Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

13 viewsSIPNP21

SIPNP21

Uploaded by

isan.structural TjsvgalavanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Annexure - XIII - Drawing - Mounting StructurelDocument1 pageAnnexure - XIII - Drawing - Mounting Structurelisan.structural TjsvgalavanNo ratings yet

- DG Exhaust Structure & BomDocument4 pagesDG Exhaust Structure & Bomisan.structural TjsvgalavanNo ratings yet

- Typical DrawingDocument16 pagesTypical Drawingisan.structural TjsvgalavanNo ratings yet

- SEFI EconfDocument65 pagesSEFI Econfisan.structural TjsvgalavanNo ratings yet

- Zamil STEEL MANUAL-283Document1 pageZamil STEEL MANUAL-283isan.structural TjsvgalavanNo ratings yet

- Kseb LT DRGDocument1 pageKseb LT DRGisan.structural TjsvgalavanNo ratings yet

- Tru Flo 125x125 08-Jan-2024 11-59-03Document1 pageTru Flo 125x125 08-Jan-2024 11-59-03isan.structural TjsvgalavanNo ratings yet

- Structural DWNGDocument12 pagesStructural DWNGisan.structural TjsvgalavanNo ratings yet

- Cutting Layouts Ismc 150Document44 pagesCutting Layouts Ismc 150isan.structural TjsvgalavanNo ratings yet

- PLC3PS8228Document12 pagesPLC3PS8228isan.structural TjsvgalavanNo ratings yet

- Technical Drawings of Major Materials of Rdss Phase1 Works: (Adopted From Approved Ksebl Specifications)Document38 pagesTechnical Drawings of Major Materials of Rdss Phase1 Works: (Adopted From Approved Ksebl Specifications)isan.structural TjsvgalavanNo ratings yet

- DB 43 RMCR, ANNEXETURE 08-Jul-2023 10-13-01Document3 pagesDB 43 RMCR, ANNEXETURE 08-Jul-2023 10-13-01isan.structural TjsvgalavanNo ratings yet

- Flange Masses (Weights) According To Standard EN 1092-1 - China Hebei Haihao Flange FactoryDocument6 pagesFlange Masses (Weights) According To Standard EN 1092-1 - China Hebei Haihao Flange Factoryisan.structural TjsvgalavanNo ratings yet

- DB 14A 08-Jul-2023 10-14-59Document5 pagesDB 14A 08-Jul-2023 10-14-59isan.structural TjsvgalavanNo ratings yet

- 2PX28 MMS Inner BoqDocument1 page2PX28 MMS Inner Boqisan.structural TjsvgalavanNo ratings yet

- DB 43 TC 2 08-Jul-2023 10-11-26Document1 pageDB 43 TC 2 08-Jul-2023 10-11-26isan.structural TjsvgalavanNo ratings yet

- DB 14 INVOICE 08-Jul-2023 14-27-41Document1 pageDB 14 INVOICE 08-Jul-2023 14-27-41isan.structural TjsvgalavanNo ratings yet

- DB43 MTRL Issue Certificate 08-Jul-2023 10-12-02Document1 pageDB43 MTRL Issue Certificate 08-Jul-2023 10-12-02isan.structural TjsvgalavanNo ratings yet

- DB 43 RMCR, Annexeture 08-Jul-2023 10-13-01 - CompressedDocument3 pagesDB 43 RMCR, Annexeture 08-Jul-2023 10-13-01 - Compressedisan.structural TjsvgalavanNo ratings yet

- DB43 TC 1 08-Jul-2023 10-10-28Document1 pageDB43 TC 1 08-Jul-2023 10-10-28isan.structural TjsvgalavanNo ratings yet

- DB 14 TC 08-Jul-2023 14-28-45Document1 pageDB 14 TC 08-Jul-2023 14-28-45isan.structural TjsvgalavanNo ratings yet

- BPCL - RC - 171 179 1 9Document9 pagesBPCL - RC - 171 179 1 9isan.structural TjsvgalavanNo ratings yet

- Yard Fencing KSEB 2Document6 pagesYard Fencing KSEB 2isan.structural TjsvgalavanNo ratings yet

- TN Try-Tpr I 2706 173755Document3 pagesTN Try-Tpr I 2706 173755isan.structural TjsvgalavanNo ratings yet

- Yard Fencing KSEB 4Document92 pagesYard Fencing KSEB 4isan.structural TjsvgalavanNo ratings yet

- BPCL - RC - 171 179 1 2Document2 pagesBPCL - RC - 171 179 1 2isan.structural TjsvgalavanNo ratings yet

- General Arrangements 2Document1 pageGeneral Arrangements 2isan.structural TjsvgalavanNo ratings yet

- Stair Structure DetailDocument2 pagesStair Structure Detailisan.structural TjsvgalavanNo ratings yet

- CochinBase Tender E 13042021detailDocument27 pagesCochinBase Tender E 13042021detailisan.structural TjsvgalavanNo ratings yet

- DocumentsDocument4 pagesDocumentsisan.structural TjsvgalavanNo ratings yet

SIPNP21

SIPNP21

Uploaded by

isan.structural Tjsvgalavan0 ratings0% found this document useful (0 votes)

13 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

13 views3 pagesSIPNP21

SIPNP21

Uploaded by

isan.structural TjsvgalavanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

BHARAT HEAVY ELECTRICALS LIMITED

TIRUCHIRAPPALL| 620 014.

QUALITY ASSURANCE

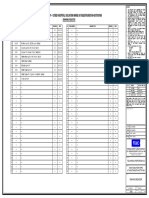

SIP: NP: 21 Rev 00 PAGE: 1 of 3

Trial Assembly procedure for Coal Bunker, Hopper & Ring Girder

REV. | DATE PREPARED REVIEWED. APPROVED

Ap

Syme | Ns -de-tenen|

7 ag - on

00 | 21.03.2015 | M.Jeyaram,SQAE | R.Rsmasamy,DGM/QA | U.Revisankaran,AGM/QARBE|

SIP:NP:21 / 00 Page 2 of 3

1.0 Scope:

This document describes the trial assembly of coal bunker, ring girder and hopper at vendor works to

ensure correct matching of individual items during assembly and welding at site. Further, it describes

necessary precautions w.r.t forming of shells, fabrication, and specific weld sequence to be followed

during execution.

2.0 Reference Document :

a

b,

c

Drawing

‘AWS D1.1M:2010

18.7215

3.0 Plate thickness details:

4.0 Forming of bunker shell /

‘a, Bunker shell plate : 12mm ( IS 2062 Gr.A)

b. Hopper plate : 12mm (iS 2062 Gr.A)

. $8 Liner plate : 4mm ( SA240 TP304)

4d. Stiffener / Ring plate : 12mm ( 1S2062 Gr.A)

fe. Ring girder : 32 /36 mm ( 1S2062 Gr.8)

i girder / hopper:

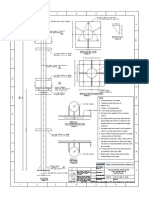

a, Bunker shell is formed out of 6 tiers each with 4 segments. Similarly, Hopper is formed out of 23

segments in total of 6 tiers. Ring girder is formed out of four segments (refer sketch given below).

b. For making shell / ring girder / hopper , required rolling machine of suitable capacity and guide roll of

required diameter shall be ensured

©. Allthe plates used for shells / ring girder / hopper shall be rolled to required shape and radius as per

drg, and joined by butt welding

4. Flange plates of ring girder shall be cut to the required profile to suit individual segment and all

segmented plates shall be edge prepared to enable butt weld,

€. SSliner plates shall be cut by plasma cutting and smooth finished

f. Rolled plates shall be locked suitably by temporary attachments to avoid buckling / opening up due to

springing action

& Welding shall be done as per approved WPS with proper welding sequence

h. Welding consumables shall be as per approved WPS / Org.

i. SS liner plates plug welding shall be completed and ground smooth to match with plate profile as per

dg. requirement

5.0 Trial assembly

5.1 Individual wall segments of Bunker shell / Ring girder / Hopper

a. Fit-up of shell /ring girder/ hopper segments shall be done by making a template using suitable punch

presses on the fabrication bed. The segmented plates thus fixed on the marking shall be checked for

verticality by Tri-square and vertical piano wire method.

b. Fit-up of hopper segments shall be done by positioning the segments with the top side ( larger

diameter of the conical section ) facing up on the fabrication bed with suitable cross bars to restrain

movement during fit-up

©. Ensure proper fit up to maintain gap between shell segments by welding long cleats to maintain

circularity.

d, Ensure that the level of supporting lug is uniform throughout the circumference of the shell for water

level ¢ 1mm,

e. Ensure OD / ID & height dimensions of the shell (segmental) as per drg. Deviation of + 4mm on

diameter of the shell is acceptable.

f. Ensure segments which are sent as loose (to be assembled at site) to be trial assembled at vendor

works with unique match mark numbers / drg. Details (as applicable) and clearly marked on all the

individual items / wall segments. The match marks are to be verified and certified before dismantling,

Page 3 of 3

8. Match marks shall be hard punched before dismantling, stenciled and bordered with white paint.

h, Ensure suitable stiffeners to be provided on individual wall segments / ring girder for handling and

transportation purpose

5.2 Trial assembly of bunker shell / Hopper

a. Bunker shell / hopper trial assembly shall be done between two consecutive tiers from bottom tier to

top tier

b. Repeat stages mentioned in S.No. 5.1b to 5.1g

The matching ends shall be clearly recorded with supporting sketch for verification purpose.

op 2.084 Dm 9 TOF

Go Sth Dh ® OTTO

SHELL PLA2MM

RING PL,

0 TER EH NTH 4 SEOMENTS

1504

FING_GiROER,

36/32"

(3 URS DoH

WH 6 SEBMENTE)

137M

HOPPER PL.12NM

fo TERS eo

WH 2 SEONENTES

RING PLI2NM

STIFFENER PL12MM

rer

COAL BUNKER, HOPPER & RING GIRDER ARRANGEMENT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Annexure - XIII - Drawing - Mounting StructurelDocument1 pageAnnexure - XIII - Drawing - Mounting Structurelisan.structural TjsvgalavanNo ratings yet

- DG Exhaust Structure & BomDocument4 pagesDG Exhaust Structure & Bomisan.structural TjsvgalavanNo ratings yet

- Typical DrawingDocument16 pagesTypical Drawingisan.structural TjsvgalavanNo ratings yet

- SEFI EconfDocument65 pagesSEFI Econfisan.structural TjsvgalavanNo ratings yet

- Zamil STEEL MANUAL-283Document1 pageZamil STEEL MANUAL-283isan.structural TjsvgalavanNo ratings yet

- Kseb LT DRGDocument1 pageKseb LT DRGisan.structural TjsvgalavanNo ratings yet

- Tru Flo 125x125 08-Jan-2024 11-59-03Document1 pageTru Flo 125x125 08-Jan-2024 11-59-03isan.structural TjsvgalavanNo ratings yet

- Structural DWNGDocument12 pagesStructural DWNGisan.structural TjsvgalavanNo ratings yet

- Cutting Layouts Ismc 150Document44 pagesCutting Layouts Ismc 150isan.structural TjsvgalavanNo ratings yet

- PLC3PS8228Document12 pagesPLC3PS8228isan.structural TjsvgalavanNo ratings yet

- Technical Drawings of Major Materials of Rdss Phase1 Works: (Adopted From Approved Ksebl Specifications)Document38 pagesTechnical Drawings of Major Materials of Rdss Phase1 Works: (Adopted From Approved Ksebl Specifications)isan.structural TjsvgalavanNo ratings yet

- DB 43 RMCR, ANNEXETURE 08-Jul-2023 10-13-01Document3 pagesDB 43 RMCR, ANNEXETURE 08-Jul-2023 10-13-01isan.structural TjsvgalavanNo ratings yet

- Flange Masses (Weights) According To Standard EN 1092-1 - China Hebei Haihao Flange FactoryDocument6 pagesFlange Masses (Weights) According To Standard EN 1092-1 - China Hebei Haihao Flange Factoryisan.structural TjsvgalavanNo ratings yet

- DB 14A 08-Jul-2023 10-14-59Document5 pagesDB 14A 08-Jul-2023 10-14-59isan.structural TjsvgalavanNo ratings yet

- 2PX28 MMS Inner BoqDocument1 page2PX28 MMS Inner Boqisan.structural TjsvgalavanNo ratings yet

- DB 43 TC 2 08-Jul-2023 10-11-26Document1 pageDB 43 TC 2 08-Jul-2023 10-11-26isan.structural TjsvgalavanNo ratings yet

- DB 14 INVOICE 08-Jul-2023 14-27-41Document1 pageDB 14 INVOICE 08-Jul-2023 14-27-41isan.structural TjsvgalavanNo ratings yet

- DB43 MTRL Issue Certificate 08-Jul-2023 10-12-02Document1 pageDB43 MTRL Issue Certificate 08-Jul-2023 10-12-02isan.structural TjsvgalavanNo ratings yet

- DB 43 RMCR, Annexeture 08-Jul-2023 10-13-01 - CompressedDocument3 pagesDB 43 RMCR, Annexeture 08-Jul-2023 10-13-01 - Compressedisan.structural TjsvgalavanNo ratings yet

- DB43 TC 1 08-Jul-2023 10-10-28Document1 pageDB43 TC 1 08-Jul-2023 10-10-28isan.structural TjsvgalavanNo ratings yet

- DB 14 TC 08-Jul-2023 14-28-45Document1 pageDB 14 TC 08-Jul-2023 14-28-45isan.structural TjsvgalavanNo ratings yet

- BPCL - RC - 171 179 1 9Document9 pagesBPCL - RC - 171 179 1 9isan.structural TjsvgalavanNo ratings yet

- Yard Fencing KSEB 2Document6 pagesYard Fencing KSEB 2isan.structural TjsvgalavanNo ratings yet

- TN Try-Tpr I 2706 173755Document3 pagesTN Try-Tpr I 2706 173755isan.structural TjsvgalavanNo ratings yet

- Yard Fencing KSEB 4Document92 pagesYard Fencing KSEB 4isan.structural TjsvgalavanNo ratings yet

- BPCL - RC - 171 179 1 2Document2 pagesBPCL - RC - 171 179 1 2isan.structural TjsvgalavanNo ratings yet

- General Arrangements 2Document1 pageGeneral Arrangements 2isan.structural TjsvgalavanNo ratings yet

- Stair Structure DetailDocument2 pagesStair Structure Detailisan.structural TjsvgalavanNo ratings yet

- CochinBase Tender E 13042021detailDocument27 pagesCochinBase Tender E 13042021detailisan.structural TjsvgalavanNo ratings yet

- DocumentsDocument4 pagesDocumentsisan.structural TjsvgalavanNo ratings yet