Professional Documents

Culture Documents

Eil Format

Eil Format

Uploaded by

sales.aquavalvesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eil Format

Eil Format

Uploaded by

sales.aquavalvesCopyright:

Available Formats

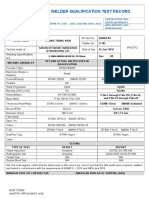

Final Inspection & Test Certificate Page 1 of 1

Work Order No. & Date Certificate No. & Date CERT/VS/15/977

Customer Name

Customer PO No. Customer PO Date.

Order Qty. 00 Nos. Ref. Drawing No. --

Valve Type GATE VALVE Valve Size & Class 15 MM 800#

QSL No. (API 6D) -- Temperature Class 800#

End Connection FLANGED END IBR / NONIBR

P.R.S.I. No. Item Code

OPERATION HANDWHEEL+LOCK OPEN Special Requirements

P.O. ITEM No. EIL SPEC SHEET No.

Manufacturing Std. Ins. & Testing Std.

Valve Sr. No. HEAT No. - BODY HEAT No.-BONNET

Material Traceability Material Heat/CT/Lot No. MTC No.

Body ASTM A105

Bonnet/Side-Piece/Cover ASTM A105

Wedge / Ball / Disc / Plug ASTM A276-T410+STELLITED

Seat Ring ASTM A276-T410

Stem ASTM A276-T410

Stud – Nut --

Gasket --

Actuator --

Dimensional Inspection

Parameters Face - Flange Bore Flange No. of Hole Stud RTJ No.

RF Dia. RF Thick. PCD

(mm) Face OD Dia. Thick. Holes Dia. Nut (If Applicable)

85 31 13

Required - -- -- 4 3/8” 3/8”X1” 55 ± 1.5 --

± 2.0 ± 0.3 ± 0.2

Observed

Pressure Test

Pressure=psi/kg/cm2 Back Seat Test Shell Test Seat Test Air Seat Test

Duration=Seconds Torque

Pressure Duration Pressure Duration Pressure Duration Pressure Duration

211 211 151

Observed 15 Sec. 15 Sec. 15 Sec. 7 Kg/cm² 15 Sec. --

Kg/cm² Kg/cm² Kg/cm²

Other Tests Applicable Method Ref. Inspection Report No. / Observation

Penetrant Examination (PT) Yes No W-P-21-06, Rev. 0

Radiographic Examination (RT) Yes No W-P-21-07, Rev. 0

Ultrasonic Examination (UT) Yes No W-P-21-08, Rev. 0

Magnetic Particle Examination (MT) Yes No W-P-21-09, Rev. 0

Anti-Static Device Test Yes No W-P-21-12, Rev. 0

Inter Granular Corrosion (IGC) Test Yes No

Helium Leak Examination Yes No

Fire Safe Test Yes No

Final Valves Visual Inspection, Shipment & Marking Verification

Company Logo Marking Yes No Flange Surface Finish Accept Reject

Size & Class Marking Yes No Valve End Covers Attach Not Attach

Material Grade Marking Yes No Valve Marking Plate API Non-API

Flow Direction Marking Yes No API Monogram Marking Applicable Not Appli.

This is to certify that the above valves are inspected and tested at our facility and certified that the valves are guaranteed for smooth and satisfactory

performance for a period of eighteen months from the date of dispatch of twelve months from the date of commissioning, whichever is earlier.

Name Designation Q.C.Engineer Initials

Name TPI Agency Sign

You might also like

- Universal Parallel Accounting: Scope Information: SymptomDocument29 pagesUniversal Parallel Accounting: Scope Information: Symptomdgz5qm8kcwNo ratings yet

- Well Handover CertificateDocument1 pageWell Handover Certificateeng7mohamed7hashimNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- SATR-A-2001V Pressure Test Report (Valve Inspection & Field Testing)Document8 pagesSATR-A-2001V Pressure Test Report (Valve Inspection & Field Testing)john ajitNo ratings yet

- Spool HT EPCMD 2 QM00 FMT PP 028 - 01Document1 pageSpool HT EPCMD 2 QM00 FMT PP 028 - 01Muthu AlaguRajNo ratings yet

- Satr A 2001VDocument8 pagesSatr A 2001Vansar aliNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16Document6 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16GOSP3 QC MechanicalNo ratings yet

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- OutputDocument17 pagesOutputankurNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test ReportGOSP3 QC MechanicalNo ratings yet

- SATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Document2 pagesSATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Ahdal NoushadNo ratings yet

- Instrument Callibration ListDocument1 pageInstrument Callibration ListAhmed OusamaNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13Document2 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13PradeepNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001ansar aliNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- OGC-FIC-003-I-Control Valve Inspection Record-Field Installation ChecklistDocument2 pagesOGC-FIC-003-I-Control Valve Inspection Record-Field Installation ChecklistTaylorNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - Finalrambihari100% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Tornillo Autop. P.BR ZN 14 X 1 1-2 T (Pat-20020)Document1 pageTornillo Autop. P.BR ZN 14 X 1 1-2 T (Pat-20020)Luisa Ortega mendozaNo ratings yet

- PRO-5711-03 Pressure Test Form Rev.04Document2 pagesPRO-5711-03 Pressure Test Form Rev.04Emy SumartiniNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- G2W0142006 3.5 PUP DP 5FT 中英文质证书Document11 pagesG2W0142006 3.5 PUP DP 5FT 中英文质证书JoseMi Vacaflor IllanesNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- SATR-A-2001 Pressure Test ReportDocument8 pagesSATR-A-2001 Pressure Test Reportjohn ajitNo ratings yet

- InspectorDocument5 pagesInspectorVictor DvornikovNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Report BV Amp 05 PT - Nippon ShokubaiDocument21 pagesReport BV Amp 05 PT - Nippon ShokubaiMuhammad Raihan ArdiantoNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- VIP Form2Document2 pagesVIP Form2Jose E RafolsNo ratings yet

- Injection Pump Maintenance ChecklistDocument2 pagesInjection Pump Maintenance ChecklisthaythamNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001razzak.me.enggNo ratings yet

- Tornillo Autop. P-BR ZN 10 X 3-4 (Pat-21138 + T)Document1 pageTornillo Autop. P-BR ZN 10 X 3-4 (Pat-21138 + T)L Caqui PascacioNo ratings yet

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Globe Valve1 DatasheetDocument1 pageGlobe Valve1 DatasheetobumuyaemesiNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Guidance 1GDocument5 pagesGuidance 1GWahyu HaryadiNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoudNo ratings yet

- OGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistDocument2 pagesOGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistTaylor100% (1)

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- CV CalibDocument1 pageCV CalibariefNo ratings yet

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- Different Gate & Glove ValvesDocument1 pageDifferent Gate & Glove Valvessales.aquavalvesNo ratings yet

- Approaching and Talking To A New Client Over A CallDocument3 pagesApproaching and Talking To A New Client Over A Callsales.aquavalvesNo ratings yet

- W.O. ListDocument2 pagesW.O. Listsales.aquavalvesNo ratings yet

- Price List 15-6-2023Document1 pagePrice List 15-6-2023sales.aquavalvesNo ratings yet

- Strategic Management MCQSDocument19 pagesStrategic Management MCQSJay Patel75% (4)

- Optical Braille Recognition Using Object Detection CNN: Ilya G. OvodovDocument6 pagesOptical Braille Recognition Using Object Detection CNN: Ilya G. Ovodovzelalem tamrieNo ratings yet

- MORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFDocument21 pagesMORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFTrejaucasNo ratings yet

- The Dice Game: Rules v2.0Document11 pagesThe Dice Game: Rules v2.0Jin ChoungNo ratings yet

- Patriarchy Kumkum SangariDocument10 pagesPatriarchy Kumkum SangariSarjoo ShahNo ratings yet

- Bill Tai of Charles River Ventures TranscriptDocument4 pagesBill Tai of Charles River Ventures TranscriptDocumented at Davos 2011 - Presented by ScribdNo ratings yet

- 100 AutoCAD Commands You Should KnowDocument37 pages100 AutoCAD Commands You Should KnowAnonymous TxYttIqsPNo ratings yet

- Design and Control of The Cumene Process: William L. LuybenDocument16 pagesDesign and Control of The Cumene Process: William L. LuybenAddan JavidNo ratings yet

- High - Rate - Filtration SystemDocument8 pagesHigh - Rate - Filtration SystemNoureddine Ait el hajNo ratings yet

- Wolves of Isle Royale Case StudyDocument3 pagesWolves of Isle Royale Case Study66dancelNo ratings yet

- Itdumpsfree: Get Free Valid Exam Dumps and Pass Your Exam Test With ConfidenceDocument5 pagesItdumpsfree: Get Free Valid Exam Dumps and Pass Your Exam Test With ConfidencejavapsycheNo ratings yet

- Experiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer ODocument30 pagesExperiment No. 12: Implementation & Verification of Line Multiplexer & Demultiplexer O5611 M.Mubeen M.yaseenNo ratings yet

- Q400-Air Cond and PressDocument38 pagesQ400-Air Cond and PressMoshiurRahman100% (2)

- Workshop 1 - StartupsDocument22 pagesWorkshop 1 - StartupsHernan MonteroNo ratings yet

- Sem 5 NotesDocument2 pagesSem 5 NotesManideep KonduruNo ratings yet

- 1st Formative Test in PPGDocument1 page1st Formative Test in PPGJacinth HeridaNo ratings yet

- Q1. A Manufacturing Firm Has Discontinued Production of A Certain Unprofitable ProductDocument3 pagesQ1. A Manufacturing Firm Has Discontinued Production of A Certain Unprofitable Productyohanis meleseNo ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet

- Aws Training Cloud Practitioner Essentials - Security - Certicate of CompletionDocument1 pageAws Training Cloud Practitioner Essentials - Security - Certicate of Completionapi-122816661No ratings yet

- Keynote 6,7,8Document16 pagesKeynote 6,7,8salome mumladzeNo ratings yet

- MorecroftDocument8 pagesMorecroftMorecroft GroupNo ratings yet

- I. Desired Learning Outcomes: Laboratory Activity 9 Test For ProteinsDocument3 pagesI. Desired Learning Outcomes: Laboratory Activity 9 Test For ProteinsErika Joille PatayonNo ratings yet

- Optical Control SystemsDocument2 pagesOptical Control SystemsimrancenakkNo ratings yet

- Cub Cadet 1212Document44 pagesCub Cadet 1212Hayden MyersNo ratings yet

- Thesis Ni Mam JesselDocument15 pagesThesis Ni Mam JesselNylram Sentoymontomo AiromlavNo ratings yet

- L2.5 Using A Compound Light Microscope OptDocument8 pagesL2.5 Using A Compound Light Microscope Optochattc100% (1)

- Chapter 5 - Evaluating Classification & Predictive PerformanceDocument25 pagesChapter 5 - Evaluating Classification & Predictive PerformancejayNo ratings yet

- 2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiDocument2 pages2003 IMO Training Camp: Contributors: Sayan, Magical, Omid HatamiHariPrasad PoilathNo ratings yet