Professional Documents

Culture Documents

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

Uploaded by

Kamil SiudowskiCopyright:

Available Formats

You might also like

- Outboard Manual 70-75-80-90-100-115Document391 pagesOutboard Manual 70-75-80-90-100-115Possis76% (75)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- 3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance IntervalsDocument92 pages3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance IntervalsJaanek Ki97% (38)

- Cat 246cDocument50 pagesCat 246cYerko Enzo100% (7)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- Caterpillar 3208 Maintenance EngDocument51 pagesCaterpillar 3208 Maintenance EngGonzalo Ferreiro Soto100% (5)

- 3512 Industrial Engine-Maintenance IntervalsDocument40 pages3512 Industrial Engine-Maintenance Intervalssiul789494% (17)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Starting Air Compressor hl2/140Document69 pagesStarting Air Compressor hl2/140Zebidah Ndoro100% (2)

- LandRover Discovery Service SheetDocument2 pagesLandRover Discovery Service Sheetmichkapp50% (2)

- SS TLS T40140-T40180 S3a-B1ct-B33g-EnDocument2 pagesSS TLS T40140-T40180 S3a-B1ct-B33g-EnAhmed El-AdawyNo ratings yet

- Bobcat MaintDocument2 pagesBobcat Maintdlewis5560No ratings yet

- Ss SSL LF Exlf t4 B 0118Document2 pagesSs SSL LF Exlf t4 B 0118Steven FryeNo ratings yet

- Ss SSL LF Exlf t3 MF Exmf It4 0118Document2 pagesSs SSL LF Exlf t3 MF Exmf It4 0118crash2804No ratings yet

- MT55 - Service ScheduleDocument2 pagesMT55 - Service Schedulesernamu85No ratings yet

- WarningDocument1 pageWarningBaiuliang BaiuliangNo ratings yet

- Sebu7763-03 BDocument4 pagesSebu7763-03 BHernan SanchezNo ratings yet

- Interval Service CB24Document4 pagesInterval Service CB24Alvaro Jose Peñata GiraldoNo ratings yet

- 3208 Marine 75v1-Up 01z1-UpDocument52 pages3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- AD45B Underground Articulated Truck - Service SheetDocument7 pagesAD45B Underground Articulated Truck - Service SheetaleciolyraNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- 3116 MaintenanceDocument33 pages3116 MaintenanceCesar Gongora100% (8)

- CAT Antes de Usar TH460BDocument4 pagesCAT Antes de Usar TH460Bmiguel0% (1)

- 01 220043enc Routine Turbine MaintenanceDocument8 pages01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- 3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance Intervals PDFDocument92 pages3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance Intervals PDFmarcosluna68100% (1)

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- Mooney M20 100 Hour Annual 2007Document2 pagesMooney M20 100 Hour Annual 2007flyokie100% (1)

- Maintenance and LubricationDocument34 pagesMaintenance and Lubricationtoppen_76100% (1)

- Shovel and DraglinesDocument9 pagesShovel and DraglinesPearl Carmona CaberteNo ratings yet

- Gmi 2202312228096Document5 pagesGmi 2202312228096Kishan PatelNo ratings yet

- Service Programme Backhoe Loaders: Construction EquipmentDocument5 pagesService Programme Backhoe Loaders: Construction EquipmentMACHINERY101GEARNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualKJDNKJZEFNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- 302 Cat Service ScheduleDocument3 pages302 Cat Service ScheduleNathan PittsNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- C15 MohDocument6 pagesC15 Mohharikrishnanpd3327No ratings yet

- 160M Maintenance IntervalDocument3 pages160M Maintenance IntervalJoko WahonoNo ratings yet

- Mantenimiento Lek 3500Document4 pagesMantenimiento Lek 3500Ana María AcostaNo ratings yet

- Yamaha 2009 Maintenance ChartsDocument7 pagesYamaha 2009 Maintenance ChartskapniasNo ratings yet

- Regular Maintenance 3: 3 ServiceDocument24 pagesRegular Maintenance 3: 3 ServiceMiguel MartínezNo ratings yet

- 4.2 Service SheetDocument2 pages4.2 Service SheetRichard PorterNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDocument51 pagesSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102No ratings yet

- Maintenance Schedule 320D FAL Series ExcavatorDocument5 pagesMaintenance Schedule 320D FAL Series ExcavatorNiten Gupta50% (2)

- Sebu6617-04 MDocument38 pagesSebu6617-04 MCDDPPJNo ratings yet

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Engine Electrical SystemDocument48 pagesEngine Electrical SystemZM OhnNo ratings yet

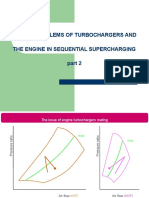

- Sequential Turbocharging Part2Document4 pagesSequential Turbocharging Part2Krzysztof DanileckiNo ratings yet

- ELECTRIC WIRING - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsDocument3 pagesELECTRIC WIRING - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsJUAN CARDONANo ratings yet

- Aircraft Tyre Maintenance - SKYbrary Aviation SafetyDocument8 pagesAircraft Tyre Maintenance - SKYbrary Aviation Safetynosh1983No ratings yet

- HHF 1000 Parts Manual 1Document6 pagesHHF 1000 Parts Manual 1Kapil AgarwalNo ratings yet

- VRF SB DF 003 US-014B14 LGSubmittal HSD ARNU123BHA2 20140320133004Document2 pagesVRF SB DF 003 US-014B14 LGSubmittal HSD ARNU123BHA2 20140320133004Heildrick ValerosoNo ratings yet

- DuraCirc 63 Hi-Flow Horizontal Top Tech SpecDocument3 pagesDuraCirc 63 Hi-Flow Horizontal Top Tech SpecDiego BorgesNo ratings yet

- Abs & TCSDocument40 pagesAbs & TCSP.Prem Kumar AP - I - MechanicalNo ratings yet

- CS54B - CompactorDocument4 pagesCS54B - CompactorhendrynNo ratings yet

- Aero 2017-01-1592 SAEDocument8 pagesAero 2017-01-1592 SAEtsfnz111No ratings yet

- 20600e Hci 750 HP 500-650 Ton Top DriveDocument2 pages20600e Hci 750 HP 500-650 Ton Top Drivejulioramca100% (1)

- Downloaded From Manuals Search EngineDocument57 pagesDownloaded From Manuals Search Engineviola beckNo ratings yet

- AutomobilesDocument9 pagesAutomobilesaaryaNo ratings yet

- U3 ISADocument26 pagesU3 ISAjeyrajiNo ratings yet

- SDLG L959F Wheel Loader BrochureDocument4 pagesSDLG L959F Wheel Loader BrochureBABA GlobalNo ratings yet

- DNV Marpol Annex VI Guide Lines LSHFO PositionsDocument32 pagesDNV Marpol Annex VI Guide Lines LSHFO Positionsch3g44No ratings yet

- ENGINEDocument41 pagesENGINEAbdel Rahman El NobyNo ratings yet

- Yanmar - b22-2Document237 pagesYanmar - b22-2jazkoNo ratings yet

- TPM Project CharterDocument45 pagesTPM Project CharteronikoyilanreNo ratings yet

- Caterpillar Cat M313D WHEELED Excavator (Prefix J3A) Service Repair Manual (J3A00001 and Up) PDFDocument27 pagesCaterpillar Cat M313D WHEELED Excavator (Prefix J3A) Service Repair Manual (J3A00001 and Up) PDFfkdmmaNo ratings yet

- Analysis of Purchase Decision and Its Impacts Towards Honda Beat Motorcycle's Customer Satisfaction Viewed Through Product Quality and Price Perception Variables at Tangerang City AreaDocument8 pagesAnalysis of Purchase Decision and Its Impacts Towards Honda Beat Motorcycle's Customer Satisfaction Viewed Through Product Quality and Price Perception Variables at Tangerang City AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 6M125A-5 SeriesDocument2 pages6M125A-5 SeriesTruong Nguyen ThanhNo ratings yet

- RHEADocument43 pagesRHEARomzen DialaNo ratings yet

- Oisd STD 127Document23 pagesOisd STD 127Priyank SutariyaNo ratings yet

- 10th Meeting of SC TED 27Document83 pages10th Meeting of SC TED 27Gaurav GuptaNo ratings yet

- RC 22 PartslistDocument1 pageRC 22 PartslistMahmoud AliNo ratings yet

- Service and Maintenance 13L IndustryDocument84 pagesService and Maintenance 13L IndustryLuciano de AlmeidaNo ratings yet

- Roke Manor Research: Sensor TechnologyDocument12 pagesRoke Manor Research: Sensor TechnologyNguyen Xuan NhuNo ratings yet

- Theory: AIM: To Determine The Traffic Volume Count of An Urban Road Stretch APPARATUS: Data Sheet, Stop WatchDocument4 pagesTheory: AIM: To Determine The Traffic Volume Count of An Urban Road Stretch APPARATUS: Data Sheet, Stop WatchStevan StrangeNo ratings yet

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

Uploaded by

Kamil SiudowskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV en

Uploaded by

Kamil SiudowskiCopyright:

Available Formats

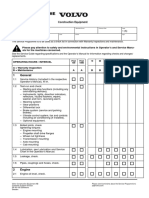

SERVICE SCHEDULE

Maintenance Intervals WARNING

Maintenance work must be done at regular intervals.

Failure to do so will result in excessive wear and early AVOID INJURY OR DEATH

failures. Instructions are necessary before operating or

servicing machine. Read and understand the

The service schedule is a guide for correct maintenance Operation & Maintenance Manual, Operator’s

of the Bobcat telescopic handler. Handbook and signs (decals) on machine. Follow

warnings and instructions in the manuals when

making repairs, adjustments or servicing. Check for

correct function after adjustments, repairs or

service. Untrained operators and failure to follow

instructions can cause injury or death.

W-2003-0807

Every 10 Hours (Before Starting The Telescopic Handler)

• Engine Oil - Check level and add as needed. Do not overfill. Check engine for oil leaks. (See page 180.)

• Engine Air Filters and Air System - Check condition indicator and empty dust cup as needed. Check for leaks.

(See page 171.)

• Engine Cooling System - Check oil cooler, radiator and air conditioner condenser. Check coolant level cold in

reservoir. Add premixed coolant as necessary. (See page 183.) Check cooling system for leaks.

• Exhaust System - Check exhaust system and exhaust after-treatment components for leaks.

• Hydraulic Fluid - Check fluid level and add as needed. (See page 193.)

• Fuel Filter - Check display panel. Remove the trapped water. (See page 177.)

• Seat Belt - Check the condition of seat belt. Clean or replace seat belt retractors as needed. Clean dirt and debris

from moving parts. (See page 104.) and (See page 164.)

• Back-up Alarm - Check for proper function. Service as necessary. (See page 81 and page 168.)

• Service Brakes - Check for function. Service as necessary.

• Parking Brakes - Check for function. Adjust or service as necessary.

• Tyres - Check for wear or damage. Inflate to correct pressure. Be sure all tyres are inflated to the same pressure.

Use only approved tyres. (See page 206.)

• Wheel Nuts - Perform every 8 hours or daily for the first week, then as scheduled. Check for loose wheel nuts and

tighten to correct torque. (See page 206.)

• Safety Signs and Safety Treads and Mirrors - Check for damaged signs (decals), safety treads and mirrors.

Replace any signs, safety treads or mirrors that are damaged or worn. (See page 38.)

• Tilt Cylinder Rod End - Lubricate with multipurpose lithium based grease. (See page 208.)

• Attachment Carrier Pins - Lubricate with multipurpose lithium based grease. (See page 208.)

Every 50 Hours

• Fuel Filter - Replace filter the first time, then as scheduled. (See page 177.)

• Engine Cooling System - Clean debris from radiator, air cooler, hydraulic fluid cooler, air conditioning condenser

(if equipped), and grille. (See page 183.)

• Engine Oil and Filter - Replace oil and filter the first time, then as scheduled. (See page 181.)

• Hydraulic / Hydrostatic Fluid Filters- Replace the three filter elements (TL34.65(X)C and TL38.70(X)) or two filter

elements (TL35.70(X)) the first time, then as scheduled. Use a genuine Bobcat filter. (See page 195.)

• Air Conditioning Belt (if equipped) - Check condition. Replace as needed. (See page 204.)

• Articulation Pins, Axle Oscillation (Front/Rear), Boom Pivot, Lift Cylinder, Levelling Cylinder - Lubricate with

multipurpose lithium based grease. (See page 208.)

• Telescopic Boom Wear Pads - Lubricate with multipurpose lithium based grease. (See page 208.)

• Hydraulic Hoses, Tubelines and Connections - Check for leaks. Repair or replace as needed.

• Harnesses - Check condition. Repair or replace as needed.

TL34.65(X)C / TL35.70(X) / TL38.70(X)

161 Operation & Maintenance Manual

SERVICE SCHEDULE (CONT’D)

Maintenance Intervals (Cont’d)

Every 100 Hours

• LLMC System - Test the LLMC calibration the first time, then as scheduled. (See page 165.)

• Wheel Nuts - Check for loose wheel nuts and tighten to correct torque. (See page 206.)

• Planetary Carriers - Replace the fluid the first time, then as scheduled. (See page 198.)

• Axle and Differential Fluid- Replace the fluid the first time, then as scheduled. (See page 199.) and (See page

200.)

• Gear Box Fluid - Check level. Replace the fluid the first time, then as scheduled. (See page 201.)

Every 250 Hours Or Every 12 Months

• LLMC System - Test the LLMC calibration (See page 165.)

• Planetary Carriers - Check level. (See page 198.)

• Axle and Differential Fluid- Check level. (See page 199.) and (See page 200.)

Every 500 Hours Or Every 12 Months

• Fuel Filter - Clean and check filter. (See page 177.)

• Engine Oil and Filter - Replace oil and filter. (See page 181.)

• Engine Cooling System - Check coolant concentration (with a refractometer). Replace as needed.

• Air Conditioning Belt (if equipped) - Check condition. Replace as needed. (See page 204.)

• Hydraulic / Hydrostatic Fluid Filters - Replace the three filter elements (TL34.65(X)C and TL38.70(X)) or two filter

elements (TL35.70(X)). Use a genuine Bobcat filter. (See page 195.)

• Hydraulic Tank Breather - Replace the hydraulic tank breather. (See page 197.)

• Axle and Differential Fluid - Replace the fluid. (See page 199 and page 200.) Maximal service time is 800 hours.

• Gear Box Fluid - Check level. (See page 201.)

• Telescopic Boom Wear Pads - Check for wear. Replace as necessary.

• Service Brake Pedal Spring - Lubricate with multipurpose lithium based grease. (See page 208.)

• Cab Air Filter and Intake Pipes - Check filter condition. Replace as necessary. Check for damage. (See page

169.)

Every 750 Hours Or Every 12 Months

• Planetary Carriers - Replace the fluid. (See page 198.)

• Axle and Differential Fluid - Replace the fluid. (See page 199.) and (See page 200.)

Every 1000 Hours Or Every 12 Months

• Battery and Cable Connectors - Check voltage. Check terminals for good contact and presence of protective

grease. (See page 189.)

• Engine Mounts - Tighten. Replace if damaged.

• Engine Air Filter - Replace the outer filter element. (See page 171.)

• Charge Air Cooler - Check entry area.

• Alternator Belt - Check condition. Replace as needed. (See page 202.)

• Hydraulic Fluid - Replace the fluid. (See page 194.)

• Gear Box Fluid - Replace the fluid. (See page 201.)

• Fastenings, Hose Unions and Clips - Replace if damaged.

• Engine Valve Clearance - Check and adjust.

Every 2000 Hours Or Every 12 Months

• Oil Separator Filter - Replace the oil separator filter. (See page 182.)

Every 3000 Hours

• Alternator Belt - Replace the belt. (See page 202.)

TL34.65(X)C / TL35.70(X) / TL38.70(X)

162 Operation & Maintenance Manual

SERVICE SCHEDULE (CONT’D)

Maintenance Intervals (Cont’d)

Every 3000 Hours Or Every 3 Years

• Diesel Exhaust Fluid (DEF) / AdBlue® Filter - Replace the diesel exhaust fluid (DEF) / AdBlue® filter.

Every 24 Months

• Coolant - Replace the coolant. (See page 184.)

Inspection Checkbook

Maintenance work must be done at regular intervals.

Failure to do so will result in excessive wear and early

failures.

The service schedule is a guide for correct maintenance

of the Bobcat telescopic handler.

The Inspection Checkbook contains the following

information:

• Doosan Bobcat EMEA s.r.o. Warranty Policy

• Doosan Bobcat EMEA s.r.o. Extended Warranty

Policy

The Inspection Checkbook has to be filled in by the

Dealer for any maintenance and service work of your

Bobcat machine. This book may be required anytime by

an authorized dealer or by Bobcat Europe, should a

breakdown occur on the Bobcat equipment. Your local

dealer can order the Inspection Checkbook.

Part number: 7296478

TL34.65(X)C / TL35.70(X) / TL38.70(X)

163 Operation & Maintenance Manual

You might also like

- Outboard Manual 70-75-80-90-100-115Document391 pagesOutboard Manual 70-75-80-90-100-115Possis76% (75)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- 3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance IntervalsDocument92 pages3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance IntervalsJaanek Ki97% (38)

- Cat 246cDocument50 pagesCat 246cYerko Enzo100% (7)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- Caterpillar 3208 Maintenance EngDocument51 pagesCaterpillar 3208 Maintenance EngGonzalo Ferreiro Soto100% (5)

- 3512 Industrial Engine-Maintenance IntervalsDocument40 pages3512 Industrial Engine-Maintenance Intervalssiul789494% (17)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Starting Air Compressor hl2/140Document69 pagesStarting Air Compressor hl2/140Zebidah Ndoro100% (2)

- LandRover Discovery Service SheetDocument2 pagesLandRover Discovery Service Sheetmichkapp50% (2)

- SS TLS T40140-T40180 S3a-B1ct-B33g-EnDocument2 pagesSS TLS T40140-T40180 S3a-B1ct-B33g-EnAhmed El-AdawyNo ratings yet

- Bobcat MaintDocument2 pagesBobcat Maintdlewis5560No ratings yet

- Ss SSL LF Exlf t4 B 0118Document2 pagesSs SSL LF Exlf t4 B 0118Steven FryeNo ratings yet

- Ss SSL LF Exlf t3 MF Exmf It4 0118Document2 pagesSs SSL LF Exlf t3 MF Exmf It4 0118crash2804No ratings yet

- MT55 - Service ScheduleDocument2 pagesMT55 - Service Schedulesernamu85No ratings yet

- WarningDocument1 pageWarningBaiuliang BaiuliangNo ratings yet

- Sebu7763-03 BDocument4 pagesSebu7763-03 BHernan SanchezNo ratings yet

- Interval Service CB24Document4 pagesInterval Service CB24Alvaro Jose Peñata GiraldoNo ratings yet

- 3208 Marine 75v1-Up 01z1-UpDocument52 pages3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- AD45B Underground Articulated Truck - Service SheetDocument7 pagesAD45B Underground Articulated Truck - Service SheetaleciolyraNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- 3116 MaintenanceDocument33 pages3116 MaintenanceCesar Gongora100% (8)

- CAT Antes de Usar TH460BDocument4 pagesCAT Antes de Usar TH460Bmiguel0% (1)

- 01 220043enc Routine Turbine MaintenanceDocument8 pages01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- 3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance Intervals PDFDocument92 pages3406E, C-10, C-12, C-15 and C-16 On-Highway Engines-Maintenance Intervals PDFmarcosluna68100% (1)

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- Mooney M20 100 Hour Annual 2007Document2 pagesMooney M20 100 Hour Annual 2007flyokie100% (1)

- Maintenance and LubricationDocument34 pagesMaintenance and Lubricationtoppen_76100% (1)

- Shovel and DraglinesDocument9 pagesShovel and DraglinesPearl Carmona CaberteNo ratings yet

- Gmi 2202312228096Document5 pagesGmi 2202312228096Kishan PatelNo ratings yet

- Service Programme Backhoe Loaders: Construction EquipmentDocument5 pagesService Programme Backhoe Loaders: Construction EquipmentMACHINERY101GEARNo ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualKJDNKJZEFNo ratings yet

- Maintenance Interval Schedule: When RequiredDocument4 pagesMaintenance Interval Schedule: When RequiredSain MezaNo ratings yet

- 302 Cat Service ScheduleDocument3 pages302 Cat Service ScheduleNathan PittsNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- C15 MohDocument6 pagesC15 Mohharikrishnanpd3327No ratings yet

- 160M Maintenance IntervalDocument3 pages160M Maintenance IntervalJoko WahonoNo ratings yet

- Mantenimiento Lek 3500Document4 pagesMantenimiento Lek 3500Ana María AcostaNo ratings yet

- Yamaha 2009 Maintenance ChartsDocument7 pagesYamaha 2009 Maintenance ChartskapniasNo ratings yet

- Regular Maintenance 3: 3 ServiceDocument24 pagesRegular Maintenance 3: 3 ServiceMiguel MartínezNo ratings yet

- 4.2 Service SheetDocument2 pages4.2 Service SheetRichard PorterNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFDocument4 pagesD8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POWERED BY 3406C Engine (SEBP2536 - 130) - Documentation PDFSaid FahmiNo ratings yet

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDocument51 pagesSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102No ratings yet

- Maintenance Schedule 320D FAL Series ExcavatorDocument5 pagesMaintenance Schedule 320D FAL Series ExcavatorNiten Gupta50% (2)

- Sebu6617-04 MDocument38 pagesSebu6617-04 MCDDPPJNo ratings yet

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Engine Electrical SystemDocument48 pagesEngine Electrical SystemZM OhnNo ratings yet

- Sequential Turbocharging Part2Document4 pagesSequential Turbocharging Part2Krzysztof DanileckiNo ratings yet

- ELECTRIC WIRING - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsDocument3 pagesELECTRIC WIRING - WHEEL EXCAVATOR Doosan DX55W - BODY PARTS - 777partsJUAN CARDONANo ratings yet

- Aircraft Tyre Maintenance - SKYbrary Aviation SafetyDocument8 pagesAircraft Tyre Maintenance - SKYbrary Aviation Safetynosh1983No ratings yet

- HHF 1000 Parts Manual 1Document6 pagesHHF 1000 Parts Manual 1Kapil AgarwalNo ratings yet

- VRF SB DF 003 US-014B14 LGSubmittal HSD ARNU123BHA2 20140320133004Document2 pagesVRF SB DF 003 US-014B14 LGSubmittal HSD ARNU123BHA2 20140320133004Heildrick ValerosoNo ratings yet

- DuraCirc 63 Hi-Flow Horizontal Top Tech SpecDocument3 pagesDuraCirc 63 Hi-Flow Horizontal Top Tech SpecDiego BorgesNo ratings yet

- Abs & TCSDocument40 pagesAbs & TCSP.Prem Kumar AP - I - MechanicalNo ratings yet

- CS54B - CompactorDocument4 pagesCS54B - CompactorhendrynNo ratings yet

- Aero 2017-01-1592 SAEDocument8 pagesAero 2017-01-1592 SAEtsfnz111No ratings yet

- 20600e Hci 750 HP 500-650 Ton Top DriveDocument2 pages20600e Hci 750 HP 500-650 Ton Top Drivejulioramca100% (1)

- Downloaded From Manuals Search EngineDocument57 pagesDownloaded From Manuals Search Engineviola beckNo ratings yet

- AutomobilesDocument9 pagesAutomobilesaaryaNo ratings yet

- U3 ISADocument26 pagesU3 ISAjeyrajiNo ratings yet

- SDLG L959F Wheel Loader BrochureDocument4 pagesSDLG L959F Wheel Loader BrochureBABA GlobalNo ratings yet

- DNV Marpol Annex VI Guide Lines LSHFO PositionsDocument32 pagesDNV Marpol Annex VI Guide Lines LSHFO Positionsch3g44No ratings yet

- ENGINEDocument41 pagesENGINEAbdel Rahman El NobyNo ratings yet

- Yanmar - b22-2Document237 pagesYanmar - b22-2jazkoNo ratings yet

- TPM Project CharterDocument45 pagesTPM Project CharteronikoyilanreNo ratings yet

- Caterpillar Cat M313D WHEELED Excavator (Prefix J3A) Service Repair Manual (J3A00001 and Up) PDFDocument27 pagesCaterpillar Cat M313D WHEELED Excavator (Prefix J3A) Service Repair Manual (J3A00001 and Up) PDFfkdmmaNo ratings yet

- Analysis of Purchase Decision and Its Impacts Towards Honda Beat Motorcycle's Customer Satisfaction Viewed Through Product Quality and Price Perception Variables at Tangerang City AreaDocument8 pagesAnalysis of Purchase Decision and Its Impacts Towards Honda Beat Motorcycle's Customer Satisfaction Viewed Through Product Quality and Price Perception Variables at Tangerang City AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 6M125A-5 SeriesDocument2 pages6M125A-5 SeriesTruong Nguyen ThanhNo ratings yet

- RHEADocument43 pagesRHEARomzen DialaNo ratings yet

- Oisd STD 127Document23 pagesOisd STD 127Priyank SutariyaNo ratings yet

- 10th Meeting of SC TED 27Document83 pages10th Meeting of SC TED 27Gaurav GuptaNo ratings yet

- RC 22 PartslistDocument1 pageRC 22 PartslistMahmoud AliNo ratings yet

- Service and Maintenance 13L IndustryDocument84 pagesService and Maintenance 13L IndustryLuciano de AlmeidaNo ratings yet

- Roke Manor Research: Sensor TechnologyDocument12 pagesRoke Manor Research: Sensor TechnologyNguyen Xuan NhuNo ratings yet

- Theory: AIM: To Determine The Traffic Volume Count of An Urban Road Stretch APPARATUS: Data Sheet, Stop WatchDocument4 pagesTheory: AIM: To Determine The Traffic Volume Count of An Urban Road Stretch APPARATUS: Data Sheet, Stop WatchStevan StrangeNo ratings yet