive arrangement that opens the specific requirements of these different ship types.

both hatch cover panels simultaneously. If required, manual To prevent access weight being carried by the seals,

quick-acting couplings can be provided making it possible for the hatch cover panels are supported on adjustable and

only one of the panels to be opened. replaceable pads all around the periphery of the coaming.

Both rack and pinion and chain drive systems can be All side rolling hatch covers, except Auto Roll covers, have

configured as an Auto Roll operation. This version features a hydraulically operated wheel lifters, and flangeless wheels

pair of pushing and securing units on either side of the hatch are used on one side of the panels to ensure that the cover

which lifts and secures the patented Auto Roll hatch cover in functions correctly in the event of distortion of the coaming.

Below: The lifting/securing

device of the patented Auto

Roll mechanism, with its

hydraulic cylinder, wheels

and wheel recess, and the

auto-cleat device at the

ship’s centre line.

Published by TTS Group ASA.

For more information and contact details, please visit ttsgroup.com

You might also like

- Manual - Paleteira Hyster s1.6 1,6tDocument88 pagesManual - Paleteira Hyster s1.6 1,6tEliel Ferreira Junior75% (4)

- Atlas Copco Drilling Solutions: Part List Model: Pv271D Rcs S/N: US004820Document854 pagesAtlas Copco Drilling Solutions: Part List Model: Pv271D Rcs S/N: US004820Edson Rodriguez100% (1)

- Final Project Design Report FinalDocument18 pagesFinal Project Design Report Finalrock starNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Macgregor&Tts Hatch CoverDocument9 pagesMacgregor&Tts Hatch CoverAlchemist_JVC100% (1)

- Deck MachineryDocument16 pagesDeck MachineryMuhammad Basiir Harun100% (1)

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622No ratings yet

- Porsgrunn Steering Gear June 2015Document4 pagesPorsgrunn Steering Gear June 2015Rooftop Gardener100% (1)

- 2017 Elantra F 2.0 Mpi-DiagramDocument1 page2017 Elantra F 2.0 Mpi-DiagramData TécnicaNo ratings yet

- Rolling Technical Information H3 PDFDocument8 pagesRolling Technical Information H3 PDFswapneel_kulkarniNo ratings yet

- Napala, Ronn Andre R. Ii-A L.O 1.2Document70 pagesNapala, Ronn Andre R. Ii-A L.O 1.2Andre NapalaNo ratings yet

- Hatch CoversDocument28 pagesHatch CoverssabeerNo ratings yet

- Hatch Cover and Its Types - by AfsarDocument16 pagesHatch Cover and Its Types - by AfsarMohammed AfsarNo ratings yet

- Macgregor Lift Away Type Hatch CoverDocument6 pagesMacgregor Lift Away Type Hatch CoverSubrat ShuklaNo ratings yet

- MPOW311WEEK13Document68 pagesMPOW311WEEK13John Loyd LavillaNo ratings yet

- Cargo Handling & Stability - I: Captain Nazim ErsenDocument79 pagesCargo Handling & Stability - I: Captain Nazim Ersenber100% (1)

- Marine Power PlantsDocument25 pagesMarine Power PlantsVinz VizenNo ratings yet

- HATCH COVERS SAFETY AND MAINTAINANCE 2022-12-02Document39 pagesHATCH COVERS SAFETY AND MAINTAINANCE 2022-12-02radu.daniel.teodoruNo ratings yet

- Cargo 4aDocument44 pagesCargo 4aumut tunalıNo ratings yet

- Lantec LH Series Hoists CatalogDocument16 pagesLantec LH Series Hoists CatalogAnonymous 1qAH6CKC100% (1)

- Deck MachineryDocument10 pagesDeck Machineryaman kumarNo ratings yet

- LMB 31003 Marine Auxliaries 2 (Assignment 1 - January 2020) : Assignment Topic: Deck MachineriesDocument31 pagesLMB 31003 Marine Auxliaries 2 (Assignment 1 - January 2020) : Assignment Topic: Deck MachineriesZarul AshraffNo ratings yet

- 116 - 1329216276 - LARS DatasheetDocument4 pages116 - 1329216276 - LARS DatasheetDário GalvãoNo ratings yet

- FMO Tutorial 1 TaneshDocument8 pagesFMO Tutorial 1 TaneshHirajanSandragesanNo ratings yet

- Handout Deck Machinery PDFDocument20 pagesHandout Deck Machinery PDFMalik ForbesNo ratings yet

- Circotech SystemDocument2 pagesCircotech Systempcorreia_81No ratings yet

- Deck Machineries On Board Ship: Presented byDocument8 pagesDeck Machineries On Board Ship: Presented byRaphael Sebuc100% (1)

- LNG 26-62Document37 pagesLNG 26-62mohkal1260No ratings yet

- BRE Side TippersDocument2 pagesBRE Side TippersjeedanNo ratings yet

- Porsgrunn Steering GearDocument4 pagesPorsgrunn Steering GearPedro EscarráNo ratings yet

- Colchester Dominion Lathe-ManualDocument35 pagesColchester Dominion Lathe-ManualTony FitzgeraldNo ratings yet

- UntitledDocument25 pagesUntitledRoshan MaindanNo ratings yet

- Ppt:-Deck MachineryDocument35 pagesPpt:-Deck Machineryaimri_cochin81% (32)

- HERRAMIENTA DE LLENADO - AutoFill PDFDocument15 pagesHERRAMIENTA DE LLENADO - AutoFill PDFluis alberto franco rodriguezNo ratings yet

- Maintenance of Chiksan Valves and Swivel JointsDocument4 pagesMaintenance of Chiksan Valves and Swivel JointsTg TarroNo ratings yet

- Deck Machineries: Windlass & Winches Onboard Offshore and AshoreDocument30 pagesDeck Machineries: Windlass & Winches Onboard Offshore and AshoreAlexEcnom100% (3)

- H2 Folding Hatch Covers - Original - 30544 PDFDocument8 pagesH2 Folding Hatch Covers - Original - 30544 PDFGILL2013No ratings yet

- Windlas PDFDocument96 pagesWindlas PDFInfant RajNo ratings yet

- Cecon Catalog PDFDocument24 pagesCecon Catalog PDFavciayNo ratings yet

- Marine BrochureDocument8 pagesMarine Brochurepramodtry100% (1)

- ResumoDocument78 pagesResumoMarco Antonio Toscano100% (2)

- Different Types of Hatch CoversDocument1 pageDifferent Types of Hatch CoversKryle DusabanNo ratings yet

- Types of Hatch CoversDocument5 pagesTypes of Hatch Coversmohamed100% (1)

- lh307 Specification Sheet EnglishDocument18 pageslh307 Specification Sheet Englishjhapd934No ratings yet

- Technical Description 100 150 Ton Hydramarine CraneDocument15 pagesTechnical Description 100 150 Ton Hydramarine Craneramya100% (2)

- Sedmicka en PDFDocument8 pagesSedmicka en PDFJasmin Selimić100% (1)

- Smarter Turret MooringDocument9 pagesSmarter Turret MooringWaldemarHusada100% (1)

- SLB Xcelis PsDocument2 pagesSLB Xcelis Pseduardo navarroNo ratings yet

- Liquid Cylinder Owners ManualDocument25 pagesLiquid Cylinder Owners Manualshan757No ratings yet

- Deck MachineryDocument18 pagesDeck MachineryJohn SnowNo ratings yet

- Catalogo MAO ING 251016 INDIA WebDocument8 pagesCatalogo MAO ING 251016 INDIA Webadam01000No ratings yet

- Mooring Systems For Floaters - FPSO Mooring System 1Document24 pagesMooring Systems For Floaters - FPSO Mooring System 1apis14No ratings yet

- Sicoma Twin Shaft Mixer Brochure JEC PDFDocument8 pagesSicoma Twin Shaft Mixer Brochure JEC PDFnirmalNo ratings yet

- Avalon-GT Release Systems and DevicesDocument8 pagesAvalon-GT Release Systems and DevicesAndry HermawanNo ratings yet

- Roro 2Document9 pagesRoro 2Krishanu AscharyaNo ratings yet

- DumperDocument17 pagesDumperRamabhadran Sundaram100% (1)

- Ga 1068Document12 pagesGa 1068Cuong DinhNo ratings yet

- LECTURE No.6: Anchor Handlers or Anchor Handling Vessels (AHV) Is Very Powerful Ships ThatDocument12 pagesLECTURE No.6: Anchor Handlers or Anchor Handling Vessels (AHV) Is Very Powerful Ships ThatMiruna ClinciuNo ratings yet

- Slide Gates Eng Guide BrochureDocument6 pagesSlide Gates Eng Guide Brochureraghunandanr1993No ratings yet

- Turret Operations in North Sea Statoil and AkersolutionDocument9 pagesTurret Operations in North Sea Statoil and Akersolutioncxb07164No ratings yet

- FPSO-Bow Mounted vs. Aft MountedDocument79 pagesFPSO-Bow Mounted vs. Aft Mountedcxb07164100% (3)

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignFrom EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Cooling Water TestingDocument6 pagesCooling Water TestingAnurag Jha100% (1)

- Flash Point Recording On BDNs To Become MandatoryDocument1 pageFlash Point Recording On BDNs To Become MandatoryAnurag JhaNo ratings yet

- AE Piston Ring ClearanceDocument1 pageAE Piston Ring ClearanceAnurag JhaNo ratings yet

- Guidance For Slow Steaming - DRAFT For PBMIDocument6 pagesGuidance For Slow Steaming - DRAFT For PBMIAnurag JhaNo ratings yet

- GAS04Document1 pageGAS04Anurag JhaNo ratings yet

- EGCS Washwater Regs in USADocument1 pageEGCS Washwater Regs in USAAnurag JhaNo ratings yet

- Positive Pay SystemDocument6 pagesPositive Pay SystemAnurag JhaNo ratings yet

- LUBEChecker Brochure ENDocument2 pagesLUBEChecker Brochure ENAnurag JhaNo ratings yet

- Critical Spares ListDocument3 pagesCritical Spares ListAnurag Jha100% (1)

- FWG TroubleshootingDocument1 pageFWG TroubleshootingAnurag JhaNo ratings yet

- Unitor Product Catalogue PDF Final Aug17Document674 pagesUnitor Product Catalogue PDF Final Aug17Anurag Jha100% (1)

- Self Jector Maintenance Manual Trouble Shooting NK-001Document100 pagesSelf Jector Maintenance Manual Trouble Shooting NK-001Anurag Jha100% (1)

- VLSFO Concerns and GuidelinesDocument5 pagesVLSFO Concerns and GuidelinesAnurag JhaNo ratings yet

- Annex B Design Guidance and Design SubmissionDocument4 pagesAnnex B Design Guidance and Design SubmissionRebi HamzaNo ratings yet

- Isuzu Css Net Epc 04 2019Document31 pagesIsuzu Css Net Epc 04 2019heathermckay140201anr100% (141)

- Haulotte Ha15i AustralieDocument60 pagesHaulotte Ha15i Australiepedro vicente baenas garciaNo ratings yet

- Caribbean Maritime University: Sheldon Dixon 20191048Document27 pagesCaribbean Maritime University: Sheldon Dixon 20191048Rushane PowellNo ratings yet

- Grammar b11Document14 pagesGrammar b11Trần PanhNo ratings yet

- 80-720-EEC Operating SpaceDocument3 pages80-720-EEC Operating Spacebasiri jayadeepNo ratings yet

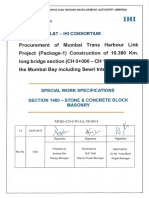

- MTHL CO C P1 GL TS 0814 SignedDocument10 pagesMTHL CO C P1 GL TS 0814 Signeddeepak925No ratings yet

- CBLM Clutch SystemDocument6 pagesCBLM Clutch Systemace ebradoNo ratings yet

- Car2DB Es CutDocument1,085 pagesCar2DB Es Cutpepe2009sNo ratings yet

- dx170w 5 5439Document24 pagesdx170w 5 5439Maurice CharlotteauxNo ratings yet

- ContentDocument4 pagesContentDmitryNo ratings yet

- GR00005300 36Document22 pagesGR00005300 36Luis David Leon GarciaNo ratings yet

- Introduction To Transportation Planning & EngineeringDocument7 pagesIntroduction To Transportation Planning & EngineeringMark Anthony Mores FalogmeNo ratings yet

- AJS Matchless Wokshop ManualDocument70 pagesAJS Matchless Wokshop ManualClaudio PerelliNo ratings yet

- LW900KN(X12)英文操作保养手册 ommDocument169 pagesLW900KN(X12)英文操作保养手册 ommirfanNo ratings yet

- Full Line Product Catalog 2021Document16 pagesFull Line Product Catalog 2021marioNo ratings yet

- Progressive Fork Springs For Harley fl19491977Document2 pagesProgressive Fork Springs For Harley fl19491977Juan AguinigaNo ratings yet

- Activity Plan of Kalol-Chekhla-SanadDocument1 pageActivity Plan of Kalol-Chekhla-Sanadroyal swamiNo ratings yet

- Atsg Transmission 4f27e DL Technical ServiceDocument10 pagesAtsg Transmission 4f27e DL Technical Servicedavid100% (57)

- Civic Ss2 2ndDocument65 pagesCivic Ss2 2ndolunloyorofiatNo ratings yet

- Technical Data: N/A Emissions 3-Phase Power Factor Factor Cos Φ = 0.8 60Hz/1800R.P.MDocument7 pagesTechnical Data: N/A Emissions 3-Phase Power Factor Factor Cos Φ = 0.8 60Hz/1800R.P.MJonathan CastilloNo ratings yet

- Farm PowerDocument18 pagesFarm PowerSushant YadavNo ratings yet

- Land Rover Range Rover SVAutobiographyDocument27 pagesLand Rover Range Rover SVAutobiographyk85m8x7jy5No ratings yet

- 5 Brake SystemDocument6 pages5 Brake SystemDadangNo ratings yet

- Damansara Avenue Proposed Flyover From MRR2 HighwayDocument29 pagesDamansara Avenue Proposed Flyover From MRR2 HighwayWhen2Meets2No ratings yet

- MD Abdul Mannan: Trainee MechanicDocument2 pagesMD Abdul Mannan: Trainee MechanicMasud DigonosticNo ratings yet