Professional Documents

Culture Documents

Cs-Rites-Door Link Mechanism (Single Link)

Cs-Rites-Door Link Mechanism (Single Link)

Uploaded by

sohelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cs-Rites-Door Link Mechanism (Single Link)

Cs-Rites-Door Link Mechanism (Single Link)

Uploaded by

sohelCopyright:

Available Formats

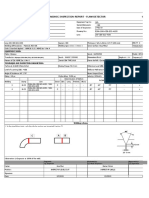

INSPECTION & TEST PLAN DOC.

NO:

ISSUE NO:

PAGE NO: 1 of 3

RITES LTD DOOR LINK MECHANISM EFFECTIVE DATE:

(QA DIVISION) ARRANGEMENT (SINGLE LINK) APPROVED BY:

Case No.: Book No: Set No:

1. Specification /Drawing: RDSO Drg. No. WD-92081-S-51&52 Alt.2

2. Date of Inspection :

3. Place of Inspection :

4. Size of lot :

5. Size of Sample :

6. Document Verification: a) Internal/ External test certificate for raw material.

b) Internal inspection/test and dimensional check report.

c) Calibration record of gauges, measuring instruments & test

equipments.

7. Tests/Checks (to be witnessed/conducted by inspector ):-

S.

Parameter Value Specified Observations Remarks

No.

Batch-wise TC of

welding consumable

i) It shall be free from visible surface may be

defects, bend, dent & all edges & reviewed/verified

corners to be grounded.

ii) Weld size shall be as per drawing

(a) Visual

& welding shall be uniform and free

from welding defects.

(Suitable declaration

iii) General Workmanship. may be obtained &

verified regarding

sequence followed

by fabricator)

As per RDSO Drg. No.

WD-91071-S-52 Alt.2

(b) Dimensional

Tolerance for untoleranced Dimension sheet

dimensions shall be as per enclosed

IS:2102 Part-I

Lever X end, Y end & Central (1 no. each), Connecting link small & large (2 nos. each), Eye

(c) bolt with spring washer, nut & lock (4 sets), Adjustable lever (3 nos.), Nut lock (4 nos.), Eye

bolt (1 no.), Bearing near and far end (4 nos. each), and Misc. items like pins, cotters etc

Prepared by- Checked by- Forwarded by-

IE: RKD Technical Cell: RAS CM: ST

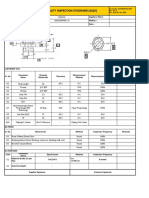

INSPECTION & TEST PLAN DOC. NO:

ISSUE NO:

PAGE NO: 2 of 3

RITES LTD DOOR LINK MECHANISM EFFECTIVE DATE:

(QA DIVISION) ARRANGEMENT (SINGLE LINK) APPROVED BY:

S.

No. Parameter Value Specified Observations Remarks

Cast Steel IS:1030 Gr. 280-520W

Ladle Analysis

%C 0.25 max.

%Mn 1.20 max.

%S 0.035 max.

%P 0.040 max.

%Si 0.60 max.

%Cu 0.40 max.

%CE 0.42 max.

As per IRS M-44/97 Test Method-

Sheet/Plate 10mm thick Either by the

Laddle Analysis Product Analysis methods specified

Tolerance in relevant parts of

(ASTM A480) ASTM A240 or by

%C 0.03 max. %C +0.005 any other

Material %Mn 0.8 to 1.5 %Mn ±0.04 established

c.3 %Si 1.00 max. %Si +0.05 instrumental/

Composition

%Cr 10.8-12.5 %Cr ±0.15 chemical method.

%Ni 1.50 max. %Ni +0.07

%P 0.03 max. %P +0.005

%S 0.03 max. %S +0.005

%Ti 0.75 max. %Ti +0.05

Components to IS:1875 CL 4 Ref. Cl. No. 6 of

Ladle Analysis . IS:1875/1992

%C 0.40-0.50 Test method-

%Mn 0.60-0.90 As per IS:228 & its

%S 0.040 max. relevant parts or

%P 0.040 max. any other

%Si 0.15-0.35 established

instrumental/

chemical method.

Manufacturer

Name/initials,

If & as specified in P.O.

(d) Marking Month & year of

(Not specified in Drg.) manufacture for

traceability

Name & Signature of IE

Note:

i. Sampling shall be done according to IS:2500 - 2000 Pt- I single sampling plan (normal) unless mentioned

otherwise.

ii. In case, a quality plan is mentioned in the Purchase Order, Inspecting Engineer shall also take the same into

consideration during inspection and mention the same in Inspection Records.

iii. In case purchase order mentions different drawing/specification, then that will be applicable.

iv. If actual size/shape of the product didn’t permit cutting of test sample for a particular specified test parameter

like tensile/bend, etc., then MTC/Lab TC for the same shall be taken into consideration, subject to testing of

Prepared by- Checked by- Forwarded by-

IE: RKD Technical Cell: RAS CM: ST

INSPECTION & TEST PLAN DOC. NO:

ISSUE NO:

PAGE NO: 3 of 3

RITES LTD DOOR LINK MECHANISM EFFECTIVE DATE:

(QA DIVISION) ARRANGEMENT (SINGLE LINK) APPROVED BY:

those specified parameters which is/are feasible (in terms of size/shape of sample piece/test specimen

intended for respective tests) and the same shall be mentioned in Inspection Records/Report.

Important:

1. Cross check original PO (Either in physical form or online)

2. Do not undertake inspection elsewhere other than the place of inspection mentioned in PO.

3. Do not undertake inspection if quantity offered is less than quantity mentioned in call letter.

4. Do not inspect part quantity unless provided in PO or authorized by client.

5. Stamp/seal complete offered lot after drawing samples for lab/in-house testing and before leaving the site.

6. Use check sheet for recording observations.

7. In case of any ambiguity in PO/Specification/Drawing/QAP/Technical Spec. annexed with PO, the same

shall be brought into the notice of vendor as well as CM for seeking necessary clarification from

Purchaser/Client.

Prepared by- Checked by- Forwarded by-

IE: RKD Technical Cell: RAS CM: ST

You might also like

- TOFD and PAUT For Weld Root CorrosionDocument38 pagesTOFD and PAUT For Weld Root CorrosionMuthumonickamNo ratings yet

- Oosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFDocument8 pagesOosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFJoshua ChuaNo ratings yet

- Aluminium 3rd Party Test Report SampleDocument2 pagesAluminium 3rd Party Test Report SampleAnand Chavan Projects-Quality100% (3)

- History of The DDR German ShepherdsDocument7 pagesHistory of The DDR German ShepherdsIvan RogachevNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Lab Report TemplateDocument8 pagesLab Report TemplateRodwell BaloyiNo ratings yet

- SIP5 7KE85 V07.80 Manual C018-6 en PDFDocument502 pagesSIP5 7KE85 V07.80 Manual C018-6 en PDFDoan Anh TuanNo ratings yet

- Philip Merlan, From Platonism To NeoplatonismDocument267 pagesPhilip Merlan, From Platonism To NeoplatonismAnonymous fgaljTd100% (1)

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- ut_amr (1)Document1 pageut_amr (1)balaNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Customer Specification Rport 12 FCDocument12 pagesCustomer Specification Rport 12 FCSridharan VenkatNo ratings yet

- Sae 1035Document2 pagesSae 1035Maintenance Plant 1 & 2No ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- General Procedure For Ultrasonic Examination ProcedureDocument28 pagesGeneral Procedure For Ultrasonic Examination ProceduredrakeNo ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet

- 64-cbc Temp Controller Calibration CartificateDocument1 page64-cbc Temp Controller Calibration CartificateCustomer SupportNo ratings yet

- Raw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Document1 pageRaw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2No ratings yet

- Wire PDFDocument3 pagesWire PDFm.aliNo ratings yet

- Validacion Software Conexiones 3 SCH 160Document29 pagesValidacion Software Conexiones 3 SCH 160RodolfoNo ratings yet

- Conexiones 3 SCH 160Document29 pagesConexiones 3 SCH 160RodolfoNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- SC 69503Document6 pagesSC 69503sujatananasoNo ratings yet

- Raw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Document2 pagesRaw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2No ratings yet

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document1 pageMill'S Test Certificate ACC. TO EN 10204 / 3.1vcumutNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Gelo HARDNESS REPORT For PB SheetDocument1 pageGelo HARDNESS REPORT For PB SheetP NAVEEN KUMARNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammar100% (1)

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Calibration CertificateDocument1 pageCalibration Certificatesathish K KumarNo ratings yet

- Test Report & Inspection CertificateDocument1 pageTest Report & Inspection CertificateAji HatmantoNo ratings yet

- Crs 000007Document2 pagesCrs 000007ahetesham marufNo ratings yet

- HDocument11 pagesHmohd as shahiddin jafriNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Sae 1010Document2 pagesSae 1010Maintenance Plant 1 & 2No ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- E027A CP Tank Anode Grid ContinuityDocument2 pagesE027A CP Tank Anode Grid ContinuityAtiq Ur RehmanNo ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Approval Sheet: Customer ManufacturerDocument7 pagesApproval Sheet: Customer ManufacturerypadillaNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Coil # 09 Inlet C-Scan ReportDocument5 pagesCoil # 09 Inlet C-Scan ReportdrakeNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- tc_amr (1)Document1 pagetc_amr (1)balaNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- Coil # 01 Inlet C-Scan ReportDocument5 pagesCoil # 01 Inlet C-Scan ReportdrakeNo ratings yet

- Contoh Painting ReportDocument1 pageContoh Painting ReportYudha Andrie Sasi ZenNo ratings yet

- AQISDocument1 pageAQISable.ankit.94No ratings yet

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- أساسيات الاتصالات الرقمية PDFDocument230 pagesأساسيات الاتصالات الرقمية PDFAbdulssalam Mohammed Hussein Khako StudentNo ratings yet

- Automag Industries, Chennai: ISI StandardsDocument2 pagesAutomag Industries, Chennai: ISI Standardsnaga1501No ratings yet

- CitoVac EnglishDocument32 pagesCitoVac EnglishJulio C. Sierra PalominoNo ratings yet

- Information Systems For Sustainable DevelopmentDocument23 pagesInformation Systems For Sustainable DevelopmentnshekhaNo ratings yet

- Ácido Sulfurico Ligas CompatíveisDocument2 pagesÁcido Sulfurico Ligas CompatíveisGuilherme Augusto de OliveiraNo ratings yet

- User'S Manual: Questions?Document32 pagesUser'S Manual: Questions?gorleanosNo ratings yet

- Us - Tsubaki - Sprocket - Catalog 2Document199 pagesUs - Tsubaki - Sprocket - Catalog 2Jairo Andrés FANo ratings yet

- (M. J. Edwards) The ''Epistle To Rheginus'' ValenDocument17 pages(M. J. Edwards) The ''Epistle To Rheginus'' ValenGlebMatveevNo ratings yet

- Variables On Both Sides of EquationsDocument17 pagesVariables On Both Sides of EquationsShatakshi DixitNo ratings yet

- Ray OpticsDocument6 pagesRay OpticsshardaviharphysicsNo ratings yet

- 1.load Test On DC Shut MotorDocument5 pages1.load Test On DC Shut Motorg3v5No ratings yet

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 pagesAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- Simple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleDocument67 pagesSimple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleMushini NagabhushanNo ratings yet

- Neptune Planet Experiment, Ariny Amos (Astronomer) - 1Document1,139 pagesNeptune Planet Experiment, Ariny Amos (Astronomer) - 1Dr. Amos ArinyNo ratings yet

- Astm D2563-94Document24 pagesAstm D2563-94Santiago AngelNo ratings yet

- Introduction To Ipgcl & PPCLDocument31 pagesIntroduction To Ipgcl & PPCLSahil SethiNo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Firearms in America 1600 - 1899Document310 pagesFirearms in America 1600 - 1899Mike100% (3)

- IfDocument44 pagesIfSean RoxasNo ratings yet

- Acceleration Theory & Business Cycles: Sem Ii - MebeDocument14 pagesAcceleration Theory & Business Cycles: Sem Ii - MebePrabhmeet SethiNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- Chapter 10b Kinetic Theory For Ideal GasesDocument3 pagesChapter 10b Kinetic Theory For Ideal GasesPathmanathan NadesonNo ratings yet

- Assign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsDocument9 pagesAssign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsAima Kha KhanNo ratings yet

- Lab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyDocument39 pagesLab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyswatiNo ratings yet

- Jul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New MexicoDocument16 pagesJul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New Mexicofriends of the Native Plant Society of New MexicoNo ratings yet