Professional Documents

Culture Documents

Operation of Dyeing Machine 01

Operation of Dyeing Machine 01

Uploaded by

Aris PurnamaCopyright:

Available Formats

You might also like

- HEALING CARDS - Crop Circles Remote Healing CardsDocument4 pagesHEALING CARDS - Crop Circles Remote Healing Cardscyberbaga71% (7)

- Batch Manufacturing Record SAMPLEDocument8 pagesBatch Manufacturing Record SAMPLETrilochan Ayurveda71% (7)

- SOP For Quality Control in Feed Production ProcessDocument15 pagesSOP For Quality Control in Feed Production ProcessBằng89% (19)

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Operation of Winding Machine 03Document2 pagesOperation of Winding Machine 03Aris PurnamaNo ratings yet

- Operation of Drying Machine 02Document2 pagesOperation of Drying Machine 02Aris PurnamaNo ratings yet

- Single-Feed Polarization Reconfigurable Patch AntennaDocument4 pagesSingle-Feed Polarization Reconfigurable Patch AntennaMuhammad Syahir BadruddinNo ratings yet

- Filling ProsesDocument8 pagesFilling ProsesIkhwan BachdimNo ratings yet

- No. Manufacturer Category Country of Origin Product: Option 1: List of External ProductsDocument1 pageNo. Manufacturer Category Country of Origin Product: Option 1: List of External ProductsThurgah VshinyNo ratings yet

- Work Standar Lube Oil PurifierDocument4 pagesWork Standar Lube Oil Purifierasri elektronikNo ratings yet

- Untitled DiagramDocument1 pageUntitled DiagramMohd Izzat Abd GhaniNo ratings yet

- Optimization of Finishing Parameters To Impart Various Finishes On Different FibresDocument41 pagesOptimization of Finishing Parameters To Impart Various Finishes On Different Fibresnagpal_aakashNo ratings yet

- Work Standar Vapor ExtractorDocument5 pagesWork Standar Vapor Extractorasri elektronikNo ratings yet

- Jigger Dyeing ProblemsDocument6 pagesJigger Dyeing ProblemsAwais Imran0% (1)

- RA HSE 12 001 Process Rev03Document3 pagesRA HSE 12 001 Process Rev03zarni77No ratings yet

- Hira of RCC WorkDocument2 pagesHira of RCC WorkGyanendra SrivastavaNo ratings yet

- EUEC Mercury NumberDocument12 pagesEUEC Mercury NumberRobert HustonNo ratings yet

- Etp Final ReportDocument12 pagesEtp Final ReportJesse OhNo ratings yet

- Topic 2 - Measurement Techniques AS LevelDocument4 pagesTopic 2 - Measurement Techniques AS LevelDellaNo ratings yet

- Remediealsolutionincottonwetprocessingshroff 140509102039 Phpapp01Document52 pagesRemediealsolutionincottonwetprocessingshroff 140509102039 Phpapp01Chiman VaghasiaNo ratings yet

- Final Assessment Assignment: Dr. M. Ahsan Akhtar Hasin Course Instructor: MGT 675Document11 pagesFinal Assessment Assignment: Dr. M. Ahsan Akhtar Hasin Course Instructor: MGT 675Nabila Nawsaba Chowdhury 1935327060No ratings yet

- CBC SaltDocument9 pagesCBC SaltChristopher RagasaNo ratings yet

- ME Lab DetailsDocument4 pagesME Lab Detailsabhilash sharanNo ratings yet

- Inspection & Test PlanDocument4 pagesInspection & Test PlanZainarul Aswad RazaliNo ratings yet

- SMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionDocument1 pageSMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionImmalatulhusnaNo ratings yet

- In House Quality SystemDocument1 pageIn House Quality SystemBem's SquadNo ratings yet

- Sami Risk AssesmentDocument2 pagesSami Risk AssesmentahmedNo ratings yet

- AgendaDocument2 pagesAgendaJonas AsoyNo ratings yet

- Kobelco Issues and ActionsDocument10 pagesKobelco Issues and Actionssonawaneyogesh694No ratings yet

- 7 Step PfmeaDocument132 pages7 Step PfmeaRajdeep SikdarNo ratings yet

- Squizeer Machine: Presented by-Ar-Rafi HridayDocument11 pagesSquizeer Machine: Presented by-Ar-Rafi HridayAr Rafi HridayNo ratings yet

- B2000 - Proper Assist PDFDocument9 pagesB2000 - Proper Assist PDFOmar Ramirez SarmientoNo ratings yet

- 16 Inj. Heading MachineDocument2 pages16 Inj. Heading Machinesktripathy.1984No ratings yet

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- QCPC Pmi FanDocument14 pagesQCPC Pmi FanMaelEdwardAritonangNo ratings yet

- Inspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesInspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Materi Cara Pembuatan PCB Di SMTDocument3 pagesMateri Cara Pembuatan PCB Di SMTrizkiamandasNo ratings yet

- Understanding PCB Assy Process: I. Summary ActivityDocument3 pagesUnderstanding PCB Assy Process: I. Summary ActivityrizkiamandasNo ratings yet

- JSA Mengelas Di Dalam Tanki BoilerDocument3 pagesJSA Mengelas Di Dalam Tanki BoilerDanangNo ratings yet

- System and Work Methodology For Casting Final 2Document6 pagesSystem and Work Methodology For Casting Final 2Dan GoNo ratings yet

- D Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesD Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- LG Panasonic SamsungDocument4 pagesLG Panasonic SamsungWan HamzahNo ratings yet

- SCX-6555N-6545N Error CodesDocument15 pagesSCX-6555N-6545N Error CodesdoranlucaNo ratings yet

- PT Afs Ws. Chi - Balikpapan Update Lokasi CCTV Diperiksa Oleh: Herry KurniawanDocument2 pagesPT Afs Ws. Chi - Balikpapan Update Lokasi CCTV Diperiksa Oleh: Herry KurniawanHerry KurniawanNo ratings yet

- Spec of ThermometerDocument2 pagesSpec of ThermometerAdme InternacionalNo ratings yet

- Test Glo-Qc-Tm-0699Document5 pagesTest Glo-Qc-Tm-0699rx bafnaNo ratings yet

- EC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCDocument8 pagesEC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCThomas GalindoNo ratings yet

- S-077000-04FRM Particulars of Lubricating OilDocument1 pageS-077000-04FRM Particulars of Lubricating OilGaurav MaithilNo ratings yet

- Specification, GCIDocument9 pagesSpecification, GCImaxmoron600No ratings yet

- Test1 MenuDocument1 pageTest1 MenuJose Luis Garcia LopezNo ratings yet

- ITEM: Paraffinic Oil: Sl. No. Parameter UOM SpecificationDocument1 pageITEM: Paraffinic Oil: Sl. No. Parameter UOM SpecificationAtul SarafNo ratings yet

- DE-QC-IT-S01 (Inspection & Test Plan)Document8 pagesDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNo ratings yet

- Predictive Maintenance: 1 Induction FurnaceDocument14 pagesPredictive Maintenance: 1 Induction Furnacenayan vyasNo ratings yet

- Coal Sampler Operation: 1. PurposeDocument7 pagesCoal Sampler Operation: 1. PurposeAnis SuryadiNo ratings yet

- Coating Procedure - Sop 06 Painting ControlDocument1 pageCoating Procedure - Sop 06 Painting ControlajimalbaljeetNo ratings yet

- Work Standard COP (English)Document3 pagesWork Standard COP (English)asri elektronikNo ratings yet

- A13T English ManualDocument1 pageA13T English ManualAndy AndyNo ratings yet

- Revise Hazop Nga Ni Ka FermenterDocument2 pagesRevise Hazop Nga Ni Ka FermenterRomel Leo100% (2)

- A Treatise On The Structure and Preservation of The ViolinDocument114 pagesA Treatise On The Structure and Preservation of The Violinkoutetsu100% (1)

- Standard Channel - EuropeanDocument2 pagesStandard Channel - EuropeanKiara Ticangan ArgelNo ratings yet

- Software Selection For Enterprise Resource Planning WhitepaperDocument12 pagesSoftware Selection For Enterprise Resource Planning WhitepaperRudyandiPradityaNo ratings yet

- New Drawer Slide Products From Accuride 2012Document2 pagesNew Drawer Slide Products From Accuride 2012Susan WitkowskiNo ratings yet

- Ci An7149nDocument4 pagesCi An7149nArturo AresgalNo ratings yet

- 3DQuickPress For Auto PartsDocument20 pages3DQuickPress For Auto PartsgdgfdNo ratings yet

- Igw GuidelinesDocument49 pagesIgw Guidelineskrul786100% (1)

- Dual Broadband Antenna: 65° 2.0 M X-Polarized RET AntennaDocument2 pagesDual Broadband Antenna: 65° 2.0 M X-Polarized RET Antennacarlosconstructor1No ratings yet

- Manual Equipo Pintura Titan SpeefloDocument32 pagesManual Equipo Pintura Titan SpeefloJulio Rolong OrtizNo ratings yet

- RF Probe-Watt MeterDocument6 pagesRF Probe-Watt MeterJaime LazoNo ratings yet

- Indian Institute of Science,: Course Programme (Me/ M Tech/ M Des) 2014Document2 pagesIndian Institute of Science,: Course Programme (Me/ M Tech/ M Des) 2014Piyush TakkarNo ratings yet

- Customers Satisfactionofbsnl ServicesDocument11 pagesCustomers Satisfactionofbsnl Servicesnira007No ratings yet

- Guidelines - Editorial GuidelinesDocument6 pagesGuidelines - Editorial GuidelinesDavid HundeyinNo ratings yet

- Chapter 1: WAN Concepts: CCNA Routing and Switching Connecting Networks v6.0Document44 pagesChapter 1: WAN Concepts: CCNA Routing and Switching Connecting Networks v6.0Ardale PalilloNo ratings yet

- Parker SSD 890 Quick Start Frames G H JDocument26 pagesParker SSD 890 Quick Start Frames G H Jeng_karamazabNo ratings yet

- Unesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsDocument8 pagesUnesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsAnonymous qDCftTW5MNo ratings yet

- MT6735 Android ScatterDocument7 pagesMT6735 Android ScatterAhmed SayedNo ratings yet

- Instrumentation in TunnelsDocument14 pagesInstrumentation in Tunnelssravan_ruby100% (2)

- Digital Control - K. M. MoudgalyaDocument151 pagesDigital Control - K. M. MoudgalyaHHOLINo ratings yet

- 10 1002@etep 4450100505 PDFDocument8 pages10 1002@etep 4450100505 PDFrsantanaNo ratings yet

- Nov Dec 2011 Theory ExamDocument118 pagesNov Dec 2011 Theory ExamHem KantNo ratings yet

- Yotamine Machine Learning SDocument10 pagesYotamine Machine Learning SJadisha YarifNo ratings yet

- Template For Lesson Plan: Students ("Who")Document3 pagesTemplate For Lesson Plan: Students ("Who")api-405712417No ratings yet

- Flexpod Select For High-Performance Oracle Rac: Nva DesignDocument21 pagesFlexpod Select For High-Performance Oracle Rac: Nva Designsushil@irdNo ratings yet

- HMC BasicDocument14 pagesHMC BasicShashankNo ratings yet

- Okanagan Charter: An International Charter For Health Promoting Universities & CollegesDocument12 pagesOkanagan Charter: An International Charter For Health Promoting Universities & CollegesAshley DayanaNo ratings yet

- J2ME Viva Questions & AnswersDocument10 pagesJ2ME Viva Questions & Answersnayanisateesh2805No ratings yet

- Datasheet: Leica Viva GNSS GS12 ReceiverDocument2 pagesDatasheet: Leica Viva GNSS GS12 ReceiverDonovan HarrellNo ratings yet

- BiPAP Oxymed HypnusDocument8 pagesBiPAP Oxymed Hypnuskeshav surgicalsNo ratings yet

Operation of Dyeing Machine 01

Operation of Dyeing Machine 01

Uploaded by

Aris PurnamaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation of Dyeing Machine 01

Operation of Dyeing Machine 01

Uploaded by

Aris PurnamaCopyright:

Available Formats

염 색 기 의 운 전

Operation of Dyeing Machine

1. Purpose

To secure the safety of the workers operating dyeing machines, and to lead them up to the standard

procedures of operating.

2. Scope

To specifies the standard procedure in operating dyeing machines.

3. Responsibility and Authority

3.1. Production GM

(1) Issue <Dyeing Recipe> when he receives <Dyeing Request> from Marketing Department.

(2) Issue <Swatch Slip> according to the contents of <Dyeing Request>

(3) Control over dyeing machines during operation.

4. Operation of Dyeing Machine

4.1. Dyeing Process

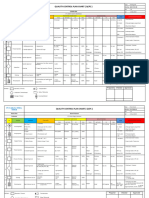

4.2. SOP of Dyeing Machine

Production GM shall put the following SOP of Dyeing machine on the open space of walls.

SOP of Dyeing Machine (for posting up)

Photo Operation Procedures

1. Identify item and quantity with Dyeing Request.

2. Identify color with Dyeing Request

Preparation

3. Dyestuff and Chemical Agent to be ready

4. Put the cheeses on the Cheese Carrier

1. Water into the Kier.

2. Carrier into the Kier

3. Solution of Dyestuff + Chemical Agent

Operating

4. Starting Motor Switch

5. Adjusting Steam Valve

6. Wash out after Dyeing

7. Move Dyed Yarn to Drying M/c

Control Mal-

Attention! Freq.

Point Function

(for Worker’s Safety)

Temp Every

1. Rubber Boots/ Rubber Gloves 1 Temp. Re-Dyeing

Check Points

±5℃ Dyeing

2. Mind possible Burn

3. Mind Short-circuit of Electricity

Longer

4. Beware of Slippery Floor 2 Time -ditto- -ditto-

Time

(Attention to:)

1. Correct Weight of Dyestuffs Control

Pressur

2. Skilled Mixing 3 Point -ditto- -ditto-

e

3. Time/Pressure ±0.2kg

You might also like

- HEALING CARDS - Crop Circles Remote Healing CardsDocument4 pagesHEALING CARDS - Crop Circles Remote Healing Cardscyberbaga71% (7)

- Batch Manufacturing Record SAMPLEDocument8 pagesBatch Manufacturing Record SAMPLETrilochan Ayurveda71% (7)

- SOP For Quality Control in Feed Production ProcessDocument15 pagesSOP For Quality Control in Feed Production ProcessBằng89% (19)

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Operation of Winding Machine 03Document2 pagesOperation of Winding Machine 03Aris PurnamaNo ratings yet

- Operation of Drying Machine 02Document2 pagesOperation of Drying Machine 02Aris PurnamaNo ratings yet

- Single-Feed Polarization Reconfigurable Patch AntennaDocument4 pagesSingle-Feed Polarization Reconfigurable Patch AntennaMuhammad Syahir BadruddinNo ratings yet

- Filling ProsesDocument8 pagesFilling ProsesIkhwan BachdimNo ratings yet

- No. Manufacturer Category Country of Origin Product: Option 1: List of External ProductsDocument1 pageNo. Manufacturer Category Country of Origin Product: Option 1: List of External ProductsThurgah VshinyNo ratings yet

- Work Standar Lube Oil PurifierDocument4 pagesWork Standar Lube Oil Purifierasri elektronikNo ratings yet

- Untitled DiagramDocument1 pageUntitled DiagramMohd Izzat Abd GhaniNo ratings yet

- Optimization of Finishing Parameters To Impart Various Finishes On Different FibresDocument41 pagesOptimization of Finishing Parameters To Impart Various Finishes On Different Fibresnagpal_aakashNo ratings yet

- Work Standar Vapor ExtractorDocument5 pagesWork Standar Vapor Extractorasri elektronikNo ratings yet

- Jigger Dyeing ProblemsDocument6 pagesJigger Dyeing ProblemsAwais Imran0% (1)

- RA HSE 12 001 Process Rev03Document3 pagesRA HSE 12 001 Process Rev03zarni77No ratings yet

- Hira of RCC WorkDocument2 pagesHira of RCC WorkGyanendra SrivastavaNo ratings yet

- EUEC Mercury NumberDocument12 pagesEUEC Mercury NumberRobert HustonNo ratings yet

- Etp Final ReportDocument12 pagesEtp Final ReportJesse OhNo ratings yet

- Topic 2 - Measurement Techniques AS LevelDocument4 pagesTopic 2 - Measurement Techniques AS LevelDellaNo ratings yet

- Remediealsolutionincottonwetprocessingshroff 140509102039 Phpapp01Document52 pagesRemediealsolutionincottonwetprocessingshroff 140509102039 Phpapp01Chiman VaghasiaNo ratings yet

- Final Assessment Assignment: Dr. M. Ahsan Akhtar Hasin Course Instructor: MGT 675Document11 pagesFinal Assessment Assignment: Dr. M. Ahsan Akhtar Hasin Course Instructor: MGT 675Nabila Nawsaba Chowdhury 1935327060No ratings yet

- CBC SaltDocument9 pagesCBC SaltChristopher RagasaNo ratings yet

- ME Lab DetailsDocument4 pagesME Lab Detailsabhilash sharanNo ratings yet

- Inspection & Test PlanDocument4 pagesInspection & Test PlanZainarul Aswad RazaliNo ratings yet

- SMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionDocument1 pageSMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionImmalatulhusnaNo ratings yet

- In House Quality SystemDocument1 pageIn House Quality SystemBem's SquadNo ratings yet

- Sami Risk AssesmentDocument2 pagesSami Risk AssesmentahmedNo ratings yet

- AgendaDocument2 pagesAgendaJonas AsoyNo ratings yet

- Kobelco Issues and ActionsDocument10 pagesKobelco Issues and Actionssonawaneyogesh694No ratings yet

- 7 Step PfmeaDocument132 pages7 Step PfmeaRajdeep SikdarNo ratings yet

- Squizeer Machine: Presented by-Ar-Rafi HridayDocument11 pagesSquizeer Machine: Presented by-Ar-Rafi HridayAr Rafi HridayNo ratings yet

- B2000 - Proper Assist PDFDocument9 pagesB2000 - Proper Assist PDFOmar Ramirez SarmientoNo ratings yet

- 16 Inj. Heading MachineDocument2 pages16 Inj. Heading Machinesktripathy.1984No ratings yet

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- QCPC Pmi FanDocument14 pagesQCPC Pmi FanMaelEdwardAritonangNo ratings yet

- Inspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesInspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Materi Cara Pembuatan PCB Di SMTDocument3 pagesMateri Cara Pembuatan PCB Di SMTrizkiamandasNo ratings yet

- Understanding PCB Assy Process: I. Summary ActivityDocument3 pagesUnderstanding PCB Assy Process: I. Summary ActivityrizkiamandasNo ratings yet

- JSA Mengelas Di Dalam Tanki BoilerDocument3 pagesJSA Mengelas Di Dalam Tanki BoilerDanangNo ratings yet

- System and Work Methodology For Casting Final 2Document6 pagesSystem and Work Methodology For Casting Final 2Dan GoNo ratings yet

- D Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesD Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- LG Panasonic SamsungDocument4 pagesLG Panasonic SamsungWan HamzahNo ratings yet

- SCX-6555N-6545N Error CodesDocument15 pagesSCX-6555N-6545N Error CodesdoranlucaNo ratings yet

- PT Afs Ws. Chi - Balikpapan Update Lokasi CCTV Diperiksa Oleh: Herry KurniawanDocument2 pagesPT Afs Ws. Chi - Balikpapan Update Lokasi CCTV Diperiksa Oleh: Herry KurniawanHerry KurniawanNo ratings yet

- Spec of ThermometerDocument2 pagesSpec of ThermometerAdme InternacionalNo ratings yet

- Test Glo-Qc-Tm-0699Document5 pagesTest Glo-Qc-Tm-0699rx bafnaNo ratings yet

- EC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCDocument8 pagesEC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCThomas GalindoNo ratings yet

- S-077000-04FRM Particulars of Lubricating OilDocument1 pageS-077000-04FRM Particulars of Lubricating OilGaurav MaithilNo ratings yet

- Specification, GCIDocument9 pagesSpecification, GCImaxmoron600No ratings yet

- Test1 MenuDocument1 pageTest1 MenuJose Luis Garcia LopezNo ratings yet

- ITEM: Paraffinic Oil: Sl. No. Parameter UOM SpecificationDocument1 pageITEM: Paraffinic Oil: Sl. No. Parameter UOM SpecificationAtul SarafNo ratings yet

- DE-QC-IT-S01 (Inspection & Test Plan)Document8 pagesDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNo ratings yet

- Predictive Maintenance: 1 Induction FurnaceDocument14 pagesPredictive Maintenance: 1 Induction Furnacenayan vyasNo ratings yet

- Coal Sampler Operation: 1. PurposeDocument7 pagesCoal Sampler Operation: 1. PurposeAnis SuryadiNo ratings yet

- Coating Procedure - Sop 06 Painting ControlDocument1 pageCoating Procedure - Sop 06 Painting ControlajimalbaljeetNo ratings yet

- Work Standard COP (English)Document3 pagesWork Standard COP (English)asri elektronikNo ratings yet

- A13T English ManualDocument1 pageA13T English ManualAndy AndyNo ratings yet

- Revise Hazop Nga Ni Ka FermenterDocument2 pagesRevise Hazop Nga Ni Ka FermenterRomel Leo100% (2)

- A Treatise On The Structure and Preservation of The ViolinDocument114 pagesA Treatise On The Structure and Preservation of The Violinkoutetsu100% (1)

- Standard Channel - EuropeanDocument2 pagesStandard Channel - EuropeanKiara Ticangan ArgelNo ratings yet

- Software Selection For Enterprise Resource Planning WhitepaperDocument12 pagesSoftware Selection For Enterprise Resource Planning WhitepaperRudyandiPradityaNo ratings yet

- New Drawer Slide Products From Accuride 2012Document2 pagesNew Drawer Slide Products From Accuride 2012Susan WitkowskiNo ratings yet

- Ci An7149nDocument4 pagesCi An7149nArturo AresgalNo ratings yet

- 3DQuickPress For Auto PartsDocument20 pages3DQuickPress For Auto PartsgdgfdNo ratings yet

- Igw GuidelinesDocument49 pagesIgw Guidelineskrul786100% (1)

- Dual Broadband Antenna: 65° 2.0 M X-Polarized RET AntennaDocument2 pagesDual Broadband Antenna: 65° 2.0 M X-Polarized RET Antennacarlosconstructor1No ratings yet

- Manual Equipo Pintura Titan SpeefloDocument32 pagesManual Equipo Pintura Titan SpeefloJulio Rolong OrtizNo ratings yet

- RF Probe-Watt MeterDocument6 pagesRF Probe-Watt MeterJaime LazoNo ratings yet

- Indian Institute of Science,: Course Programme (Me/ M Tech/ M Des) 2014Document2 pagesIndian Institute of Science,: Course Programme (Me/ M Tech/ M Des) 2014Piyush TakkarNo ratings yet

- Customers Satisfactionofbsnl ServicesDocument11 pagesCustomers Satisfactionofbsnl Servicesnira007No ratings yet

- Guidelines - Editorial GuidelinesDocument6 pagesGuidelines - Editorial GuidelinesDavid HundeyinNo ratings yet

- Chapter 1: WAN Concepts: CCNA Routing and Switching Connecting Networks v6.0Document44 pagesChapter 1: WAN Concepts: CCNA Routing and Switching Connecting Networks v6.0Ardale PalilloNo ratings yet

- Parker SSD 890 Quick Start Frames G H JDocument26 pagesParker SSD 890 Quick Start Frames G H Jeng_karamazabNo ratings yet

- Unesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsDocument8 pagesUnesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsAnonymous qDCftTW5MNo ratings yet

- MT6735 Android ScatterDocument7 pagesMT6735 Android ScatterAhmed SayedNo ratings yet

- Instrumentation in TunnelsDocument14 pagesInstrumentation in Tunnelssravan_ruby100% (2)

- Digital Control - K. M. MoudgalyaDocument151 pagesDigital Control - K. M. MoudgalyaHHOLINo ratings yet

- 10 1002@etep 4450100505 PDFDocument8 pages10 1002@etep 4450100505 PDFrsantanaNo ratings yet

- Nov Dec 2011 Theory ExamDocument118 pagesNov Dec 2011 Theory ExamHem KantNo ratings yet

- Yotamine Machine Learning SDocument10 pagesYotamine Machine Learning SJadisha YarifNo ratings yet

- Template For Lesson Plan: Students ("Who")Document3 pagesTemplate For Lesson Plan: Students ("Who")api-405712417No ratings yet

- Flexpod Select For High-Performance Oracle Rac: Nva DesignDocument21 pagesFlexpod Select For High-Performance Oracle Rac: Nva Designsushil@irdNo ratings yet

- HMC BasicDocument14 pagesHMC BasicShashankNo ratings yet

- Okanagan Charter: An International Charter For Health Promoting Universities & CollegesDocument12 pagesOkanagan Charter: An International Charter For Health Promoting Universities & CollegesAshley DayanaNo ratings yet

- J2ME Viva Questions & AnswersDocument10 pagesJ2ME Viva Questions & Answersnayanisateesh2805No ratings yet

- Datasheet: Leica Viva GNSS GS12 ReceiverDocument2 pagesDatasheet: Leica Viva GNSS GS12 ReceiverDonovan HarrellNo ratings yet

- BiPAP Oxymed HypnusDocument8 pagesBiPAP Oxymed Hypnuskeshav surgicalsNo ratings yet