Professional Documents

Culture Documents

Product Data Sheet BORNIT Asphalt Repair Mortar English

Product Data Sheet BORNIT Asphalt Repair Mortar English

Uploaded by

Doru DoruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data Sheet BORNIT Asphalt Repair Mortar English

Product Data Sheet BORNIT Asphalt Repair Mortar English

Uploaded by

Doru DoruCopyright:

Available Formats

PRODUCT DATA SHEET

Asphalt Repair Mortar status from 06 August 2020

page 1/4

SERVICE-HOTLINE +49 375 2795 123

Asphalt Repair Mortar

bitumen | road construction | potholes | excavations | repair mortar | mortar

short information consumption

• multi-component repair asphalt • approx. 20 kg/m² per cm of layer

• for fast closure of breakouts and thickness

unevennesses

• adjustment of traffic areas to inlets,

manhole covers and other

transitions storage note

• layer thicknesses of 5 to 20 mm • frost-free, avoid exposure to heat

(RE 30) above +30 °C and direct solar

• layer thicknesses of 10 to 30 mm irradiation

(RE 50) • in originally closed container

• quick hardening, cold-applicable storable for 3 months

• grain size 0 to 3 mm or 0 to 50 mm

complementary products

cleaning follow-up products

• BORNIT® MultiClean • WK stirrer (lifting - small quantities)

• BORNIT® MultiClean Spray • MK stirrer (lifting - large quantities)

• BORNIT® Bitumen Cleaner

content item EAN code colour sufficient for:

Asphalt Repair Mortar RE 30

18 kg / bucket 6700000137 4 017228 00905 6 black approx. 0.9 m²

24 bucket (432 kg) / euro pallet

Asphalt Repair Mortar RE 50

18 kg / bucket 6700000138 4 017228 00906 3 black approx. 0.9 m²

24 bucket (432 kg) / euro pallet

Observe mixing order!

BORNIT-Werk Aschenborn GmbH | Reichenbacher Straße 117 | 08056 Zwickau

Tel. +49 375 - 2795 - 0 | Fax +49 375 - 2795 - 150 | info@bornit.de | www.bornit.de

Each construction project is different - obtain information before getting started!

Service-Hotline +49 375 2795 123

PRODUCT DATA SHEET

Asphalt Repair Mortar status from 06 August 2020

page 2/4

SERVICE-HOTLINE +49 375 2795 123

areas of application

BORNIT® Repair Mortar RE 30 is used for the fast closure of breakouts and unevennesses as well as the

adjustment of traffic areas to inlets, manhole covers, surrounds and other transitions.

Due to the grain size of BORNIT® Repair Mortar RE 30, layer thicknesses of 2 to 20 mm can be produced.

Higher layer thicknesses are possible with repeated application. The surfaces produced are traversable after

60 minutes.

product data in brief

product type multi-component repair material for asphalt and concrete surfaces

base chippings, bitumen, mineral hardener component

density at +20 °C Liquid component: approx. 0.90 g/cm³

Powder component: 2.75-3.20 g/cm³

Grit component: approx. 2.90 g/cm³

solvent none

application shovel, trowel, pounder

colour(s) black

consistency plastic after mixing

processing temperature (ambient and at least +5 °C

substrate)

processing time workable for approx. 5 - 10 minutes, at higher temperatures the

working time can be extremely shortened

thorough hardening time approx. 60 minutes

PH-value Liquid component: > 2.0

Powder component: 11.0 - 13.5

storage frost-free, avoid exposure to heat above +30 °C and direct solar

irradiation

shelf life in originally closed container storable for 3 months

GISCODE ZP1

BBP10

substances hazardous to health in terms none

of the ordinance on hazardous materials

hazard class according to ADR none

cleaning BORNIT® MultiClean Spray, BORNIT® MultiClean, BORNIT®

Bitumen Cleaner

Mixing time max. 2 minutes

Mixing order 1. mix grit with an anchor stirrer 2. mix in powder component dry 3.

mix in approx. 1.5 litres of water (consistency - earth-moist concrete)

4. shake and mix in emulsion (total mixing time max. 2 minutes!!!)

type and properties

BORNIT® Repair Mortar RE 30 is a multi-component, cold-applicable repair mortar for asphalt or concrete

traffic areas. The mineral portion (grain size 0/3 mm) required for preparing the mixture ready for processing

is included in the delivery container just as the polymer-modified bitumen emulsion (plastic bottle) and the

accelerator (plastic bag). The latter must be dosed depending on the temperature and, upon application of

the entire quantity, shortens the processing time, e.g. at 25 °C, to approx. 5 to 10 minutes.

BORNIT-Werk Aschenborn GmbH | Reichenbacher Straße 117 | 08056 Zwickau

Tel. +49 375 - 2795 - 0 | Fax +49 375 - 2795 - 150 | info@bornit.de | www.bornit.de

Each construction project is different - obtain information before getting started!

Service-Hotline +49 375 2795 123

PRODUCT DATA SHEET

Asphalt Repair Mortar status from 06 August 2020

page 3/4

SERVICE-HOTLINE +49 375 2795 123

advantages

• good adhesion

• solvent free

• economical and cost-cutting, due to low equipment and material costs and effort

surface

The substrate must be firm and clean.

processing

The substrate for application must be clean, free from oil and grease, as well as have sufficient strength and

load-bearing capacity (asphalt). Soil, grit or antifreeze substrates are not suitable!

Loose particles as well as standing water must be removed. With summer outdoor temperatures,

moistening of the substrate is recommended. Processing must not be undertaken in the rain or at outside

temperatures below +5 °C. In very hot weather (over +25 °C) or upon using materials stored under hot

conditions (e.g. in a vehicle), the processing time can shorten such that processability is lost during mixing

already. Therefore, application should always be undertaken during a cooler time of day.

The coordinated components can be mixed right in the container. First, the accelerator (small bag) is

admixed with the crushed sand in a dry state. Subsequently, up to 1.5 litres of water are admixed in portions

under stirring, until the consistency of an earth-moist concrete is achieved.

The bitumen emulsion must be shaken well prior to use, and is then added to the prepared mixture.

Blending is undertaken using a trowel, shovel or slow-running stirrer, until a uniform brown colouring is

achieved.

The mixing time should not exceed 1-2 minutes.

Depending on the outside temperature, the repair compound stays processable for 5 to 10 minutes – the

higher the temperatures, the shorter the processing time applies as a rule. The repair compound is filled into

the prepared spot to be repaired and smoothed using a trowel or shovel applying slight pressure.

Subsequently, sand is spread onto the surface.

consumption

approx. 20 kg/m² per cm of layer thickness

health and fire protection, occupational safety

To ensure safe handling of the product, the physical, safety, toxicological and ecological information

provided online, the information in the current safety data sheet and the additional information on the label

must be read and followed before purchasing or using the product! The applicable regulations, ordinances

and laws must be complied with.

In case of doubt, please contact the BORNIT® application technology department or the BORNIT® service

hotline on +49 375 2795 123.

notes component A

BORNIT-Werk Aschenborn GmbH | Reichenbacher Straße 117 | 08056 Zwickau

Tel. +49 375 - 2795 - 0 | Fax +49 375 - 2795 - 150 | info@bornit.de | www.bornit.de

Each construction project is different - obtain information before getting started!

Service-Hotline +49 375 2795 123

PRODUCT DATA SHEET

Asphalt Repair Mortar status from 06 August 2020

page 4/4

SERVICE-HOTLINE +49 375 2795 123

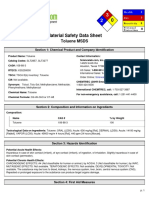

Hazard pictograms

signal word Gefahr

Hazard-determining Portland cement, Portland cement (dust)

components for labelling

H-records H315: Causes skin irritation.

H318: Causes serious eye damage.

H335: May cause respiratory irritation.

P-records P261: Avoid breathing dust/fume/gas/mist/vapours/spray.

P280: Wear protective gloves/protective clothing/eye protection/face protection/hearing protection.

P302 + P352: IF ON SKIN: Wash with plenty of water and soap.

P305 + P351 + P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if

present and easy to do. Continue rinsing.

P310: Immediately call a doctor.

P333 + P313: If skin irritation or rash occurs: Get medical advice/attention.

recommended, personal

protective equipment:

component B

H-records H412: Harmful to aquatic life with long lasting effects.

P-records P273: Avoid release to the environment.

P501: Dispose of contents/container to a suitable recycling or disposal facility.

recommended, personal

protective equipment:

disposal note

Only recycle completely empty containers. Material residues can be disposed of according to AVV-ASN:

170302 (bituminous mixtures, except for those falling under 170301).

note

This datasheet replaces any previous technical information about the product. Thus, this information is no

longer valid. The details have been compiled according to the latest state of application technology. Please

observe, however, that, depending on the state of the construction object, deviations from the method of

application suggested in the datasheet may be required. Unless agreed otherwise in individual contracts,

any information contained in the datasheet shall be non-binding and thus does not represent an agreed

product constitution. We reserve the right to any changes in the information contained in this datasheet

anytime. We recommend informing yourself about possible changes on our website www.bornit.de.

BORNIT-Werk Aschenborn GmbH | Reichenbacher Straße 117 | 08056 Zwickau

Tel. +49 375 - 2795 - 0 | Fax +49 375 - 2795 - 150 | info@bornit.de | www.bornit.de

Each construction project is different - obtain information before getting started!

Service-Hotline +49 375 2795 123

You might also like

- TM9-2320-304-14&p M1120 A2Document1,320 pagesTM9-2320-304-14&p M1120 A2pascalbausset100% (1)

- Work Order: Water Proofing of Toilets As Approved Method & DetailsDocument8 pagesWork Order: Water Proofing of Toilets As Approved Method & DetailsSwapnil Sharma100% (1)

- SparklingStars - Workplace Health and Safety PolicyDocument13 pagesSparklingStars - Workplace Health and Safety PolicyStephanie NGNo ratings yet

- HIRA NewDocument107 pagesHIRA NewPrabhakaran Gurunathan100% (1)

- HT MT: Smartset Thermo-Setting Solutions TechnologyDocument8 pagesHT MT: Smartset Thermo-Setting Solutions Technologygradisco36No ratings yet

- Jigsaw AssessmentDocument8 pagesJigsaw AssessmentNur Syafiqah Abu BakarNo ratings yet

- Sodium Chloride MSDSDocument9 pagesSodium Chloride MSDSMelroy D'souzaNo ratings yet

- Msds For CharcoalDocument7 pagesMsds For CharcoalIrwan KraskalNo ratings yet

- Health Facility Preparedness Readiness Rapid Assessment Checklist For COVID-19-icddrb-V10Document38 pagesHealth Facility Preparedness Readiness Rapid Assessment Checklist For COVID-19-icddrb-V10Taufiq SamadNo ratings yet

- Product Data Sheet BORNIT Grundbit EnglishDocument3 pagesProduct Data Sheet BORNIT Grundbit EnglishDoru DoruNo ratings yet

- Product Data Sheet BORNIT Reactive Asphalt EnglishDocument3 pagesProduct Data Sheet BORNIT Reactive Asphalt EnglishDoru DoruNo ratings yet

- Nanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument5 pagesNanocrete FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureVelmurugan BalasubramanianNo ratings yet

- Pre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDocument2 pagesPre-Formed, Self-Adhesive Rubber Bitumen/high Density Polyethylene Damp Proof MembraneDaniel PratamaNo ratings yet

- Alccobond BM - TB - GPDocument6 pagesAlccobond BM - TB - GPzuber shaikhNo ratings yet

- Pe 460 PDS GB 1218Document4 pagesPe 460 PDS GB 1218tri vien nguyen ngocNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- 6.6 Bondit SBRDocument4 pages6.6 Bondit SBRCristal Haze VictoriaNo ratings yet

- Bitu-Impervi LMDocument2 pagesBitu-Impervi LMJoeNo ratings yet

- Consol Grout 600 MF PDFDocument2 pagesConsol Grout 600 MF PDFKhaerul SidikNo ratings yet

- Jotafloor SF PR 150: Technical Data SheetDocument5 pagesJotafloor SF PR 150: Technical Data SheetSudu SalianNo ratings yet

- PAGEL EH196 Epoxy GroutDocument2 pagesPAGEL EH196 Epoxy GroutMUHAMMAD NOMANNo ratings yet

- Single Component Shrink-Free Structural Grout: FeaturesDocument2 pagesSingle Component Shrink-Free Structural Grout: Featuresmathewsujith31No ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Berger BisonFlex Wall Putty DataSheetDocument2 pagesBerger BisonFlex Wall Putty DataSheetdonaldduckmummyNo ratings yet

- TDS - Soudal Repair Express CementDocument2 pagesTDS - Soudal Repair Express CementЗоранNo ratings yet

- Comfort: Universal Thin-Bed Adhesive MortarDocument2 pagesComfort: Universal Thin-Bed Adhesive MortarVaittianathan MahavapillaiNo ratings yet

- TDS Weberdry 360 PUDocument3 pagesTDS Weberdry 360 PUMahmoudFarhatNo ratings yet

- FB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngDocument4 pagesFB 12 STC 025 en 03 - Struttura Raso Fino - RF 248 - EngrogirosNo ratings yet

- Muki EPS: Technical DataDocument3 pagesMuki EPS: Technical DataMohamed FarhanNo ratings yet

- Catalog enDocument14 pagesCatalog envishalNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Datarobi setiawanNo ratings yet

- Screedmaster: Rapid Repair MortarDocument2 pagesScreedmaster: Rapid Repair MortarAlex BocicaNo ratings yet

- MU-301 PlasterPlus - 0 - 2Document1 pageMU-301 PlasterPlus - 0 - 2Juniar Putra TheflyingdeadmanNo ratings yet

- MU-301 PlasterPlus 0Document1 pageMU-301 PlasterPlus 0M Herlangga TagalumbangNo ratings yet

- Product Datasheet - Nippon Floor-Pro-304-WB-Epoxy-PU-Hybrid-ClearDocument3 pagesProduct Datasheet - Nippon Floor-Pro-304-WB-Epoxy-PU-Hybrid-ClearArun StarlightNo ratings yet

- Sigmazinc 158 New PDFDocument7 pagesSigmazinc 158 New PDFgst ajahNo ratings yet

- Repair-Mortar Tec EngDocument2 pagesRepair-Mortar Tec EngPedroNo ratings yet

- Sikalastic®-8440: Product Data SheetDocument3 pagesSikalastic®-8440: Product Data SheetGeorge EnescuNo ratings yet

- SikaMonoTop 3020 en CORP 08 2020 1 1Document4 pagesSikaMonoTop 3020 en CORP 08 2020 1 1Mohamed Osama AshmawyNo ratings yet

- PACTOBond SBR-DatasheetDocument2 pagesPACTOBond SBR-DatasheethidiNo ratings yet

- Sta t03 Roff Stone Tile Adhesive 20 KGDocument2 pagesSta t03 Roff Stone Tile Adhesive 20 KG1am17ec014 ashnal ahmedNo ratings yet

- Sikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor HardenerDocument5 pagesSikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor Hardenermusiomi2005No ratings yet

- General Purpose Tile Adhesion Mortar: Tile Adhesive For Indoor AreasDocument2 pagesGeneral Purpose Tile Adhesion Mortar: Tile Adhesive For Indoor AreasVaittianathan MahavapillaiNo ratings yet

- 2566 - 30305 - Epoxy Grundierharz GH 50 - 20200513 - 110701Document4 pages2566 - 30305 - Epoxy Grundierharz GH 50 - 20200513 - 110701Maha MuflehNo ratings yet

- 2201 TDS RubbercoatDocument1 page2201 TDS RubbercoatMeet NaikNo ratings yet

- Sikagrout® GP: Product Data SheetDocument4 pagesSikagrout® GP: Product Data SheetCatherine Fatima Mae LeynoNo ratings yet

- Tuffkote: Epigard Epoxy Finish Bipigard Cte XLDocument2 pagesTuffkote: Epigard Epoxy Finish Bipigard Cte XLSHATABDI- DELNo ratings yet

- Sikafloor - 161 G PDFDocument4 pagesSikafloor - 161 G PDFShaik FazilNo ratings yet

- Durofloor Pu 211 11Document5 pagesDurofloor Pu 211 11Levan EradzeNo ratings yet

- Bentonite Bentonite Is Clay Containing Not Less Than 70% of MontmorilloniteDocument7 pagesBentonite Bentonite Is Clay Containing Not Less Than 70% of MontmorilloniteDavid ReskyNo ratings yet

- Sikadur®-42 IN: Product Data SheetDocument4 pagesSikadur®-42 IN: Product Data SheetJackson OmindiNo ratings yet

- Gypsum Plaster: Product Description Physical PropertiesDocument1 pageGypsum Plaster: Product Description Physical PropertiesImtiyazNo ratings yet

- GypsumPlasterDataSheet1 2 PDFDocument1 pageGypsumPlasterDataSheet1 2 PDFImtiyazNo ratings yet

- GypsumPlasterDataSheet1 2 PDFDocument1 pageGypsumPlasterDataSheet1 2 PDFImtiyazNo ratings yet

- TDS-PST DYNACOAT 1K Primer Surfacer Grey 200629 EnglishDocument4 pagesTDS-PST DYNACOAT 1K Primer Surfacer Grey 200629 EnglishTyler CroegaertNo ratings yet

- DS Granipan F20Document1 pageDS Granipan F20faridNo ratings yet

- Biofix 2022 inDocument5 pagesBiofix 2022 inSahil KaliaNo ratings yet

- Bipigard ST Cte Black PDFDocument2 pagesBipigard ST Cte Black PDFKhirod KroutNo ratings yet

- Alccoseal (QS)Document2 pagesAlccoseal (QS)Siddhesh Kamat MhamaiNo ratings yet

- Sikafloor® 161 HCDocument6 pagesSikafloor® 161 HCRenan SantosNo ratings yet

- Sikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerDocument2 pagesSikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerBruno AlfanoNo ratings yet

- Extract Page 1Document1 pageExtract Page 1SebastianAnNo ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- DR Fixit Floor Repair Mortar 66 1Document3 pagesDR Fixit Floor Repair Mortar 66 1Suzaikumar R SanglikarNo ratings yet

- Flyer Asphalt Pore SealerDocument4 pagesFlyer Asphalt Pore SealerDoru DoruNo ratings yet

- Instalay 30 Technical SpecificationDocument2 pagesInstalay 30 Technical SpecificationshanNo ratings yet

- AA13K Eng-Lindab - 20160226Document1 pageAA13K Eng-Lindab - 20160226Doru DoruNo ratings yet

- Division of Continuing Education Conduct AgreementDocument2 pagesDivision of Continuing Education Conduct AgreementDoru DoruNo ratings yet

- Product Data Sheet BORNIT Grundbit EnglishDocument3 pagesProduct Data Sheet BORNIT Grundbit EnglishDoru DoruNo ratings yet

- Declaration of Performance - T45 - Glossy - 0.70 - enDocument1 pageDeclaration of Performance - T45 - Glossy - 0.70 - enDoru DoruNo ratings yet

- City Promenade LuxembourgDocument4 pagesCity Promenade LuxembourgDoru DoruNo ratings yet

- Qcs Manual 2 38Document228 pagesQcs Manual 2 38Doru DoruNo ratings yet

- Nfpa 60-90Document31 pagesNfpa 60-90Doru DoruNo ratings yet

- Nfpa 1-30Document30 pagesNfpa 1-30Doru DoruNo ratings yet

- Dewa Phase Iii 800 MW PV Solar Power ProjectDocument14 pagesDewa Phase Iii 800 MW PV Solar Power ProjectPEMCO InspectionNo ratings yet

- GRASASDocument2 pagesGRASASJose Leonardo Peñaloza SuarezNo ratings yet

- SCRSDS-0280 v1 BinaxNOW COVID-19 Reagent SDS - US 195 - 4Document6 pagesSCRSDS-0280 v1 BinaxNOW COVID-19 Reagent SDS - US 195 - 4AbbySantosNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- 3.co - Deb1032 - Occupational Safety and HealthDocument11 pages3.co - Deb1032 - Occupational Safety and Healthwan nu’aimNo ratings yet

- MS150118 00eDocument170 pagesMS150118 00eabdou02014No ratings yet

- Kuisioner Chandra AsriDocument8 pagesKuisioner Chandra AsriTumbal PogoNo ratings yet

- MSDS TolueneDocument6 pagesMSDS TolueneSamuel AgusNo ratings yet

- Risk Assessments and Plans of Work: Asbestos EssentialsDocument3 pagesRisk Assessments and Plans of Work: Asbestos EssentialsMark BrewardNo ratings yet

- Hira For Steel Structural Erection WorkDocument26 pagesHira For Steel Structural Erection Workகண்ணன் ரவிச்சந்திரன்100% (1)

- Electrical Safety TrainingDocument52 pagesElectrical Safety TrainingtueresuecoNo ratings yet

- RA For Smart LockerDocument2 pagesRA For Smart LockerSuresh NaiduNo ratings yet

- Usechh 2000Document2 pagesUsechh 2000NeybilNo ratings yet

- Record Room HiraDocument14 pagesRecord Room HirakailashNo ratings yet

- Air Duct Servicing NC IIDocument91 pagesAir Duct Servicing NC IIMEL ANGELESNo ratings yet

- Carbon Dioxide Handling ManualDocument13 pagesCarbon Dioxide Handling Manualrafik1995No ratings yet

- Construction ErgonomicsDocument33 pagesConstruction ErgonomicsShailesh AtkariNo ratings yet

- COVID-19 EHS PlanDocument18 pagesCOVID-19 EHS Planyusuf BakhtiarNo ratings yet

- CSS Module-Melc 1-3 Grade 11Document22 pagesCSS Module-Melc 1-3 Grade 11Rina Brucal-DimayugaNo ratings yet

- TR Cookery NC IIDocument95 pagesTR Cookery NC IIvenieroseNo ratings yet

- Old - KPS - Sop - Hse - 008 Personal Protective Equipment V1.2Document10 pagesOld - KPS - Sop - Hse - 008 Personal Protective Equipment V1.2Norman CoetzeeNo ratings yet

- Industrial Training Presentation 2Document25 pagesIndustrial Training Presentation 2zarith sofeaNo ratings yet

- IGC2 Sample AnswersDocument7 pagesIGC2 Sample Answerspapaji75% (4)