Professional Documents

Culture Documents

SIZING Meter Run - R2

SIZING Meter Run - R2

Uploaded by

Alberto ReyesCopyright:

Available Formats

You might also like

- SIC001 Salton Induction Cooker Instruction ManualDocument18 pagesSIC001 Salton Induction Cooker Instruction ManualShawn FynnNo ratings yet

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: This Stamp Displays The Acrobat Folder PathsDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: This Stamp Displays The Acrobat Folder PathsBruno GerbasiNo ratings yet

- Applicator Sizing - FlowDocument3 pagesApplicator Sizing - FlowJocker GreickNo ratings yet

- Data Sheet Equipos Sist. Impulsión DieselDocument15 pagesData Sheet Equipos Sist. Impulsión DieselJorge InostrozaNo ratings yet

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- 100-76 WiloDocument5 pages100-76 WiloKhamees Marwan MuhiesenNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Abb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussDocument32 pagesAbb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussAbdessalem BougoffaNo ratings yet

- Pump System 17k BPD 143psi CunduacánDocument5 pagesPump System 17k BPD 143psi CunduacánGerry RamirezNo ratings yet

- VLM Aire de Planta e InstrumentosDocument1 pageVLM Aire de Planta e InstrumentosJorge RodríguezNo ratings yet

- Datasheet AP B175N 65C 43Document1 pageDatasheet AP B175N 65C 43Dennis Koay Soon NgaiNo ratings yet

- Bivhuiser 2023 868Document8 pagesBivhuiser 2023 868Mathías Huillca CameronNo ratings yet

- PerformancedatasheetDocument1 pagePerformancedatasheetagmech.duenasNo ratings yet

- Ficha Técnica American MarshDocument8 pagesFicha Técnica American MarshCarlos PerezNo ratings yet

- DSS4HGDocument1 pageDSS4HGagmech.duenasNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Flow Calculation: II. Constants I. Flow EquationDocument1 pageFlow Calculation: II. Constants I. Flow EquationAndrey Pachón FrancoNo ratings yet

- Aspire Installation Data Pack - Bank Negara Malaysia (RC) .AspireDocument7 pagesAspire Installation Data Pack - Bank Negara Malaysia (RC) .Aspireindran SuppiahNo ratings yet

- Pump Performance Curve: Customer Project NameDocument1 pagePump Performance Curve: Customer Project NamedonjazonNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidagustin_agustin33No ratings yet

- Versión 1.5 Orifice Gasflow Calcule - ExcelDocument5 pagesVersión 1.5 Orifice Gasflow Calcule - ExceledwinmenaNo ratings yet

- Danfoss Scroll Compressor HRP060T4LP6 121L1726Document4 pagesDanfoss Scroll Compressor HRP060T4LP6 121L1726Delarenus SianiparNo ratings yet

- Oklahoma City Ho: 9500 Series Pilot Operated Safety Relief Valve SizinDocument6 pagesOklahoma City Ho: 9500 Series Pilot Operated Safety Relief Valve SizinCamila Florencia ScarlatoNo ratings yet

- REYQ T.idownloadDocument60 pagesREYQ T.idownloadAnonymous Cpe6vcNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions LiquidmarcoaqmNo ratings yet

- Cerapan Transmitter PressureDocument8 pagesCerapan Transmitter Pressurefikri nashrulNo ratings yet

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 pagesQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqNo ratings yet

- Pumps SelectionDocument10 pagesPumps Selectionabdullah abdalganiNo ratings yet

- Data Sheet FD 250-200-500Document2 pagesData Sheet FD 250-200-500ngocdhxd92No ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- 5597 03 DB Racine Vortex Insertion Liquid Flow Meter RNLDocument4 pages5597 03 DB Racine Vortex Insertion Liquid Flow Meter RNLdileepNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions Liquidfrank rodriguezNo ratings yet

- Data Sheet SCP 150 530 HA-160 4Document3 pagesData Sheet SCP 150 530 HA-160 4AndiNo ratings yet

- Danfoss ERR100Document1 pageDanfoss ERR100Ayu AnnisaNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidagmech.duenasNo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- Sina Control Co. Designer & Manufacturer CoDocument2 pagesSina Control Co. Designer & Manufacturer Cohcsharma1967No ratings yet

- Bomba Final 3 PDFDocument259 pagesBomba Final 3 PDFDiegNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidmsh16000No ratings yet

- Peerless Pump 1 X 2 - 10 Detailed Datasheet-50 HZDocument6 pagesPeerless Pump 1 X 2 - 10 Detailed Datasheet-50 HZAdewunmi OlufemiNo ratings yet

- Documents 24Document8 pagesDocuments 24paachangaNo ratings yet

- 2 ST Pump Data Sheet - 1-ADocument1 page2 ST Pump Data Sheet - 1-Acruz romeroNo ratings yet

- 1) SCP-200-460-HA (280kw, 4 Pole) Data SheetDocument6 pages1) SCP-200-460-HA (280kw, 4 Pole) Data Sheetنايفف بن عبداللهNo ratings yet

- Eppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawDocument18 pagesEppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawBassem Ben FrajNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidDr Junaid Hassan MasoodiNo ratings yet

- CRN - 15531 - AGAEHQQE - CC FlowDocument12 pagesCRN - 15531 - AGAEHQQE - CC FlowRan NadavNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- Sizing FLO 8X5B 20230531T074832Z032Document5 pagesSizing FLO 8X5B 20230531T074832Z032amilasriNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Fan Coil Units Standard Type: FCU/2020/R1Document3 pagesFan Coil Units Standard Type: FCU/2020/R1Ahmed SohailNo ratings yet

- CPS 3X3X11 - 3500 RPMDocument1 pageCPS 3X3X11 - 3500 RPMLuis SudNo ratings yet

- PP86S20 400m3.hr at 88.2m TDH Performance DatasheetDocument1 pagePP86S20 400m3.hr at 88.2m TDH Performance DatasheetDH_TeknikNo ratings yet

- SSC SA-6533 YOKE Cat 16MDocument3 pagesSSC SA-6533 YOKE Cat 16MEngineering ProductionNo ratings yet

- Data Sheets: For Standard Refrigerants Standard SeriesDocument3 pagesData Sheets: For Standard Refrigerants Standard Seriessyahril boonieNo ratings yet

- Static Pressure Calculations V1.1Document1 pageStatic Pressure Calculations V1.1sachinsaklani23No ratings yet

- Structural Engineering Division: SubjectDocument18 pagesStructural Engineering Division: Subjecthaidarullah0060116No ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- 07TD Series: Water Cooled Condensing UnitDocument4 pages07TD Series: Water Cooled Condensing UnitFelix YewNo ratings yet

- A Guide To Ventilation Exhaust FansDocument4 pagesA Guide To Ventilation Exhaust FansLoter BelautNo ratings yet

- Catalog 250-8 Maverick™ II Commercial Packaged Rooftop SystemsDocument102 pagesCatalog 250-8 Maverick™ II Commercial Packaged Rooftop SystemsRich PasquesiNo ratings yet

- Concentric ReducerDocument2 pagesConcentric ReducerGousePeerzadeNo ratings yet

- Rep Prod AccesDocument32 pagesRep Prod AccesÁngel TapiaNo ratings yet

- RT 24 VhsDocument13 pagesRT 24 VhsNinoslav ArsićNo ratings yet

- DAIKIN Service ManualDocument266 pagesDAIKIN Service ManualTeodoran Doru100% (9)

- ON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetDocument8 pagesON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetAndrei-Lucian MilitaruNo ratings yet

- Valves & Hose Bibs: How To Fix A Leaky Hose BibDocument2 pagesValves & Hose Bibs: How To Fix A Leaky Hose BibTheKeyNo ratings yet

- 1.nodes: Node Design Conditions/Parameters Drawings / ReferencesDocument3 pages1.nodes: Node Design Conditions/Parameters Drawings / ReferencesNKNo ratings yet

- W 169 AirconDocument6 pagesW 169 Aircon羽田凌志No ratings yet

- Site Description: Al Wathba Desert Resort Project No. A090Document1 pageSite Description: Al Wathba Desert Resort Project No. A090sambhuprakashNo ratings yet

- BoqDocument5 pagesBoqharishNo ratings yet

- Hvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerDocument36 pagesHvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerMohd Tarique AnwarNo ratings yet

- NFPA 13 - TrainingDocument135 pagesNFPA 13 - TrainingMani Vannana100% (6)

- Carrier LDU ManualDocument123 pagesCarrier LDU Manualdafrie rimbaNo ratings yet

- The Soil PipeDocument15 pagesThe Soil PipeClasolNo ratings yet

- Toshiba Rotary Compressor Tech Specs PDFDocument1 pageToshiba Rotary Compressor Tech Specs PDFcalvin.bloodaxe4478100% (2)

- Compresores DanfossDocument2 pagesCompresores DanfossrocagomezaNo ratings yet

- SAE 3000 PsiDocument27 pagesSAE 3000 PsiWilson JustinoNo ratings yet

- Yhje##zj6axborx Brochure GeneralDocument4 pagesYhje##zj6axborx Brochure GeneralFernando CabreraNo ratings yet

- Yhje 12 To 24 Zj6axborxDocument4 pagesYhje 12 To 24 Zj6axborxNOITIER ALBERTO GARANADOS ANo ratings yet

- Minimizing Energy Consumption in Water Heating: Presented byDocument29 pagesMinimizing Energy Consumption in Water Heating: Presented byyekambaramNo ratings yet

- 1D Engine Cooling System Rz4eDocument73 pages1D Engine Cooling System Rz4eYuber CuevasNo ratings yet

- Sample of Nfpa Hydraulic CalculationDocument14 pagesSample of Nfpa Hydraulic Calculationzasza100% (1)

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Service Report: Nature of ProblemDocument2 pagesService Report: Nature of Problemjherson gravidesNo ratings yet

- 48es 1PDDocument28 pages48es 1PDJake JohnsonNo ratings yet

- TABLE OF CONTENTS E1Document8 pagesTABLE OF CONTENTS E1MohitNo ratings yet

SIZING Meter Run - R2

SIZING Meter Run - R2

Uploaded by

Alberto ReyesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIZING Meter Run - R2

SIZING Meter Run - R2

Uploaded by

Alberto ReyesCopyright:

Available Formats

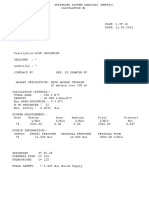

SICK | MAIHAK, Inc.

4140 World Houston Parkway, Suite 180

Houston, TX 77032-2490

Phone: 281-436-5100 Fax: 281-436-5200

Phone: 877-FLOWSIC (877- 356-9742)

www.FLOWSIC600.com

Quoted To Quote Number Date ( mm/dd/yyyy )

ETM TURBO MAQUINARIA_R2 02/01/2024

Meter Sizing Calculator Sized By

Version 5.0 Fredy Vazquez

21/02/2012

Meter Type Meter Bore Project Description

4 Path Tapered bore (standard)

Full bore (Pipe ID)

Units Reference Conditions (for volumetric calculations) Operating Conditions Station

(For general calcs.) Number of Minimum Maximum Units

US Units Press. Base: 14.73 psia Meter Runs Flowrate: 10.0 105.0 MMSCFD

SI Units Temp. Base: 60 °F 1 Pressure: 1052.52 1103.73 psig

Atm. Press: 14.73 psia Temperature: 80.6 113 °F

Composition Meter/Piping Criteria

Allowable Gas Velocity API-RP 14E Calc. Suggested meter/pipe size: 8 in.

Gulf Coast in Pipe of "Ve" Pipe Size (NPS): 8

Minimum: 1 ft/sec C: 160 Sched (NPS 2 to 24): 40

Maximum: 80 ft/sec Ve: 83 ft/sec Wall Thickness (NPS 30 to 48):

Volume Range Calculation Meter/Pipe Data Calculation Operating Velocities/Flowarates

@ Min Flow @ Max Flow @ Min Flow @ Max Flow

Conditions Conditions Units Pipe ID: 7.981 in. Conditions Conditions

Flowrate: 10.0 105.0 MMSCFD Meter Size: 8" (DN 200) Meter: 4.527 54.770 ft/sec

Pressure: 1,103.7 1,052.5 psig Pipe: 3.977 48.114 ft/sec

Temperature: 80.6 113 °F Actual Flowrate: 4973.4 60174.7 ACFH

Compressibility (Pf & Tf): 0.869902 0.902384 Flow Capacities:

Compressibility (Pb & Tb): 0.997858 Actual @ Min Flow @ Max Flow

Units Units

Actual Flowrate: 4,973.4 60,174.7 ACFH Flowrate Conditions Conditions

Capacity @ 1 ft/s: 1,250.7 ACFH 2.5 2.2 MMSCFD

Gas Density (r): 3.7254 3.233 lb/ft³ Capacity @ 100 ft/s: 125,067.5 ACFH 251.5 218.2 MMSCFD

Extended Capacity: 197,761.7 ACFH 397.6 345.1 MMSCFD

Cautions and Warnings Caution/Warning Explanation

1 Min Velocity in Pipe Legend

1 Max Velocity in Pipe 1 OK

1 Min Velocity in Meter 2 Caution

1 Max Velocity in Meter 3 Potential Problem

1 Temp/Press Range

Charts Recommended Meter Operating Range based on Allowable Min/Max Pipe Velocity and Manufacturer's Recommended Max Velocity.

Meter Operating and Capacity Range Based on Actual Flowrates Min Operating Range Utilized Capacity

Meter Operating Range

4,973.4 60,174.7

Based on Input Data

Recommended Meter

1,208.5 100,089.4 197,761.7

Operating Range

0 50,000 100,000 150,000 200,000 250,000

Actual Flowrate (ACFH)

Velocity Through Meter Min Meter Operating Range Utilized Velocity Range

Velocity in Meter

4.5 54.8

Based on Input Data

Recommended Meter

1.1 91.1 180.0

Operating Range

0 20 40 60 80 100 120 140 160 180 200

Velocity (ft/sec)

Velocity Through Meter Run Piping Min Min

Velocity in Pipe

4.0 48.1

Based on Input Data

Allowable Velocity

1.0 80.0

Range in Pipe

0 10 20 30 40 50 60 70 80 90

Velocity (ft/sec)

SIZING meter run_R2.xlsx Page 1 of 2

SICK | MAIHAK, Inc.

4140 World Houston Parkway, Suite 180

Houston, TX 77032-2490

Phone: 281-436-5100 Fax: 281-436-5200

Phone: 877-FLOWSIC (877- 356-9742)

www.FLOWSIC600.com

Quoted To Quote Number Date ( mm/dd/yyyy )

ETM TURBO MAQUINARIA_R2 02/01/2024

Meter Sizing Calculator Sized By

Version 5.0 Fredy Vazquez

21/02/2012

Meter Type Meter Bore Project Description

4 Path Tapered bore (standard)

Full bore (Pipe ID)

Meter Specifications Station

Dimensions

Flange Rating: ANSI 600 A: 23.622 in C: 16.500 in Meter Type: 4 Path Meter Bore: Beveled

B: 21.045 in D: 13.780 in Meter Weight: 419 lb

8.11 in

B

D

A C

Maximum Allowable Operating Pressure (MAOP) NOTE: The calculations in this section are not intended to replace actual engineering calculations!

Design Code: ASTM B31.3 Pipe OD (D): 8.625 in. Coefficient (Y): 0.4 Pipe MAOP: 1342 psig

Pipe Grade: ASTM A106 Grade B Wall Thick. (t): 0.322 in. Design Factor (F):

Flange Spec.: ASME B16.5 -2003 Stress (Y) 20 Ksi Location factor (L): Flange MAWP: 1360 psig

Location Class: Loc. Class 1, Div. 1 Joint Factor (E): 1.00 Temp Derate Factor (T):

Corrosion Allowance: 0 in

Meter Run Length, Weight & Volume Estimation

The generic drawing below shows all the major components/assemblies which comprise a standard meter run (unidirectional or bidirectional). Only fill in the data

for those components/assemblies which will actually be used to construct the meter run. Leave the data in unused components/assemblies blank. This calculator

assumes that the flow conditioner will be a CPACL Nova 50E.

Specify units for tube length inches D (Nominal Pipe Diameters)

Upstream Meter Tube(s) Downstream Meter Tube(s)

U/S 1 U/S 2 D/S 1 D/S 2

Length: 5 5 D Length: 5 D

# of Thred-O-Lets: # of Thred-O-Lets: 2

Flow Conditioner: Yes No Flow Conditioner: Yes No

U/S 1 U/S 2 D/S 1 D/S 2

40 in 40 in 23.622 in 40 in 0 in

(293 lb) (293 lb) (419 lb) (297 lb) (0 lb)

(The dimensions and weights in the above drawing do not

0.25 in include gaskets and studs/nuts. This information is, 0 in

(11.4 lb) however, included in the Table below) (0 lb)

Total Meter Run Assembly Length, Weight and Volume (approximate)

U/S 1 U/S 2 D/S 1 D/S 2 Flow Studs/

Meter Gaskets Total

Spool Spool Spool Spool Conditioner nuts

Length 23.622 40 40 40 0 0.25 0.625 n/a 144.497 in

Weight 419 293 293 297 0 11.4 n/a 67.2 1380.6 lb

Volume 0.601 1.158 1.158 1.158 0 n/a n/a n/a 4.075 Ft³ (act)

Comments:

SIZING meter run_R2.xlsx Page 2 of 2

You might also like

- SIC001 Salton Induction Cooker Instruction ManualDocument18 pagesSIC001 Salton Induction Cooker Instruction ManualShawn FynnNo ratings yet

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: This Stamp Displays The Acrobat Folder PathsDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: This Stamp Displays The Acrobat Folder PathsBruno GerbasiNo ratings yet

- Applicator Sizing - FlowDocument3 pagesApplicator Sizing - FlowJocker GreickNo ratings yet

- Data Sheet Equipos Sist. Impulsión DieselDocument15 pagesData Sheet Equipos Sist. Impulsión DieselJorge InostrozaNo ratings yet

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- 100-76 WiloDocument5 pages100-76 WiloKhamees Marwan MuhiesenNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Abb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussDocument32 pagesAbb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussAbdessalem BougoffaNo ratings yet

- Pump System 17k BPD 143psi CunduacánDocument5 pagesPump System 17k BPD 143psi CunduacánGerry RamirezNo ratings yet

- VLM Aire de Planta e InstrumentosDocument1 pageVLM Aire de Planta e InstrumentosJorge RodríguezNo ratings yet

- Datasheet AP B175N 65C 43Document1 pageDatasheet AP B175N 65C 43Dennis Koay Soon NgaiNo ratings yet

- Bivhuiser 2023 868Document8 pagesBivhuiser 2023 868Mathías Huillca CameronNo ratings yet

- PerformancedatasheetDocument1 pagePerformancedatasheetagmech.duenasNo ratings yet

- Ficha Técnica American MarshDocument8 pagesFicha Técnica American MarshCarlos PerezNo ratings yet

- DSS4HGDocument1 pageDSS4HGagmech.duenasNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Flow Calculation: II. Constants I. Flow EquationDocument1 pageFlow Calculation: II. Constants I. Flow EquationAndrey Pachón FrancoNo ratings yet

- Aspire Installation Data Pack - Bank Negara Malaysia (RC) .AspireDocument7 pagesAspire Installation Data Pack - Bank Negara Malaysia (RC) .Aspireindran SuppiahNo ratings yet

- Pump Performance Curve: Customer Project NameDocument1 pagePump Performance Curve: Customer Project NamedonjazonNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidagustin_agustin33No ratings yet

- Versión 1.5 Orifice Gasflow Calcule - ExcelDocument5 pagesVersión 1.5 Orifice Gasflow Calcule - ExceledwinmenaNo ratings yet

- Danfoss Scroll Compressor HRP060T4LP6 121L1726Document4 pagesDanfoss Scroll Compressor HRP060T4LP6 121L1726Delarenus SianiparNo ratings yet

- Oklahoma City Ho: 9500 Series Pilot Operated Safety Relief Valve SizinDocument6 pagesOklahoma City Ho: 9500 Series Pilot Operated Safety Relief Valve SizinCamila Florencia ScarlatoNo ratings yet

- REYQ T.idownloadDocument60 pagesREYQ T.idownloadAnonymous Cpe6vcNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions LiquidmarcoaqmNo ratings yet

- Cerapan Transmitter PressureDocument8 pagesCerapan Transmitter Pressurefikri nashrulNo ratings yet

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 pagesQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqNo ratings yet

- Pumps SelectionDocument10 pagesPumps Selectionabdullah abdalganiNo ratings yet

- Data Sheet FD 250-200-500Document2 pagesData Sheet FD 250-200-500ngocdhxd92No ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- 5597 03 DB Racine Vortex Insertion Liquid Flow Meter RNLDocument4 pages5597 03 DB Racine Vortex Insertion Liquid Flow Meter RNLdileepNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions Liquidfrank rodriguezNo ratings yet

- Data Sheet SCP 150 530 HA-160 4Document3 pagesData Sheet SCP 150 530 HA-160 4AndiNo ratings yet

- Danfoss ERR100Document1 pageDanfoss ERR100Ayu AnnisaNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidagmech.duenasNo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- Sina Control Co. Designer & Manufacturer CoDocument2 pagesSina Control Co. Designer & Manufacturer Cohcsharma1967No ratings yet

- Bomba Final 3 PDFDocument259 pagesBomba Final 3 PDFDiegNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions Liquidmsh16000No ratings yet

- Peerless Pump 1 X 2 - 10 Detailed Datasheet-50 HZDocument6 pagesPeerless Pump 1 X 2 - 10 Detailed Datasheet-50 HZAdewunmi OlufemiNo ratings yet

- Documents 24Document8 pagesDocuments 24paachangaNo ratings yet

- 2 ST Pump Data Sheet - 1-ADocument1 page2 ST Pump Data Sheet - 1-Acruz romeroNo ratings yet

- 1) SCP-200-460-HA (280kw, 4 Pole) Data SheetDocument6 pages1) SCP-200-460-HA (280kw, 4 Pole) Data Sheetنايفف بن عبداللهNo ratings yet

- Eppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawDocument18 pagesEppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawBassem Ben FrajNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidDr Junaid Hassan MasoodiNo ratings yet

- CRN - 15531 - AGAEHQQE - CC FlowDocument12 pagesCRN - 15531 - AGAEHQQE - CC FlowRan NadavNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- Sizing FLO 8X5B 20230531T074832Z032Document5 pagesSizing FLO 8X5B 20230531T074832Z032amilasriNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Fan Coil Units Standard Type: FCU/2020/R1Document3 pagesFan Coil Units Standard Type: FCU/2020/R1Ahmed SohailNo ratings yet

- CPS 3X3X11 - 3500 RPMDocument1 pageCPS 3X3X11 - 3500 RPMLuis SudNo ratings yet

- PP86S20 400m3.hr at 88.2m TDH Performance DatasheetDocument1 pagePP86S20 400m3.hr at 88.2m TDH Performance DatasheetDH_TeknikNo ratings yet

- SSC SA-6533 YOKE Cat 16MDocument3 pagesSSC SA-6533 YOKE Cat 16MEngineering ProductionNo ratings yet

- Data Sheets: For Standard Refrigerants Standard SeriesDocument3 pagesData Sheets: For Standard Refrigerants Standard Seriessyahril boonieNo ratings yet

- Static Pressure Calculations V1.1Document1 pageStatic Pressure Calculations V1.1sachinsaklani23No ratings yet

- Structural Engineering Division: SubjectDocument18 pagesStructural Engineering Division: Subjecthaidarullah0060116No ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- 07TD Series: Water Cooled Condensing UnitDocument4 pages07TD Series: Water Cooled Condensing UnitFelix YewNo ratings yet

- A Guide To Ventilation Exhaust FansDocument4 pagesA Guide To Ventilation Exhaust FansLoter BelautNo ratings yet

- Catalog 250-8 Maverick™ II Commercial Packaged Rooftop SystemsDocument102 pagesCatalog 250-8 Maverick™ II Commercial Packaged Rooftop SystemsRich PasquesiNo ratings yet

- Concentric ReducerDocument2 pagesConcentric ReducerGousePeerzadeNo ratings yet

- Rep Prod AccesDocument32 pagesRep Prod AccesÁngel TapiaNo ratings yet

- RT 24 VhsDocument13 pagesRT 24 VhsNinoslav ArsićNo ratings yet

- DAIKIN Service ManualDocument266 pagesDAIKIN Service ManualTeodoran Doru100% (9)

- ON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetDocument8 pagesON/OFF Zone Valves (PN 16) AMZ 112, AMZ 113: Data SheetAndrei-Lucian MilitaruNo ratings yet

- Valves & Hose Bibs: How To Fix A Leaky Hose BibDocument2 pagesValves & Hose Bibs: How To Fix A Leaky Hose BibTheKeyNo ratings yet

- 1.nodes: Node Design Conditions/Parameters Drawings / ReferencesDocument3 pages1.nodes: Node Design Conditions/Parameters Drawings / ReferencesNKNo ratings yet

- W 169 AirconDocument6 pagesW 169 Aircon羽田凌志No ratings yet

- Site Description: Al Wathba Desert Resort Project No. A090Document1 pageSite Description: Al Wathba Desert Resort Project No. A090sambhuprakashNo ratings yet

- BoqDocument5 pagesBoqharishNo ratings yet

- Hvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerDocument36 pagesHvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerMohd Tarique AnwarNo ratings yet

- NFPA 13 - TrainingDocument135 pagesNFPA 13 - TrainingMani Vannana100% (6)

- Carrier LDU ManualDocument123 pagesCarrier LDU Manualdafrie rimbaNo ratings yet

- The Soil PipeDocument15 pagesThe Soil PipeClasolNo ratings yet

- Toshiba Rotary Compressor Tech Specs PDFDocument1 pageToshiba Rotary Compressor Tech Specs PDFcalvin.bloodaxe4478100% (2)

- Compresores DanfossDocument2 pagesCompresores DanfossrocagomezaNo ratings yet

- SAE 3000 PsiDocument27 pagesSAE 3000 PsiWilson JustinoNo ratings yet

- Yhje##zj6axborx Brochure GeneralDocument4 pagesYhje##zj6axborx Brochure GeneralFernando CabreraNo ratings yet

- Yhje 12 To 24 Zj6axborxDocument4 pagesYhje 12 To 24 Zj6axborxNOITIER ALBERTO GARANADOS ANo ratings yet

- Minimizing Energy Consumption in Water Heating: Presented byDocument29 pagesMinimizing Energy Consumption in Water Heating: Presented byyekambaramNo ratings yet

- 1D Engine Cooling System Rz4eDocument73 pages1D Engine Cooling System Rz4eYuber CuevasNo ratings yet

- Sample of Nfpa Hydraulic CalculationDocument14 pagesSample of Nfpa Hydraulic Calculationzasza100% (1)

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Service Report: Nature of ProblemDocument2 pagesService Report: Nature of Problemjherson gravidesNo ratings yet

- 48es 1PDDocument28 pages48es 1PDJake JohnsonNo ratings yet

- TABLE OF CONTENTS E1Document8 pagesTABLE OF CONTENTS E1MohitNo ratings yet