Professional Documents

Culture Documents

Pump Installation and Commisioning Check List

Pump Installation and Commisioning Check List

Uploaded by

a.albin.jrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Installation and Commisioning Check List

Pump Installation and Commisioning Check List

Uploaded by

a.albin.jrCopyright:

Available Formats

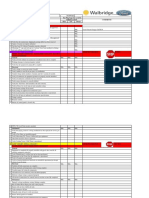

CHECK LIST FOR PUMP INSTALLATION & PREPARATION FOR COMMISSIONING

Done/

Check points Photo/document to be provided for checking

Not yet

Pump & motor

1 Photo of pump baseplate after grouting

3 Photo of pump inlet and outlet pipeline connection

Make sure pump installation has been done according to Photo of cooling water/ flushing/ sealing pipe

4

installation manual provided by EGP. connection

5 Photo of motor grounding and power supply

Photo of installation and wiring for instrument

6

monitoring cabinet

Before commissioning, piping system shall be cleaned up and

7 make sure there is no dirt and impurities in the piping, welding slag

must be removed from welding parts.

Before commissioning, alignment for pump and motor shall be

done according to procedure specified in installation manual, and Please provide final alignment result to us for

8

make sure alignment result is within acceptance criteria which is checking.

also given in installation manual.

Flush the bearing housing with light oil (not petroleum products)

9 and drain the oil. Then fill lubricate (VG46 turbine oil) to 1/2-2/3 of

the oil sight glass.

Before commissioning, pump inlet strainer must be cleaned to

10

prevent evacuation caused by debris blockage.

Connection of pump inlet/outlet nozzle and pipes at site shall be

done properly, make sure there is no force or dislocation on the

11

pump nozzle.Stress-free inspection shall be done for piping

connection.

Make sure pump rotor can rotates smoothly when being turned

manually.If abnormal sound is found or rotor does not rotate

12 smoothly, pump shall be disassembled and condition of rotor parts

such as casing wear rings and impeller wear rings shall be

checked.

Make sure supply of liquid for commissioning and cooling water is

13 available; Make sure that the inlet valve for the pump is open

properly and the pump venting has been completed successfully.

Make sure all instrument and mechanical seal system have been

14

proven functional.

Check motor rotating direction and do motor solo run test before

coupling to the pump, make sure rotating direction of motor is Please provide motor solo run test record to us for

15

correct and motor runs in good condition without any abnormal checking.

noise or vibration.

Variable Frequency Drive

1 Photo of room where VFDs are installed

Make sure installation for VFD has been completed properly

2 Photo of VFDs after installation

according to the installation drawings and user manual provided.

Photo of fixation of VFDs' cabinet foot (make sure the

3

mounting floor is level )

Photo of high voltage power supply input/output

4 cable, cable from switch cabinet to transformer,

protection parameter setting for switch cabinet

5 Photo of VFDs grounding and resistance test result

6 Make sure wiring for VFD has been completed according to the Interior photo of transformer cabinet (open the door)

installation drawings and user manual provided.

7 Interior photo of power cell cabinet (open the door)

8 Photo of VFD control cabinet cable and logic diagram

9 Photo of motor grounding and power supply

Key points which must be checked to ensure sucessful installation and preparation.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Instruction Manual F-502 Compression Testing Machine MN-F-502Document22 pagesInstruction Manual F-502 Compression Testing Machine MN-F-502siaromezNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Testing and Commissioning of Starter Panels Variable Frequency Drives VFDsDocument3 pagesTesting and Commissioning of Starter Panels Variable Frequency Drives VFDsHumaid ShaikhNo ratings yet

- Testing and Commissioning of Motor Control Center Method StatementDocument3 pagesTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- Greatork IOM ... MANUALDocument36 pagesGreatork IOM ... MANUALRAMESH RAMASAMY100% (2)

- MethodDocument406 pagesMethodAswc Baed0% (1)

- PEEC Electronic System Functional TestsDocument66 pagesPEEC Electronic System Functional TestsRichard Chua0% (1)

- Chiller McQuay WSC (200-1250ton) WDC (400-2500ton) Chiller Centrifugo - Enfriado - Por - Agua PDFDocument100 pagesChiller McQuay WSC (200-1250ton) WDC (400-2500ton) Chiller Centrifugo - Enfriado - Por - Agua PDFNanasaheb Patil100% (2)

- Sequence of Operation: For Fans& Blowers Start-UpDocument4 pagesSequence of Operation: For Fans& Blowers Start-UpMark CabralNo ratings yet

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocument4 pagesPurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNo ratings yet

- T&C Plan For Ayalamalls Manila BayDocument5 pagesT&C Plan For Ayalamalls Manila BayKarl Jared MasanqueNo ratings yet

- Insitum 16 32 64S 64 Installation Manual V04Document86 pagesInsitum 16 32 64S 64 Installation Manual V04Victor BlancoNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- 200 500 Su PDFDocument150 pages200 500 Su PDFElvis Eliud HernándezNo ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- Method Statement For Precommissioning & Commissioning of Extract FansDocument3 pagesMethod Statement For Precommissioning & Commissioning of Extract Fansvin ss100% (1)

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- Pre-Commissioning & Commissioning Procedure-IOCL MATHURADocument21 pagesPre-Commissioning & Commissioning Procedure-IOCL MATHURAzakirhussainNo ratings yet

- Method Statement For Precommissioning & Commissioning of Central Battery SystemDocument3 pagesMethod Statement For Precommissioning & Commissioning of Central Battery Systemvin ssNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Corrective and Preventive Maintenance ChecklistDocument2 pagesCorrective and Preventive Maintenance ChecklisttmamputsiNo ratings yet

- Actuador Electrico RotorkDocument16 pagesActuador Electrico RotorkAriel AgueroNo ratings yet

- CSC IOM Manual BombaDocument18 pagesCSC IOM Manual BombaLuis Sánchez RoblesNo ratings yet

- INS&COMM ProcedureDocument11 pagesINS&COMM ProcedurezainahmedscribdNo ratings yet

- HPV Conversion ProceduresDocument48 pagesHPV Conversion ProceduresIanNo ratings yet

- Testing & Commissioning of Chilled Water Pressurization UnitsDocument3 pagesTesting & Commissioning of Chilled Water Pressurization Unitsvin ssNo ratings yet

- Method Statement T&C FIRE PROTECTION SYSTEMDocument10 pagesMethod Statement T&C FIRE PROTECTION SYSTEMcic engineeringNo ratings yet

- SG-0015-04 BMT Installation GuideDocument10 pagesSG-0015-04 BMT Installation Guideمحمد الاطرشNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- Xyz Company: PurposeDocument5 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- CR CRI CRN CRT Installation Guide PDFDocument28 pagesCR CRI CRN CRT Installation Guide PDFSarbendu PaulNo ratings yet

- 0 515 010 358 - Quartz Clock-Engine Hour Meter InstallationDocument2 pages0 515 010 358 - Quartz Clock-Engine Hour Meter InstallationAsep KurniawanNo ratings yet

- Lab Module 01 Maintenance & Troubleshoot Centrifugal PumpDocument12 pagesLab Module 01 Maintenance & Troubleshoot Centrifugal Pumpazroy06No ratings yet

- Testing & Commissioning of Split Air Conditioning AC UnitsDocument3 pagesTesting & Commissioning of Split Air Conditioning AC Unitsvin ssNo ratings yet

- Generic Test & Acceptance ChecklistDocument24 pagesGeneric Test & Acceptance ChecklistM Kashif JunaidNo ratings yet

- F8941 - PRV Commissioning Check SheetDocument26 pagesF8941 - PRV Commissioning Check SheetRANJINI02VNo ratings yet

- T&CDocument13 pagesT&CAbdurRahmanFNo ratings yet

- PC4204 Relay Output Module: V 2.1 - Installation InstructionsDocument2 pagesPC4204 Relay Output Module: V 2.1 - Installation Instructionsrobsanchez1981No ratings yet

- Downhole Unit Installation & DismantlingDocument40 pagesDownhole Unit Installation & DismantlingomerkhalidhameedNo ratings yet

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- PLT 7Document5 pagesPLT 7eclecticindia1No ratings yet

- SM 67Document12 pagesSM 67eys.automotricesNo ratings yet

- D TS ComRepDocument259 pagesD TS ComRepihackn3wtonNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- Method Statement For The Testing of Domestic PumpDocument11 pagesMethod Statement For The Testing of Domestic Pumpa100% (1)

- Air Handling Units COB AHU-10ADocument3 pagesAir Handling Units COB AHU-10AHernan RomeroNo ratings yet

- Strength TesterDocument9 pagesStrength TesterAnonymous TYGiADNo ratings yet

- STVF5 - SSVF5 Installation & AdjustingDocument51 pagesSTVF5 - SSVF5 Installation & Adjustingnursoleh202No ratings yet

- Mde 4709aDocument8 pagesMde 4709awotanelNo ratings yet

- IM Rime 4000 CompleteDocument37 pagesIM Rime 4000 CompleteVivi Puspita SariNo ratings yet

- Lighting Control System Testing & Commissioning ProcedureDocument4 pagesLighting Control System Testing & Commissioning ProcedurehassanabunafeesahNo ratings yet

- Booster Pump CommissioningDocument24 pagesBooster Pump CommissioningOnur Sürücü100% (5)

- M & e MST - 038 Rev. 0Document3 pagesM & e MST - 038 Rev. 0Anonymous 3eHGEDbxNo ratings yet

- WB MDX Stoerungsuche Spezielle Fehler enDocument56 pagesWB MDX Stoerungsuche Spezielle Fehler enTuanHaNo ratings yet

- Electromagnetic Flowmeter: Installation and Operating InstructionsDocument80 pagesElectromagnetic Flowmeter: Installation and Operating InstructionsavikbhaiNo ratings yet

- CS 3 Phase Inverters Commissioning Checklist FINALDocument5 pagesCS 3 Phase Inverters Commissioning Checklist FINALarunghandwalNo ratings yet

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Oil Pump Service and RepairDocument9 pagesOil Pump Service and RepairToriTo Levy100% (1)

- Building Hybrid Cloud With Azure StackDocument369 pagesBuilding Hybrid Cloud With Azure StacktelecomprofiNo ratings yet

- Solicitation-Letter ExampleDocument2 pagesSolicitation-Letter ExampleBryan Dave PublicoNo ratings yet

- Samsung-Cw21z503 21z453Document4 pagesSamsung-Cw21z503 21z453Anonymous 4aChpF1hZNo ratings yet

- Magnaloy ProdCatDocument222 pagesMagnaloy ProdCatDANIEL LNo ratings yet

- Suspended SlabDocument2 pagesSuspended SlabaikalessNo ratings yet

- Ahnay Series: Bi-66-580 To Bi-66-600Document2 pagesAhnay Series: Bi-66-580 To Bi-66-600Eureka SolarNo ratings yet

- NICE3000 EN81-20 BR en Singles Web V0.1Document12 pagesNICE3000 EN81-20 BR en Singles Web V0.1mohammed shamsherNo ratings yet

- HY510N HawYangDocument10 pagesHY510N HawYangacwindNo ratings yet

- Dunning Letter Setup and Usage in Oracle r12Document7 pagesDunning Letter Setup and Usage in Oracle r12Ali xNo ratings yet

- UntitledDocument17 pagesUntitledAmbre SolaireNo ratings yet

- IXPs Part 2Document84 pagesIXPs Part 2pohsengNo ratings yet

- MIS Ch01Document41 pagesMIS Ch01Mohammad RaditNo ratings yet

- Fuel Efficiency Improvement in Petrol Engine by Using Water InjectionDocument4 pagesFuel Efficiency Improvement in Petrol Engine by Using Water InjectionmunawarpmNo ratings yet

- Software Dev Advt CTDocument4 pagesSoftware Dev Advt CTAdhara MukherjeeNo ratings yet

- Httpsjacksonemc - smarthub.coopservicessecuredbillPdfService2023 06-9-1112157.pdfaccount 1112157×tamp 1686289249000&sDocument2 pagesHttpsjacksonemc - smarthub.coopservicessecuredbillPdfService2023 06-9-1112157.pdfaccount 1112157×tamp 1686289249000&sRegina HudsonNo ratings yet

- Touchless Touch Screen TechnologyDocument23 pagesTouchless Touch Screen TechnologyIndupriya KatariNo ratings yet

- Service and Maintenance D4, D6Document106 pagesService and Maintenance D4, D6Tiên Lê Trần MỹNo ratings yet

- Stay FitDocument11 pagesStay Fitsavio pullkotilNo ratings yet

- Xii CS Practical FileDocument41 pagesXii CS Practical FilezakNo ratings yet

- Car Chassis Basics and HowDocument11 pagesCar Chassis Basics and HowRafael Elles50% (2)

- Senior Network and Security Engineer With 5+ Years of ExpDocument3 pagesSenior Network and Security Engineer With 5+ Years of Expkurban2015No ratings yet

- AvusaDocument31 pagesAvusasafinditNo ratings yet

- Pic Graphics L.C.D. Scope: Ccoonnssttrruuccttiioonnaall PprroojjeeccttDocument5 pagesPic Graphics L.C.D. Scope: Ccoonnssttrruuccttiioonnaall PprroojjeeccttAllahrakha LambooNo ratings yet

- Simple / Hardwired / Logic Controller / Zelio: System User GuideDocument64 pagesSimple / Hardwired / Logic Controller / Zelio: System User GuideJimi DbonoNo ratings yet

- DQ - IQ DocumentsDocument13 pagesDQ - IQ DocumentsAlonso Garcia100% (1)

- Maintenance Officer Phewdaisy Chishimba Chansa CVnoteDocument5 pagesMaintenance Officer Phewdaisy Chishimba Chansa CVnotePhewdaisy chishimbaNo ratings yet

- Barbie: Making Products Smarter With Artificial IntelligenceDocument2 pagesBarbie: Making Products Smarter With Artificial Intelligencerock starNo ratings yet

- Satyam Singh SE FileDocument28 pagesSatyam Singh SE Filesatyam singhNo ratings yet